Vibrating screen drilling fluid anti-splash mechanism for desert petroleum drilling

A technology of drilling mud and vibrating screen, which is applied in the direction of mobile filter element filter, filtration separation, separation method, etc., can solve the problems of recyclable liquid phase loss of drilling fluid, etc., and achieve the goals of reducing load, improving utilization rate, and slowing down scraping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

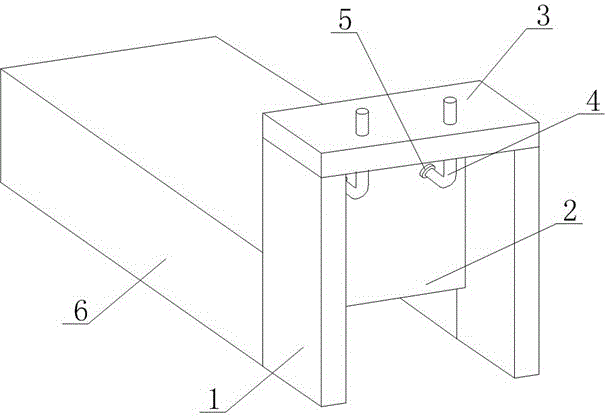

[0025] Such as figure 1 As shown, the present invention is an anti-splash mechanism for vibrating screen drilling mud used for desert drilling and extraction. It includes two parallel anti-splash plates 1. The bottom of the anti-splash plate 1 is perpendicular to the horizontal plane, and the top of the anti-splash plate 1 is equipped with a top plate 3 , The top plate 3 is connected to the two splash plates 1, a spray plate 2 is arranged between the splash plates 1, and the spray plate 2 is perpendicular to the splash plate 1, the top of the spray plate 2 is connected to the top plate 3, and the bottom of the spray plate 2 There is a gap between the bottom of the splash plate 1 and the bottom of the splash plate 1. A number of inlet elbows 4 are installed above the top plate 3. The part of the inlet elbow 4 above the top plate 3 is perpendicular to the top plate 3, and the bottom end of the inlet elbow 4 penetrates the top plate 3 From the top to the bottom of the top plate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com