Patents

Literature

82 results about "Potassium aluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium aluminate is an inorganic compound with the formula KAlO₂, which in aqueous solution exists as K[Al(OH)₄]. It is used as a dyeing and printing mordant, as a paper sizing, as an accelerant in the setting of concrete.

Cement Compositions and Methods of Using the Same

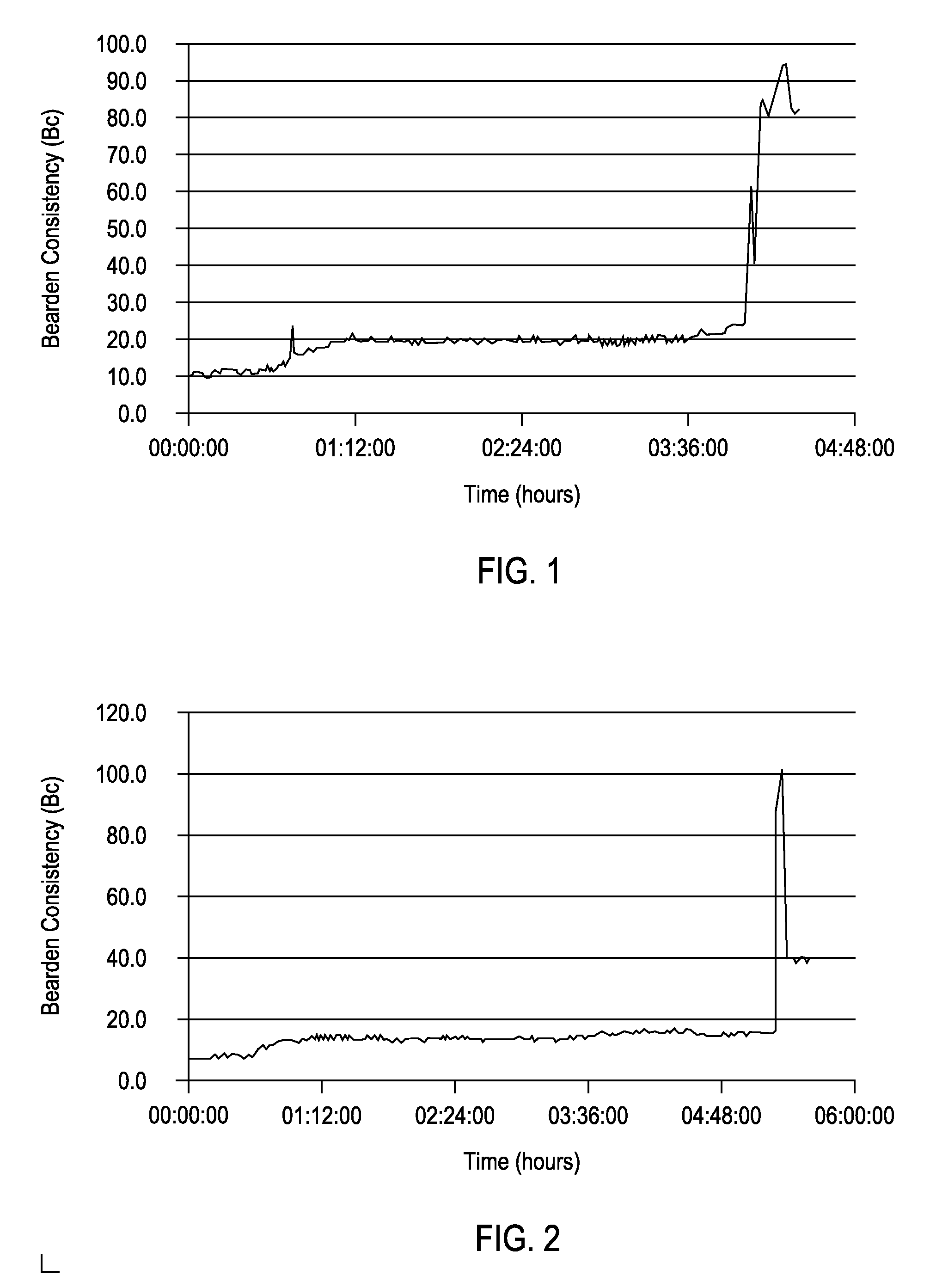

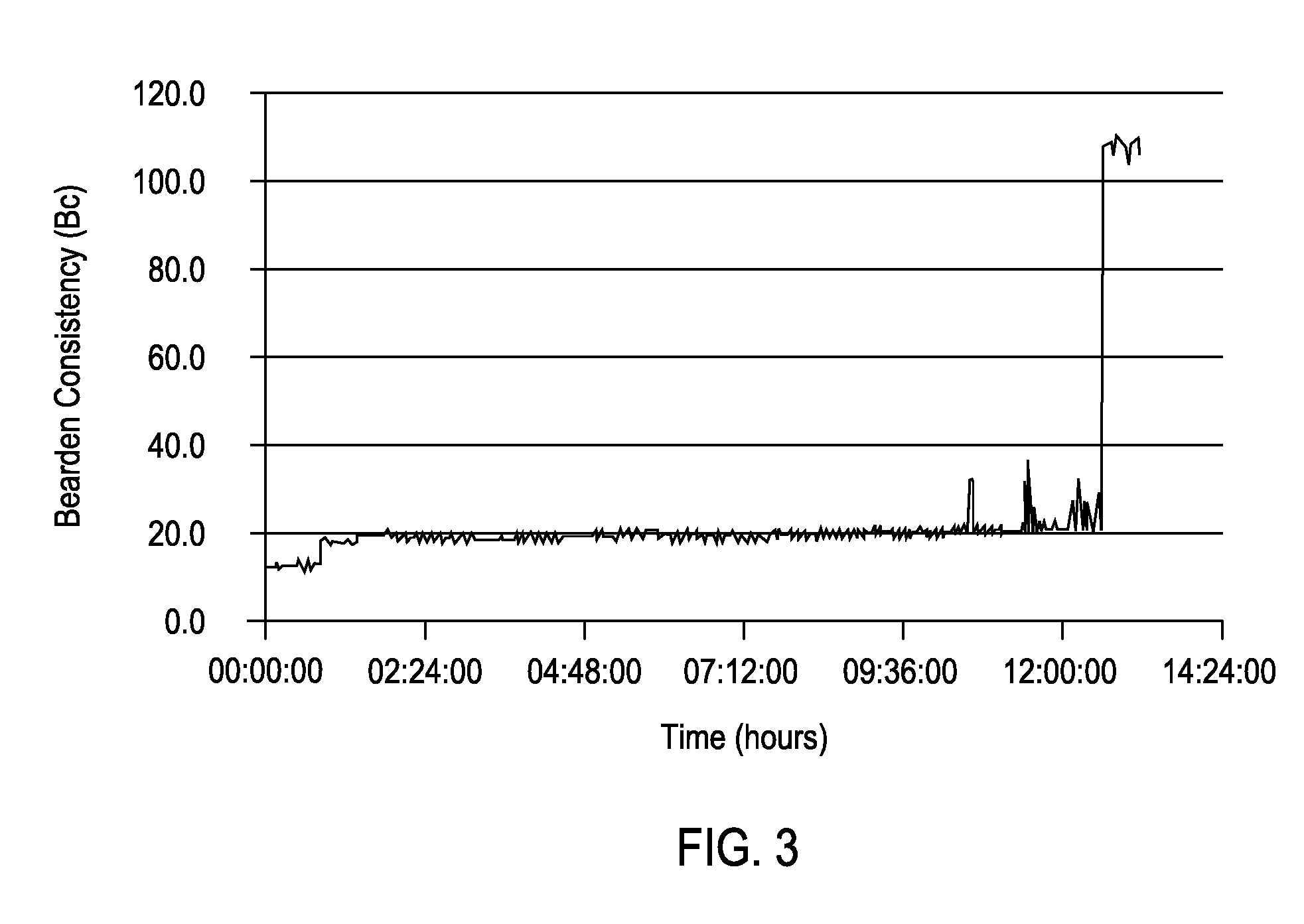

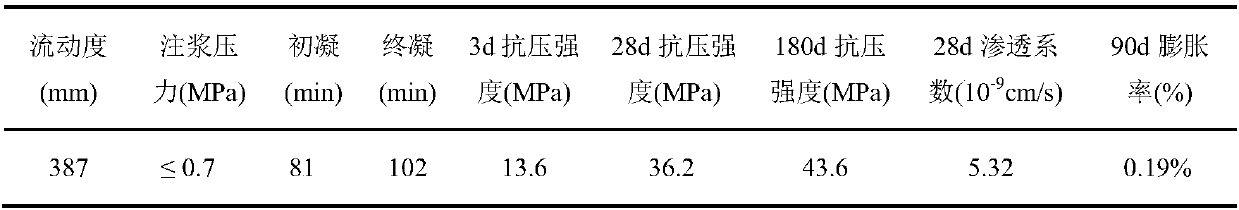

The present invention relates to cement compositions and their use in cementing operations. The cements comprise an aluminosilicate; a sodium aluminate, a calcium aluminate, a potassium aluminate, or a combination thereof; and water. In some cases the cement does not include Portland cement. The cement may be used in a subterranean formation having corrosive components therein, wherein the set cement sheath is resistant to degradation from the corrosive components within the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

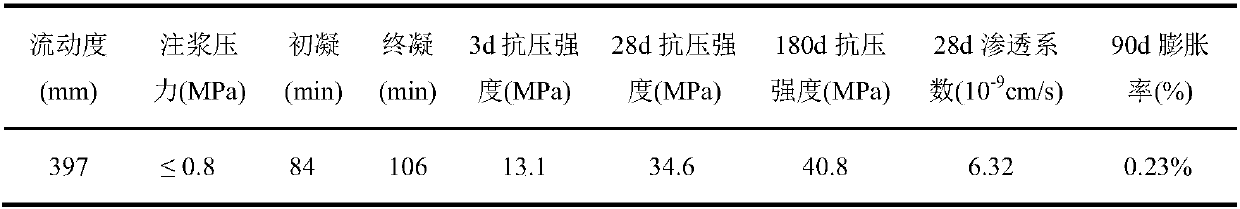

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

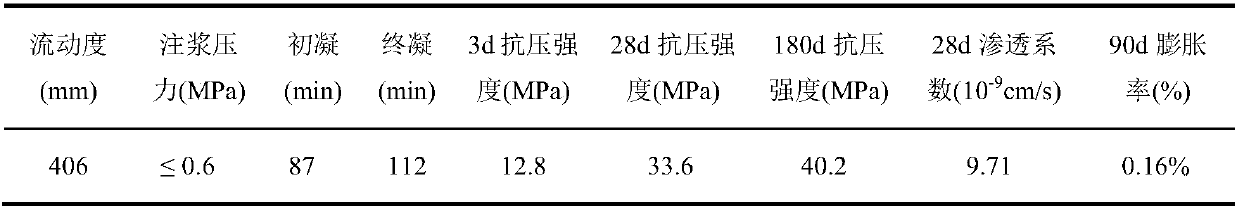

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

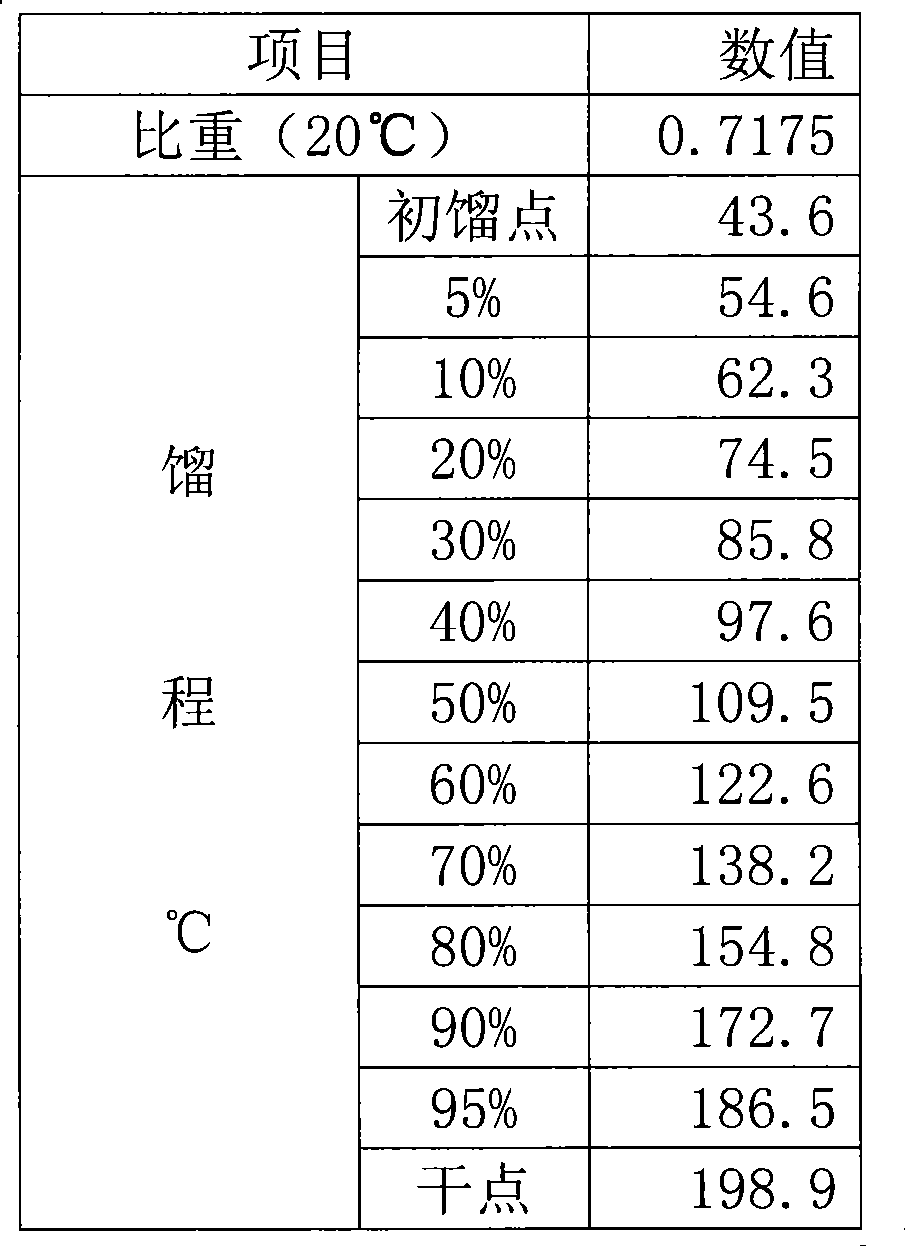

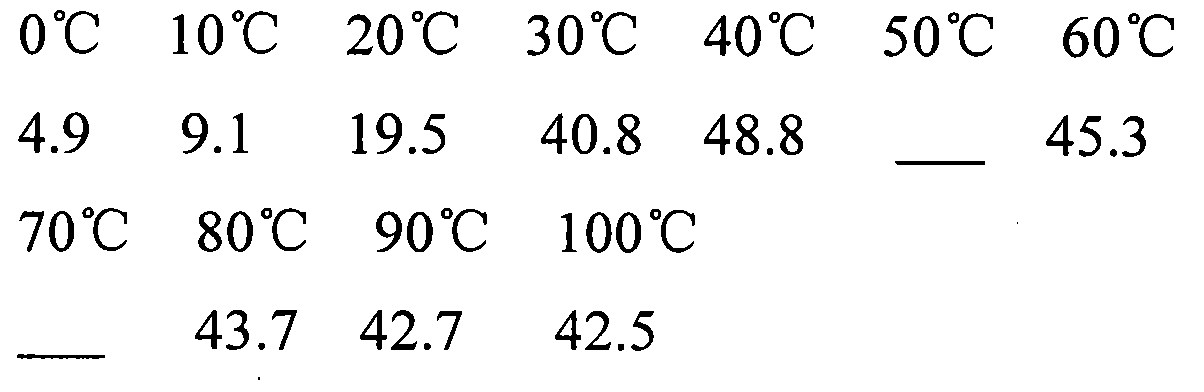

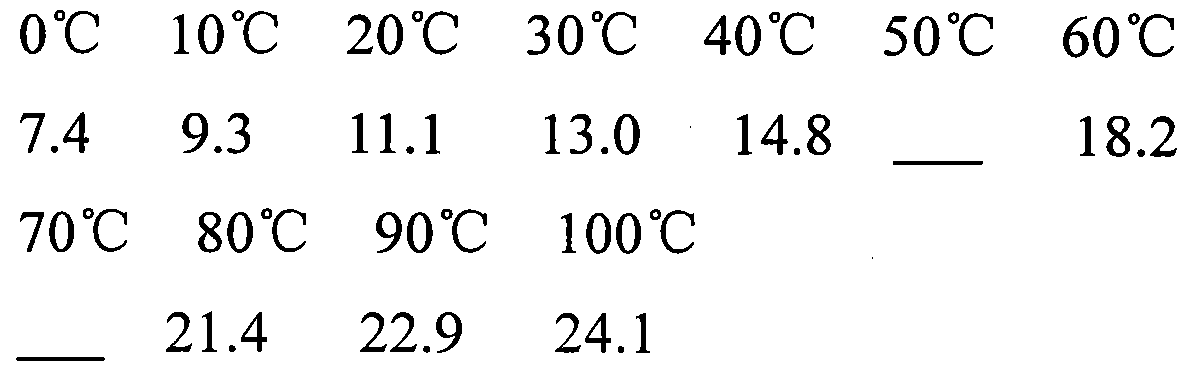

Pyrolysis furnace tube for cracking petroleum hydrocarbon

The invention provides a cracking furnace tube for cracking petroleum hydrocarbon. The furnace tube contains active components for performing catalytic cracking reaction on the petroleum hydrocarbon and has catalytic cracking activity. The components of potassium aluminate, calcium vanadate, alkaline earth metal, transition metal oxide, silicon-aluminum zeolite and the like which have catalytic activities, and / or the components of alkali metal and the like with coking resistance, are added or adhered to the inner side or the surface of the tube, or are added directly in the process of manufacturing the tube by the methods of coating, infiltration, sintering, plasma spraying and the like so as to obtain the tube which is provided with an inner surface coating, or contains the components with catalytic activities in the whole tube from the inside to the outside, and / or contains the components with coking resistance. Using the furnace tube, the prior ethene device is not necessary to be changed at all, only the furnace tube which has the catalytic function or the furnace tube which is in the cracking furnace is processed, thus the industrialization can be achieved quite easily in theprior cracking device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Resource recycling method of industrial phosphogypsum waste residues

ActiveCN104211099AResource conservationHigh chemical puritySulfate/bisulfate preparationCalcium/strontium/barium oxides/hydroxidesHydrogen SulfateSilicic acid

The invention discloses a resource recycling method of industrial phosphogypsum waste residues and relates to the technical field of inorganic chemical industry. The method comprises the following steps: carrying out a reaction on gypsum calcium sulfate and concentrated sulfuric acid to generate calcium hydrogen sulfate; carrying out a reaction on calcium hydrogen sulfate which is 1 time and a sodium hydroxide NaOH or potassium hydroxide KOH aqueous solution which is 4 times; filtering or precipitating and separating to recover calcium hydroxide, limonite, silicic acid and calcium fluoride and CaHPO4; and obtaining sodium sulfate / potassium sulfate, sodium aluminate or potassium aluminate and calcium acetate Ca(CH3COO)2. The method is mainly applied to resource recycling of industrial phosphogypsum waste residues.

Owner:济宁理工思源商务服务有限公司

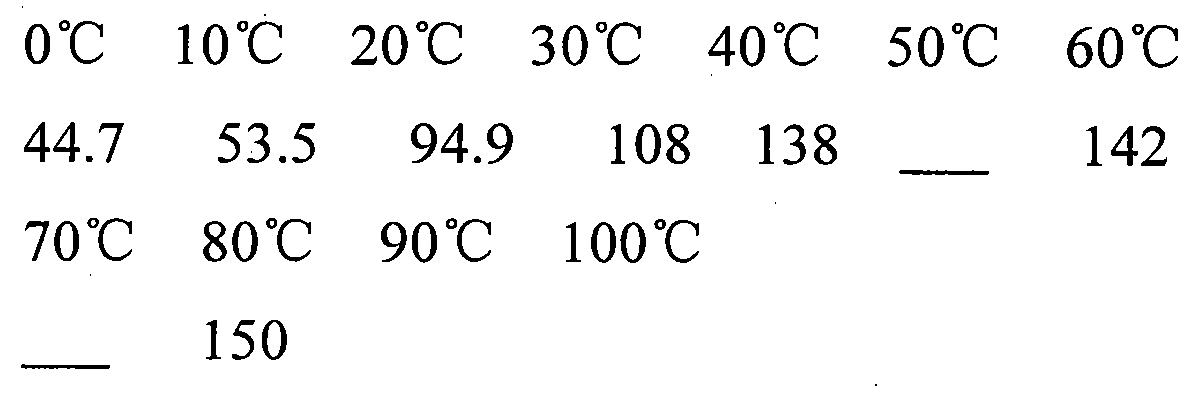

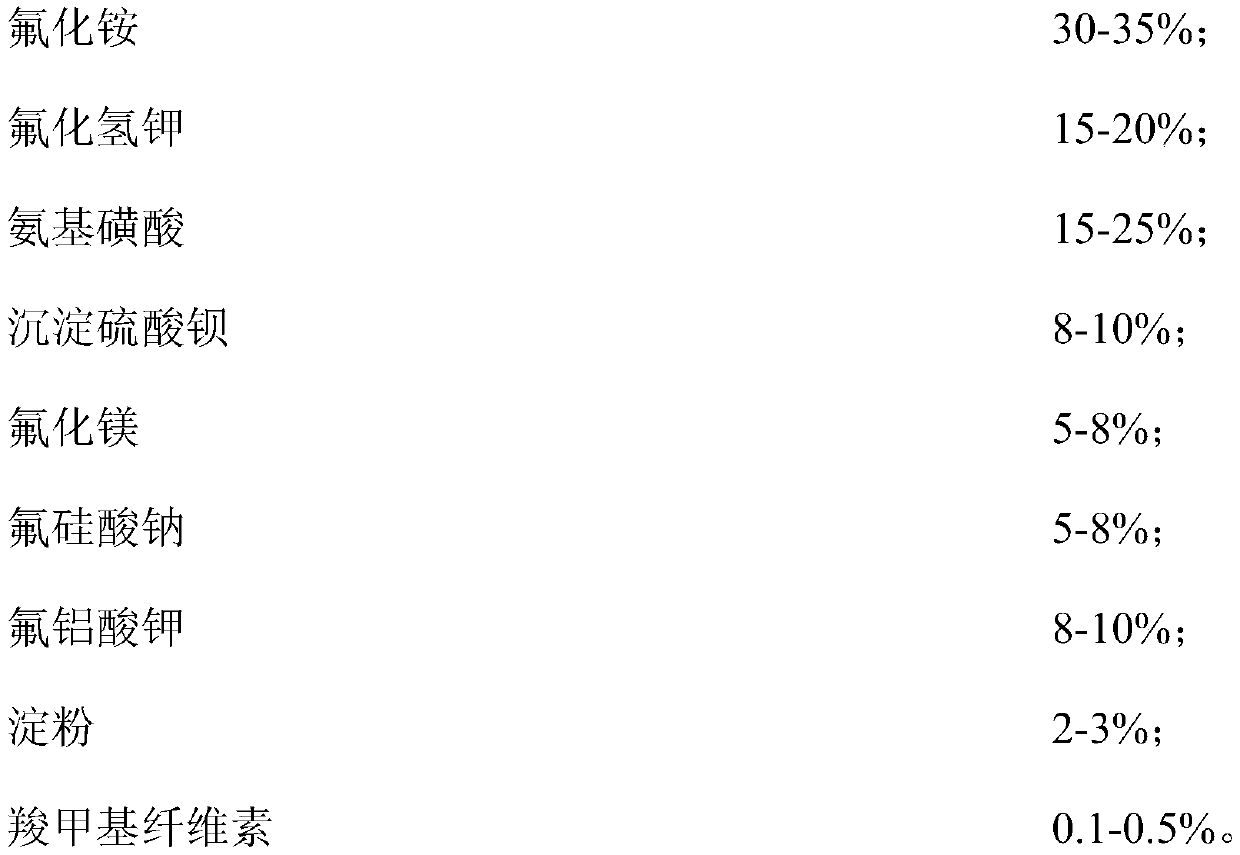

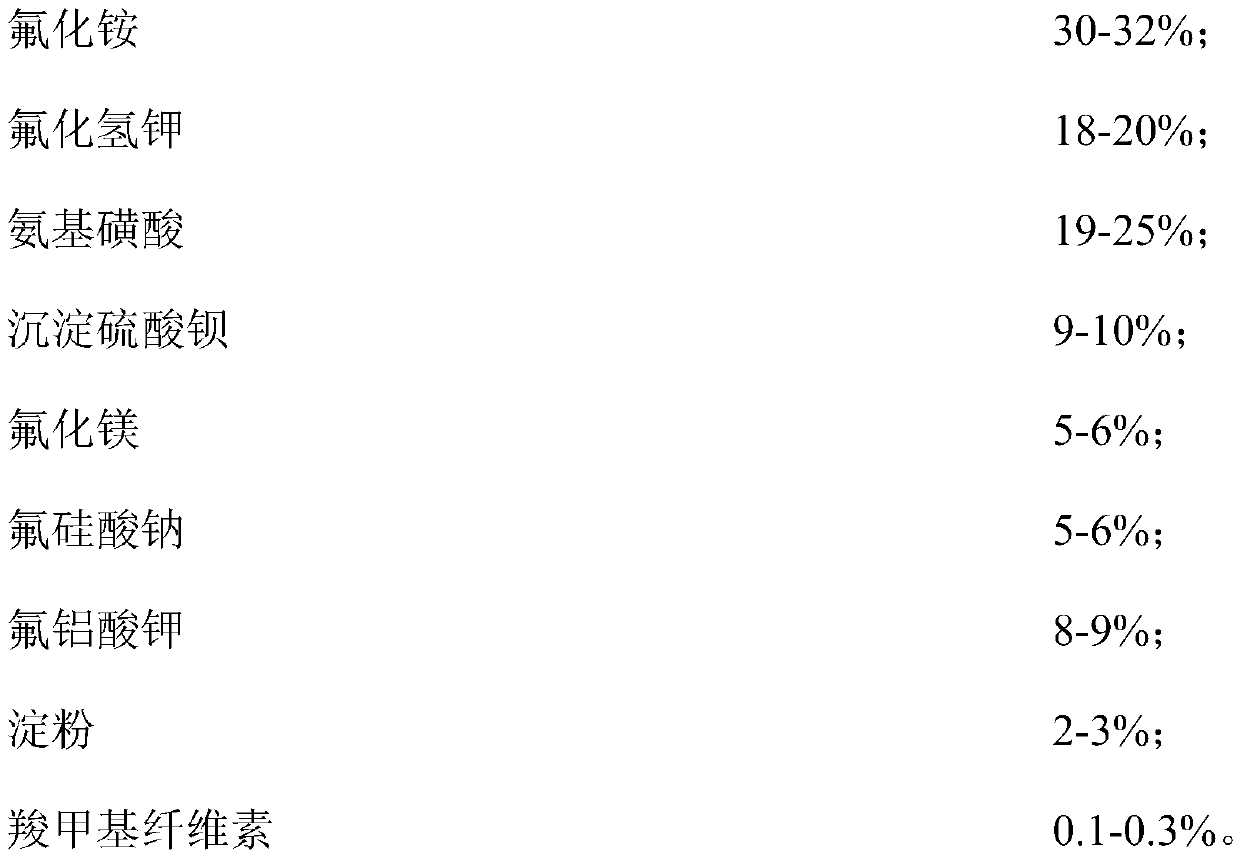

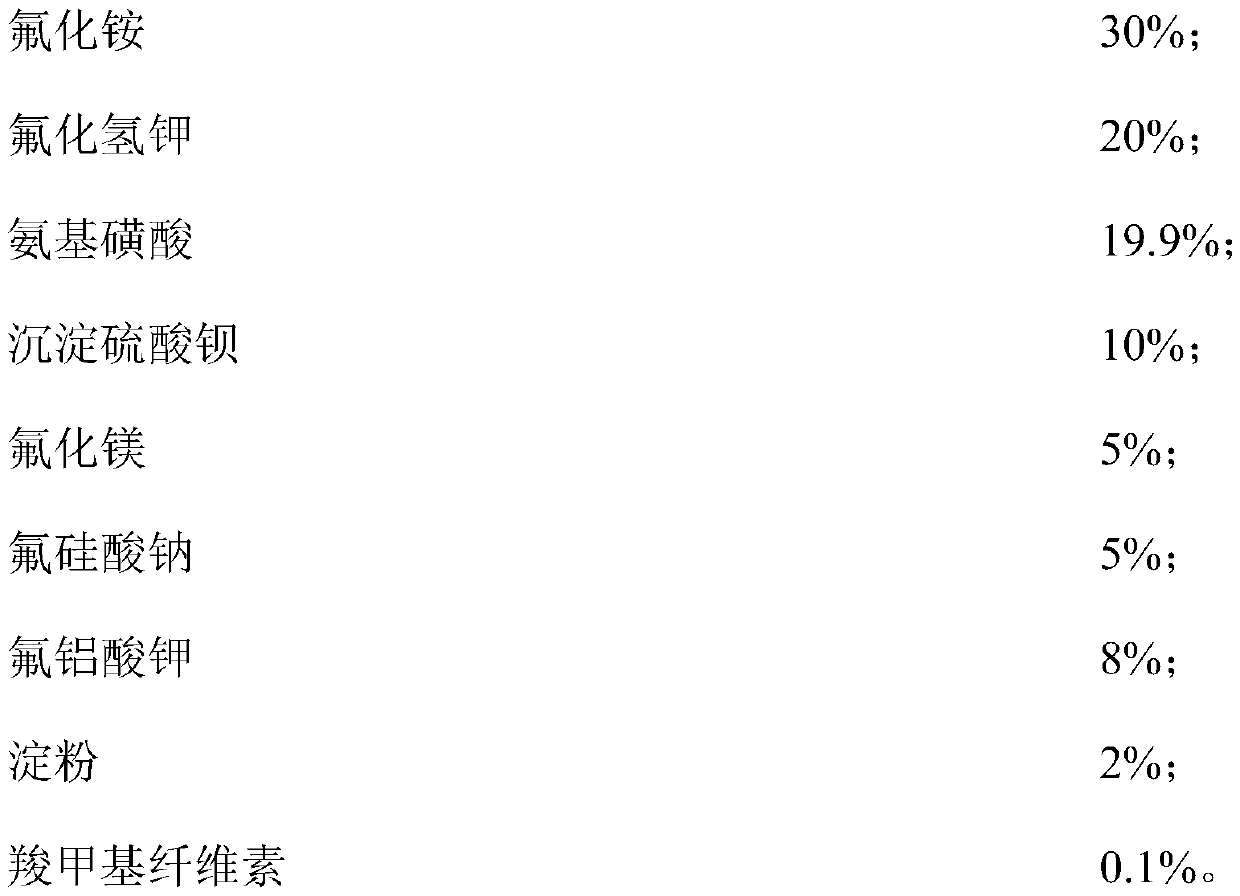

High-alumina glass frosting powder and use method thereof

ActiveCN111204984AModerate acidityAvoid corrosionSurface treatment compositionsStrong acidsPotassium aluminate

The invention relates to a high-alumina glass frosting powder and a use method thereof. The high-aluminum glass frosting powder is prepared from the following components in percentage by mass: 30 to 35 percent of ammonium fluoride, 15 to 20 percent of potassium bifluoride, 15 to 25 percent of sulfamic acid, 8 to 10 percent of precipitated barium sulfate, 5 to 8 percent of magnesium fluoride, 5 to8 percent of sodium fluosilicate, 8 to 10 percent of potassium fluoroaluminate, 2 to 3 percent of starch and 0.1 to 0.5 percent of carboxymethyl cellulose. Sulfamic acid is used as an acidity regulator; the formula is further optimized and limited; the problems of corrosivity, safety, environmental friendliness and the like caused by traditional inorganic strong acid curing are avoided; in addition, the frosting liquid cured by adding water has the advantages of proper acidity and uniform and stable system, the surface roughness Ra of the high-aluminum glass is controlled between 0.1 [mu]m and2.0 [mu]m, the effective frosting and control effects of the high-aluminum glass are realized, and the high-alumina glass frosting powder has wide applicability.

Owner:广州亦盛环保科技有限公司

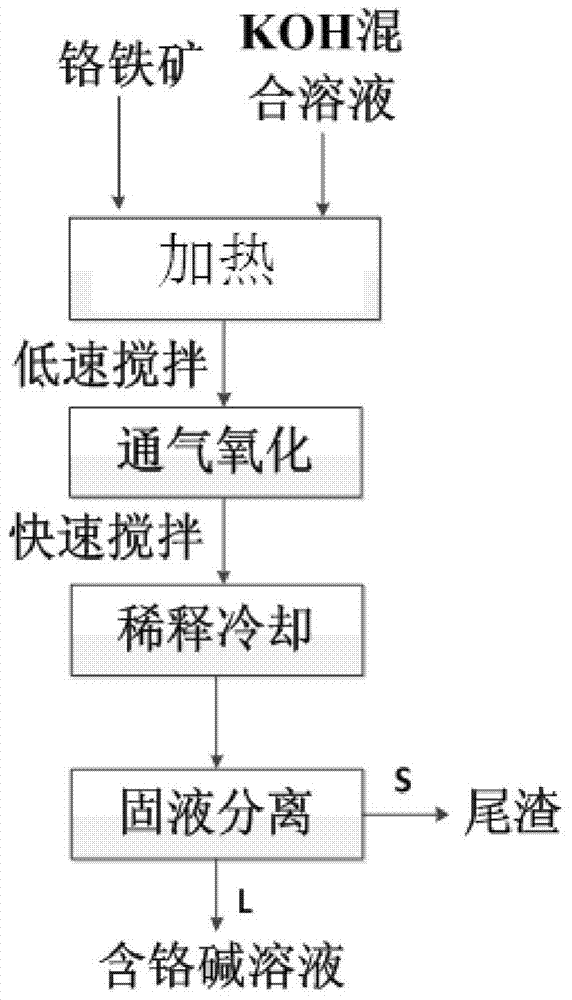

Method for extracting chromium from chromite by leaching

ActiveCN104726705ALow in chromiumEmission reductionProcess efficiency improvementPotassiumPotassium hydroxide

The invention relates to a method for extracting chromium from chromite by pressure leaching, which comprises the following steps: mixing chromite and / or pretreated chromite with a potassium hydroxide water solution, a potassium carbonate water solution and a potassium metaaluminate water solution to obtain an original slurry; adding the original slurry into a high-pressure autoclave, introducing oxidizing gas, and carrying out pressure leaching oxidizing reaction to obtain a reaction slurry; and carrying out solid-liquid separation to respectively obtain iron-rich tailings and a solution containing potassium chromate, potassium hydroxide, potassium carbonate, potassium aluminate and other water-soluble impurity components. The method has the advantages of greatly lower reaction temperature and low energy consumption, and effectively lowers the production cost, and the maximum chromium extraction yield can reach 97% above. Besides, the volume of the high-pressure autoclave can be 200L, and the reaction medium has the same proportioning as the industrial circulating liquor, so that the process is very close to the industrial process and can easily implement industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

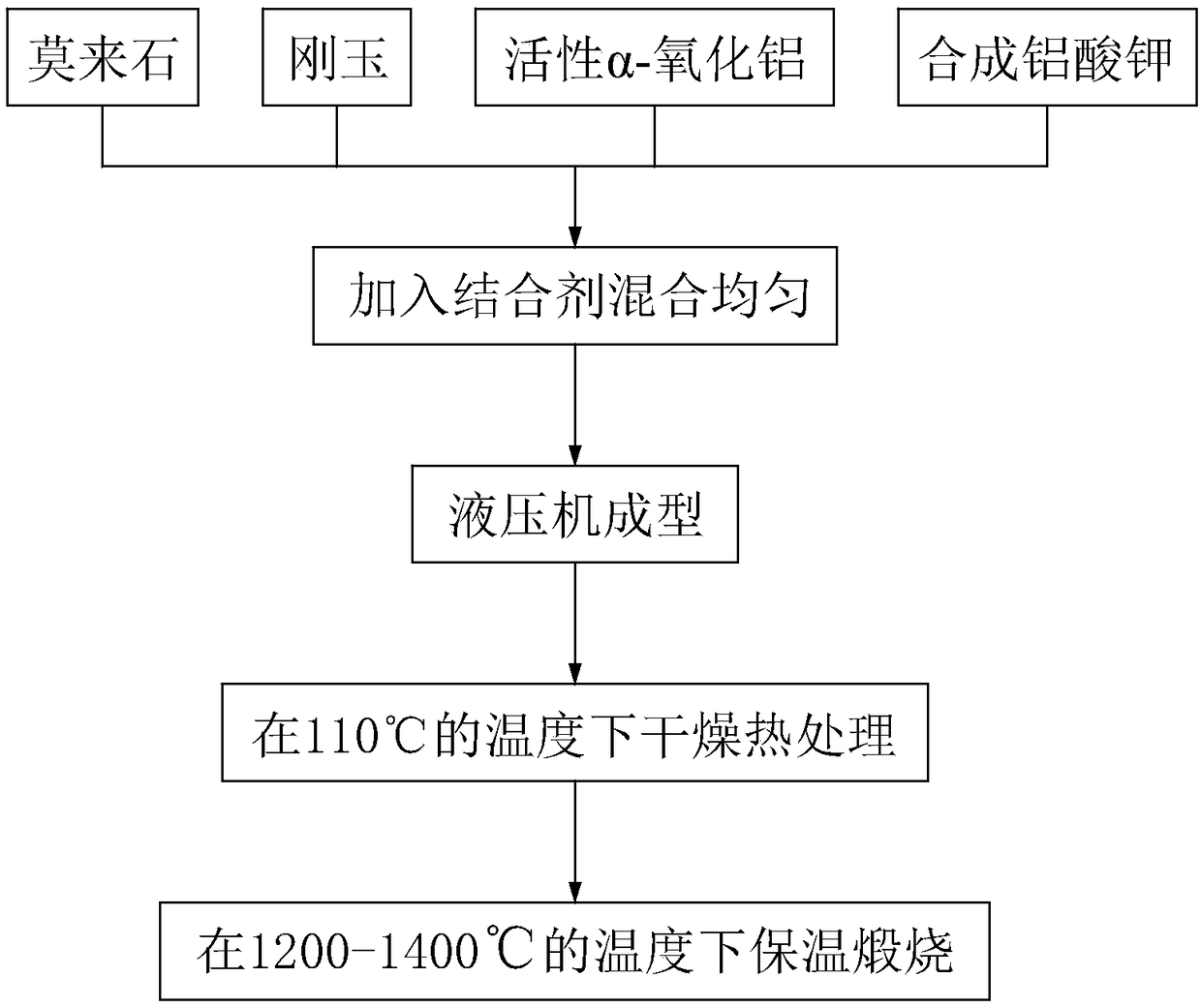

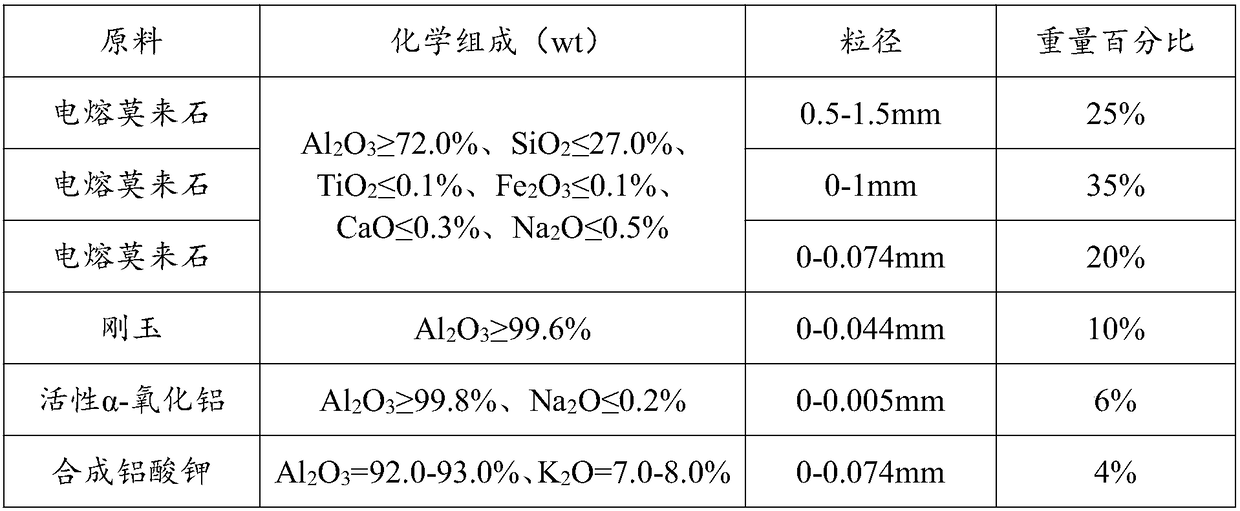

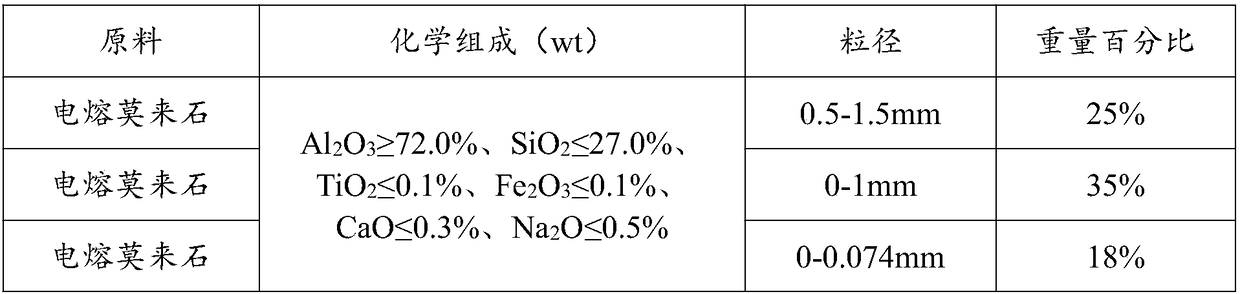

Sagger and preparation method thereof

ActiveCN108341666AImprove thermal shock resistanceReduce liquid phase osmosisCharge supportsMullitePotassium aluminate

The invention provides a sagger which is prepared from the following raw materials in percentage by weight: 65-87 percent of mullite, 5-10 percent of corundum, 3-7 percent of activated alpha-aluminumoxide and 5-10 percent of synthetic potassium aluminate; and the synthetic potassium aluminate is prepared from the following chemical components in percentage by weight: 92.0-93.0 percent of Al2O3 and 7.0-8.0 percent of K2O. The sagger has stronger thermal shock resistance and erosion resistance and can be used for calcining a ternary anode material. The invention also provides a preparation method of the sagger.

Owner:ZHENGZHOU UNIV

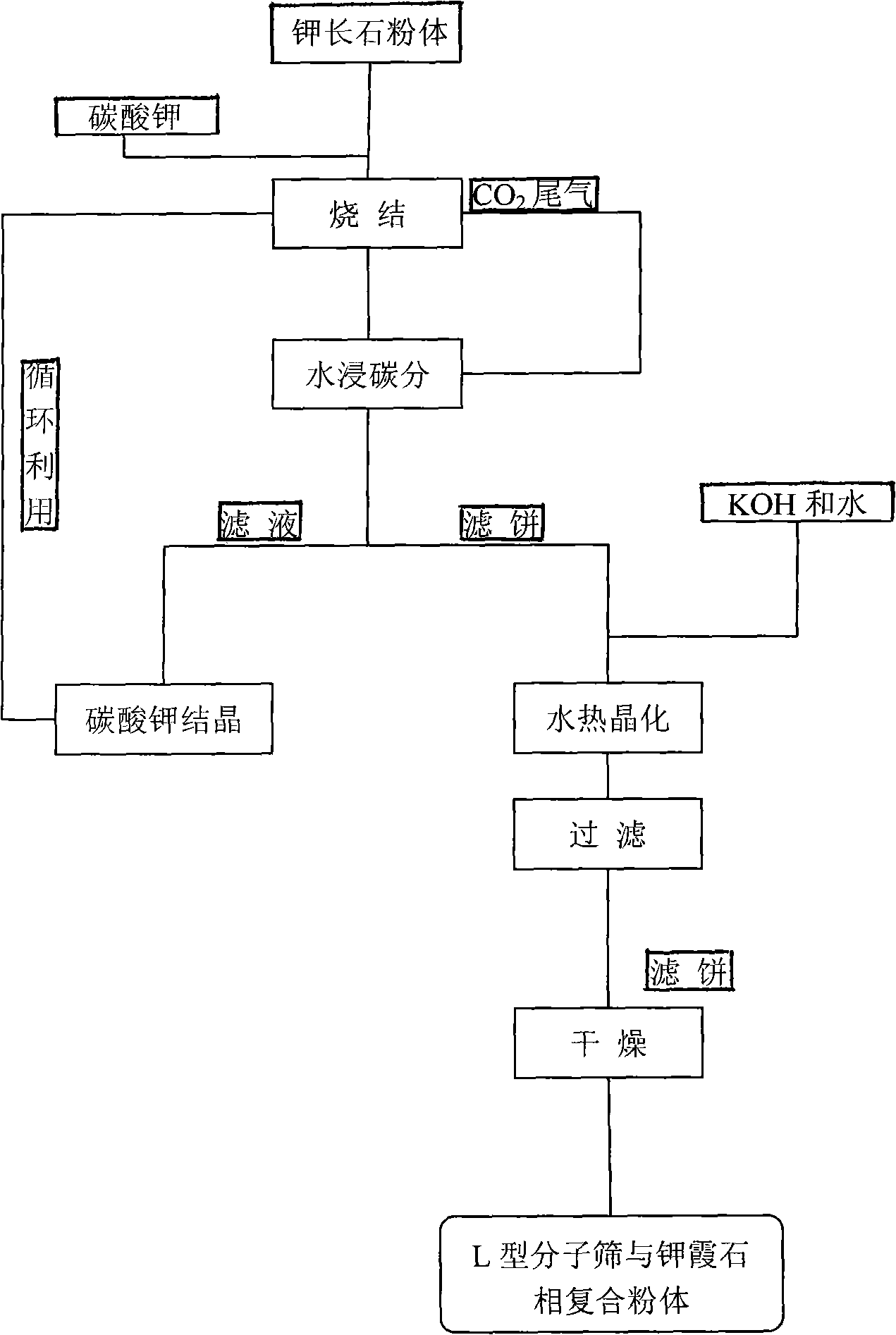

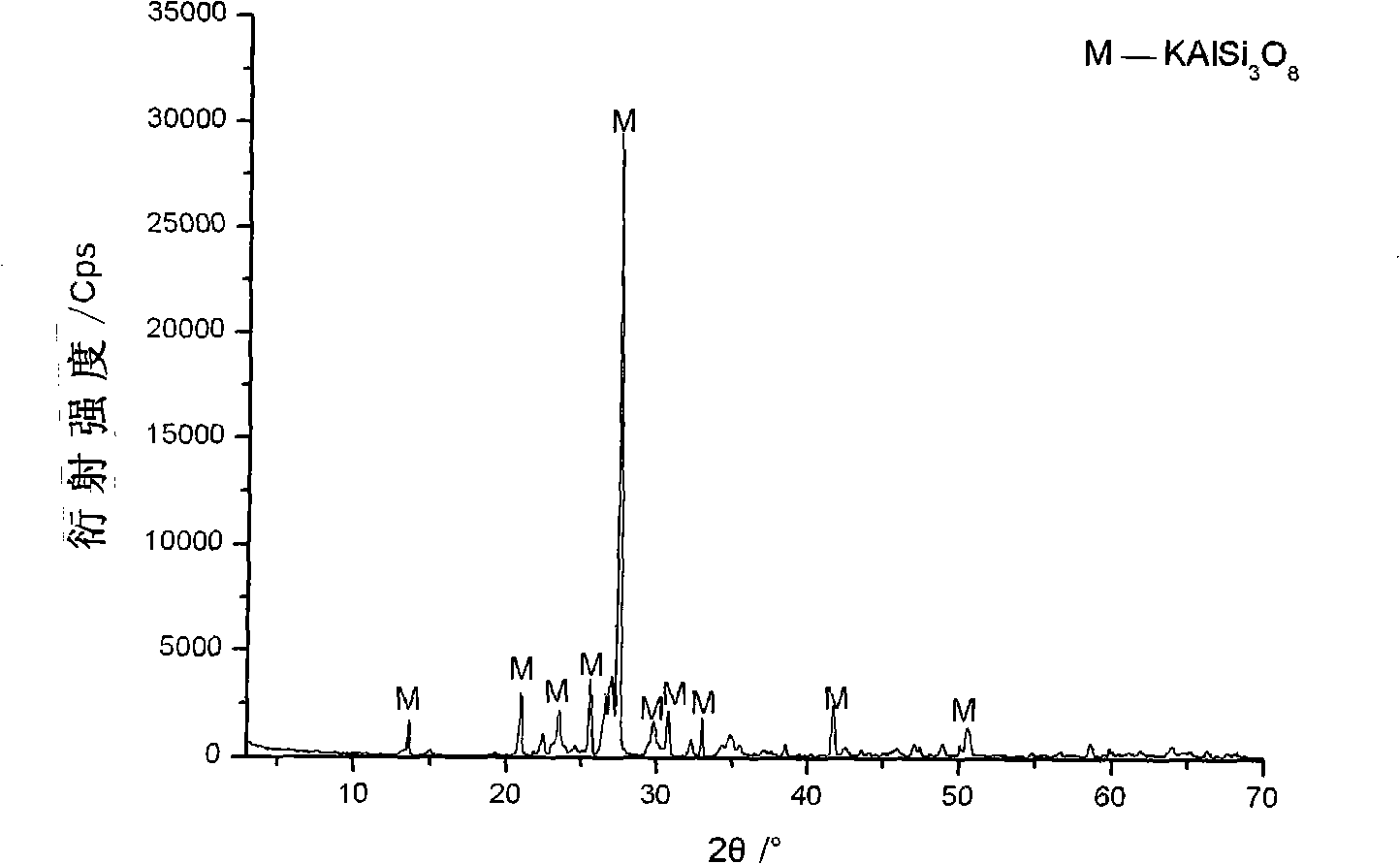

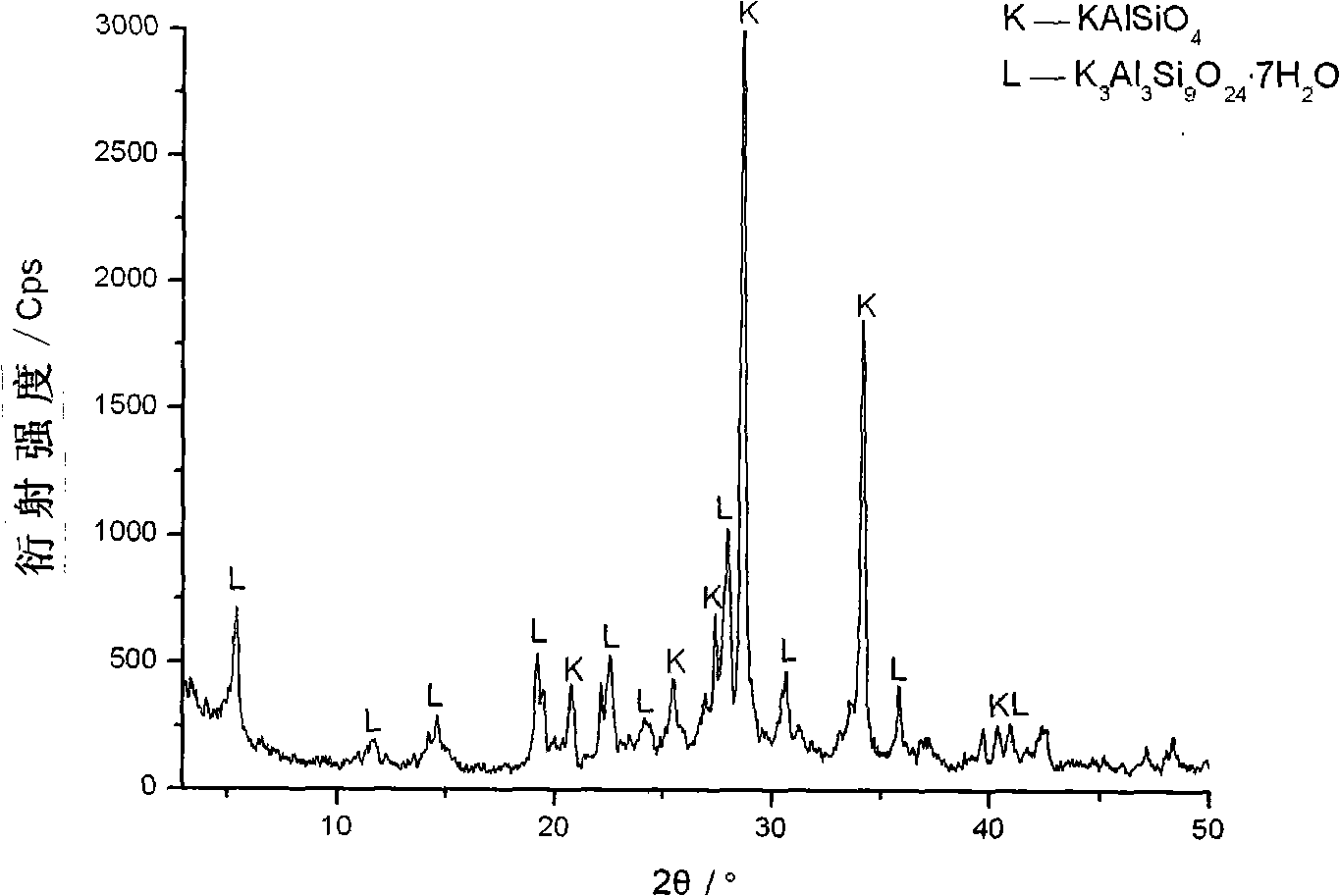

Process for preparing potassium molecular sieve based slow-release fertilizer carrier from potassium feldspar powder

The invention relates to a process for preparing potassium molecular sieve based slow-release fertilizer carrier from potassium feldspar powder. The process comprises the following steps of: crushing raw potassium feldspar ores, grinding, carrying out ore dressing pretreatment to obtain the potassium feldspar powder of a certain granularity, then mixing the potassium feldspar powder with potassium carbonate based on a certain ratio, and sintering at 750-900 DEG C; hydrothermally leaching the sintered potassium silicate or potassium aluminate materials at 100-200 DEG C, and introducing CO2 to slurry obtained after the hydrothermal leaching at 70-90 DEG C until the pH value is reduced to 8-9; filtering the slurry, and washing a filter cake; mixing the carbon filter cake with potassium hydroxide and water, stirring, hydrothermally crystallizing, filtering, washing, and drying an obtained solid at 105 DEG C to obtain the product of compound powder of an L-type molecular sieve and a facellite phase, which can be used as a potassium composite molecular sieve based slow-release fertilizer carrier material. The invention has the advantages of low material cost, no three wastes (waste gas,waste water, industrial residue) discharge in the process and no pollution to the environment and facilitates the implementation and the generalization.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for producing hydrogen and potassium alum from waste aluminum cans

InactiveCN102295270ASave bauxiteSave energySolid waste disposalHydrogen productionSizingRaw material

It is undoubtedly a good way to kill two birds with one stone by using waste aluminum cans to produce new energy hydrogen and environmental protection products potassium alum. Hydrogen has many uses. Hydrogen burns in oxygen and releases a lot of heat. The temperature of its flame-oxygen flame reaches 3000°C, which can be used for welding or cutting metals. As a fuel, hydrogen has the characteristics of abundant resources, high combustion calorific value and less pollution. Potassium alum plays an important role in water purification, paper sizing, paint printing and dyeing, lake pigment pharmaceuticals, paint making, tanning, fiberboard processing, as well as rubber and metallurgy, colored glass, food industry, agriculture, etc. . The invention uses waste aluminum cans as raw materials, produces hydrogen through potassium hydroxide solution, further neutralizes potassium aluminate solution with sulfuric acid, and obtains high-quality potassium alum through crystallization, filtration, washing and centrifugal dehydration. The invention not only eliminates pollution, but also can achieve the purpose of turning waste into wealth and utilizing waste, and is a good method that kills two birds with one stone.

Owner:刘方旭

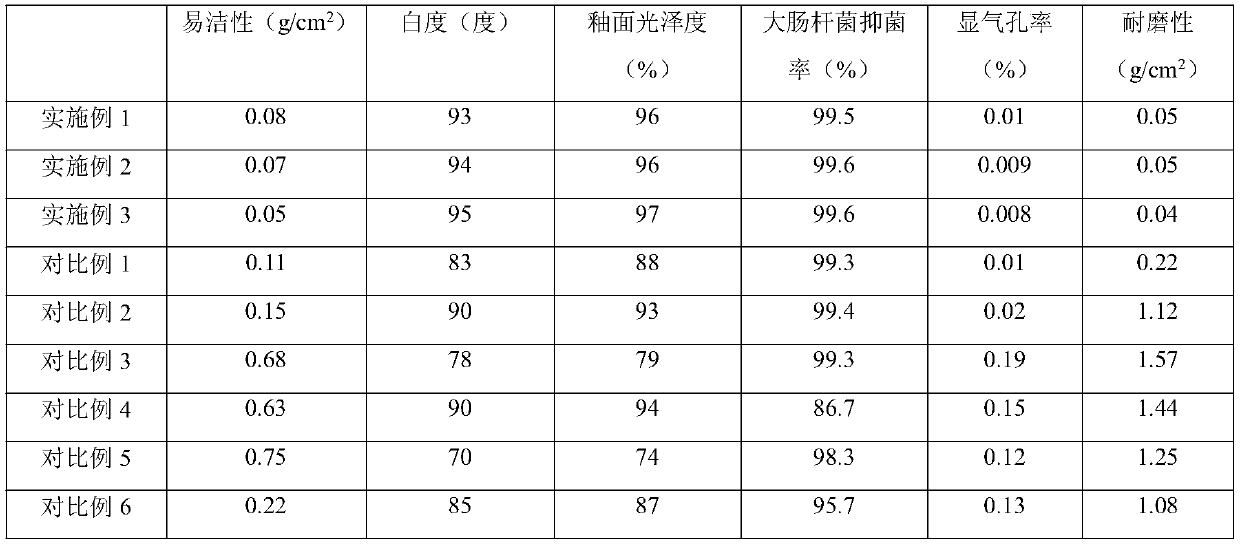

Porcelain formula and manufacturing process thereof

The invention provides a porcelain formula and a manufacturing process thereof. Soft kaolin, flint clay, potassium feldspar and large ball mud are used as raw materials to prepare a matrix material; silicon dioxide, potassium fluoroaluminate, cerium dioxide, yttrium oxide, aluminum borate whiskers, nano-zinc oxide, cerium-graphene nano-particles and large ball mud superfine powder are used as rawmaterials to prepare glaze, the raw materials of the glaze are properly matched in thickness, the compactness of a glaze layer is improved, the apparent porosity is low, contamination is not likely tohappen, the wear resistance is good, and the bactericidal effect is achieved. The matrix material and the glaze material generate light interaction, so that the porcelain has relatively high whiteness and glossiness, and the attractiveness is greatly improved.

Owner:贺俊威

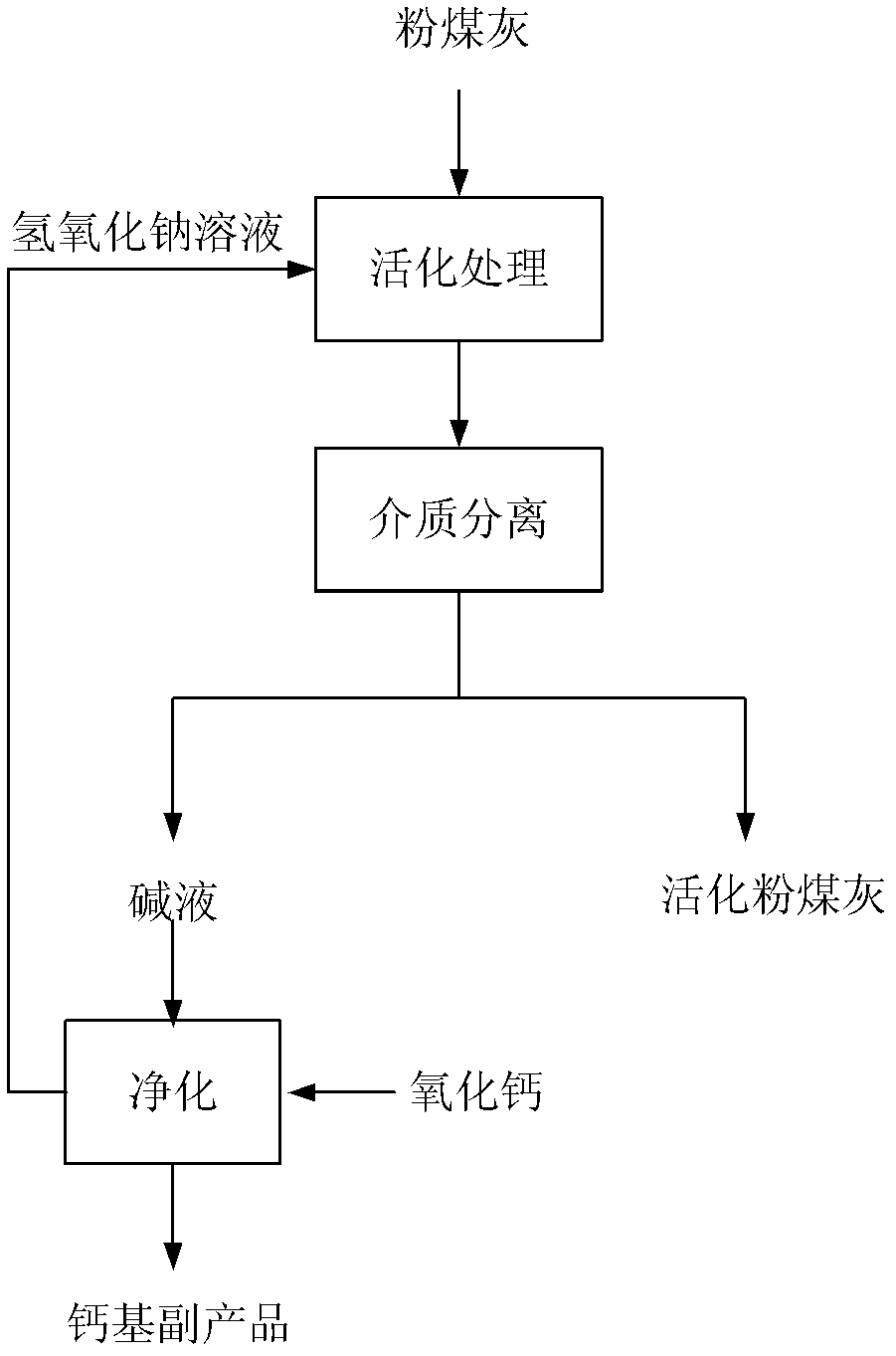

Fly ash low-temperature wet activating treatment method

InactiveCN103373738AReduce energy consumptionReduce equipment investmentSolid waste disposalAluminium oxides/hydroxidesPotassium aluminateBiological activation

The invention provides a fly ash low-temperature wet activating treatment method, comprising the following steps of: (1) mixing the fly ash with the strong alkali solution of which the concentration is 300-700g / l, to perform activating treatment, wherein the volume-to-mass ratio of the alkali solution and the fly ash is (3:1)-(20:1) (ml / g), the activating temperature is 130-180 DEG C, the activating time is 0.5-10 hours, and the activating pressure is normal pressure to 0.5Mpa; performing liquid-solid separation after activation to get the crude alkali liquor and the activated fly ash; (2) diluting the crude alkali liquor, then, adding calcium oxide into the diluted crude alkali liquor for purification, performing liquid-solid separation to get calcareous residues and strong alkali solution, wherein the calcareous residues is output to the system as byproducts, and the strong alkali solution is recycled for fly ash activating treatment. In the method, the alkali solution is NaOH water solution, KOH water solution, sodium aluminate solution or potassium aluminate solution, after being activated, the fly ash is dissolved out by diluted acid, and the dissolution rate of aluminum oxide is up to 95-99%. In the method, the activation temperature is low, the activation effect is excellent, the activation process cannot cause secondary pollution, and essential conditions for follow-up fly ash treatment, especially for extraction of aluminum oxide, zeolite preparation, and the like, are created.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

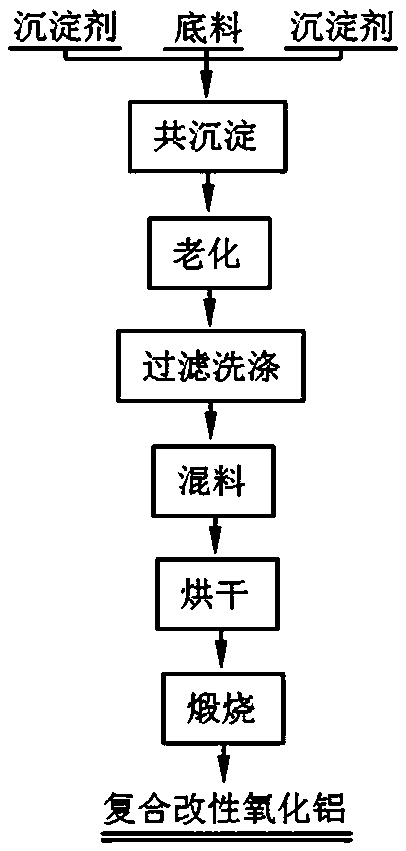

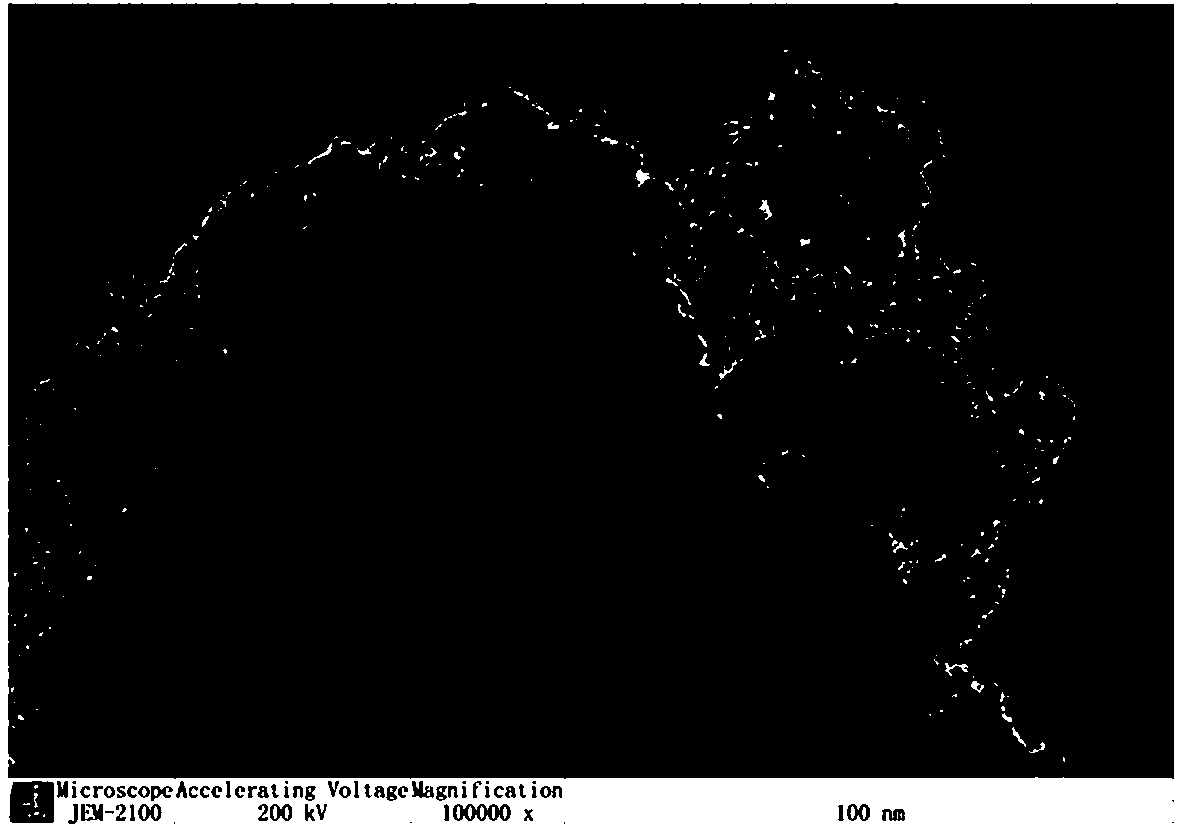

Automobile tail gas purification catalyst carrier and preparation method thereof

ActiveCN109513432ACatalyst carriersDispersed particle separationAluminium hydroxidePotassium aluminate

The invention discloses an automobile tail gas purification catalyst carrier and a preparation method thereof. The impurity Na content in the automobile tail gas purification catalyst carrier is lowerthan 400ppm; the apparent density is 1.8g / L or higher; the specific surface area at 950 DEG C at 2h is 110m<2> / g or higher; the pore volume is 0.4ml / g or higher. According to a preparation method, sodium aluminate / potassium aluminate are used as raw materials, and nitric acid, modification agents and surfactants are used as auxiliary materials; coprecipitation, aging, filtering washing, drying, roasting and crushing are performed; then, modified aluminum hydroxide or aluminum oxide is used as raw materials, surfactant and oxidizing agent containing modified aluminum hydroxide or aluminum oxide slurry is used as substrate materials; precipitators and modification agents are jointly sprayed into a bottom solution for precipitation; after the precipitation, aging, filtering washing, materialmixing, drying, roasting and crushing are performed to obtain the composite modified automobile tail gas purification catalyst carrier of composite modification aluminum oxide; the contents of impurities Na, S, P and the like are low; the requirements of the automobile tail gas purification agent carrier can be met.

Owner:KUNMING METALLURGY INST +1

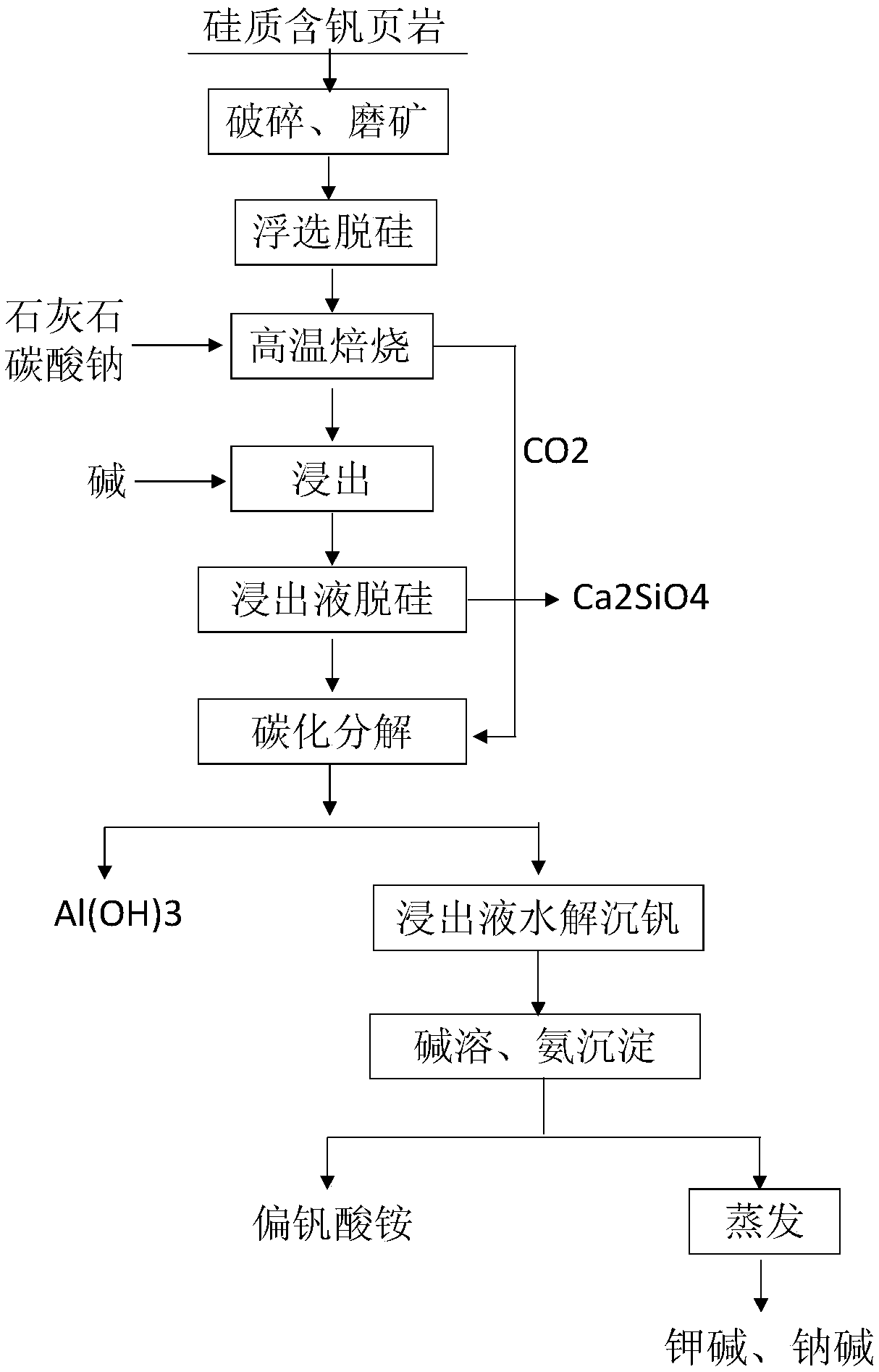

Beneficiation-metallurgy combination process with function of comprehensive recovery for vanadium, aluminum, potassium and silicon in vanadium-containing siliceous shale

ActiveCN107586947ARaise the gradeReduce manufacturing costAlkaline-earth metal silicatesProcess efficiency improvementCarbonizationPotassium

The invention relates to the field of beneficiation and metallurgy with a function of comprehensively recovering valuable components such as vanadium, aluminum, potassium and silicon from the vanadium-containing siliceous shale as a raw material. The process comprises steps as follows: the low-grade vanadium-containing siliceous shale is taken as the raw material, firstly, the vanadium-containingsiliceous shale is desiliconized with a flotation method, vanadium ore concentrate is uniformly mixed with excessive limestone and sodium carbonate, a mixture is subjected to high-temperature roastingin a rotary kiln, and products such as potassium aluminate, potassium ferrite, calcium metavanadate, calcium orthosilicate, carbon dioxide and the like are obtained; the sintered products are dissolved in a dilute alkaline solution, after a dissolution solution is desiliconized and purified, carbon dioxide gas produced by the rotary kiln is introduced into a closed container for carbonization reaction, Al(OH)3 precipitates are separated out, a dealumination solution is subjected to hydrolytic precipitation under the acidic condition, coarse vanadium is obtained and dissolved with alkali, ammonium chloride is added, ammonium metavanadate is obtained, a final solution is a potassium-rich and sodium-rich solution and evaporated step by step, and potash and soda are obtained. According to theinvention, the problem of environmental pollution produced by stockpiling of stone coal leaching residues is solved completely.

Owner:CENT SOUTH UNIV

Method for preparing superfine alumina by solid-phase reaction

InactiveCN102344156AHigh selectivityHigh yieldAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPotassium aluminateAmmonium sulfate

The invention discloses a method for preparing superfine alumina by reacting alkaline aluminum salt powder (such as sodium aluminate, potassium aluminate and the like) and acid powder raw materials (aluminum chloride, aluminum sulfate, aluminum nitrate, oxalic acid, citric acid, trichloroacetic acid, ammonium chloride, ammonium sulfate and the like) to overcome the defect of difficulty in filtering and washing in a liquid-phase precipitation method. The method is characterized by comprising the following steps of: (1) performing solid-phase reaction, namely mixing the acid powder raw materials and alkaline aluminum salt powder, heating to over 60 DEG C to evaporate water generated by reaction, and keeping materials in a basically dried solid state; and (2) filtering and washing and drying, namely after cooling, mixing the materials and water to obtain suspension, filtering, washing and drying. The temperature of the solid-phase reaction is lower than temperature of harmful gas such as nitrogen oxide, sulfur oxide, carbon monoxide and the like decomposed by a reactant system; and if the temperature of the solid-phase reaction is lower than temperature when the required crystal is formed, calcining is performed at the temperature of 500 to 1,200 DEG C after filtering, washing and drying so as to prepare the required crystal.

Owner:SHANDONG AOPENG NEW MATERIAL TECH

Polyurethane gloss white finish for furniture

InactiveCN106752855AHigh fullnessImprove the level ofPolyurea/polyurethane coatingsToluene diisocyanatePotassium aluminate

The embodiment of the invention discloses a polyurethane gloss white finish for furniture, which comprises a main agent, a curing agent and a diluent, wherein the main agent comprises synthetic fatty acid resin, n-butyl acetate, a defoaming agent, a flatting agent and white paste; the white paste comprises synthetic fatty acid resin, n-butyl acetate, a dispersing agent, titanium dioxide, and nanometer silicon potassium aluminate powder; the curing agent comprises toluene diisocyanate trimer, hexamethylene diisocyanate trimer, and n-butyl acetate; the diluent comprises n-butyl acetate, dimethylbenzene and propylene glycol monomethyl ether acetate. According to the polyurethane gloss white finish for the furniture, the nanometer silicon potassium aluminate powder is utilized, so that the sand mark covering capability and the fullness of a finish film can be improved, and the aims of reducing dark bubbles and improving a flatting effect are achieved.

Owner:展辰新材料集团股份有限公司 +6

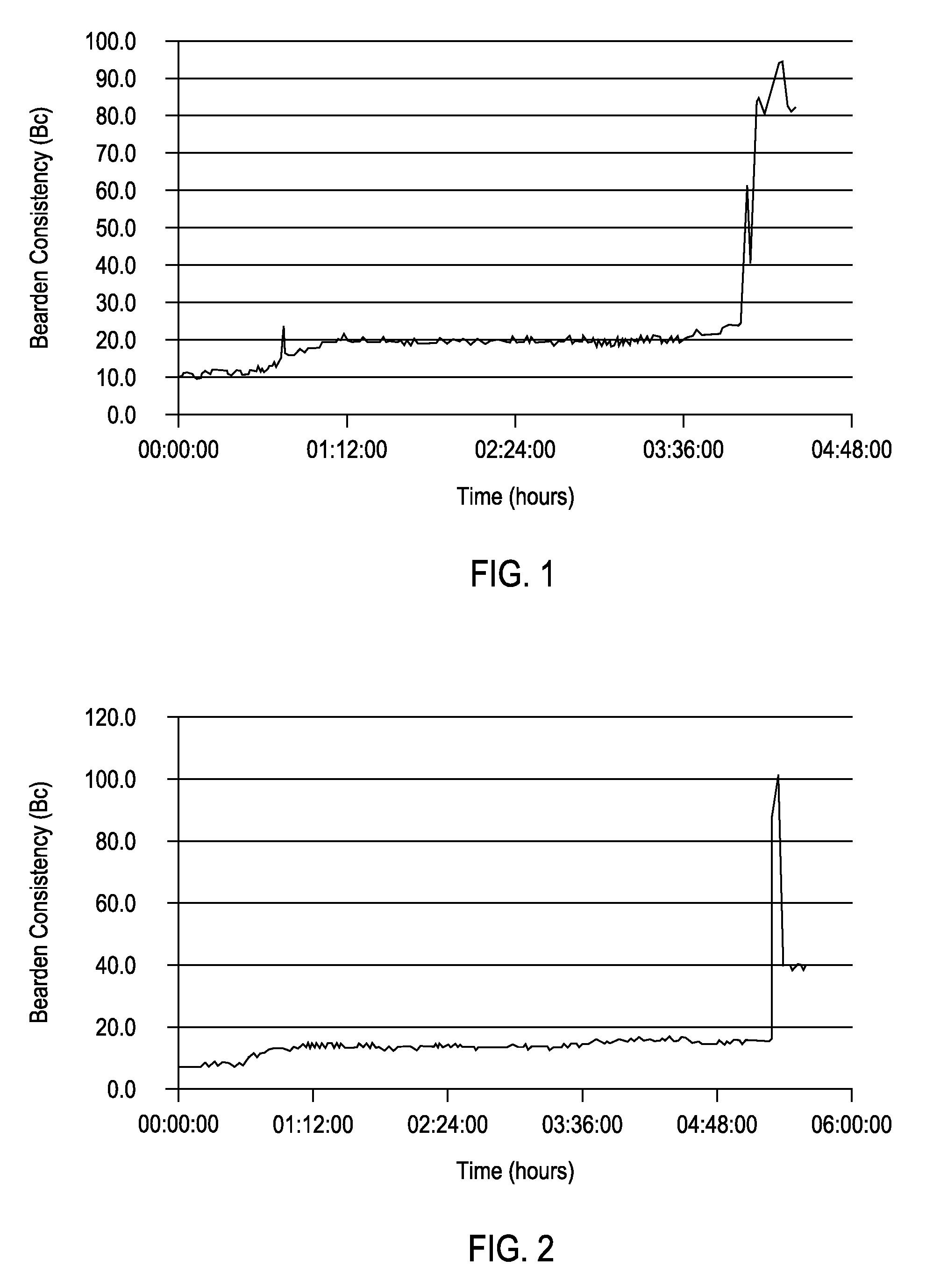

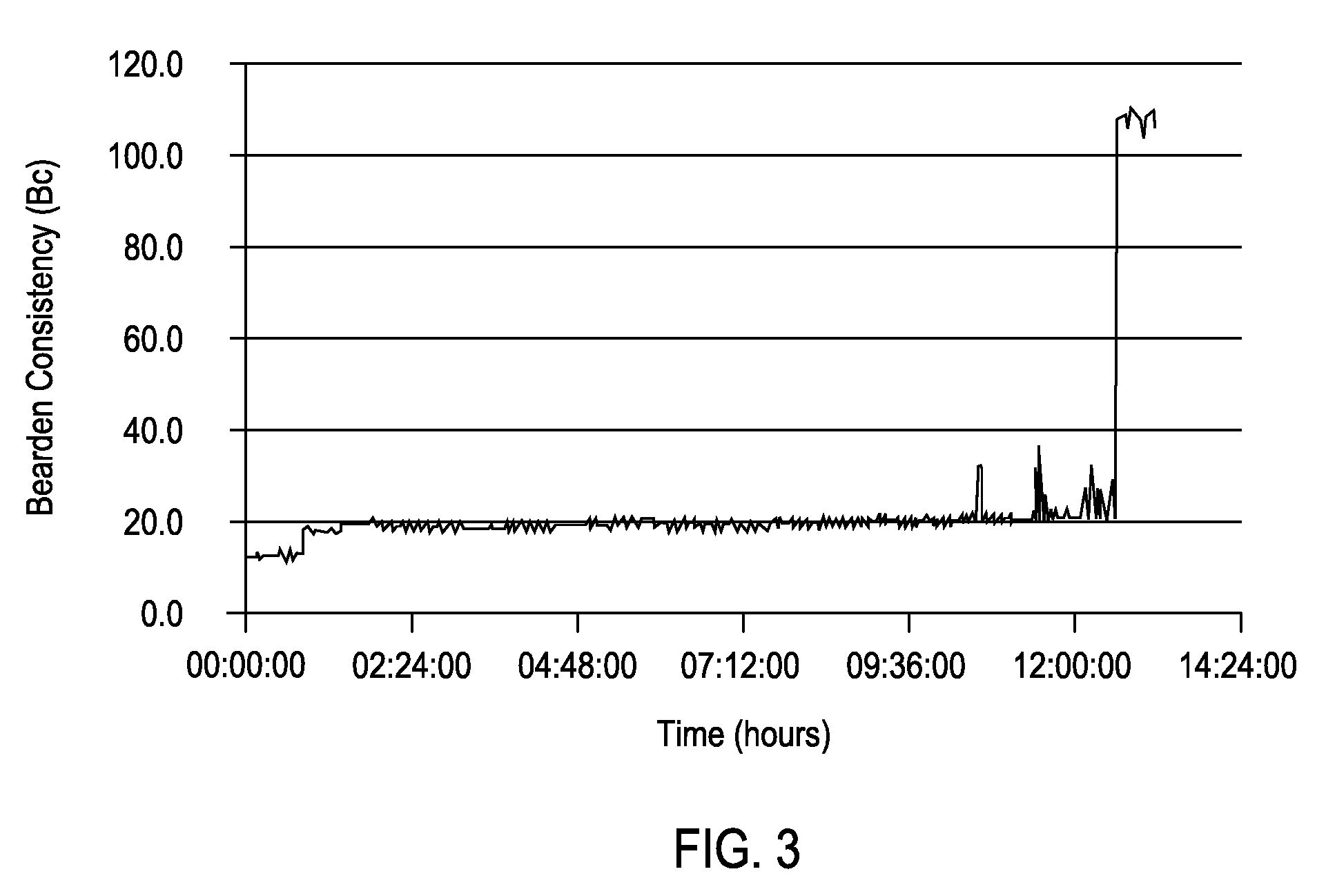

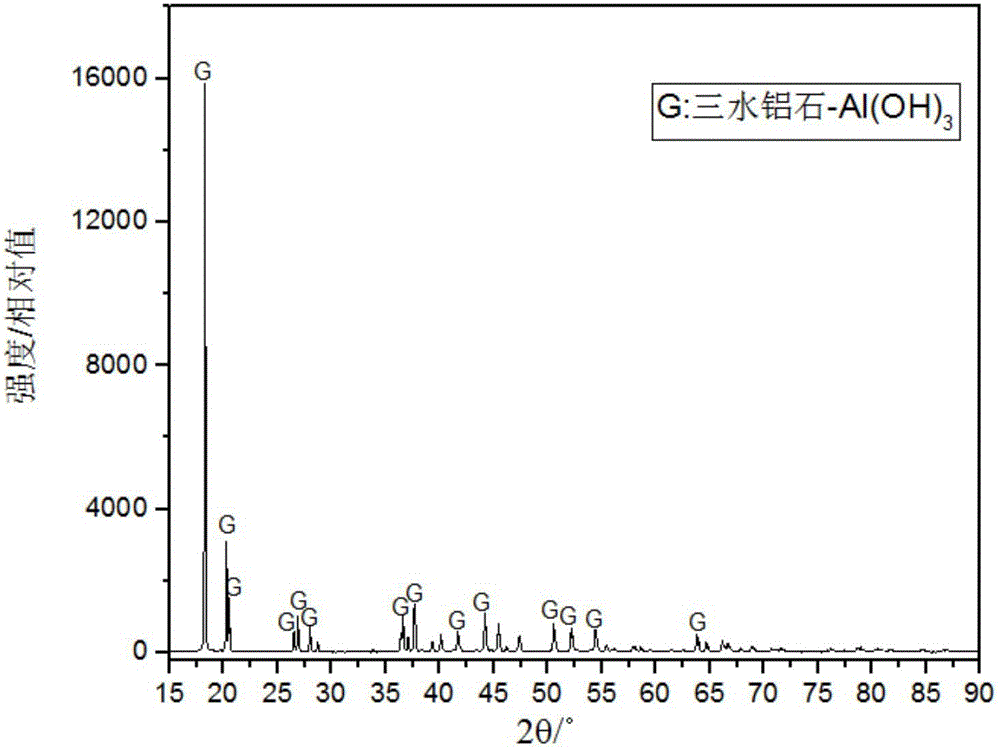

Cement compositions and methods of using the same

Cement compositions may comprise an aluminosilicate; a sodium aluminate, a calcium aluminate, a potassium aluminate, or a combination thereof; and water. In some cases, the cement does not include Portland cement. The cement may be used in a subterranean formation having corrosive components therein, wherein the set cement sheath is resistant to degradation from the corrosive components within the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

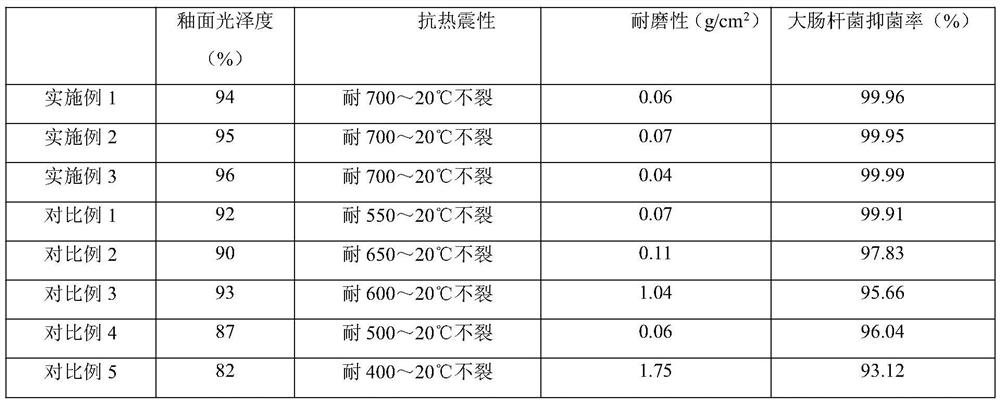

Wear-resistant antibacterial ceramic and processing method thereof

InactiveCN111792913AImprove quality requirementsGood antibacterial effectClaywaresAir atmospherePyrophyllite

The invention relates to wear-resistant antibacterial ceramic and a processing method thereof. The processing method includes the steps that a body material is fired for the first time to form a plainbody, then glaze is applied to the two faces of the plain body to form glaze layers, and firing is conducted for the second time, and then the wear-resistant antibacterial ceramic is obtained, wherein the body material is made of raw materials such as sodium bentonite, coke gemstone, pyrophyllite, dolomite, and the like, the glaze is prepared from silicon dioxide, potassium fluoroaluminate, boronoxide, barium oxide, yttrium oxide, titanium-silicon co-doped graphene, large ball mud and other raw materials. Wherein the second firing comprises three-stage heating and heat preservation and three-stage cooling, each heating and heat preservation is sequentially carried out in an air atmosphere, a nitrogen atmosphere and a hydrogen atmosphere, and the three-stage cooling is natural cooling, rapid cooling and natural cooling. The obtained ceramic product has excellent antibacterial performance and wear resistance, and meets the high-quality requirements of ceramics.

Owner:许洁

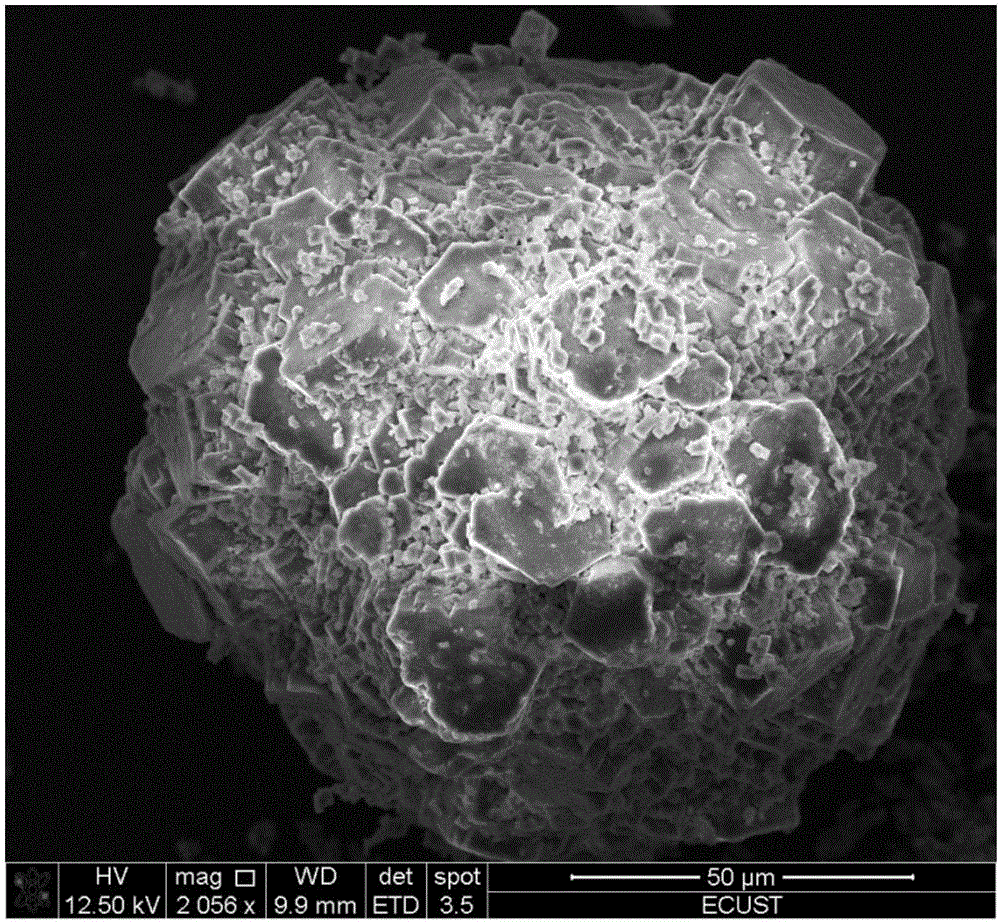

Technique for decomposing potassium aluminate solution seed crystal to produce aluminum hydroxide

ActiveCN106830029AImprove decomposition rateHigh purityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationWater bathsDecomposition

The invention relates to the field of alkaline medium wet metallurgy and particularly discloses a technique for decomposing potassium aluminate solution seed crystal to produce aluminum hydroxide. The technique comprises the steps of (A) pouring a potassium aluminate solution to a reactor, controlling the alkali concentration to be 200-280g / L and the caustic ratio of the solution to be 1.35-1.75, starting water bath circulating and stirring, controlling an initial temperature of decomposition to be 60-90 DEG C; (B) adding aluminum hydroxide seed crystal to a system, and stirring for decomposing, wherein the seed crystal coefficient is 0.5-4.0 and the stirring rate is 100-500rpm; and (C) cooling the decomposition system to 40-50 DEG C, after seed crystal decomposition reaction is terminated, stopping water bath circulating and stirring, and filtering and separating to obtain a seed pregnant solution and an aluminum hydroxide product. According to the method, the decomposition rate can reach 70% under an operation condition, and is much higher than 55% seed crystal decomposition efficiency of a traditional sodium aluminate system; and meanwhile, the product is high in purity, good in shape and form and large in particle size.

Owner:EAST CHINA UNIV OF SCI & TECH

Glaze firing process method for ceramic ware

The invention provides a glaze firing process method for ceramic ware, which comprises the steps of applying ground glaze to the surface of a ceramic green body, performing high-temperature glaze firing, applying cover glaze to the surface of the ground glaze, and performing low-temperature glaze firing, wherein the ground glaze is obtained by mixing and ball-milling silicon dioxide, coal gangue powder and potassium fluoroaluminate, the cover glaze is prepared by the steps of calcining tourmaline powder, gallium nitride powder and heat-treated liquid polyacrylonitrile to prepare composite graphene, compounding the composite graphene with medical stone powder to obtain a filler, and finally carrying out ball milling and mixing on the filler and silicon dioxide. The glaze firing process provided by the invention is simple in method, high in glaze glossiness, relatively good in wear resistance and thermal shock resistance, good in use experience, and capable of promoting the generation of negative ions and playing roles in bacteriostasis and health care.

Owner:潮州市裕业陶瓷有限公司

Environment-friendly corrosion-free self-brazing solder for brazing aluminum alloy and copper alloy and preparation method thereof

ActiveCN111633355AWell mixedReduce wasteWelding/cutting media/materialsSoldering mediaPotassium aluminateFiller metal

The invention belongs to the technical field of metal welding, particularly relates to brazing between dissimilar metals of aluminum alloy and copper alloy, and particularly relates to environment-friendly corrosion-free self-brazing solder for brazing the aluminum alloy and the copper alloy and a preparation method thereof. According to the self-brazing solder, zinc-aluminum alloy serves as brazing filler metal, cesium fluoroaluminate and potassium fluoroaluminate eutectic mixed salt serves as brazing flux, and the zinc-aluminum alloy brazing filler metal comprises, by weight, 0.5%-5.5% of Al, smaller than or equal to 0.5% of Fe, smaller than or equal to 0.25% of Cu and the balance Zn; and the brazing filler metal and the brazing flux are evenly mixed, stable product performance is guaranteed, and consistency of batch production is good.

Owner:常州鑫力航金属新材料有限公司

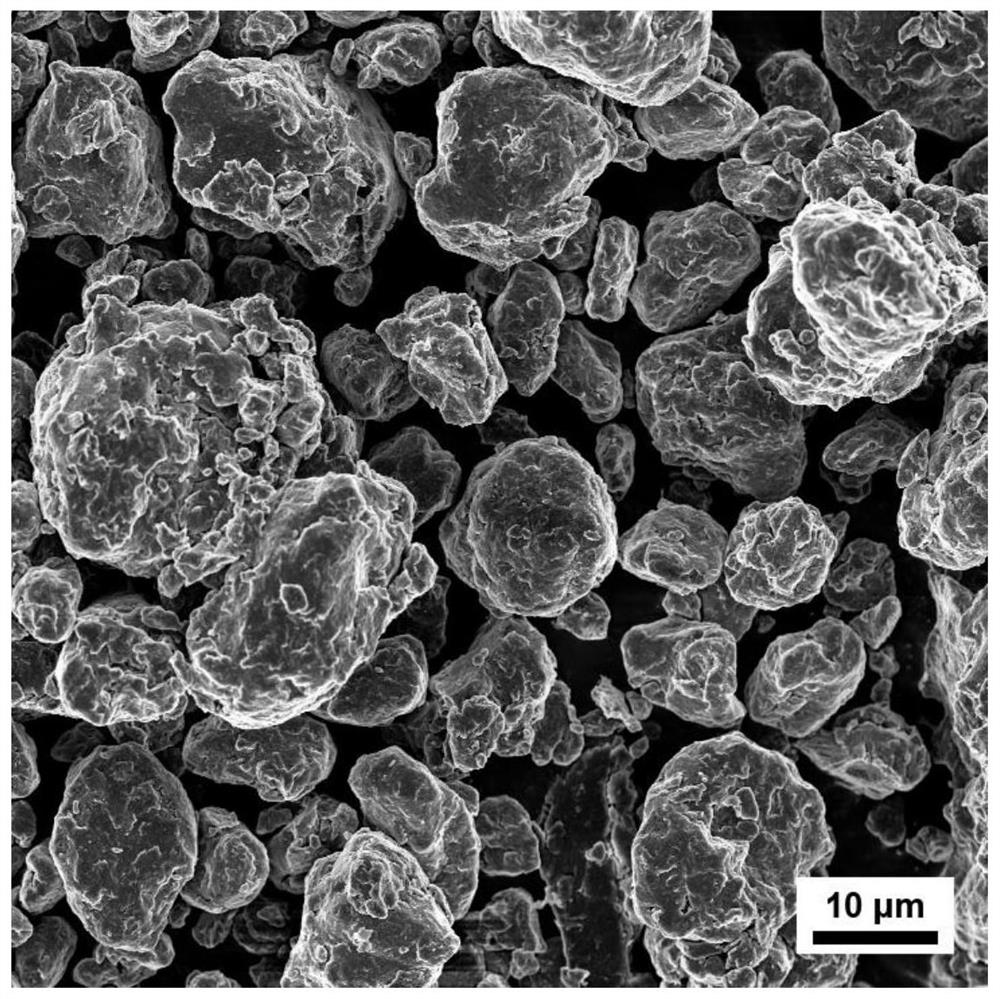

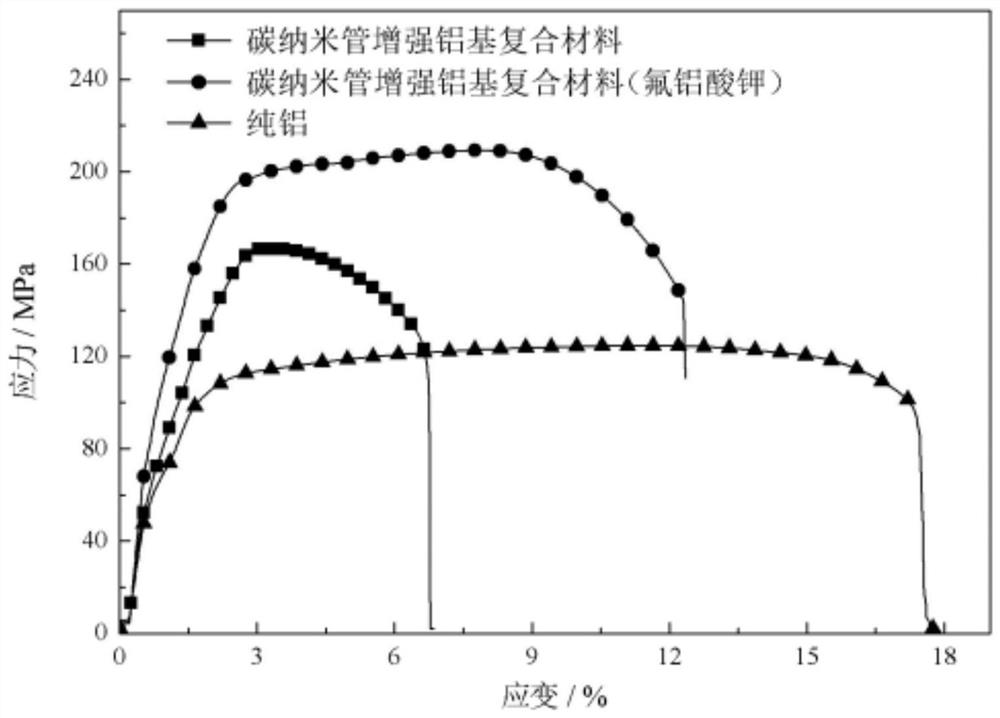

Smelting process of carbon nanotube reinforced aluminum matrix composite

The invention provides a smelting process of a carbon nanotube reinforced aluminum matrix composite. The smelting process comprises the following steps: carrying out ball-milling mixing dispersing ona smelting assistant, a carbon nanotube and aluminum / aluminum alloy powder in a planetary ball mill to obtain mixed powder; putting the mixed powder into a mold for cold pressing to obtain a carbon nanotube-aluminum / aluminum alloy precast block; and pressing the carbon nanotube-aluminum / aluminum alloy precast block into molten aluminum through a bell jar, carrying out smelting under stirring, carrying out standing, and then carrying out casting molding, wherein the smelting assistant is any one of potassium boroaluminate (KBF4), potassium titanium fluoroaluminate (K2TiF6), potassium fluoroaluminate (K3AlF6) or sodium fluoroaluminate (Na3AlF6). According to the smelting process of the carbon nanotube reinforced aluminum matrix composite, the carbon nanotube reinforced aluminum matrix composite is prepared through the smelting process, the efficient dispersion of the carbon nanotube in the smelting process is realized, meanwhile, traditional metal smelting equipment can be used, and thusthe smelting process has the advantages of being simple, small in investment, high in product strength and the like and is suitable for industrial mass production.

Owner:WUHAN NANRUI ELECTRIC POWER ENG TECH EQUIP +4

Polishing method of potassium aluminate chip

InactiveCN1817562AUnique methodSimple methodPolishing machinesSemiconductor/solid-state device manufacturingMicroscopic observationPotassium aluminate

A method for polishing the wafer of lithium aluminate includes such steps as growing lithium aluminate crystal by pull method, cutting to become wafer, putting it in the solution of hydrochloric acid or nitric acid, heating at 80-100 deg.C for 15-30 min, blowing N2 for drying, choosing more smooth surface by microscope, putting it on rubber disc, coarse grinding with alumina powder, fine polishing with polishing SiO2 liquid, and polishing with neutral diamond sand liquid.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

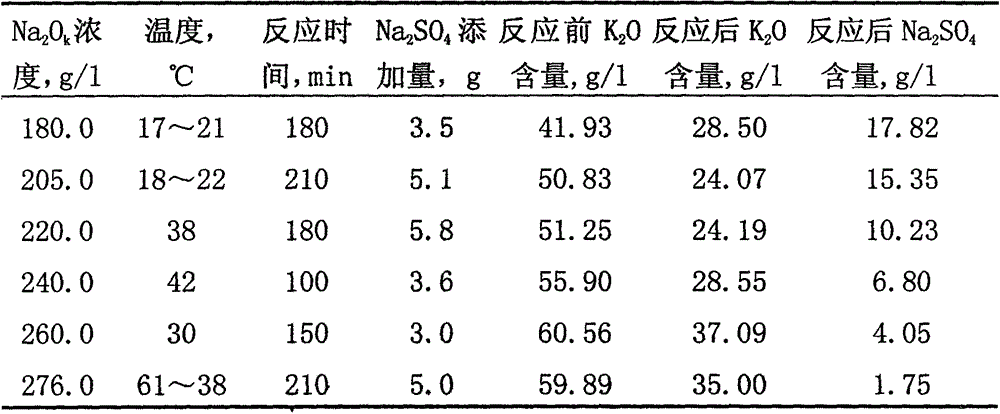

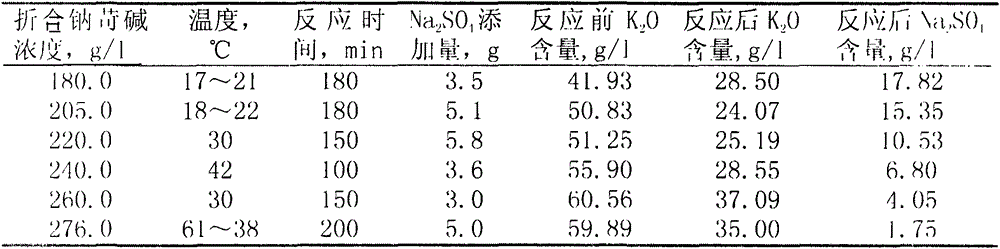

Method for separating potassium oxide from potassium-containing sodium aluminate solution

InactiveCN104016390AIncrease productionRecycling by the wayAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali metal oxidesPotassium lowEvaporation

The invention discloses a method for separating potassium oxide from a potassium-containing sodium aluminate solution, relating to a method comprising the steps of in the production of aluminum oxide, introducing SO4<2-> by adding one or a mixture of more of sodium sulfate, aluminum sulfate (basic aluminum sulfate) and an alunite ore into seeded precipitation evaporation liquor, converting potassium oxide into potassium sulfate, and performing precipitation and separation in a form of sodium aphthitalite, wherein the precipitation is implemented under high-causticizing alkali and low-temperature conditions, so that residual sodium sulfate in the solution can be avoided, and the solution can be purified; sodium aphthitalite can be used for dissolving and separating out a potassium sulfate product by virtue of variable temperature, and sodium sulfate can be recycled; or a high-potassium low-sodium ore is used for generating a pure potassium aluminate solution by using a limestone sintering method, and then the pure potassium aluminate solution is subjected to a replacement reaction with sodium aphthitalite to generate potassium sulfate and sodium aluminate; potassium chloride also can be used for converting sodium aphthitalite into pure potassium sulfate. The method disclosed by the invention can be used for producing aluminum oxide and potassium sulfate by adopting nepheline and the alunite ore by virtue of a multiple process technology, and also can be used for producing chemicals namely aluminum oxide and potassium sulfate by adopting high-silicon ores such as potassium feldspar, lepidolite and illite by virtue of an acid-alkali combination method.

Owner:赵凿元

Method for producing cement and cement kiln dust simultaneously through potassium feldspar

InactiveCN105314903AAchieve mass productionEase supplyClinker productionPotassium fertilisersIronstoneMetasilicate

The invention discloses a method for producing cement and cement kiln dust simultaneously through potassium feldspar. The method comprises the following steps that limestone, sandstone, potassium feldspar, iron powder and a fluorite additive are crushed and then mixed, wherein the mixture comprises, by weight, 72-77% of limestone, 17-20% of potassium feldspar, 2-6% of sandstone, 2-4% of iron ore and 1-2% of fluorite additive, and the sum of the percentages of all the components is 100%; the mixed raw materials are ground into raw materials with the granularity of 0.08-0.10 mm; the raw materials are evenly mixed and then fed into a kiln system, high-sulphur coal is adopted as fuel, and preheating, decomposition, calcination and cooling are carried out to obtain cement clinker; in the calcination process, K2O in the potassium feldspar is volatilized and compounded with SO2 and CO2 in high-sulfur coal soot to form K2SO4 and K2CO3 at first and then form potassium metasilicate and potassium aluminate to be concentrated in a kiln along with soot; kiln dust containing potassium is recycled through an efficient recycling device and processed into potassic fertilizer.

Owner:LUOYANG MINGLI TECH DEV

Method for separating potassium oxide from potassium-containing sodium aluminate solution

InactiveCN104445277AAchieve separationAchieve purificationAlkali metal oxidesDissolutionPotassium aluminate

The invention relates to a method for co-producing potassium sulfate by separating potassium oxide from a potassium-containing sodium aluminate solution while producing aluminum oxide from minerals, containing an aluminum element and a potassium element, such as non-soluble potassium ores or bauxite. The method is characterized by comprising the steps of adding one or the mixture of sodium sulfate, aluminum sulfate (alkaline aluminum sulfate), potassium (sodium) alum and alunite ores (pure alunite) into the potassium-containing sodium aluminate solution for introducing SO4<2-> to convert potassium oxide in the sodium aluminate solution into potassium sulfate, precipitating and separating potassium sulfate in a glaserite form, and purifying glaserite into potassium sulfate by virtue of methods of variable temperature dissolution and separation, potassium chloride conversion and potassium aluminate replacement. According to the method, the precipitation is carried out under conditions of high caustic alkali and low temperature, so that the residue of sodium sulfate in the solution can be avoided, and the solution is purified. A Bayer process is not influenced, accumulated potassium oxide can be recycled from a circulating mother solution for the production of aluminum oxide, and aluminum oxide and potassium sulfate can be produced by virtue of the non-soluble potassium ores such as nepheline and potassium feldspar as well as alunite ores or artificial pure alunite by a parallel-combined process.

Owner:赵凿元

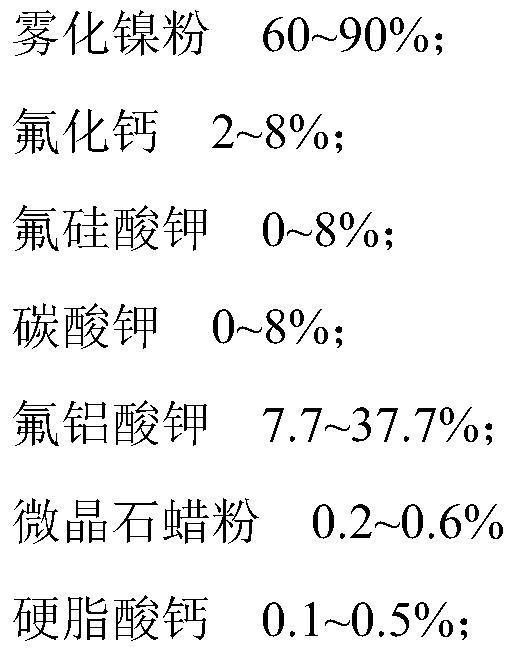

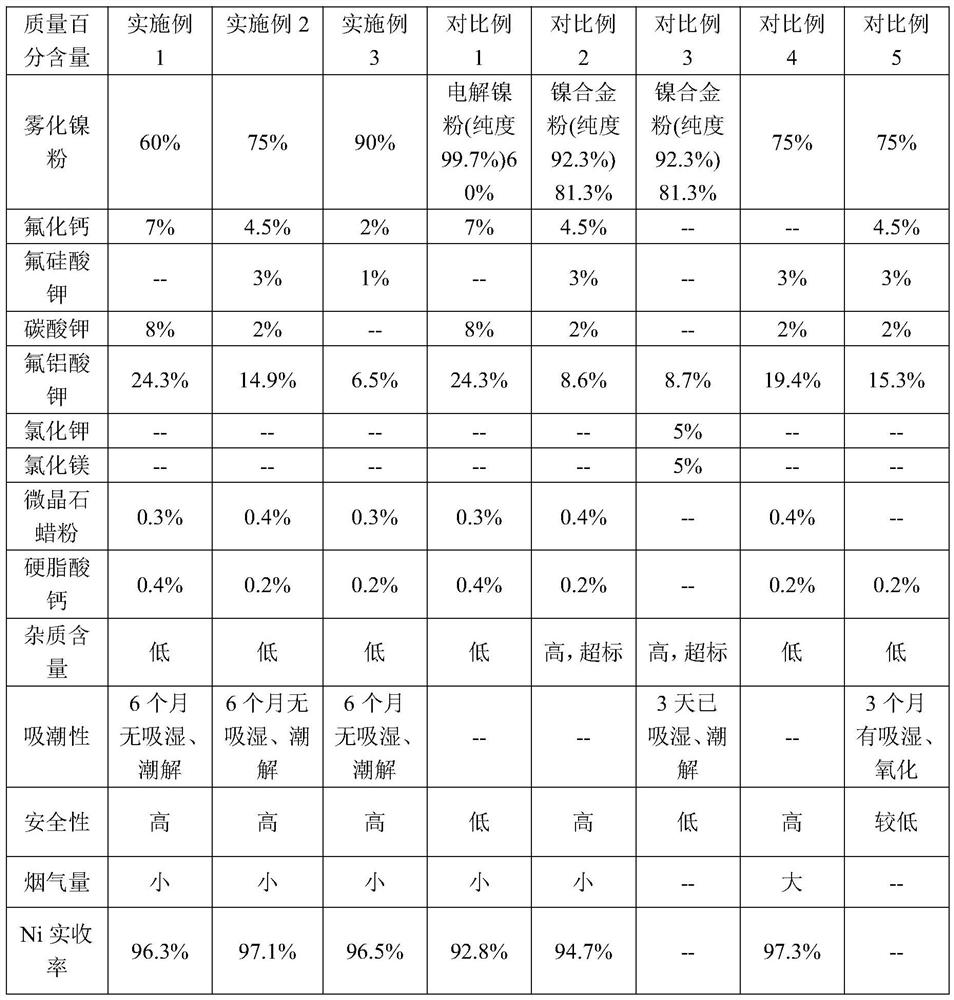

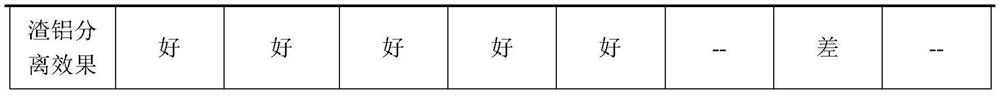

Nickel element additive for aluminum alloy

The invention relates to a nickel element additive for an aluminum alloy, comprising the following components in percentage by mass: 60-90% of atomized nickel powder; 2-8% of calcium fluoride; 0-8% of potassium fluosilicate; 0-8% of potassium carbonate; 7.7%-37.7% of potassium fluoroaluminate; 0.2-0.6% of microcrystalline wax powder; and 0.1-0.5% of calcium stearate. The mixed materials are pressed into a round cake shape through a hydraulic machine, the weight of a single block is 500-1500 g, and the density is 4.0-5.5 g / cm3. According to the nickel element additive, under the condition of 700-740 DEG C, when the Ni content is 0.5-2.3%, the casting yield of 96% or above can be achieved within 10-20 min, the impurity content is low, the melting speed is high, the casting yield is high, the smoke amount is small, and safety is good.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

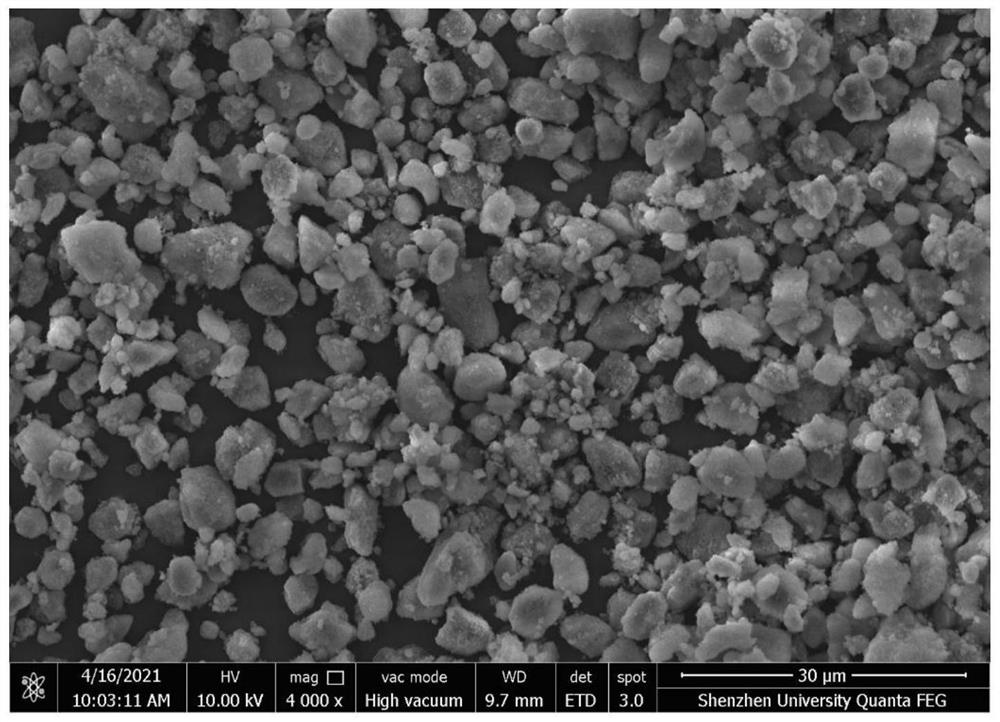

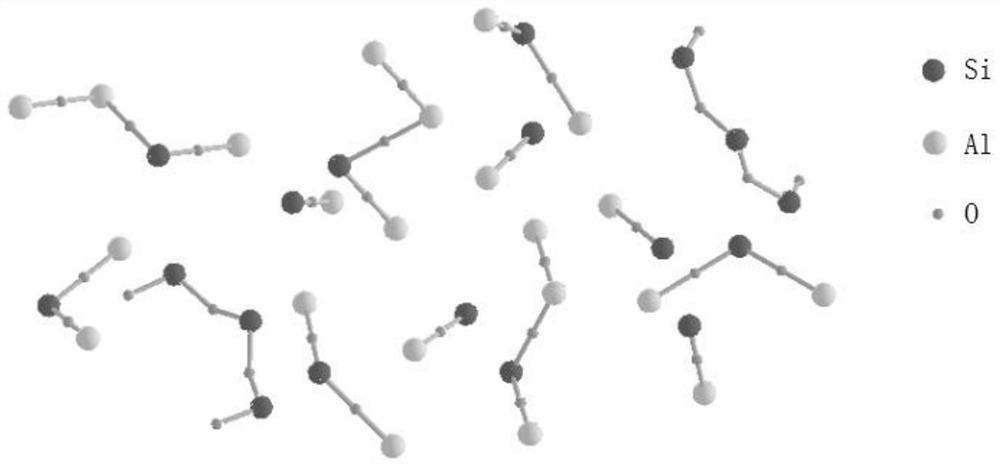

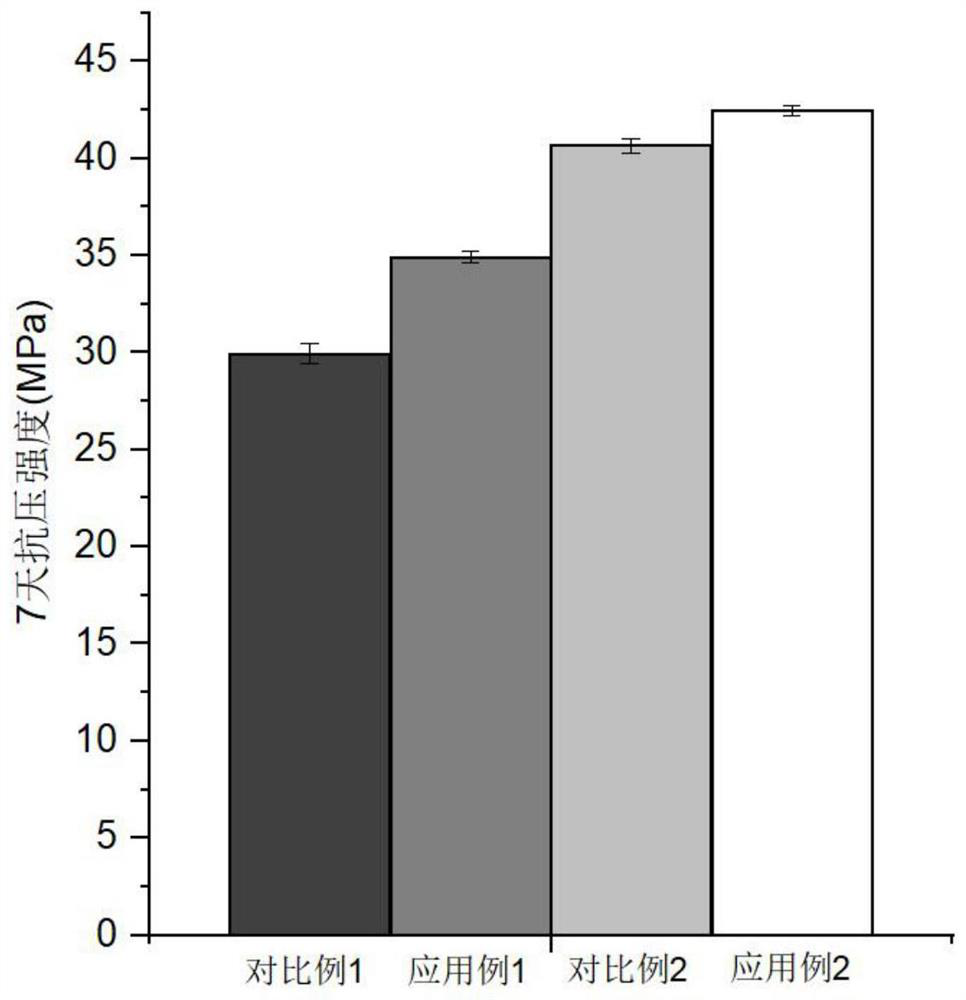

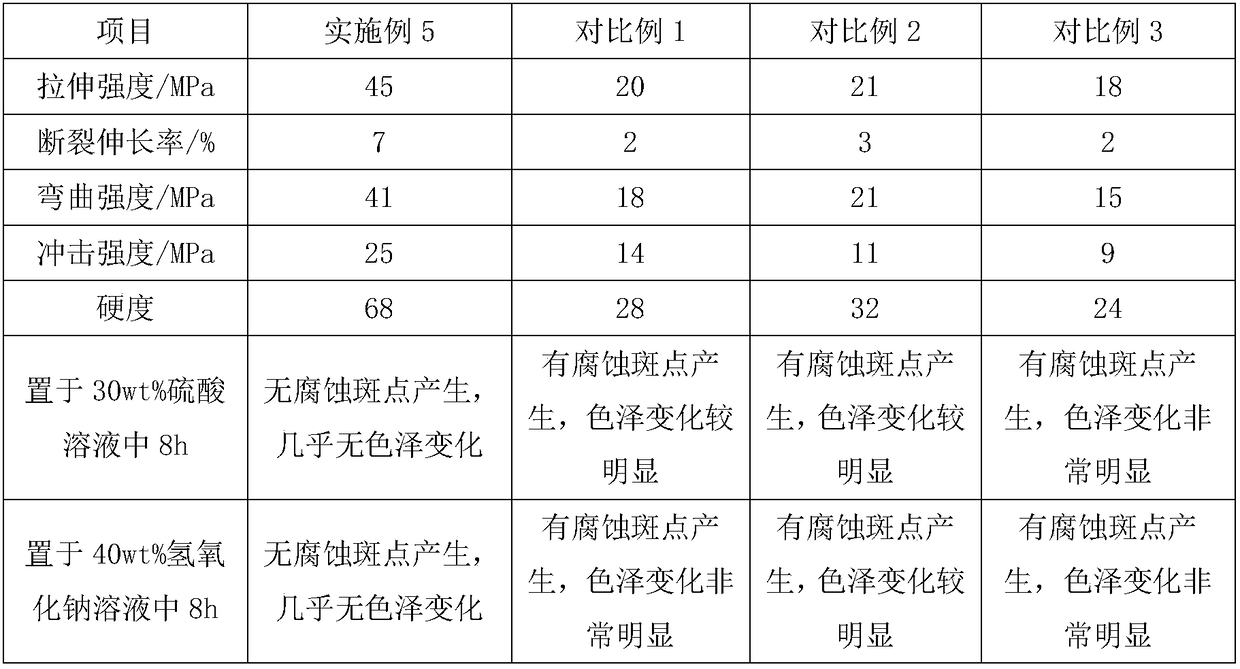

Potassium aluminosilicate nanogel precursor admixture and application thereof in low-calcium-system geopolymer

ActiveCN113548823AUniform and dense pore structureAvoid affecting the mechanical propertiesCement productionHydration reactionGeopolymer

The invention provides a potassium aluminosilicate nanogel precursor admixture and application thereof in a low-calcium-system geopolymer, belonging to the technical field of geopolymer admixtures. The potassium aluminosilicate nanogel precursor external admixture provided by the invention has a structure of a high-activity potassium aluminosilicate short-chain structure, is a precursor of the low-calcium-system geopolymer, and comprises the following chemical components: K2O, SiO2 and Al2O3, wherein molar ratio of K to Si is 1.0-4.0, and a molar ratio of Al to Si is 0.25-1.5. When the potassium aluminosilicate nanogel precursor admixture provided by the invention is added into a low-calcium-system geopolymer matrix material, the hydration process of the low-calcium-system geopolymer such as metakaolin can be effectively optimized, internal reaction is balanced, and a pore structure is improved; and thus, the mechanical properties of the material are improved, the problems of harsh maintenance conditions, non-uniform hydration reaction and substandard mechanical properties of the low-calcium-system geopolymer are effectively solved, and a feasible scheme is provided for application of the low-calcium-system geopolymer.

Owner:SHENZHEN UNIV

Wear-resistant ceramic material as well as preparation method and application thereof

InactiveCN108148398AImprove wear resistanceImprove mechanical propertiesAdditive manufacturing apparatusTO-18Wear resistant

The invention discloses a wear-resistant ceramic material as well as a preparation method and application thereof. The wear-resistant ceramic material is prepared from the following raw materials in parts by weight: 30 to 55 parts of nylon fiber, 10 to 25 parts of ceramic micropowder, 11 to 17 parts of dimethylaminoisopropanol, 14 to 18 parts of trisodium phosphate, 8 to 16 parts of cyanuric chloride, 6 to 9 parts of mordenite powder, 4 to 9 parts of isopropyl titanate and 2 to 6 parts of potassium aluminate. The wear-resistant ceramic material disclosed by the invention is prepared from nylonfiber, ceramic micropowder, dimethylaminoisopropanol, trisodium phosphate, cyanuric chloride, mordenite powder, isopropyl titanate and potassium aluminate, and has the advantages of good wear resistance, excellent mechanical properties and corrosion resistance, simple preparation process, and easiness in industrial production.

Owner:季梅

Hydrocarbon reforming catalyst for directly reducing iron with gas group and preparation method

InactiveCN104998651ACleavage rate slows downImprove carbon resistanceMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPotassium aluminate

Owner:SICHUAN TIANYI SCI & TECH

Efficient magnesium-containing aluminum alloy refining and slagging dual-purpose flux and preparation method thereof

The invention relates to an efficient magnesium-containing aluminum alloy refining and slagging dual-purpose flux and a preparation method thereof, and belongs to the field of alloy smelting. The fluxcomprises the following components of, in percentage by weight, 30%-55% of magnesium chloride, 10%-45% of potassium chloride, 1%-5% of potassium feldspar, 0%-20% of calcium fluoride and 2%-10% of potassium fluoroaluminate. The flux preparation process comprises the following steps of (1), fully mixing magnesium chloride, potassium chloride, potassium fluoroaluminate, calcium fluoride and other salts which are dried at 240-300 DEG C for 3-5 hours, melting in a resistance furnace, heating to 650-750 DEG C, keeping the temperature, and stirring for 10-30 minutes to obtain a uniform salt melt; (2), pouring the salt melt into a mold for cooling, and solidifying into a blocky flux; and (3), crushing the blocky flux into particles with the average particle size of about 0.5 cm, and fully mixingthe particles with dry potassium feldspar to obtain the magnesium-containing aluminum alloy melt refining and slagging flux. The magnesium-containing aluminum alloy flux does not contain sodium salt,has refining and slagging effects, and is an ideal flux for magnesium-containing aluminum alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com