Photocuring 3D printing nanoparticle reinforced metal part and preparation method thereof

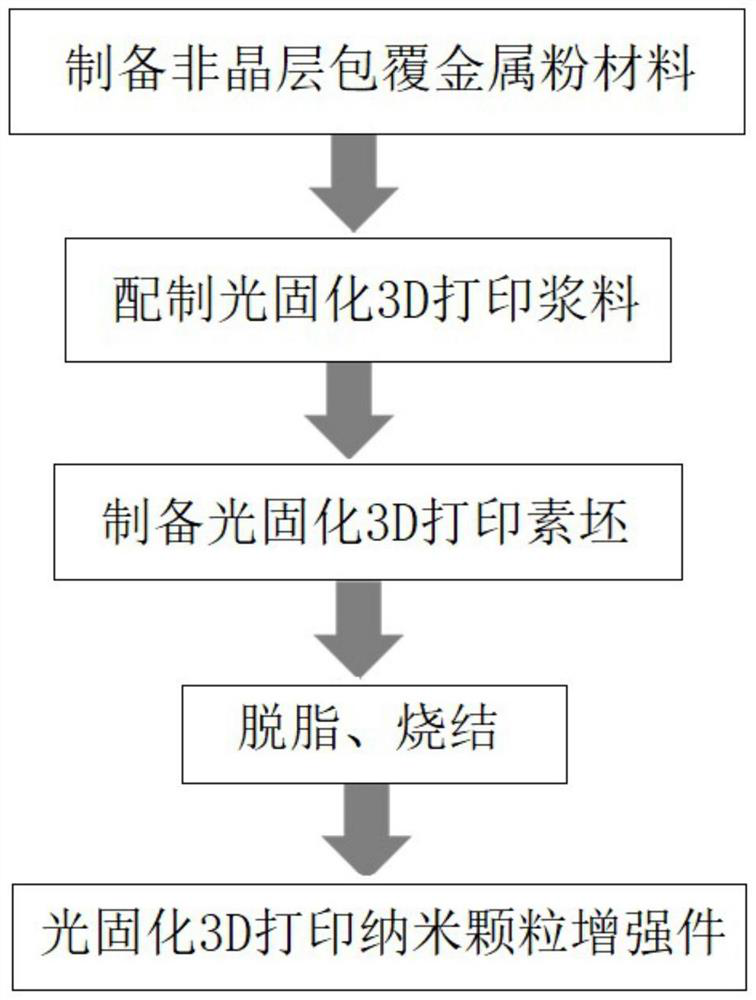

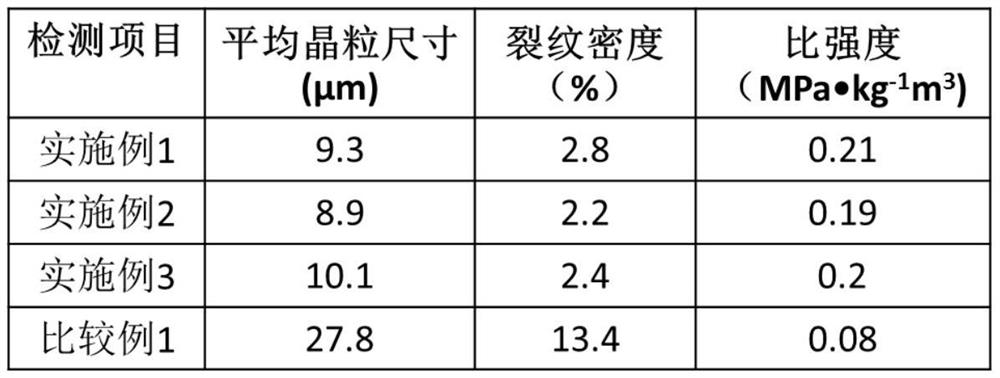

A 3D printing and nanoparticle technology, applied in metal processing equipment, additive manufacturing, additive processing, etc., can solve the problems of unavailable photocurable structure, uncurable photosensitive resin, poor dispersion of metal powder, etc., to achieve good dispersion, Easy to crystallize and release heat, lowering the effect of sintering degreasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment prepares a light-cured 3D printing nanoparticle-reinforced metal part, which specifically includes the following steps:

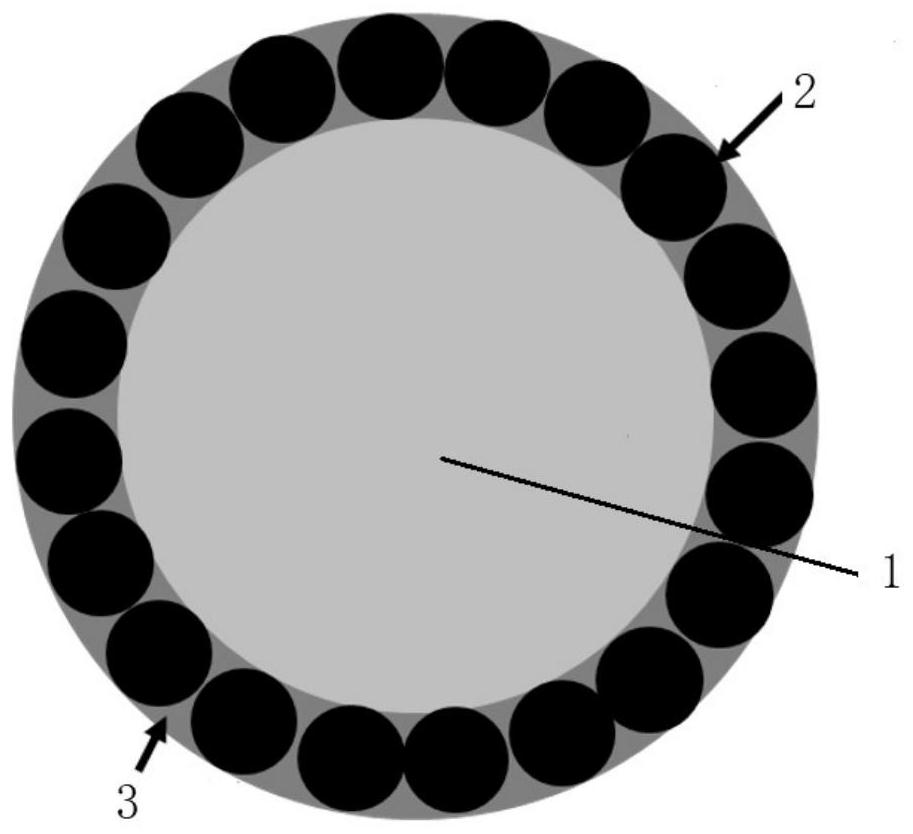

[0067] Preparation of amorphous layer coating metal powder material: first with 250g particle diameter FeCrMoCB amorphous powder (wherein, the mass fraction of Fe is 57%, the mass fraction of Cr is 23%, the mass fraction of Mo is 18%, C The mass fraction of B is 1.5%, the mass fraction of B is 0.5%) and 100g of polyacrylic acid are placed in a beaker and mixed and heated to 50 ° C, and after mechanical stirring for 60 minutes, the temperature is raised to 100 ° C, while mechanical stirring Slowly add 50g of benzoyl peroxide and 700g of FeCrTiAlWMoTaCBZr metal powder (wherein, the massfraction of Fe is 58.25, the massfraction of Cr is 21%, the massfraction of Ti is 8%, the massfraction of Al is 10 microns) The mass fraction is 4.5%, the mass fraction of W is 4%, the mass fraction of Mo is 2%, the mass fraction of Ta is 2%, the mass fra...

Embodiment 2

[0075] This embodiment prepares a light-cured 3D printing nanoparticle-reinforced metal part, which specifically includes the following steps:

[0076] Preparation of amorphous layer coated metal powder material: first 150g of FeAlNbB amorphous powder with particle diameter of 120nm (wherein, the mass fraction of Fe is 71.5%, the mass fraction of Al is 24%, the mass fraction of Nb is 4%, B The mass fraction is 0.5%) and 150g of chloroacrylic acid are mixed in a beaker and heated to 60°C, and after 90 minutes of mechanical stirring, the temperature is raised to 90°C, and 100g of benzene peroxide is slowly added to it while mechanically stirring tert-butyl formate and 600g particle diameter are the FeTiAlNbCB metal powder (alloy powder of 30 microns, wherein, the massfraction of Fe is 60%, the massfraction of Ti is 18%, the massfraction of Al is 17%, the massfraction of Nb is 4%, the mass fraction of C is 0.5, and the mass fraction of B is 0.5%), and the coating step is carried ...

Embodiment 3

[0084] This embodiment prepares a light-cured 3D printing nanoparticle-reinforced metal part, which specifically includes the following steps:

[0085] Preparation of amorphous layer coated metal powder material: first 200g of FeCrSiBMn amorphous powder with a particle diameter of 100nm (the mass fraction of Fe is 69.5%, the mass fraction of Cr is 24%, the mass fraction of Si is 4%, the mass fraction of B Fraction is 0.5%, the mass fraction of Mn is 2%) and 120g polyacrylic acid are placed in the beaker and mixed and heated up to 55 ℃, and after mechanical stirring for 100 minutes, then raise the temperature to 80 ℃, while mechanical stirring Slowly add 80g of benzoyl peroxide and 600g of FeCrAlSiMoBMn metal powder (alloy powder, wherein the massfraction of Fe is 58%, the massfraction of Cr is 21%, the massfraction of Al is 17%, Si The mass fraction of Mo is 2%, the mass fraction of Mo is 1%, the mass fraction of B is 0.5%, and the mass fraction of Mn is 0.5%), and the coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com