Method for preparing superfine alumina powder

A technology of ultra-fine alumina and alumina, applied in the field of alumina, can solve the problems of demanding alumina powder dispersibility, and achieve the effect of excellent dispersion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

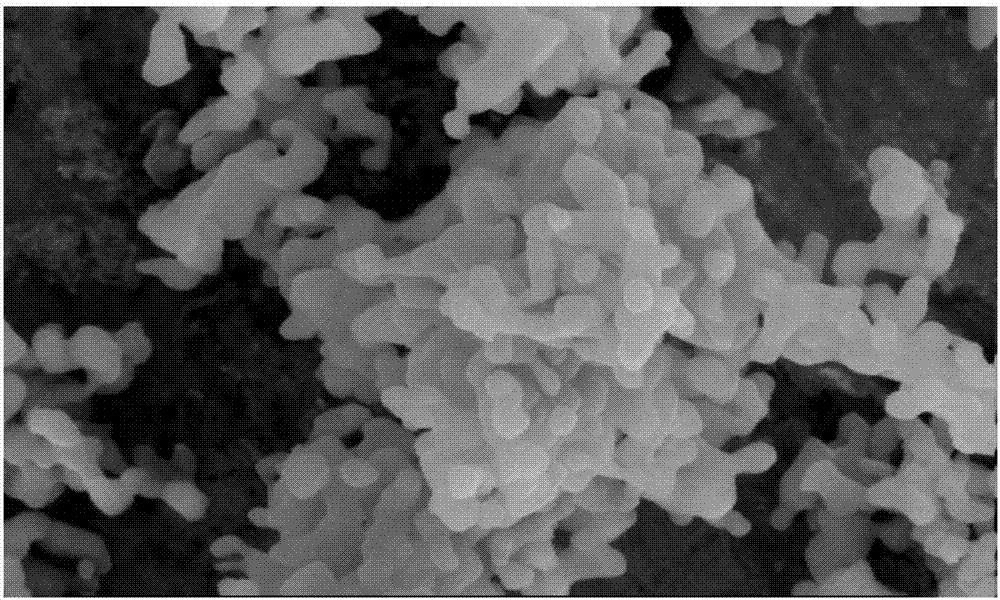

[0023] The raw material used in the preparation method of the present invention, that is, the initial alumina slurry, may be commercially available conventional alumina powder. In industry, the calcining method is usually used to prepare a large amount of alumina powder. However, such an alumina powder preparation process is difficult to prepare alumina powder with excellent performance. Especially in the face of increasingly stringent battery performance requirements, higher and higher requirements are put forward for the particle size distribution and dispersibility of alumina powder. However, the present invention can remarkably improve the particle size distribution, dispersibility and other properties of the alumina powder only by adjusting the grinding steps and related parameters. Advantageously, the alumina powder used as the raw material has an average particle diameter of less than 10 μm. The particles in common alumina powders are usually normally distributed. Th...

Embodiment 1

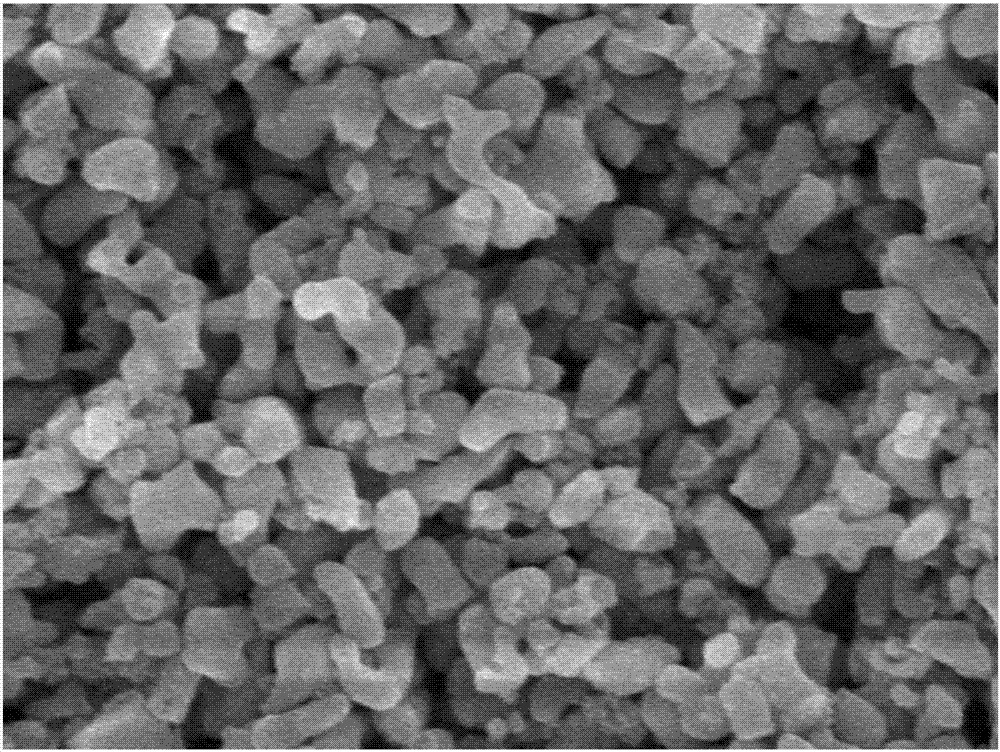

[0048] Add 4kg of zirconium beads with a diameter of 5.3mm to the rough mill, then add 800-1000g of deionized water, then weigh 1kg of the above-mentioned high-purity α-alumina with a purity of 99.99%, add it, start stirring, and add the high-purity [5g] sodium hexaphosphate with 0.5% of the mass of α-alumina is used for surface modification, and after ball milling at a speed of 30r / min for 3 hours, the stirring is stopped, the slurry is passed through a 100-mesh filter, and then transferred to a fine grinder. Medium zirconium beads have a diameter of 1 mm and a mass of 1 kg. Continue ball milling at a speed of 2000 r / min. Add metasodium hexaphosphate with a mass of 0.5% [5 g] of high-purity α-alumina in portions every half an hour, ball mill for 2 hours, and grind the resulting slurry The raw materials were dried and crushed to obtain alumina powder.

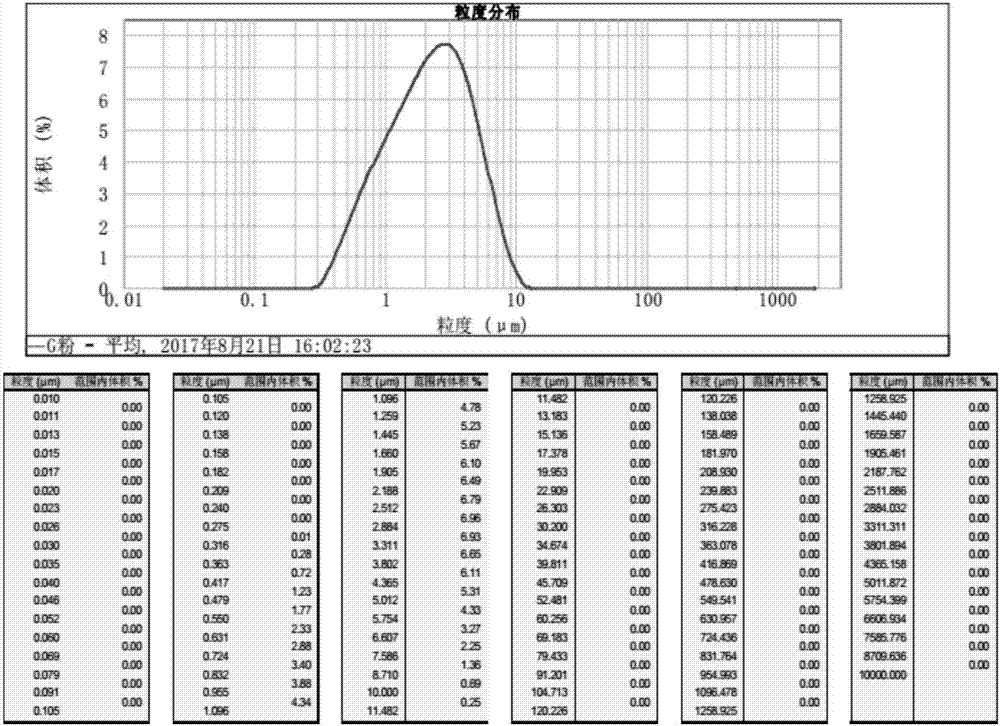

[0049] Weigh 40g of the obtained powder in a colorimetric tube, add 60g of deionized water, shake well for 5min, let stand fo...

Embodiment 2

[0052] Add 4kg of zirconium beads with a diameter of 5.3mm to the rough mill, then add 800-1000g of deionized water, then weigh 1kg of the above-mentioned high-purity α-alumina with a purity of 99.99%, add it, start stirring, and add the high-purity α-alumina mass 0.5% [5g] polyacrylic acid for surface modification, after ball milling at 30r / min for 3 hours, stop stirring, pass the slurry through a 100-mesh filter, and transfer it to a fine grinder, and zirconium in the fine grinder Bead diameter 1mm, mass 1kg, continue ball milling at a speed of 2000r / min, add polyacrylic acid accounting for 0.5% [5g] of high-purity α-alumina in portions every half hour, ball mill for 2 hours, dry the obtained slurry, Pulverize to obtain alumina powder.

[0053] Weigh 40g of the obtained powder in a colorimetric tube, add 60g of deionized water, shake well for 5min, let stand for 48h, and observe the sedimentation situation.

[0054] The obtained powder data: D10 is 0.324μm, D50 is 1.023μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com