Preparation method of novel chip-type oxygen sensor

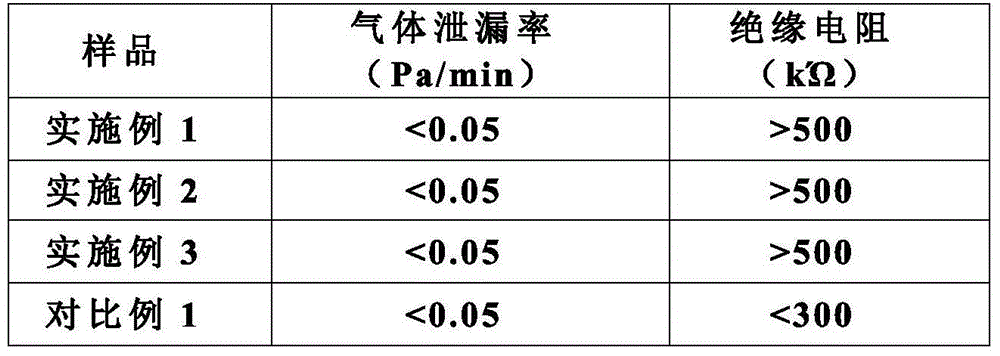

A technology of oxygen sensor and sensor substrate, which is applied in the field of sensors, can solve the problems of affecting sensor signal, leakage of heating circuit, increasing the cost of oxygen sensor, etc., and achieve the effect of reducing production cost and increasing insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

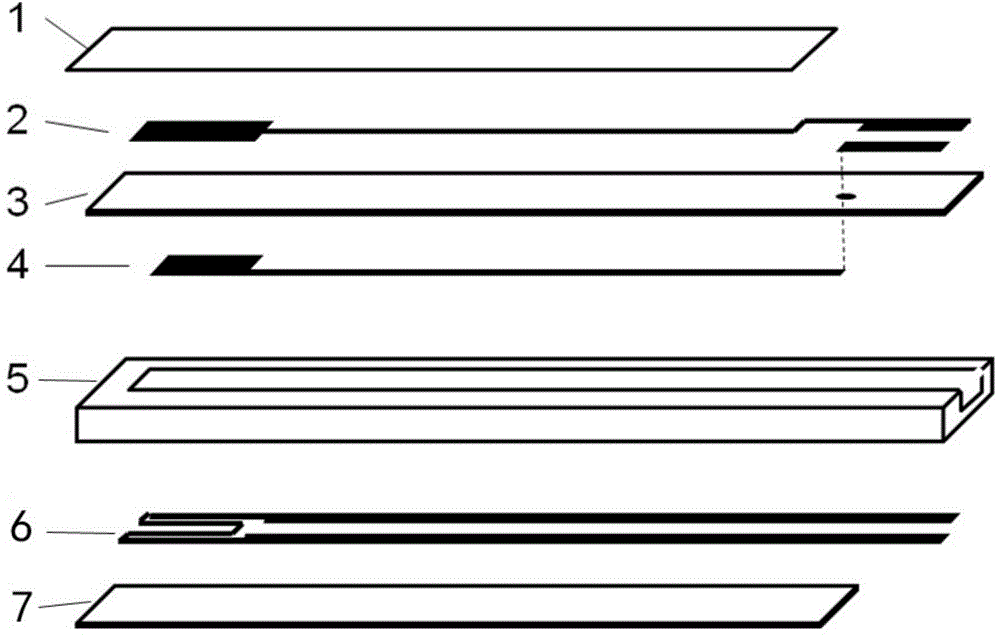

[0025] The present invention provides a kind of preparation method of novel chip sensor, comprises the following steps:

[0026] (1) Make a casting sheet with oxide-doped zirconia powder as the sensor substrate, print the external electrode Pt and the internal electrode Pt on the upper and lower sides of the sensor substrate, and print a porous protective layer on the top of the external electrode and then dry it , sintering to obtain a sensitive layer;

[0027] (2) Mix aluminum oxide powder with silicon oxide powder or magnesium oxide powder, add 8% PVB, 5% triethanolamine, 5% polyethylene glycol, 40% absolute ethanol and 32% butanone, after 24 hours After ball milling, it is cast into a ceramic sheet with a thickness of 0.3mm, and then cut into a sheet with grooves and a sheet without grooves, which are laminated to form a reference substrate and then sintered. The formed reference substrate has a cavity, and the cavity The length matches the reference base body and opens o...

Embodiment 1

[0039] ① Make a sensitive layer

[0040] 2~8mole%Y 2 o 3Put 100g of doped zirconia powder in a ball mill, add 150g of ethanol, 5g of triethanolamine, 2g of glycerin, and 7g of polyvinyl alcohol, and mix for 35 hours to prepare a slurry with a viscosity of 5400mPa.s in a casting machine. The casting sheet with a thickness of 0.1-0.5mm is used as the sensor substrate, and then the outer electrode and the inner electrode are printed on both sides of the sensor substrate with platinum electrode paste, and then a porous protective layer is printed on the outer electrode, and after drying at 60-400°C , Sintered at 1350-1550°C.

[0041] ②Make a reference matrix

[0042] Mix aluminum oxide powder with 1-5wt% silicon oxide powder or magnesium oxide powder, add 8% PVB, 5% triethanolamine, 5% polyethylene glycol, 40% absolute ethanol and 32% methyl ethyl ketone, after 24 After being ball-milled for hours, it was cast into cast sheets with a thickness of 0.3-0.5mm, and then three of t...

Embodiment 2

[0047] Others are the same as in Example 1, except that the zirconia powder used to make the sensor matrix is doped with 2-8 mole% of MgO; when making the reference matrix, the content of silicon oxide or magnesium oxide powder is 5wt%, and the The thickness of the cavity is 1mm, and the thickness of the concave cavity is 0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com