Movement swing conveying device for mining drill pipe

A technology for conveying devices and drill pipes, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., which can solve the problems of small drill pipe reserves, time-consuming and laborious, and inability to adjust, so as to improve flexibility, practicability, and good coordination , to ensure the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

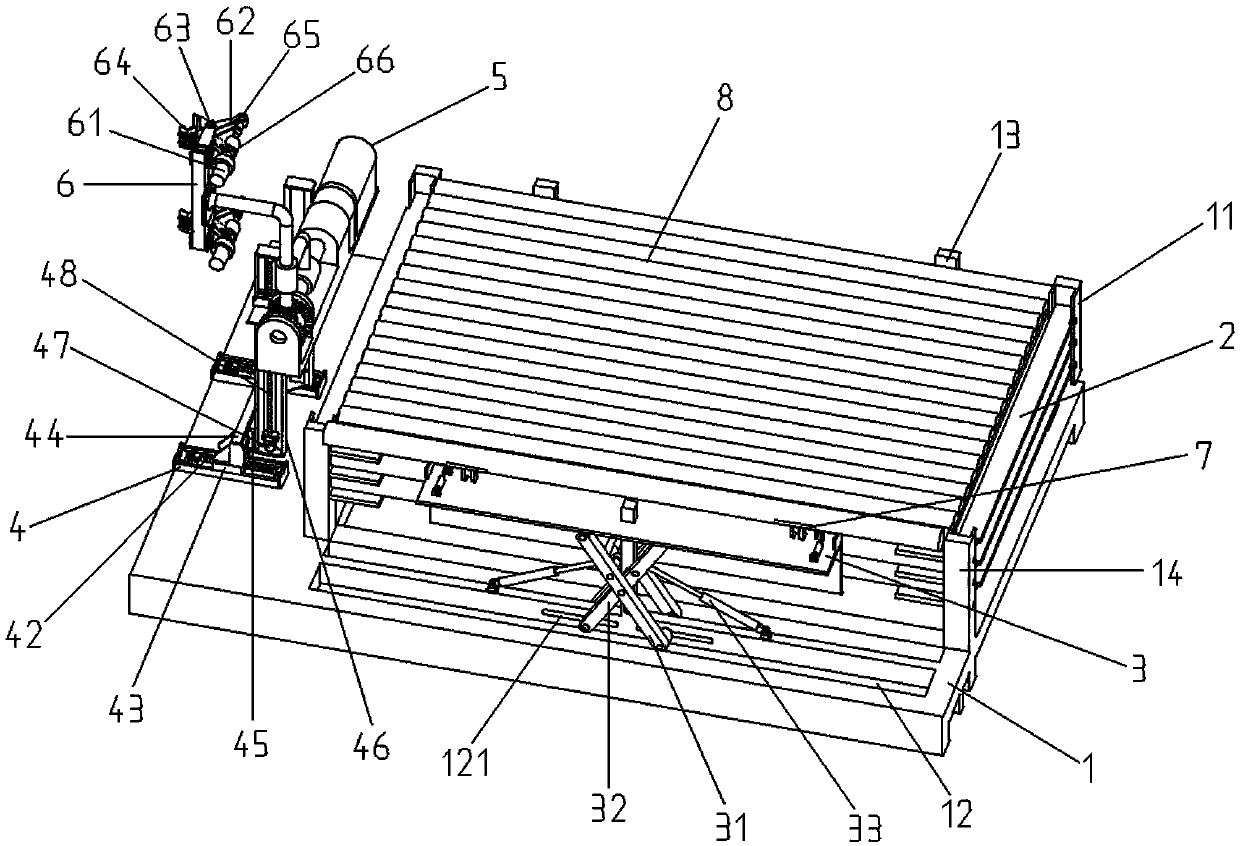

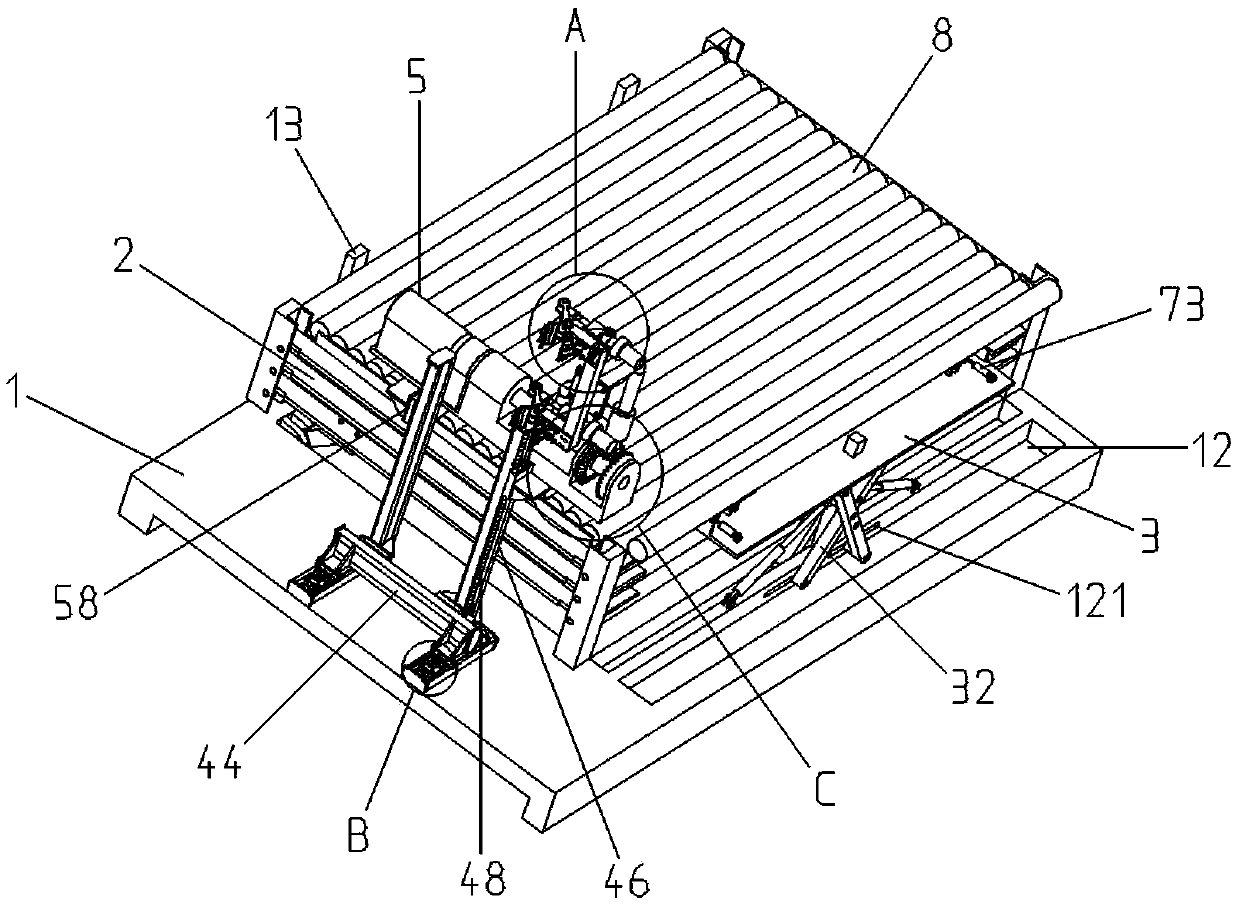

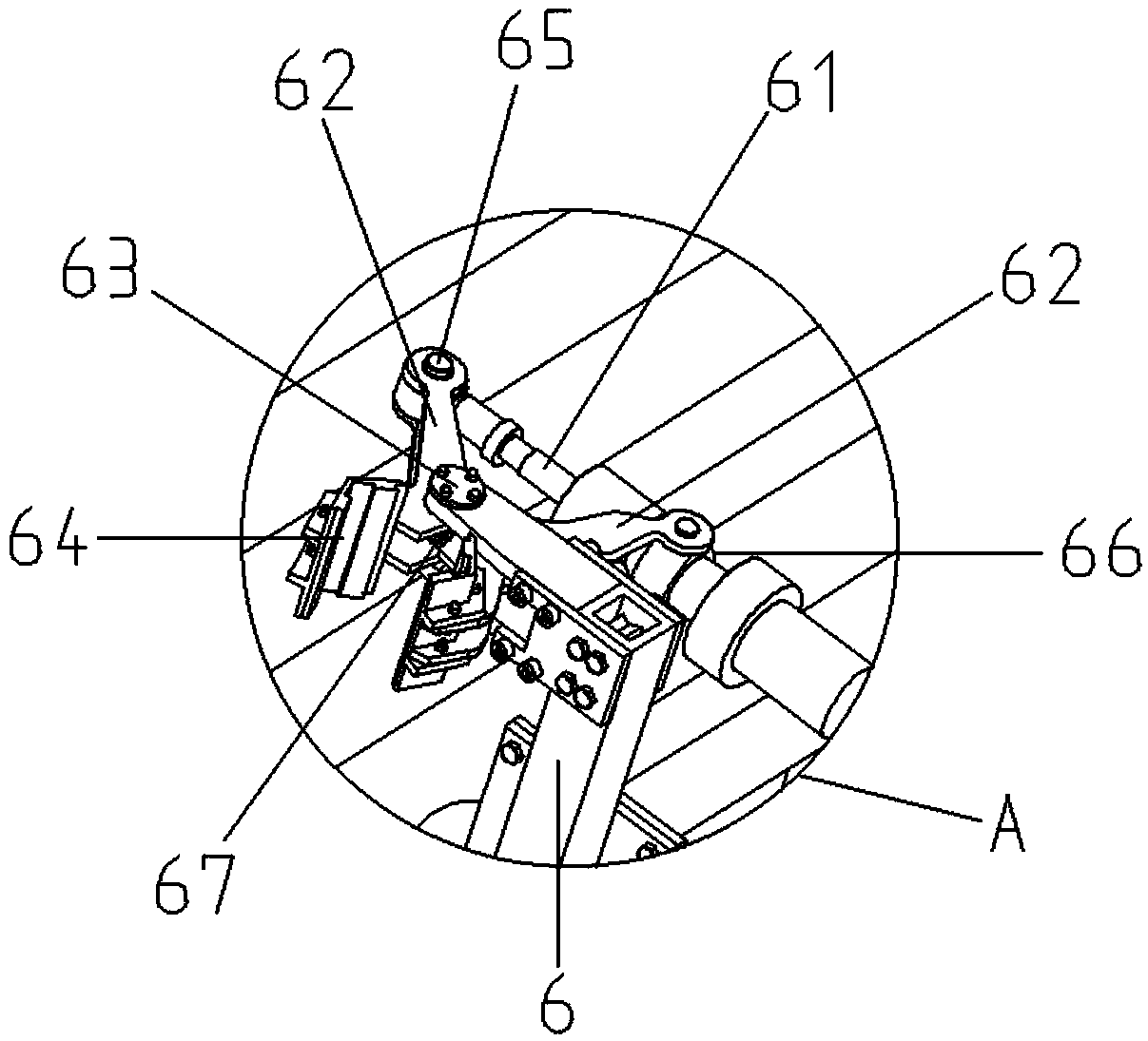

[0030] Such as Figures 1 to 8 As shown, a drilling rod shifting and transporting device for geological mines includes a chassis body 1, a rear assembly block 11, a shaft assembly block 111, a working groove 12, a supporting bottom chute 121, a limit stop rod 13, and a front assembly rod 14. Dressing plate 2, tilt drive hydraulic cylinder 21, support plate 22, plate body installation shaft 23, lifting plate 3, outer support rod 31, inner support rod 32, lifting drive cylinder 33, limit baffle 34, cross positioning shaft 35. Drive installation shaft 36, sliding groove block 37, supporting top chute 371, lateral sliding module 4, lateral rotary motor 41, lateral screw 42, lateral slider 43, matching internal thread 431, lateral sliding module 44, lateral Slider 45, longitudinal sliding module 46, longitudinal rotary motor 47, longitudinal screw rod 48, coupling 49, overturning module 5, longitudinal slider 58, clamping installation frame 6, clamping drive cylinder 61, clamp body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com