Water scrubber for waste incineration fly ash and water washing method

A waste incineration fly ash and water washer technology, which is applied in liquid cleaning methods, chemical instruments and methods, and separation methods, can solve the problems of low manual washing efficiency, low sample uniformity, and small fly ash particle size. Achieve good circulation and shearing capacity, high uniformity of chlorine salt removal, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

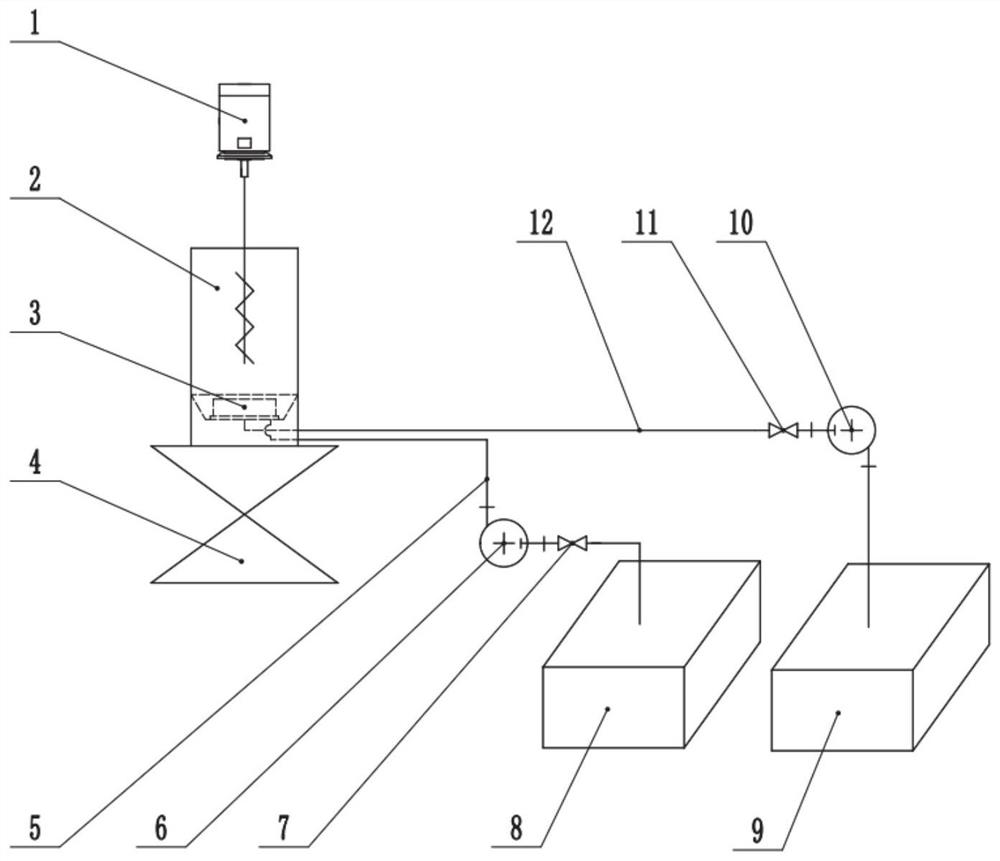

[0053] An automatic water scrubber for waste incineration fly ash, comprising:

[0054] A stirring container 2 for receiving fly ash and mixing the fly ash with water, the bottom of the stirring container is provided with an inverted truncated groove.

[0055] Stirring device 1 for stirring the mixed solution of fly ash and water, the stirring device adopts a six-curved leaf open turbine agitator.

[0056] A lifting device 4 for adjusting the relative height of the stirring container 2 and the stirring device 1 .

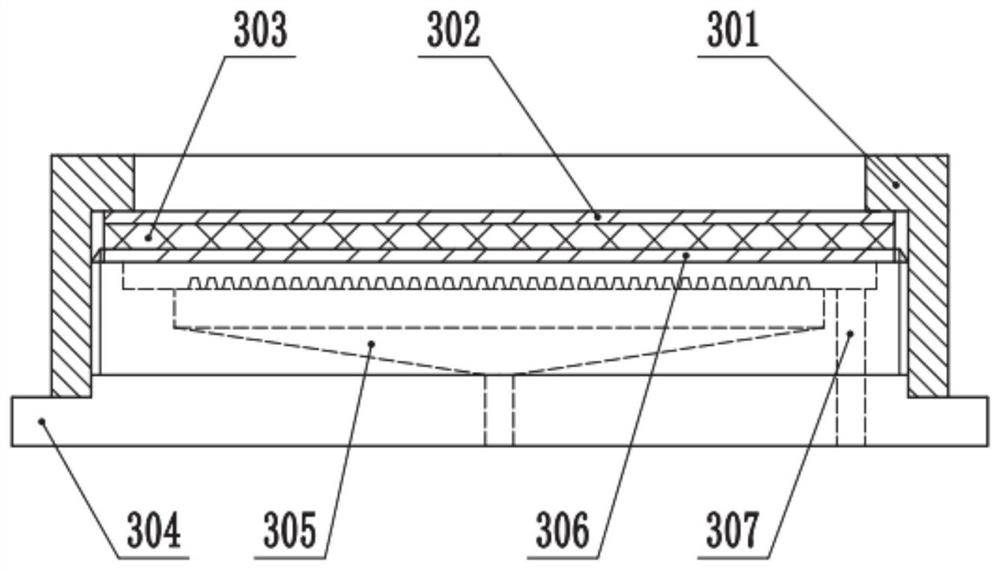

[0057] A filter device 3 for receiving the solution discharged from the stirring container and separating the solution from solid to liquid, the filter device 3 is composed of a sealing element, a filter element and a recoil element, and the sealing element is threaded, The core part is composed of "first punching screen 302+ultrafine glass fiber filter membrane 303+second punching screen 306", and the flushing surface 305 of the recoil element is provided with fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com