Roller type washing and peeling machine

A drum type, peeling machine technology, applied in the peeling of vegetables or fruits, food processing, food science, etc., can solve the problem of not considering the inertial mechanics and motion trajectory of agricultural products, centrifugal motion to enhance surface friction peeling effect, structural design Issues such as no in-depth research have been carried out to achieve the effect of improving resource utilization, enhancing efficiency and functionality, and compact organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

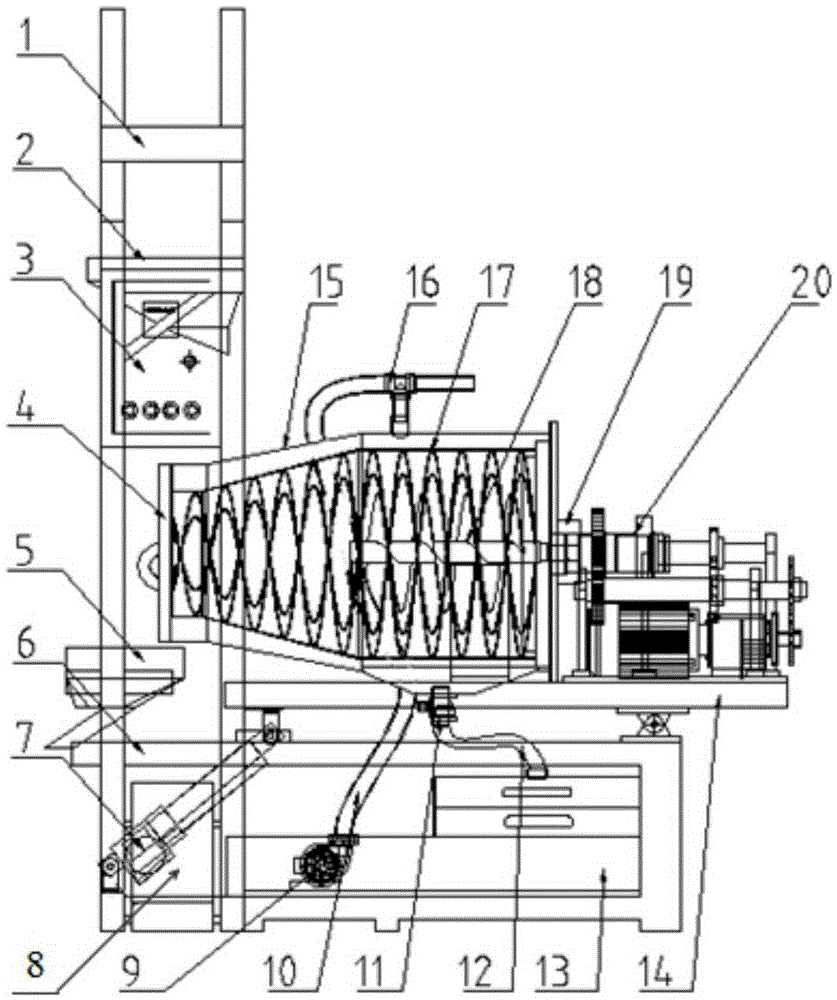

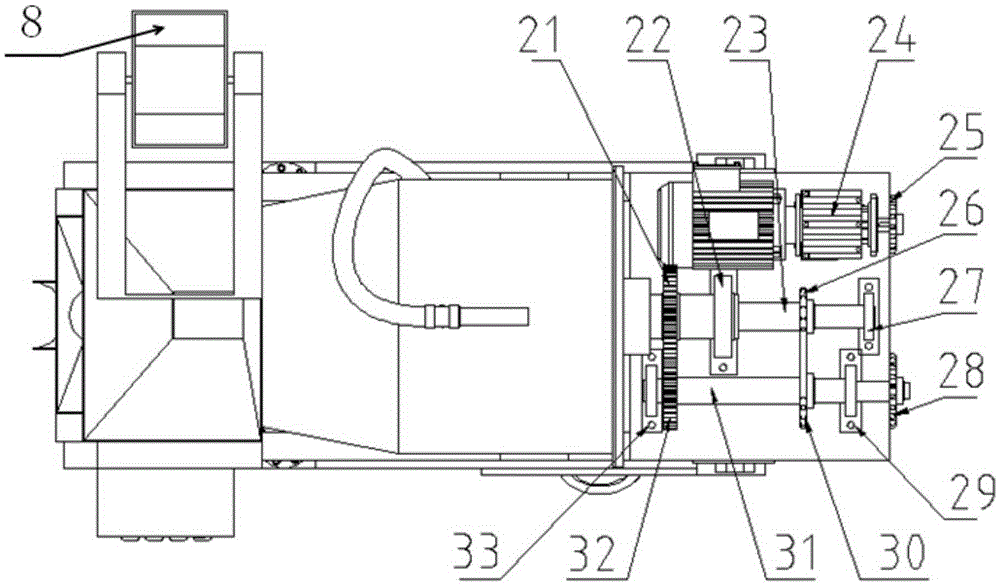

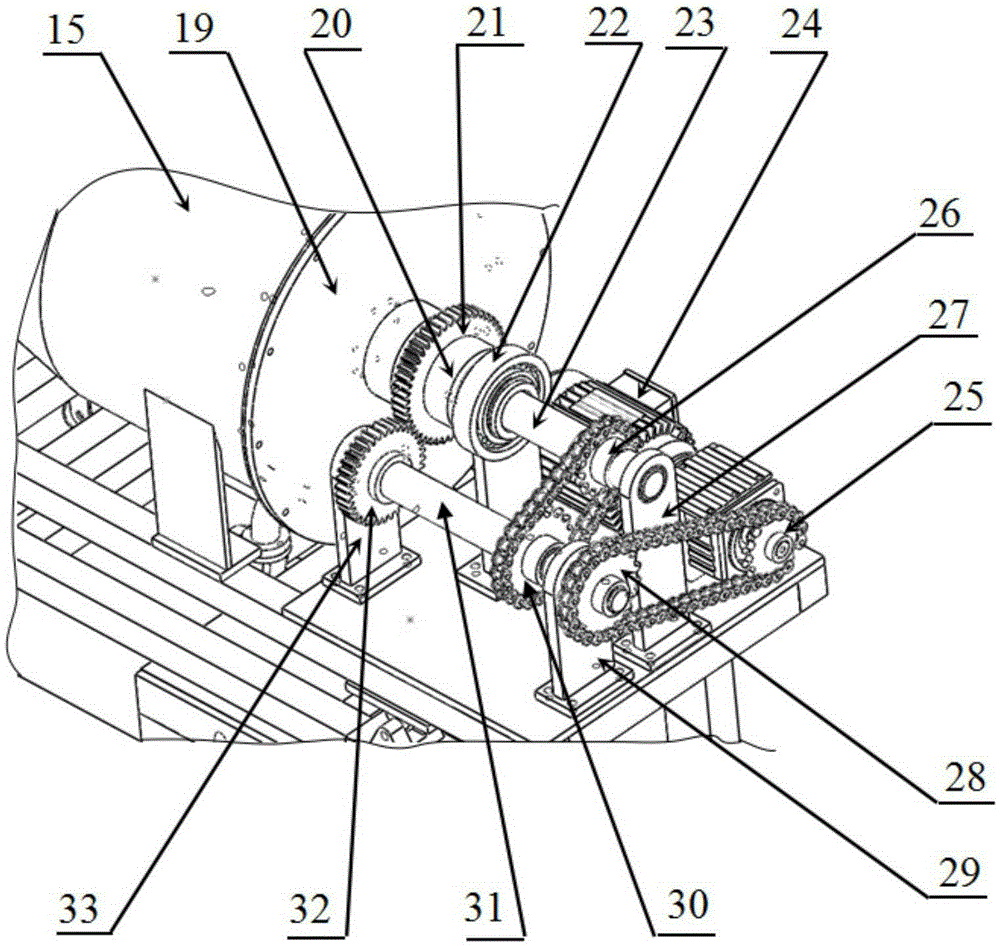

[0033] According to the drum type cleaning and peeling machine of the present invention such as Figure 1-5 shown. It includes a horizontal frame 6 and a vertical feeding rack 1, a drum cleaning device is arranged horizontally on the horizontal rack 1, a power unit for driving the drum cleaning device, and a water circulation system connected with the drum cleaning device; the feeding rack There is also a feeding and discharging device docked with the drum cleaning device on the top.

[0034] Wherein, the feeding rack 1 is integrally connected to the frame 6, moves back and forth along the feeding rack 1, and turns over at the highest point to lead into a hopper 8 for agricultural products to be cleaned. A feeding hopper 2 is arranged on the feeding rack 1 for feeding. The feeding port of the feeding hopper 2 corresponds to the dumping position after the hopper 8 is overturned, and the feeding port of the feeding hopper 2 corresponds to the feeding port of the cylinder body wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com