Alumina slurry, method for producing same, and coating liquid

a technology of alumina slurry and alumina slurry, which is applied in the direction of cell components, sustainable manufacturing/processing, and final product manufacturing, etc., can solve the problems of short circuit, sometimes failed to suppress abnormal heat generation in separators composed of polyolefin porous films, etc., and achieve excellent shape stability and suppress powder falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production of Alumina Slurry 1

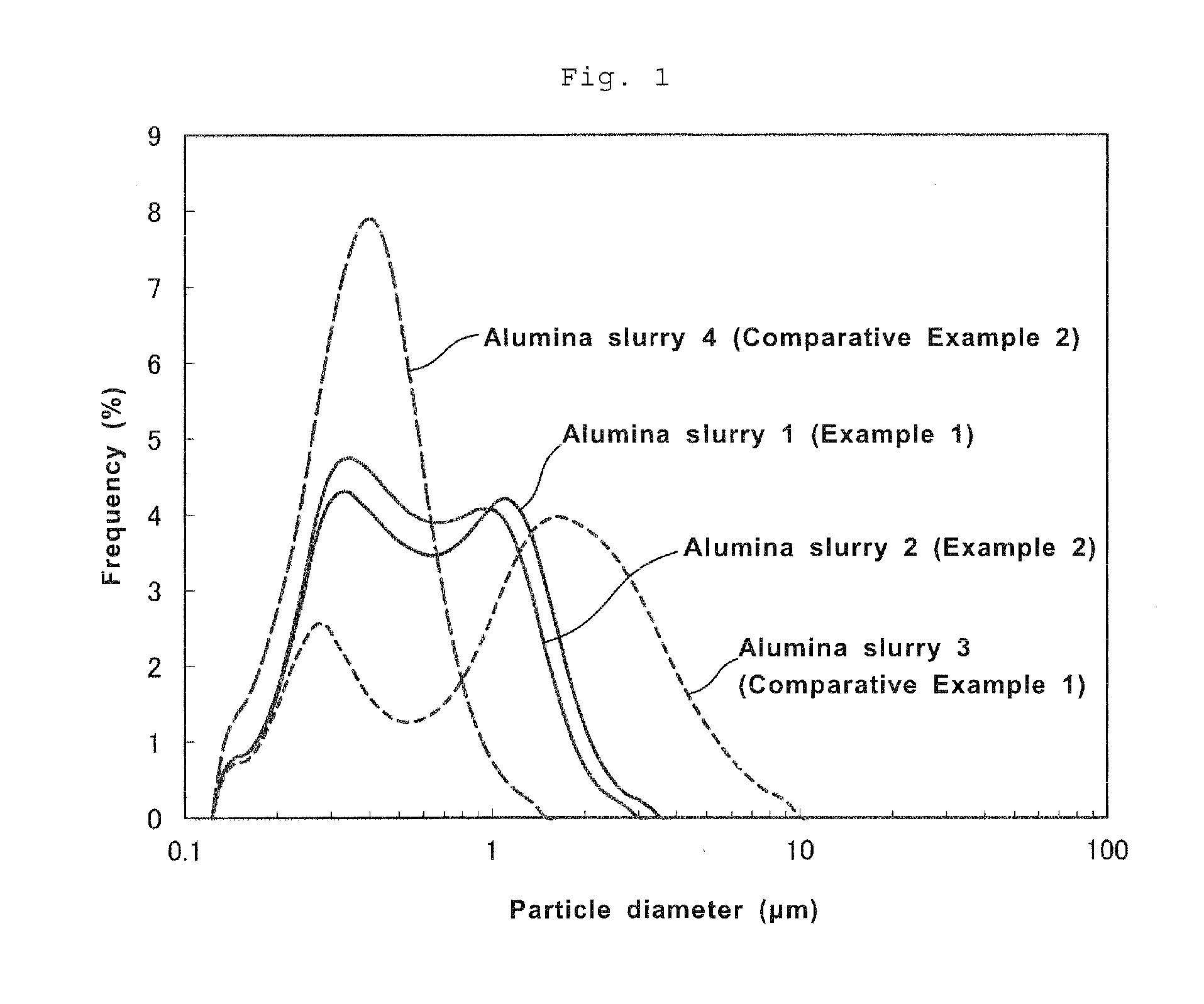

[0126]Alumina particles having a BET specific surface area of 4.1 m2 / g and an average particle diameter of 6.2 μm were added to water so that the concentration of alumina became 30% by weight while stirring the alumina particles to obtain an alumina-water suspension. Subsequently, using Dyno-Mill (KDL-PILOT A model) manufactured by AG MASCHINENFABRIK BASEL, dispersion was performed under wet grinding conditions (circumferential speed: 10 m / second, material of beads: ZrO2, diameter of beads; 1.0 mm, filling ratio of beads: 85% by volume, flow rate: 0.5 L / minute, and retention time: 4.4 minutes) in a path system to obtain an alumina slurry 1.

[0127]In the alumina slurry 1, a viscosity was 2.75 Pa·s, alumina particles included had an average particle diameter of 0.57 μm, and the amount of coarse particles of 10 μm or more was 3 ppm or less. The alumina slurry 1 was evaporated to dryness. As a result, the thus measured content of Zr in solid alumina was 1,01...

example 2

[0142]Using the same operation as in Example 1, except that wet grinding conditions were changed as follows: circumferential speed: 10 m / second, material of beads: ZrO2, diameter of beads: 1.0 mm, filling ratio of beads: 85% by volume, flow rate: 0.5 L / minute, and retention time: 5.8 minutes, an alumina slurry 2 of Example 2 was produced. In the thus obtained alumina slurry 2, a viscosity was 3.04 Pa·s, alumina particles included had an average particle diameter of 0.52 μm, and the amount of coarse particles of 10 μm or more was 3 ppm or less. The alumina slurry was evaporated to dryness. As a result, the thus measured content of Zr in solid alumina was 1,270 ppm calculated on a weight basis.

[0143]As is apparent from particle diameter distribution of alumina particles in the alumina slurry 2 shown in FIG. 1, alumina particles in the alumina slurry 2 were alumina particles, wherein

[0144]particles having a particle diameter of less than 0.2 μm accounts for 4.6% by weight,

[0145]particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com