Method for manufacturing automobile transmission limiting ring

A technology for automotive gearboxes and limit rings, which is applied in the field of metal processing, and can solve the problems of reducing gear interchangeability, long processing time for grooves, and increasing manufacturing costs, so as to achieve small deformation, shorten manufacturing time, and reduce waste products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of automobile transmission limit ring of the present invention comprises the following steps:

[0025] (1) Use 20CrMoH as the raw material to cut into material sections, grind the surface through centerless grinding, then spray the lubricant, and dry the lubricant; Check whether there are cracks, etc., and if there are, it will be judged as unqualified; then spray lubricant on its surface. The commonly used lubricant is graphite or organic polymer lubricant to lubricate.

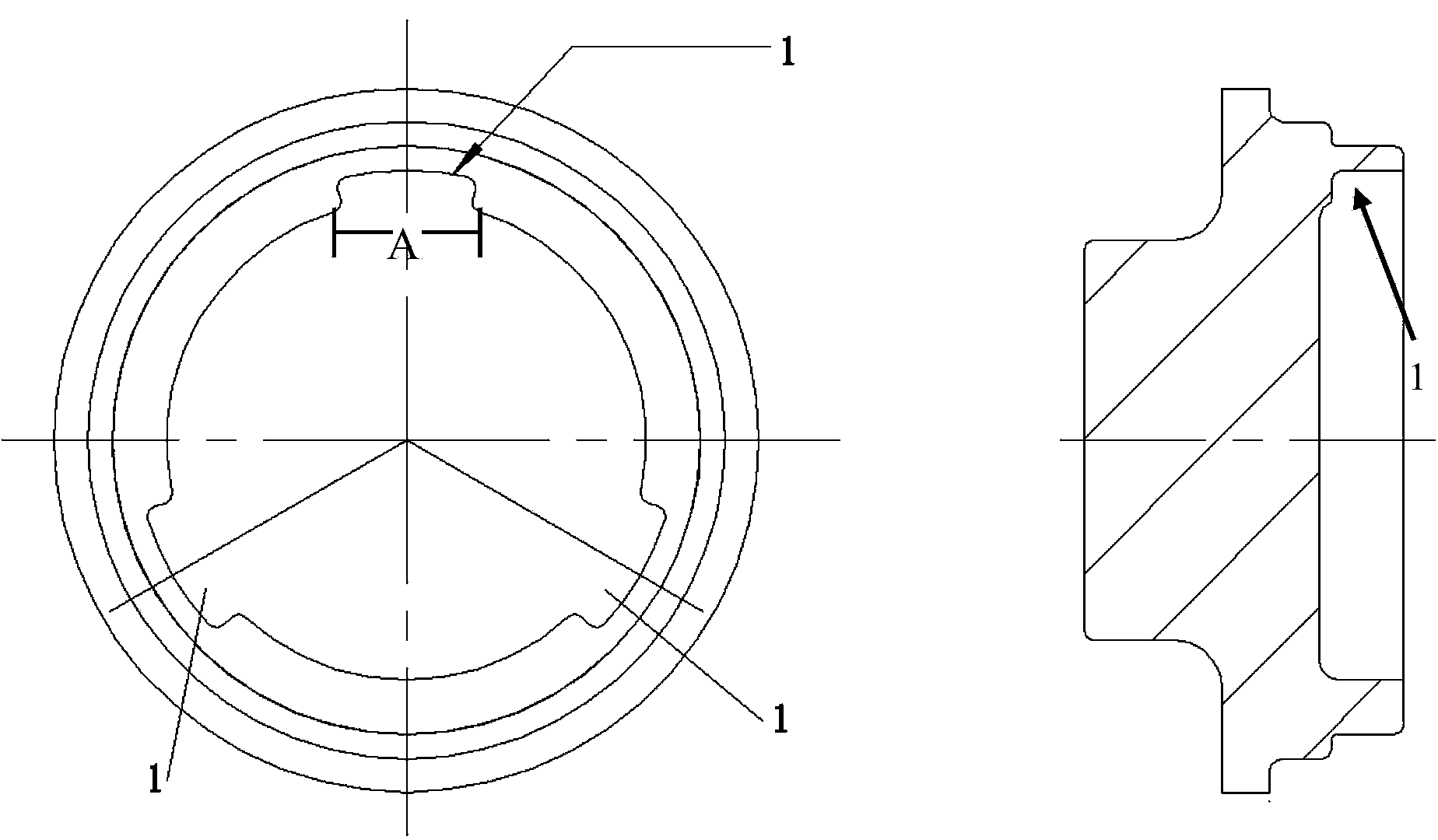

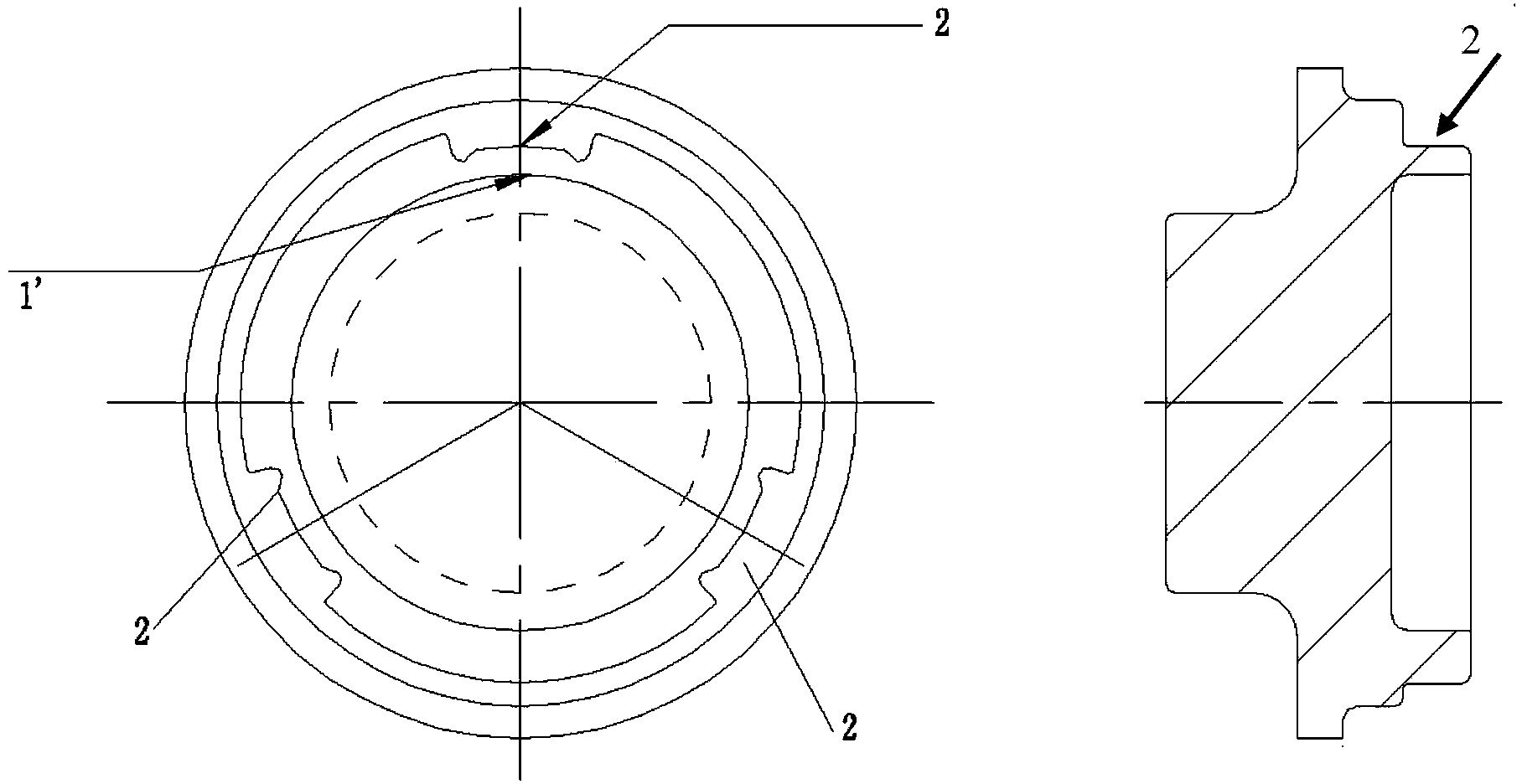

[0026] (2) Heat the blank to 750°C-800°C in an intermediate frequency induction heating furnace with a protective atmosphere, and warm forge it on a press to form a pre-forged billet. The inner wall of the pre-forged billet is equally distributed with three grooves, and the angle between 120° (see figure 1 ). The protective atmosphere is to add protective nitrogen or inert gas into the medium frequency induction heating furnace to prevent the billet from being severely oxidize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com