Nickel element additive for aluminum alloy

A nickel element and additive technology, applied in the field of aluminum alloys, can solve problems such as aluminum dust endangering human health, high impurity content, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

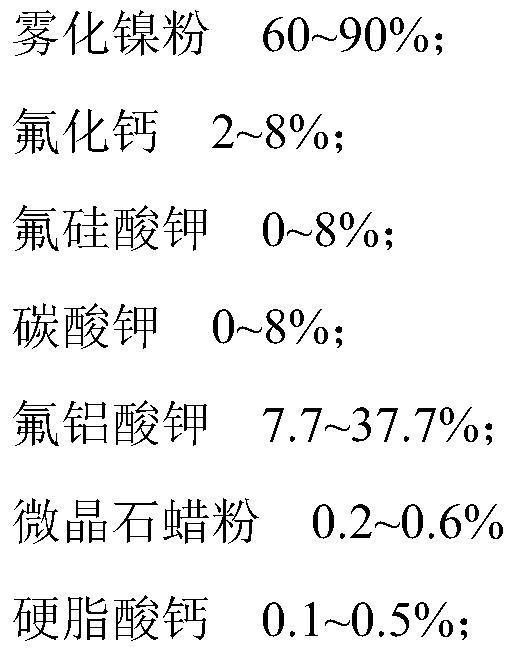

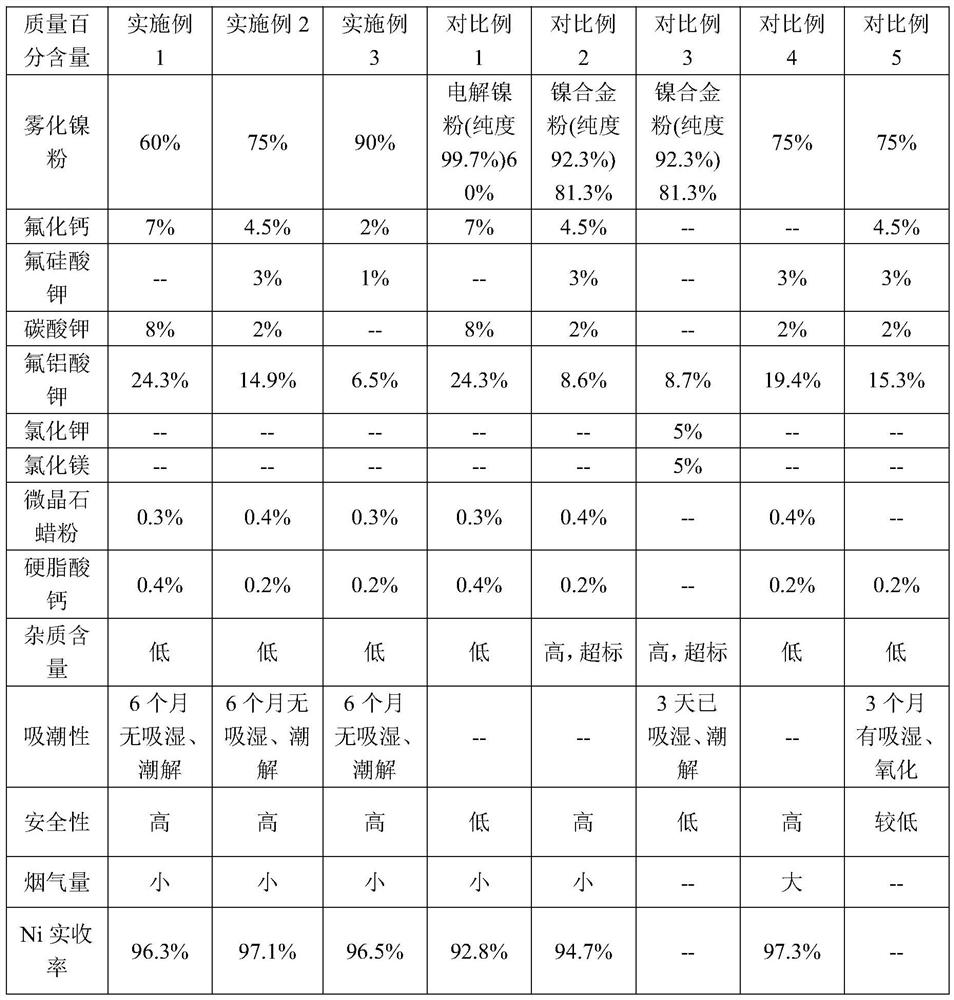

[0032] A nickel element additive for aluminum alloys, its components and mass percentages are 60% of water atomized nickel powder, 7% of calcium fluoride, 8% of potassium carbonate, 24.3% of potassium fluoroaluminate, and 0.3% of microcrystalline paraffin wax powder , Calcium stearate 0.4%.

[0033] The materials that meet the requirements are batched according to the formula ratio involved in the present invention, and each batch of batches is 600 kg, and the materials are put into a mixer for mixing, and the mixing time is 20 minutes. Then, use a hydraulic press to press the mixed material into a round cake shape, the weight of a single piece is 500±10 grams, and the density: 4.2-4.4g / cm 3 , the nickel element additive made is tested for composition, density and moisture. After passing the test, it is wrapped with aluminum foil, and packed according to 2.5 kg / bag and 20 kg / carton.

[0034]The nickel element additive prepared according to Example 1 is used to add nickel elem...

Embodiment 2

[0037] A nickel element additive for aluminum alloys, its components and mass percentages are 75% of gas-atomized nickel powder, 4.5% of calcium fluoride, 3% of potassium fluorosilicate, 2% of potassium carbonate, and 14.9% of potassium fluoroaluminate , Microcrystalline paraffin powder 0.4%, calcium stearate 0.2%.

[0038] The materials that meet the requirements are batched according to the formula ratio involved in the present invention, and each batch of batches is 1000 kg, and the materials are put into a mixer for mixing, and the mixing time is 30 minutes. Then, use a hydraulic press to press the mixed material into a round cake shape, the weight of a single piece is 500±10 grams, and the density: 4.6-4.8g / cm 3 , the nickel element additive made is tested for composition, density and moisture. After passing the test, it is wrapped with aluminum foil, and packed according to 2.5 kg / bag and 20 kg / carton.

[0039] The nickel element additive prepared according to Example 2...

Embodiment 3

[0042] A nickel element additive for aluminum alloys, the nickel content is 90%, and its components and mass percentages are 90% of water atomized nickel powder, 2% of calcium fluoride, 1% of potassium fluorosilicate, and 6.5% of potassium fluoroaluminate %, microcrystalline paraffin powder 0.3%, calcium stearate 0.2%.

[0043] The materials that meet the requirements are batched according to the formula ratio involved in the present invention, and each batch of batches is 1500 kg, and the materials are put into a mixer for mixing, and the mixing time is 40 minutes. Then, use a hydraulic press to press the mixed material into a round cake, with a single piece weight of 1000±10 grams and a density of 5.0-5.2g / cm 3 , the nickel element additive made is tested for composition, density and moisture, and wrapped in aluminum foil after passing the test, and packed according to 3 kg / bag and 24 kg / carton.

[0044] The nickel element additive prepared according to Example 3 is used to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com