High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

An ultra-fine cement and grouting material technology, applied in the field of grouting reinforcement in civil engineering, can solve the problems of ineffective injection, complex formula, high cost, and achieve the effect of reducing material cost, large flow diffusivity, and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

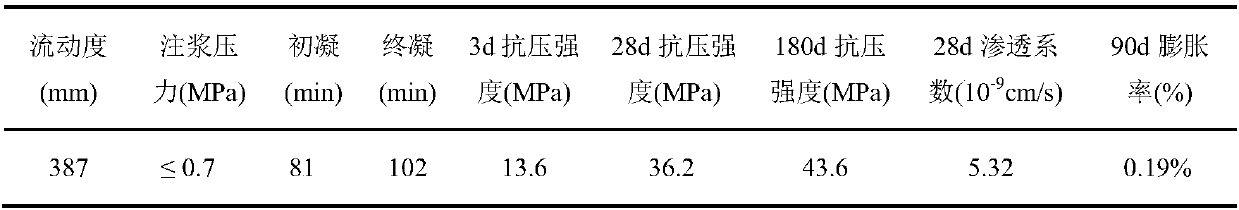

Embodiment 1

[0055] 1. The components and mass ratio are: 60 parts of Portland cement clinker, 35.5 parts of auxiliary cementing material, and 4.5 parts of desulfurized gypsum; among them, the weight parts of each component of auxiliary cementing material are as follows: 43 parts of slag, 10.5 parts of steel slag 32 parts, 32 parts of fly ash, 10 parts of limestone powder, 4.5 parts of silica fume, 9.7 parts of high-performance composite regulator; the parts by weight of each component in the high-performance composite regulator are as follows: 8 parts of sodium hydroxide, silicic acid 7 parts of sodium, 6 parts of potassium metaaluminate, 13.3 parts of calcium chloride, 12.8 parts of lithium chloride, 8 parts of triethanolamine, 21 parts of alum, 20 parts of aluminum sulfate, 0.29 parts of hydroxypropyl methylcellulose, acrylate polymer 2.1 parts, 0.11 parts of polypropylene fiber (length ≤ 3mm), 1.4 parts of polycarboxylate superplasticizer.

[0056] 2. Application of grouting treatment:...

Embodiment 2

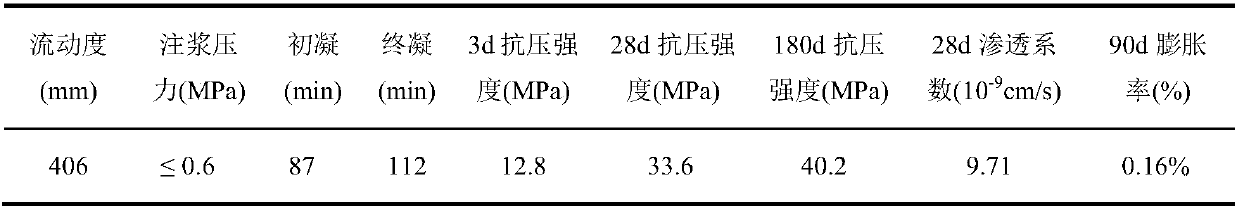

[0061] 1. The components and mass ratio are: 65 parts of Portland cement clinker, 30 parts of auxiliary cementing material, and 5 parts of desulfurized gypsum; among them, the parts by weight of each component of auxiliary cementing material are as follows: 45 parts of slag, 8.5 parts of steel slag 33.5 parts of fly ash, 9 parts of limestone powder, 4 parts of silica fume, and 8.7 parts of high-performance composite regulator; the parts by weight of each component in the high-performance composite regulator are as follows: 7 parts of sodium hydroxide, 8 parts of sodium, 7 parts of potassium metaaluminate, 13.6 parts of calcium chloride, 12.8 parts of lithium chloride, 7 parts of triethanolamine, 21 parts of alum, 20 parts of aluminum sulfate, 0.12 parts of hydroxypropyl methylcellulose, ethylene-vinyl acetate 1.9 parts of copolymer, 0.08 parts of polypropylene fiber (length ≤ 3mm), 1.5 parts of polycarboxylate superplasticizer.

[0062] 2. Application of grouting treatment: th...

Embodiment 3

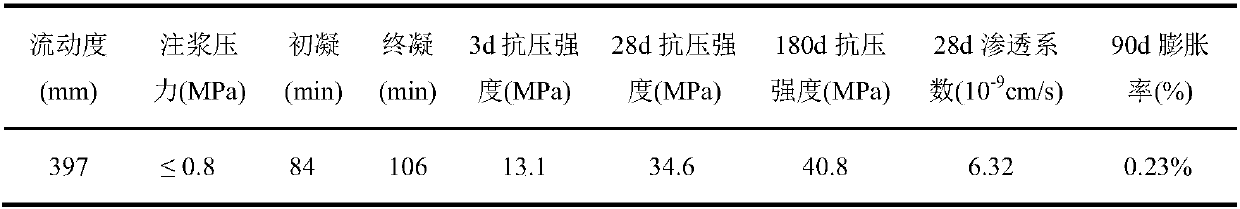

[0067] 1. The components and mass ratio are: 65 parts of Portland cement clinker, 30 parts of auxiliary cementing material, and 5 parts of desulfurized gypsum; among them, the weight parts of each component of auxiliary cementing material are as follows: 42 parts of slag, 9 parts of steel slag 36 parts, 36 parts of fly ash, 9 parts of limestone powder, 4 parts of silica fume, 8.9 parts of high-performance composite regulator; the parts by weight of each component in the high-performance composite regulator are as follows: 7 parts of sodium hydroxide, 8 parts of sodium, 7 parts of potassium metaaluminate, 13.6 parts of calcium chloride, 12.8 parts of lithium chloride, 7 parts of triethanolamine, 21 parts of alum, 20 parts of aluminum sulfate, 0.12 parts of hydroxypropyl methylcellulose, ethylene-vinyl acetate 1.98 parts of copolymer, 1.5 parts of polycarboxylate superplasticizer.

[0068] 2. Application of grouting treatment: the particle size of the cement-based grouting mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com