Reaction type compound crusher

A compound crusher and counterattack technology, applied in grain processing and other directions, can solve the problem of poor uniformity of finished particles in the crushing effect, and achieve the effect of regular and smooth finished particle shape, improved particle quality and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the technical solution of the present invention will be described in detail through specific examples.

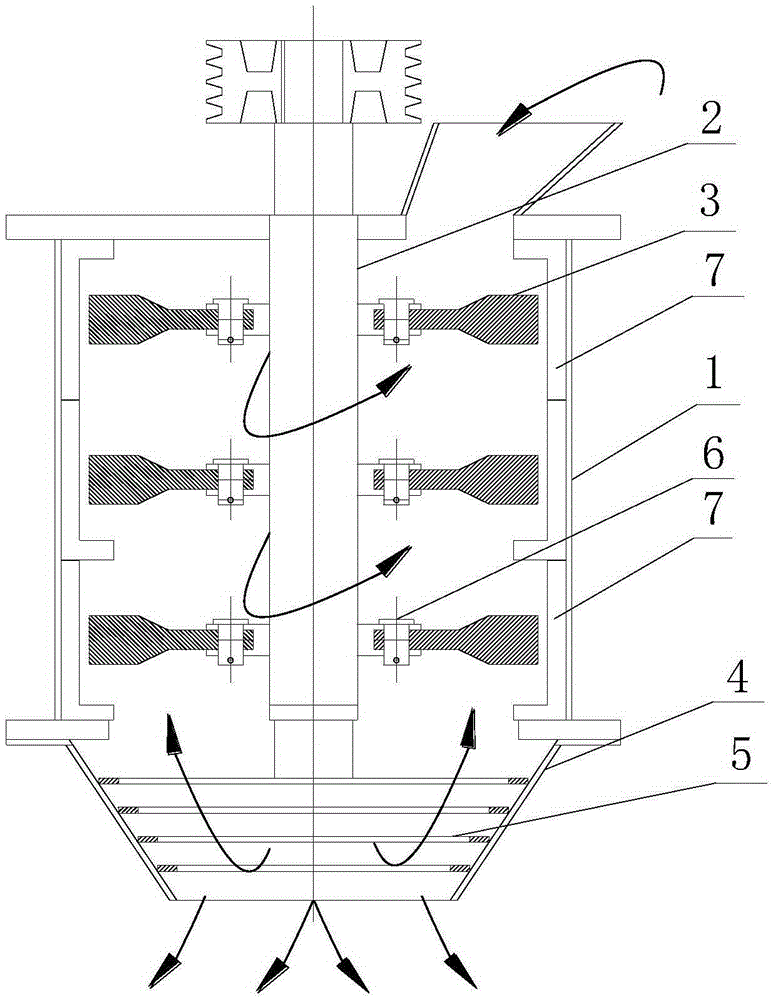

[0023] like figure 1 as shown, figure 1 It is a structural schematic diagram of an impact compound crusher proposed by the present invention.

[0024] refer to figure 1 , an impact compound crusher proposed in an embodiment of the present invention, comprising: a cylinder body 1, a rotating shaft 2, a breaking hammer 3, a cover plate 4, an impact ring 5 and a driving mechanism, wherein:

[0025] One end of the barrel 1 is open, and the other end is closed; the end face of the barrel 1 and located at the closed end is provided with a mounting hole and a feeding port, and the mounting hole is on the same line as the center line of the barrel 1, and the feeding port is located at the installation One side of the hole; one end of the rotating shaft 2 extends into the cylinder body 1 through the installation hole and is rotationally connected with the cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com