Composite protection plate with non-equal-diameter ceramic balls and application and manufacturing method

A production method and technology of ceramic balls, which are used in protective equipment, transportation and packaging, and the structure of armor plates, etc., can solve the problems of insufficient toughness, splashing, and decreased resistance to secondary strikes, so as to improve the integrated performance and expand the receiving capacity. The effect of force area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

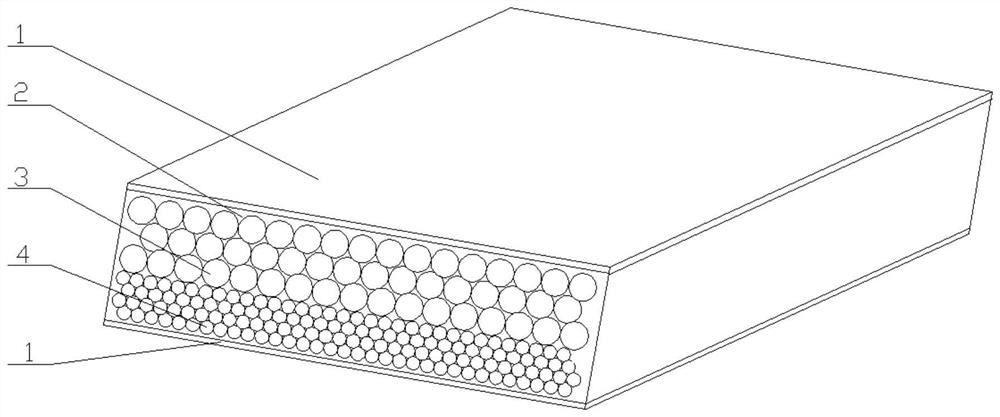

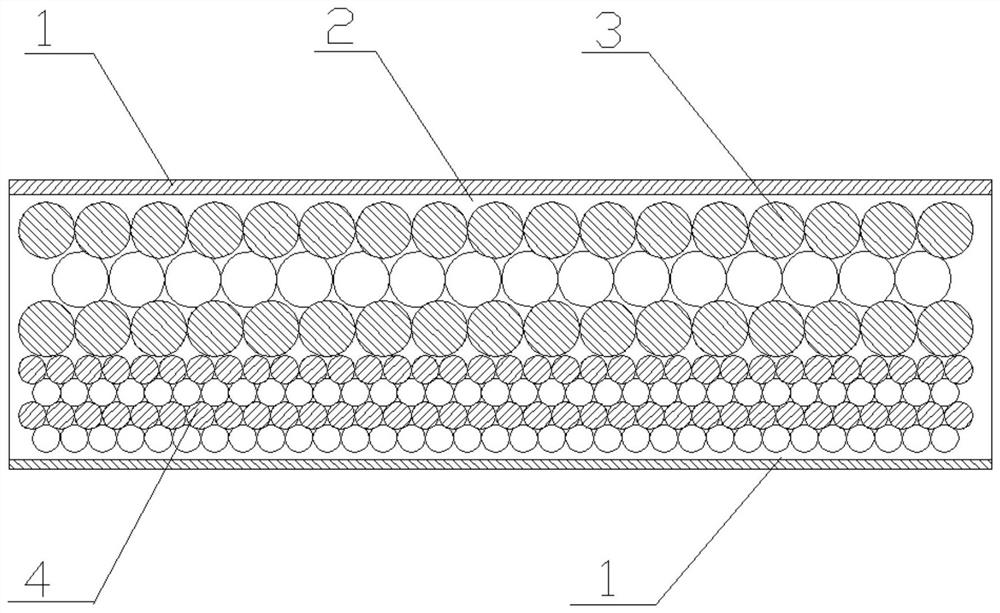

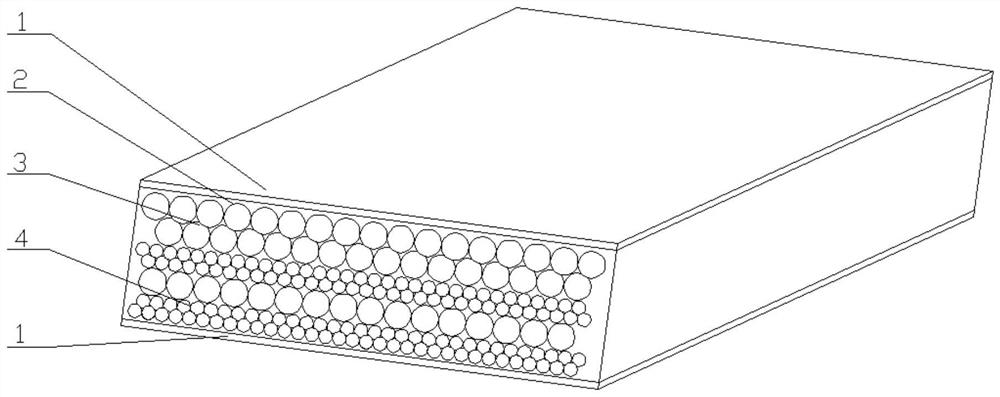

[0069] Such as figure 1 and figure 2 As shown, in Example 1, a composite protective plate with non-equal-diameter ceramic balls includes a face plate 1, a core material 2 and ceramic balls, and the upper and lower sides of the face plate 1 are arranged at intervals. The panel is made of 7039 aluminum alloy, which has good bulletproof performance and high cost performance; the size and shape of the panel are determined according to actual engineering needs. The size of the panels is 24cm×24cm×4.2cm, and the thickness of the panels is 0.2cm.

[0070] The core material 2 is a whole piece of core material 2 made of polymer viscoelastic material filled between two panels. The core material is covered with 7 layers of ceramic balls, and the core material has 2 different diameters. Ceramic balls are respectively large-diameter ceramic balls 3 and small-diameter ceramic balls 4. The 7-layer ceramic ball layer is 3 layers of large-diameter ceramic ball layers and 4 layers of small-d...

Embodiment 2

[0087] Design 4 groups of parallel experiments, the ratio of bullet diameter and the diameter of large-diameter ceramic ball 3 is respectively 0.67, 0.8, 1, 1.2, all the other are the same as embodiment 1

[0088] The bullet is round-headed and penetrates at an initial velocity of 600m / s. The anti-penetration data of the four groups of composite protective plates under the change of bullet diameter is shown in Table 2:

[0089] Table 2: Anti-penetration data of 4 groups of composite protective panels under different projectile diameters

[0090]

[0091] From the data in Table 2, it can be seen that under the condition of projectile penetration at an initial velocity of 600m / s, the protective plate has the best effect in resisting projectile diameter when the ratio of the diameter of the large-diameter ceramic ball is 0.8 to 1 times.

Embodiment 3

[0093] Design 7 groups of parallel experiments, the ratio of the diameter of the large-diameter ceramic ball 3 and the small-diameter ceramic ball 4 is respectively 3.3, 2.5, 2, 1.6, 1.3, 1.0, 0.7, and the rest are the same as in Example 1

[0094] A bullet with a diameter of 8.08mm and a flat-headed projectile penetrated into 7 groups of parallel tests at an initial velocity of 600m / s. The performance of the shield will be analyzed from whether the shield is penetrated, the depth of the crater, and the degree of damage to the back bullet. The anti-penetration parameters of the 7 sets of composite shields are shown in Table 3:

[0095] Table 3: Anti-penetration parameters of 7 groups of composite protective panels

[0096]

[0097] From the data in Table 3, it can be seen that when the bullet penetrates at an initial velocity of 600m / s, the penetration resistance performance is better when the diameter ratio of the large-diameter ceramic ball to the small-diameter ceramic b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com