Method for preparing nanocomposite dielectric film

A dielectric film and nanocomposite technology, applied in chemical instruments and methods, components of fixed capacitance, circuits, etc., can solve the problem of small dielectric constant, inconvenient miniaturization of capacitors, and inability to meet the requirements of military high energy storage density capacitors, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

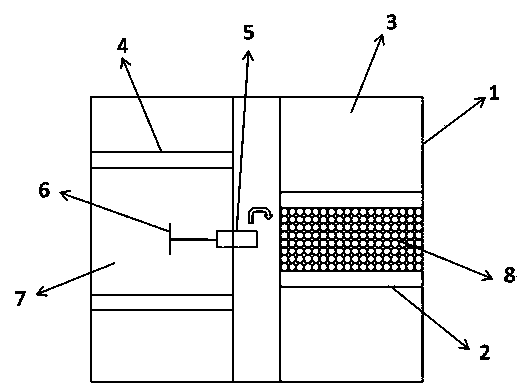

[0056] Polyvinylidene fluoride (PVDF) polymer dielectric materials are dissolved in organic solvents such as dimethyl sulfoxide to form a well-dispersed solution of PVDF. Barium titanate (BaTiO 3 ) nanoparticles and conductive polymer poly-3,4-ethylenedioxythiophene (PEDOT) nanoparticles are mixed and dissolved in organic solutions such as chloroform to form two well-dispersed solutions of nanoparticles. The obtained dispersion solution was dripped onto the surface of ultrapure water in different tanks of the LB membrane using a microsampler, so that PVDF and nanoparticles spread on the surface of ultrapure water. Control the sliding barrier of the LB film groove ( figure 1 2 and 4) respectively compress the PVDF and nanoparticles in the groove to the film-forming pressure to obtain a tightly arranged PVDF film ( figure 1 7) and nanoparticle films ( figure 1 Medium 8). The PVDF dielectric nano-thin film was first prepared on the substrate by the method of LB film horizonta...

Embodiment 2

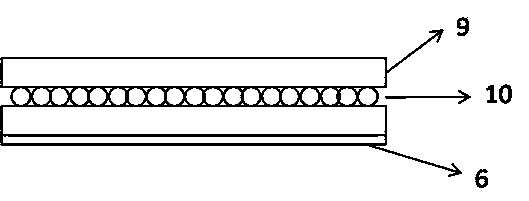

[0067] Such as figure 2 , the nano particle material is barium titanate and polypyrrole.

[0068] The preparation process of the nanocomposite dielectric film is similar to that of Embodiment 1. Since the nanoparticle materials are barium titanate and polypyrrole, PVDF-BaTiO 3 / Polypyrrole nanoparticles-PVDF composite nano-dielectric film structure.

Embodiment 3

[0070] Such as figure 2 , the nano particle material is barium titanate and polyaniline.

[0071] The preparation process of the nanocomposite dielectric film is similar to that of Embodiment 1. Since the nanoparticle materials are barium titanate and polypyrrole, PVDF-BaTiO 3 / Polyaniline nanoparticles-PVDF composite nano-dielectric film structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com