A citric acid-producing microorganism strain and a method for producing citric acid by fermenting starch sugar thereof

A technology of citric acid and microorganisms, applied in the field of fermentation engineering, can solve the problems of complex fermentation products, inability to upgrade, and the production of various miscellaneous acids, etc., and achieve the effects of simple production process, high conversion rate of sugar and acid, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] A method for constructing a fermentation strain of a high-yielding citric acid microorganism, the strain integrates multiple copies of the pyruvate carboxylase PC gene, the pyruvate dehydrogenase PD gene and the alternate oxidase Aox1 gene in the Aspergillus niger genome into the Aspergillus niger genome, using The recombinant Aspergillus niger strain produces citric acid by fermentation; the expression of the pyruvate carboxylase PC gene is regulated by the Pgla promoter, and the pyruvate dehydrogenase PD gene and the alternate oxidase Aox1 gene are regulated by the PgpdA promoter.

Embodiment 2

[0106] Aspergillus niger strain Aspergillus niger The method for preparing citric acid by strain 101-HAC11 preservation number CGMCC No.12480:

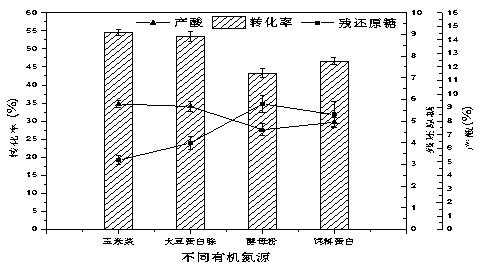

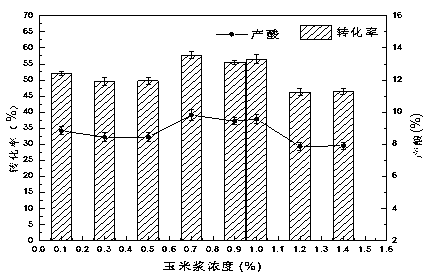

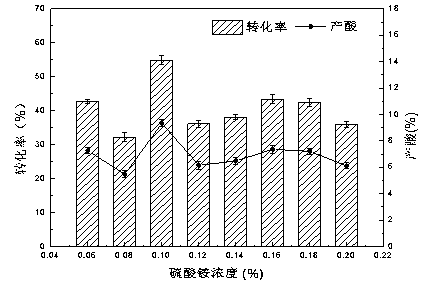

[0107] (1) The fermentation strain used is Aspergillus niger strain Aspergillus niger 101-HAC11 preservation number CGMCCNo.12480, fermentation medium composition (g / L): glucose 200g, corn steep liquor 60 g / L, (NH 4 ) 2 SO 4 9g / L, MgSO 4 ·7H 2 O 0.05g / L, K 2 HPO , 4g / L, CuSO 4 0.8 mg / L ZnSO 4 0.02 g / L, CaCl 2 2.0 g / L, KCl 0.1 g / L, FeSO 4 0.34 mg / L pH 5.0~5.5;

[0108] (2) Fermentation culture control conditions: control the inoculum amount of 10% (v / v), control the seed age at 27 hours, insert the cultured seeds into the fermentation medium, the culture temperature is 30 °C, and the fermentation ventilation volume is 0.1 m 3 / m 3 .min, the tank pressure is 0.07 MPa, the stirring speed is 80 rev / min, the fermentation time is 50 hours, and sterile air is passed into the fermentation process.

Embodiment 3

[0110] Aspergillus niger strain Aspergillus niger The method for preparing citric acid by strain 101-HAC11 preservation number CGMCC No.12480:

[0111] (1) The fermentation strain used is Aspergillus niger strain Aspergillus niger 101-HAC11 preservation number CGMCCNo.12480, fermentation medium composition (g / L): glucose 260g, corn steep liquor 80 g / L, (NH 4 ) 2 SO 4 11 g / L, MgSO 4 ·7H 2 O 0.15g / L, K 2 HPO , 6g / L, CuSO 4 0.8 mg / L ZnSO 4 0.02 g / L, CaCl 2 2.0 g / L, KCl0.1 g / L, FeSO 4 0.34 mg / L pH 5.0~5.5;

[0112] (2) Fermentation culture control conditions: control the inoculum amount of 15% (v / v), control the seed age at 27 hours, insert the cultured seeds into the fermentation medium, the culture temperature is 40°C, and the fermentation ventilation volume is 0.15m 3 / m 3 min, the tank pressure is 0.12 MPa, the stirring speed is 100 rev / min, the fermentation time is 60 hours, and sterile air is passed into the fermentation process, and the citric acid outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com