Capacity coupling plasma reactor and control method thereof

A plasma reactor, capacitive coupling technology, applied in the direction of plasma, electrical components, etc., can solve the problem of not being able to use different hardware equipment and any processing technology in one design, achieve simple mechanism, achieve uniform distribution, and improve uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

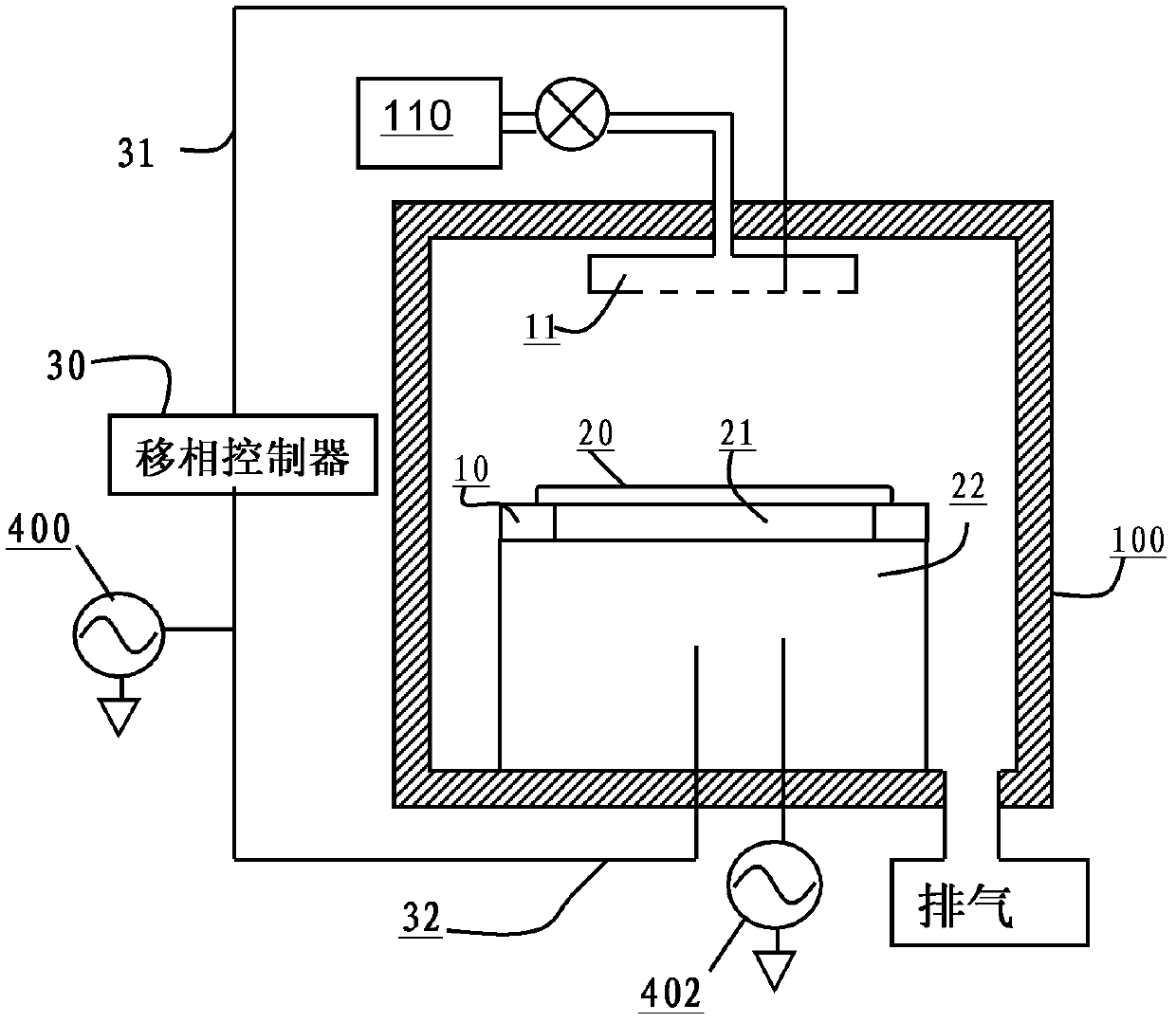

[0013] figure 1 A schematic longitudinal sectional view of a plasma processing apparatus according to the prior art is shown. Those skilled in the art understand that, in the prior art, a plasma processing device generally includes: a processing container 100 composed of a vacuum chamber whose interior is a closed space; The seat includes a lower electrode 22; and an upper electrode 11 arranged on the top of the base opposite to the base, the upper electrode is usually used as a gas nozzle at the same time, typically as a gas shower head, the gas shower head is connected to to process gas source 110.

[0014] The shape of the lower electrode 22 is adapted to the upper electrode 10; a substrate fixing device 21 for fixing the substrate 20 is arranged above the base, typically an electrostatic chuck. A substrate to be processed, such as a wafer, is placed above the substrate holding device 21 . Surrounding the substrate fixing device 21 and the substrate 20 also includes an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com