Magnetron sputtering target and magnetron sputtering device adopting same

A magnetron sputtering device and magnetron sputtering technology, applied in sputtering coating, ion implantation coating, coating and other directions, can solve the problems of reducing the utilization rate of target material, uneven particle distribution, affecting the quality of coating and so on , to achieve the effect of improving the utilization rate of the target material, improving the uniformity of the coating, and increasing the number of impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

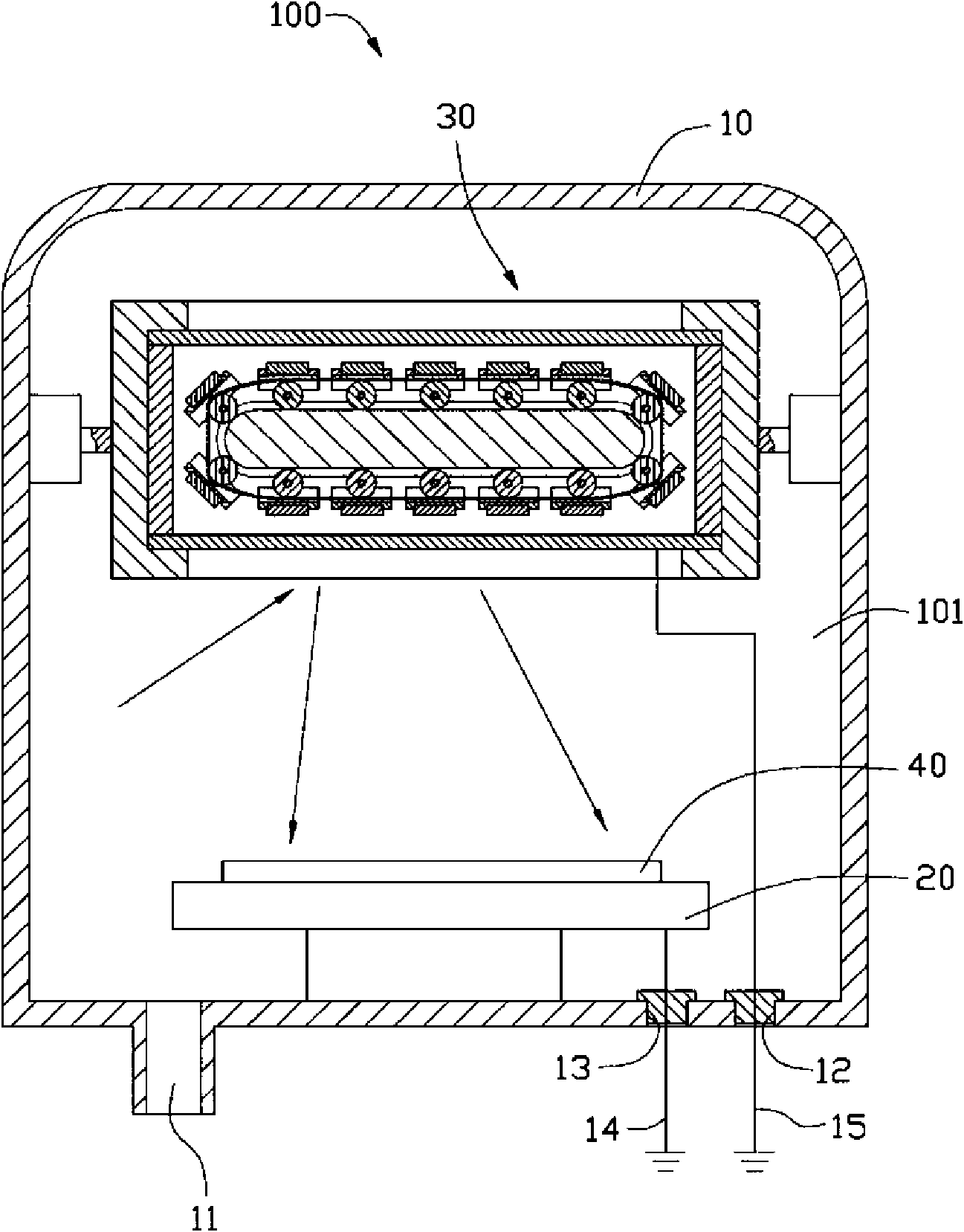

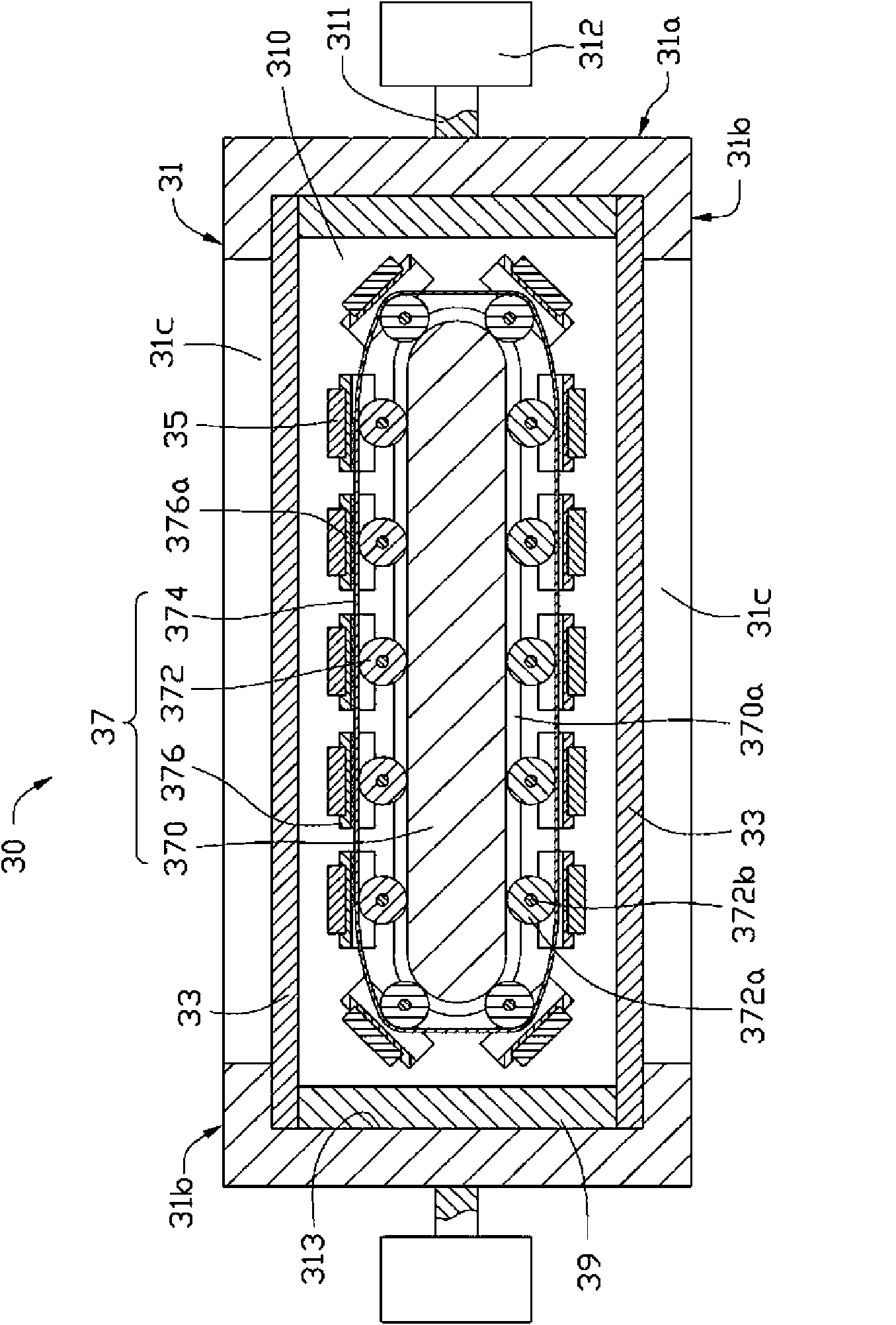

[0013] Such as figure 1 As shown, a magnetron sputtering device 100 provided in an embodiment of the present invention is used for coating a substrate 40 to be coated by impacting coating particles on a target. In this embodiment, the coating particles are Ar + particle. The magnetron sputtering device 100 includes a shield 10 , a substrate holder 20 and a magnetron sputtering target 30 . The shielding cover 10 is formed with a first cavity 101 , and the substrate carrier 20 and the magnetron sputtering target 30 are both located in the first cavity 101 . The substrate carrying seat 20 is disposed facing the magnetron sputtering target 30 , and is used for carrying the substrate 40 to be coated. The magnetron sputtering target 30 is pivotally connected to the inner wall of the shield 10 .

[0014] The shielding cover 10 is provided with a vacuum hole 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com