Dustproof textile equipment

A technology for textile equipment and dust prevention, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, which can solve problems such as troubles and achieve the effect of improving cleanliness and rapid cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

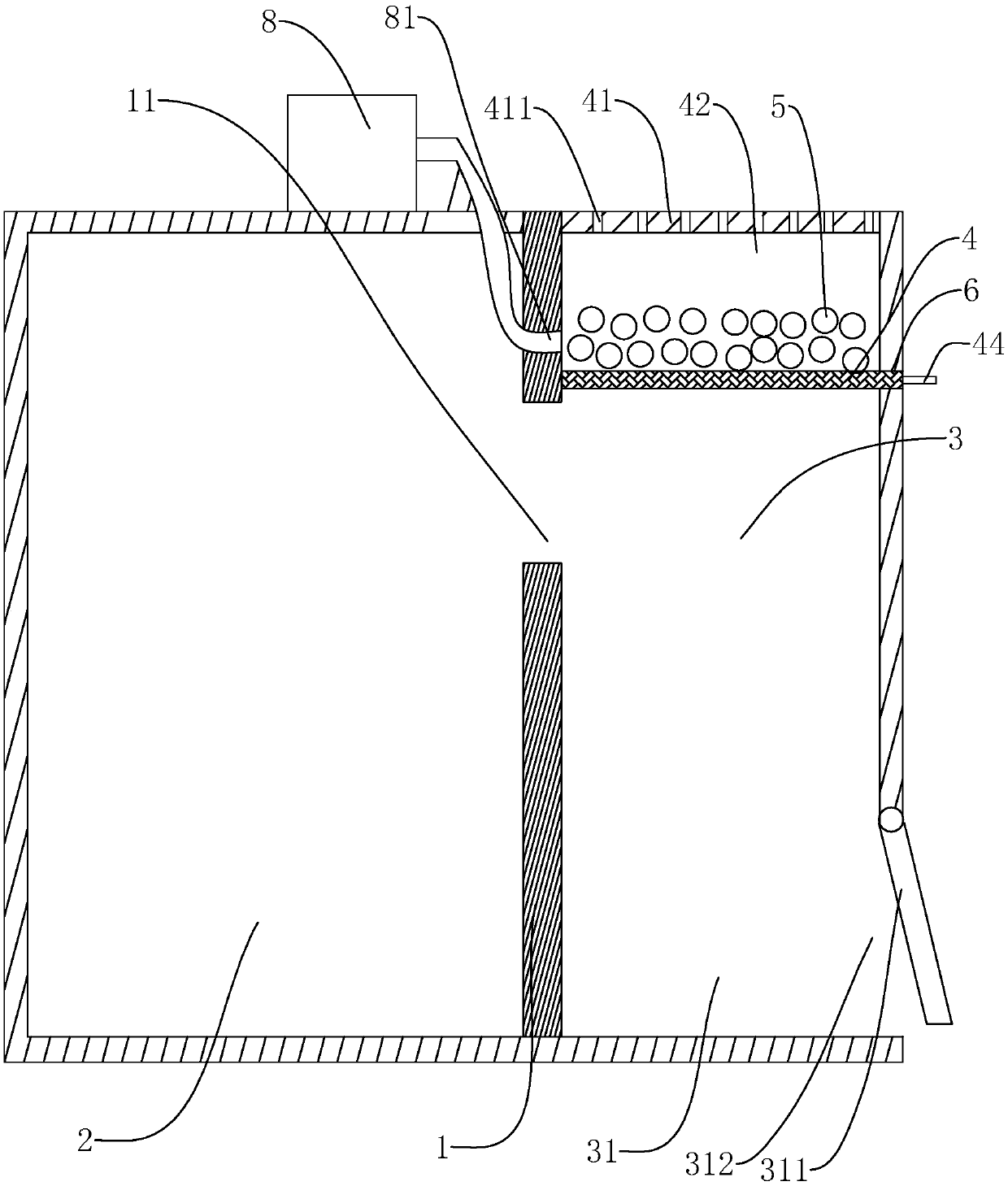

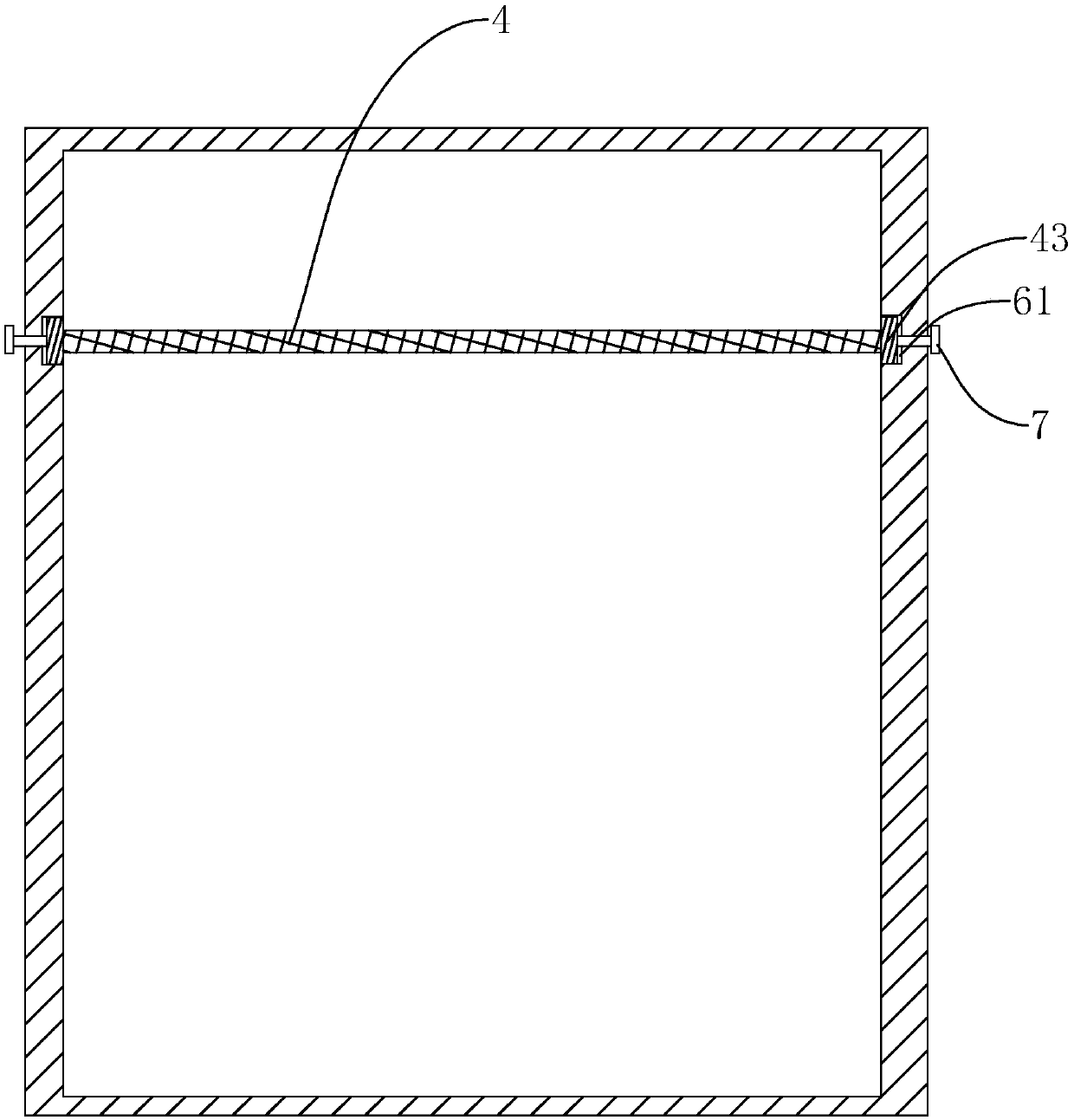

[0023] A kind of anti-dust textile equipment provided by this embodiment has a structure such as Figure 1-3 As shown, it includes the shell, and there is a partition 1 inside the shell. The partition 1 divides the shell into an equipment room 2 and a dust removal room 3. The equipment room 2 is used to place equipment, and the dust removal room 3 provides dust removal space. The partition The upper end of 1 is provided with a channel 11 for connecting the equipment room 2 and the dust removal room 3, that is, the dust generated in the equipment room 2 enters the dust removal room 3 through the channel 11, and the dust removal room 3 processes the dust so that it cannot reach the workshop, so as to Ensure the air quality in the workshop.

[0024] A dust storage chamber 31 is formed below the dust removal chamber 3 , and a dust outlet 312 is opened near the lower end of the dust storage chamber 31 , and a closing plate 311 is hinged at the dust outlet 312 .

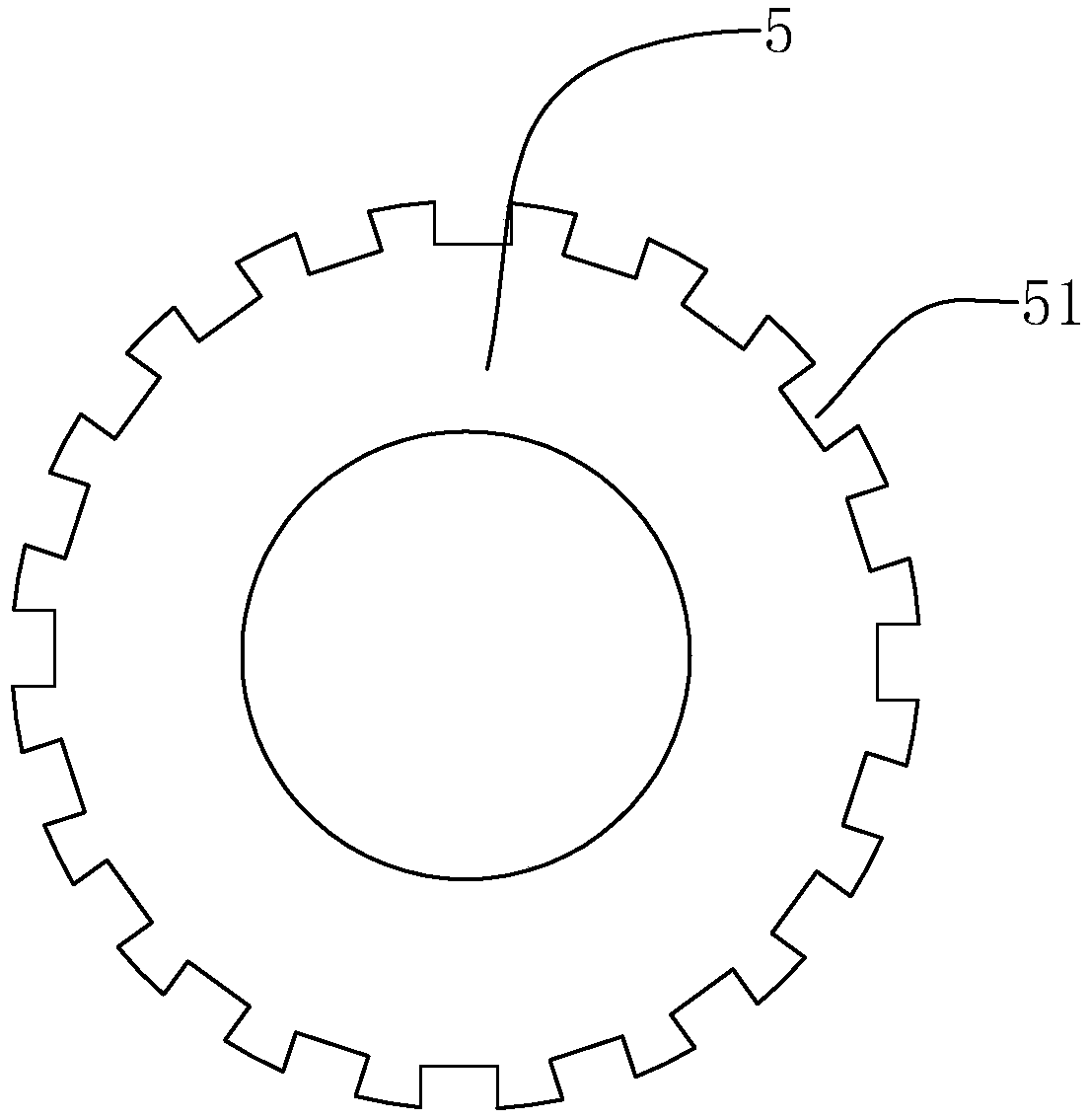

[0025] The dust r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com