Boehmite/aluminum oxide composite lithium ion battery coating electrode piece

An ion battery and alumina technology, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode manufacturing, etc., can solve problems such as lithium dendrite puncture, battery fire, explosion, etc., and achieve cycle life improvement, cost reduction, and safety good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of boehmite / alumina composite lithium-ion battery coated pole piece, on the surface of the pole piece of lithium battery coating a layer of boehmite / alumina slurry, described boehmite / alumina slurry consists of the following Made of raw materials in parts by weight: 0.5-1.3 parts of surfactant, 0.5-1.0 parts of thickener, 5.0-10.0 parts of binder, 0.1-0.5 parts of dispersant, 20.0-50.0 parts of boehmite / alumina mixture , 2.0-6.0 parts of defoamer, 30.0-70.0 parts of solvent.

[0024] The mass ratio of the boehmite to alumina is 1:4.

[0025] The particle diameters of the boehmite and alumina are both 200nm, and the alumina is α-Al 2 o 3 .

[0026] The surfactant is sodium dodecylbenzenesulfonate.

[0027] The thickener is sodium carboxymethylcellulose.

[0028] The binder is polyvinyl alcohol (PVA).

[0029] The defoamer is C 2 h 5 Oh.

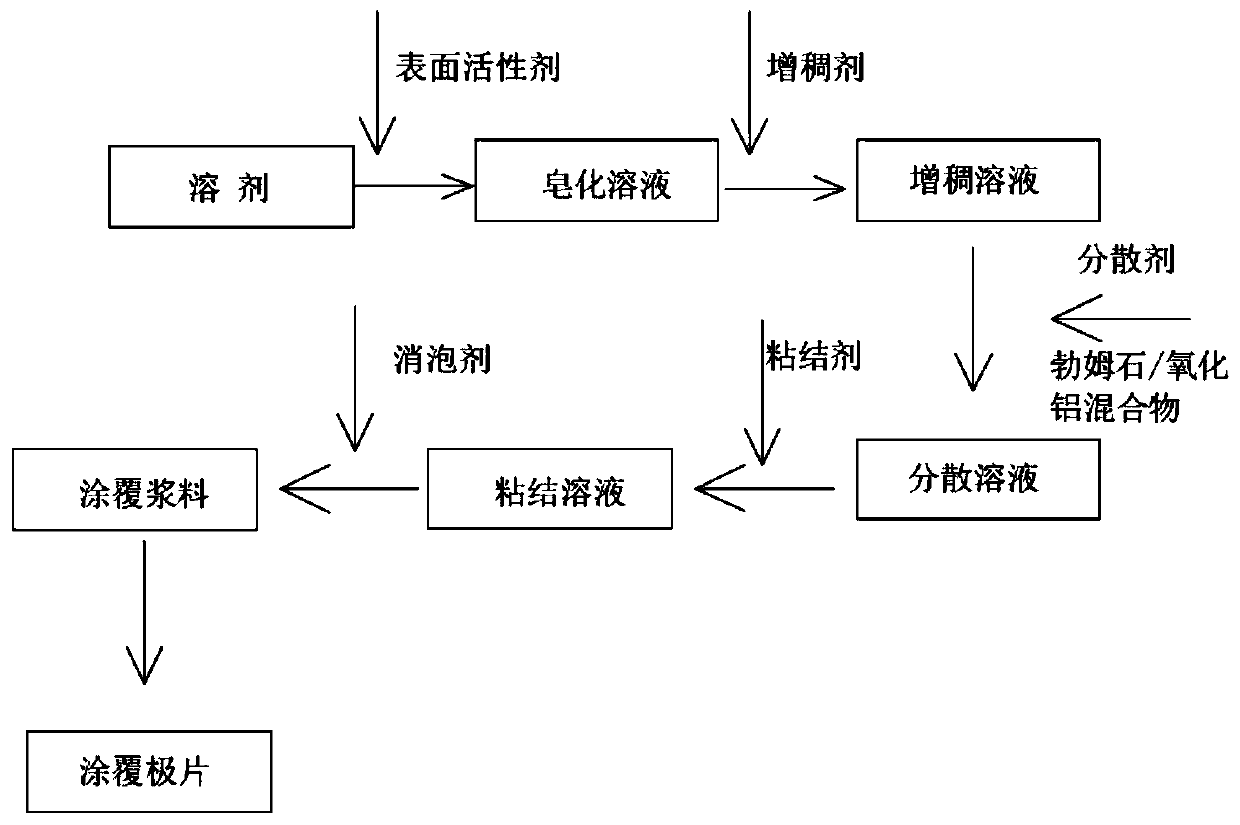

[0030] A method for preparing a boehmite / alumina composite lithium-ion battery coated pole piece as described above, c...

Embodiment 2

[0037] A kind of boehmite / alumina composite lithium-ion battery coated pole piece, on the surface of the pole piece of lithium battery coating a layer of boehmite / alumina slurry, described boehmite / alumina slurry consists of the following Made from raw materials in parts by weight: 0.7 parts of surfactant, 0.8 part of thickener, 4.0 parts of binder, 0.3 part of dispersant, 40.0 parts of boehmite / alumina mixture, 4 parts of defoamer, 50.2 parts of solvent .

[0038] The mass ratio of the boehmite to alumina is 1:2.

[0039] The particle diameters of the boehmite and alumina are both 400nm, and the alumina is α-Al 2 o 3 .

[0040] The surfactant is C 11 h 23 CON(CH 2 CH 2 Oh) 2 (coconut oil fatty acid diethanolamide).

[0041] The thickener is xanthan gum.

[0042] The binder is selected from gum arabic.

[0043] The defoamer is polyglycerol ether.

[0044] A method for preparing a boehmite / alumina composite lithium-ion battery coated pole piece as described above, c...

Embodiment 3

[0051]A kind of boehmite / alumina composite lithium-ion battery coated pole piece, on the surface of the pole piece of lithium battery coating a layer of boehmite / alumina slurry, described boehmite / alumina slurry consists of the following Made of raw materials in mass percent: 1.3 parts of surfactant, 1.0 part of thickener, 10.0 parts of binder, 0.5 part of dispersant, 50.0 parts of boehmite / alumina mixture, 6.0 parts of defoamer, and 31.2 parts of solvent.

[0052] The mass ratio of the boehmite to alumina is 3:4.

[0053] The particle diameters of the boehmite and alumina are both 600nm, and the alumina is β-alumina.

[0054] Described tensio-active agent is (C 2 h 4 O) n C 16 h 34 O (polyoxyethylene ether).

[0055] The thickener is gelatin.

[0056] The binder is a silane coupling agent, specifically vinyltriethoxysilane.

[0057] The defoamer is a mixture of ethanol and glycerol ether with a mass ratio of 1:3.

[0058] A method for preparing a boehmite / alumina com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com