Double-layer stirring paddle combination device

A technology of combining device and stirring paddle, which is applied to mixers, mixers, transportation and packaging with rotary stirring devices, etc. Not applicable to problems such as active organisms, to achieve the effects of shortening mixing time, improving liquid-solid suspension, and improving circulation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

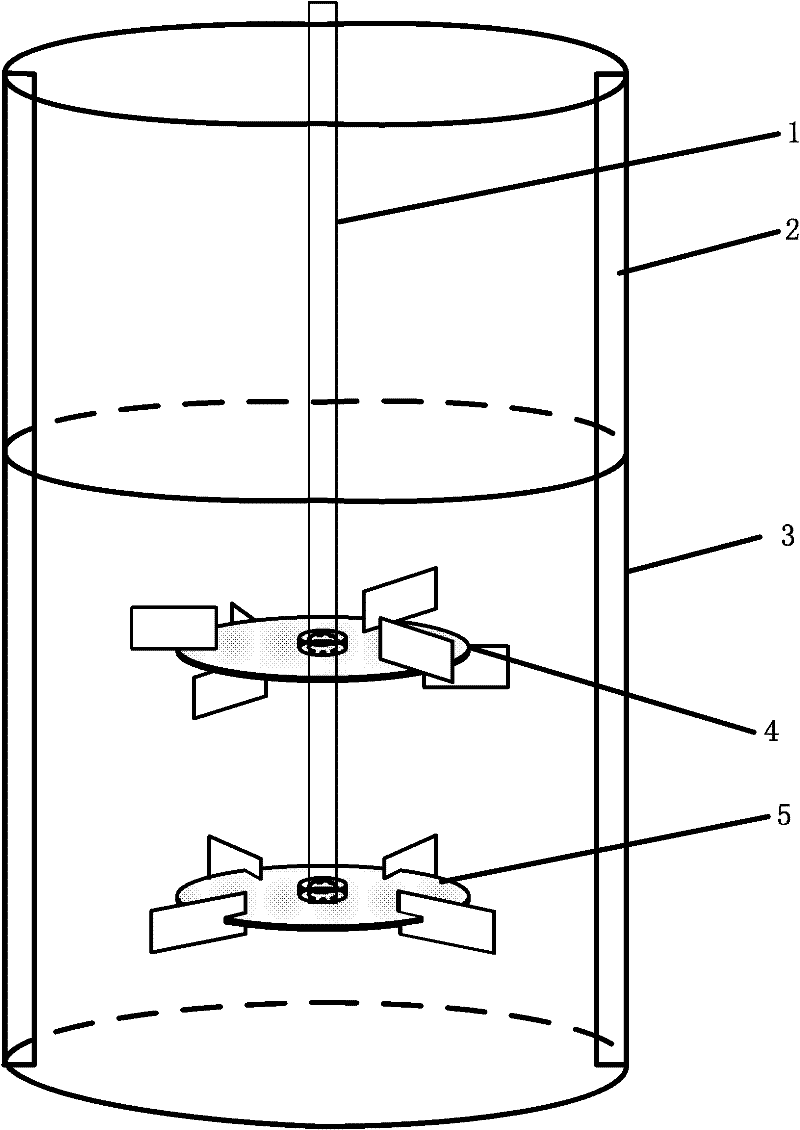

[0016] For the liquid-solid two-phase system, tap water is used as the liquid phase and quartz sand is used as the solid phase (density 2650kg / m 3 , particle size range 75-150μm). The liquid level in the tank is 532mm high, the diameter of the stirring paddles is 127mm, the height of the lower paddle from the bottom is 127mm, and the distance from the upper paddle to the liquid surface is 60mm.

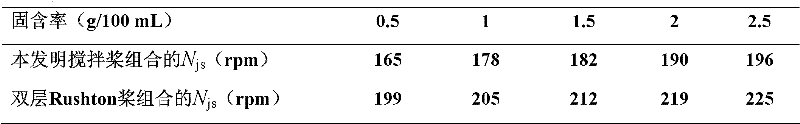

[0017] The critical off-bottom suspension is a very important dispersion state in the liquid-solid mixing operation. At this time, the effective contact area between the solid phase and the liquid phase reaches the maximum value, and the corresponding speed is called the critical off-bottom suspension speed (N js ), N js It can be used to measure the ability of the stirring paddle to suspend solids. The following table provides the critical off-bottom suspension rotational speed N of the combination stirring paddle of the present invention and the combination of traditional double R...

Embodiment 2

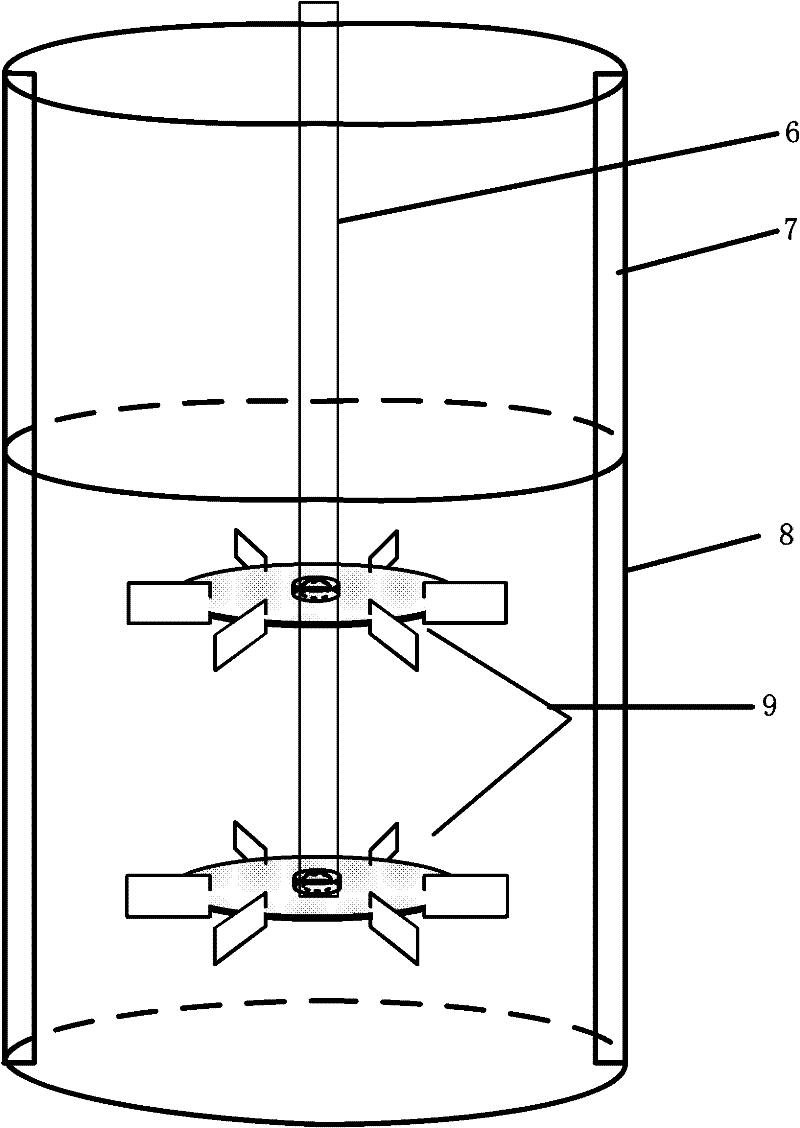

[0021] For the gas-liquid two-phase system, in the stirred tank device with the structure as described in Example 1, tap water is used as the liquid phase, air is used as the gas phase, and the annular gas distributor is passed in from the bottom of the stirring paddle, and the ventilation rate is 0.2m 3 / h.

[0022] The following table shows the different rotational speeds (s -1 ) power consumption per unit volume (kW / m 3 ). It can be seen that the stirring paddle combination device of the present invention has obvious improvement in power consumption under the gas-liquid two-phase condition, and the power consumption per unit volume under the same rotating speed condition is about 60.0% to 77.93% of the traditional double-layer Rushton paddle combination .

[0023] Table 2. Comparison of power consumption per unit volume for different impeller combinations

[0024]

Embodiment 3

[0026] The mixing time is an important parameter to characterize the mixing performance of the stirred tank reactor. In this embodiment, in a stirred tank with a structure such as that of Example 1, the conductometric method was used to measure the temperature of the single liquid phase system at different stirring speeds (s -1 ) macroscopic mixing time (s) under the condition. Concrete implementation is as follows: with saturated NaCl solution (250g / L) as tracer, add in the liquid level place of stirring tank, conductance electrode is placed on the other side near the bottom of the tank, for measuring the change of local conductivity with time, The output signal of the conductivity electrode is amplified and converted by the computer for data acquisition and processing. Since the output signal of the conductivity meter always fluctuates to a certain extent, it is generally considered that the difference between the output signal of the conductivity meter and the average valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com