Stirring method and stirring apparatus thereof

A stirring method and technology of a stirring device, which are applied in mixers with rotary stirring devices, chemical instruments and methods, dissolution and other directions, can solve the problems such as the inability to adjust the speed and direction of stirring blades, and achieve reasonable structural design, high stability, and high stability. The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

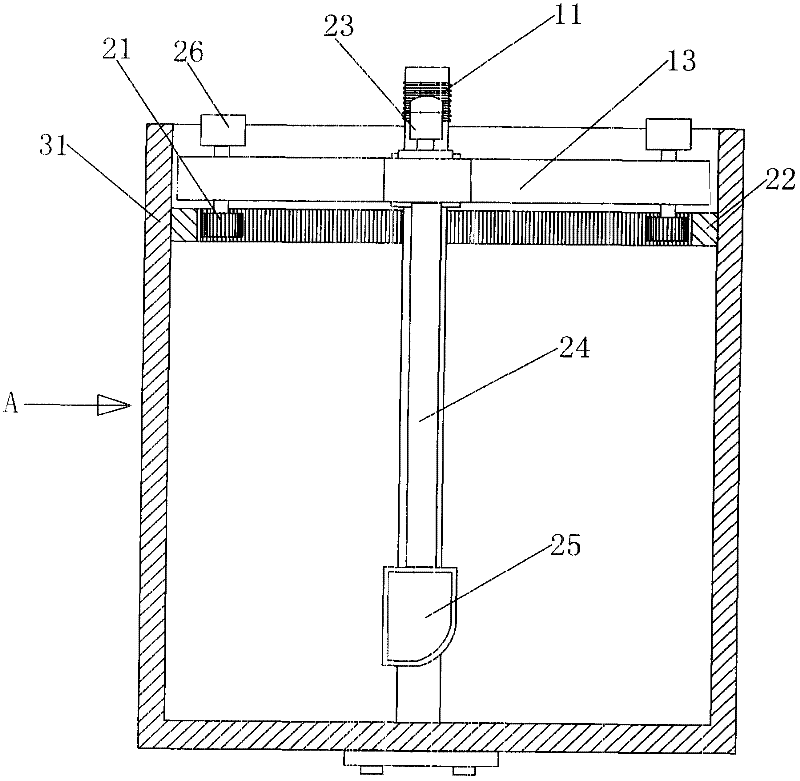

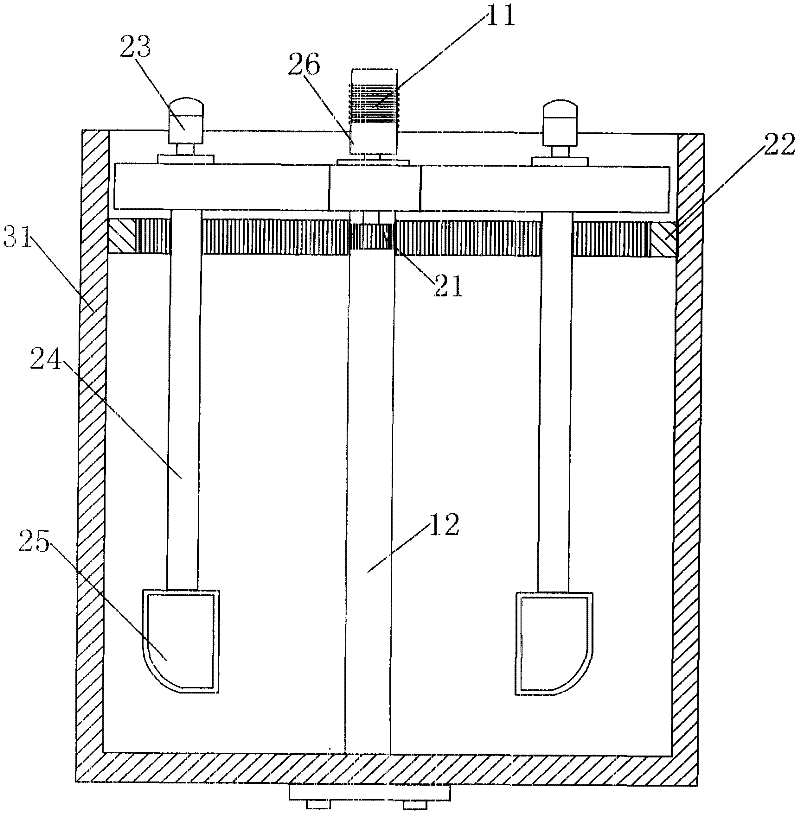

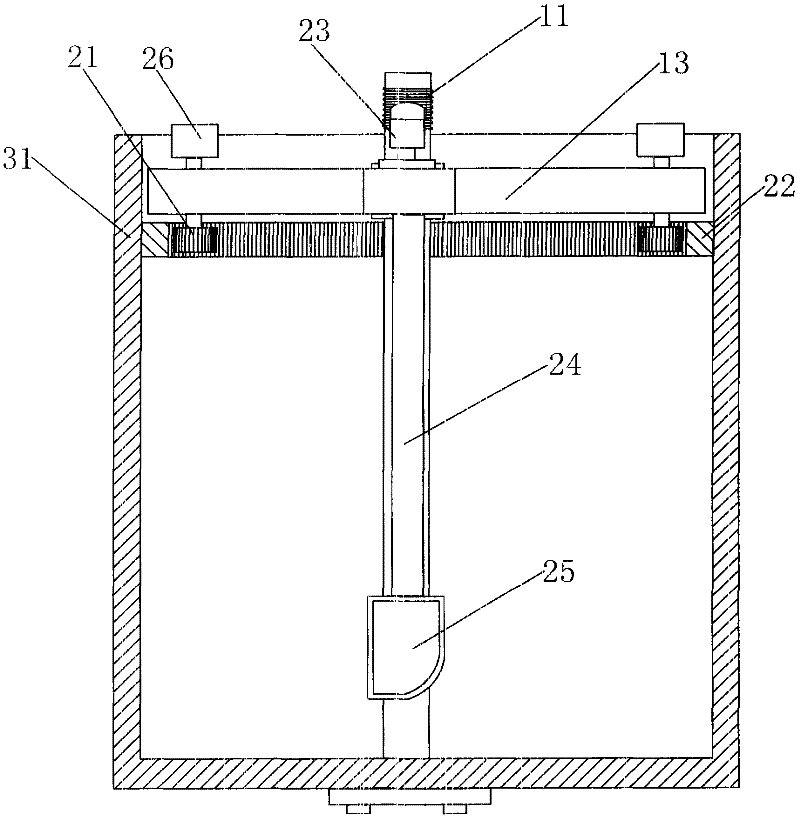

[0026] The mixing method adopts a combination of revolution and rotation. By adopting a main shaft, the bottom of the main shaft is erected in a container. The upper part of the main shaft is pivotally connected to the revolving support, the revolving support is a planetary support, and the upper part of the planetary support is relative to the pivot Two auxiliary drive shafts are provided, and an auxiliary drive motor is connected to the two auxiliary drive shafts, and the auxiliary drive motor rotates under the drive of the auxiliary drive shaft. Two revolving motors are provided at the other two opposite ends of the planetary carrier. The revolving motors respectively drive and connect the two driving gears. The inner wall of the container is provided with a toothed belt meshing with the gears. When the revolving motor drives the gears to rotate, the toothed belts mesh with the gears. The revolution bracket produces revolution. An electric slip ring is arranged at the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com