High-alumina glass frosting powder and use method thereof

A high-alumina glass and frosting powder technology, applied in chemical instruments and methods, surface etching compositions, etc., can solve the problems of difficult control, fast etching rate, etc., to avoid corrosion, system uniformity and stability, and reduce adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

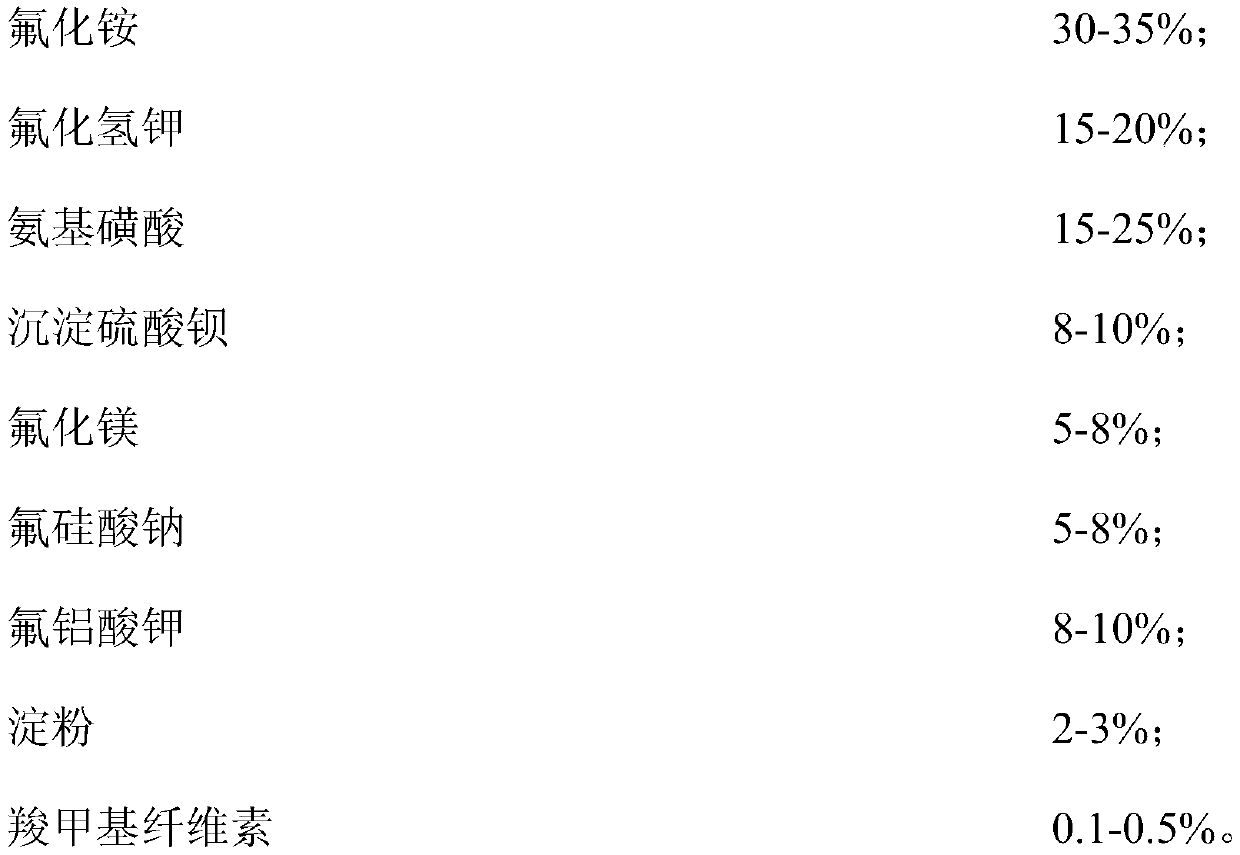

[0048] This embodiment provides a high-alumina glass frosting powder, and the high-alumina glass frosting powder includes the following components according to mass percentage:

[0049]

[0050] Using the high-alumina glass frosting powder for the frosting operation of Corning GG5 type high-alumina glass workpieces, the specific use method includes the following steps:

[0051] (1) The high-alumina glass frosting powder and water are mixed according to the mass ratio of 1:0.2, and then aged at 40° C. for 48 hours to obtain a high-alumina glass frosting liquid;

[0052] (2) Adopt the mode of showering sand, carry out frosting with the high-alumina glass frosting solution described in step (1) to be frosted Corning GG5 type high-alumina glass workpiece, wherein the temperature of controlling frosting is 30 ± 2 ℃, Sand time is 60s.

[0053] The glass surface roughness Ra of the Corning GG5 high-alumina glass workpiece obtained in this example is 0.1 μm.

Embodiment 2

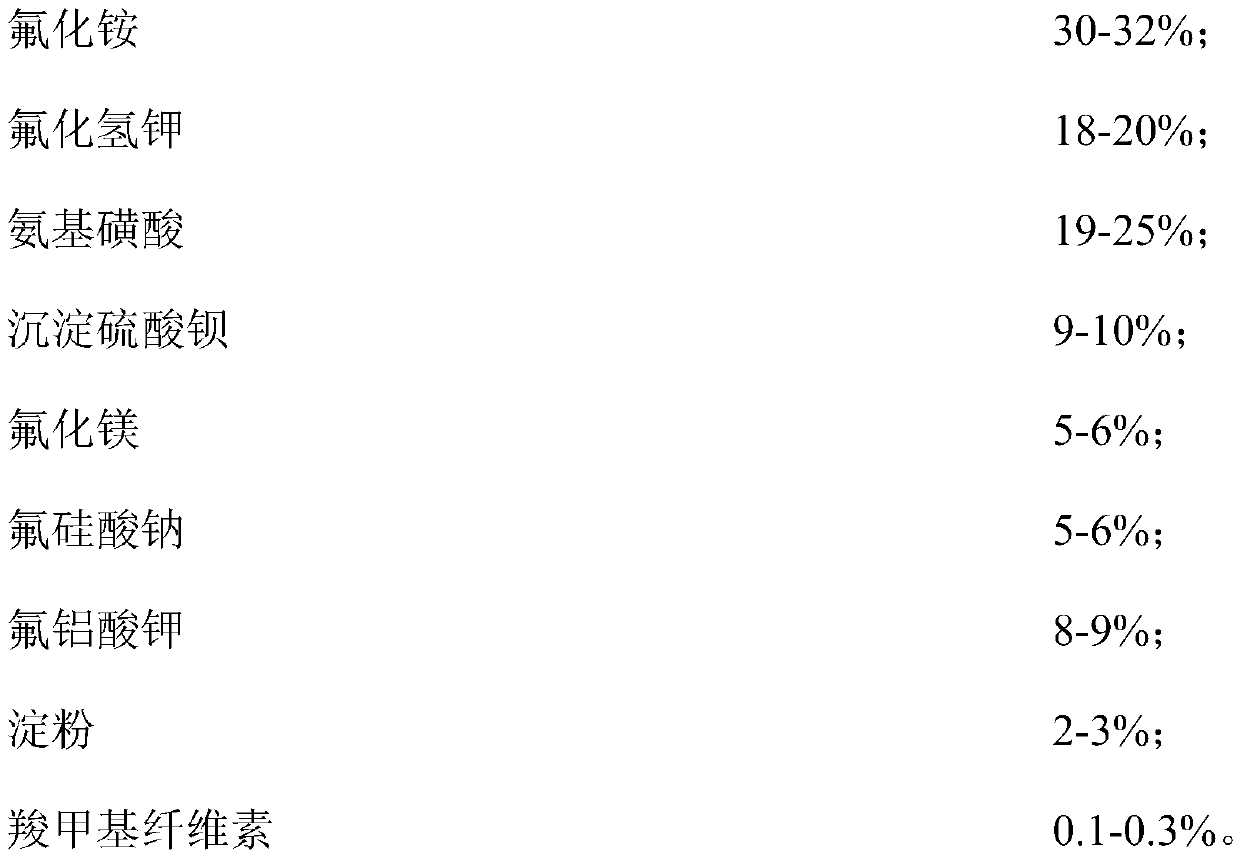

[0055] This embodiment provides a high-alumina glass frosting powder, and the high-alumina glass frosting powder includes the following components according to mass percentage:

[0056]

[0057] Using the high-alumina glass frosting powder for the frosting operation of Asahi Glass AGC type high-alumina glass workpieces, the specific use method includes the following steps:

[0058] (1) The high-alumina glass frosting powder and water are mixed according to the mass ratio of 1:0.5, and then aged at 60° C. for 24 hours to obtain a high-alumina glass frosting liquid;

[0059] (2) Using the method of sand showering, the high-alumina glass frosting solution described in step (1) is used to frost the Asahi Glass AGC type high-alumina glass workpiece to be frosted, wherein the temperature of the frosting is controlled to be 30 ± 2 ° C, and the frosting The sand time is 300s.

[0060] The glass surface roughness Ra of the Asahi Glass AGC type high alumina glass workpiece obtained ...

Embodiment 3

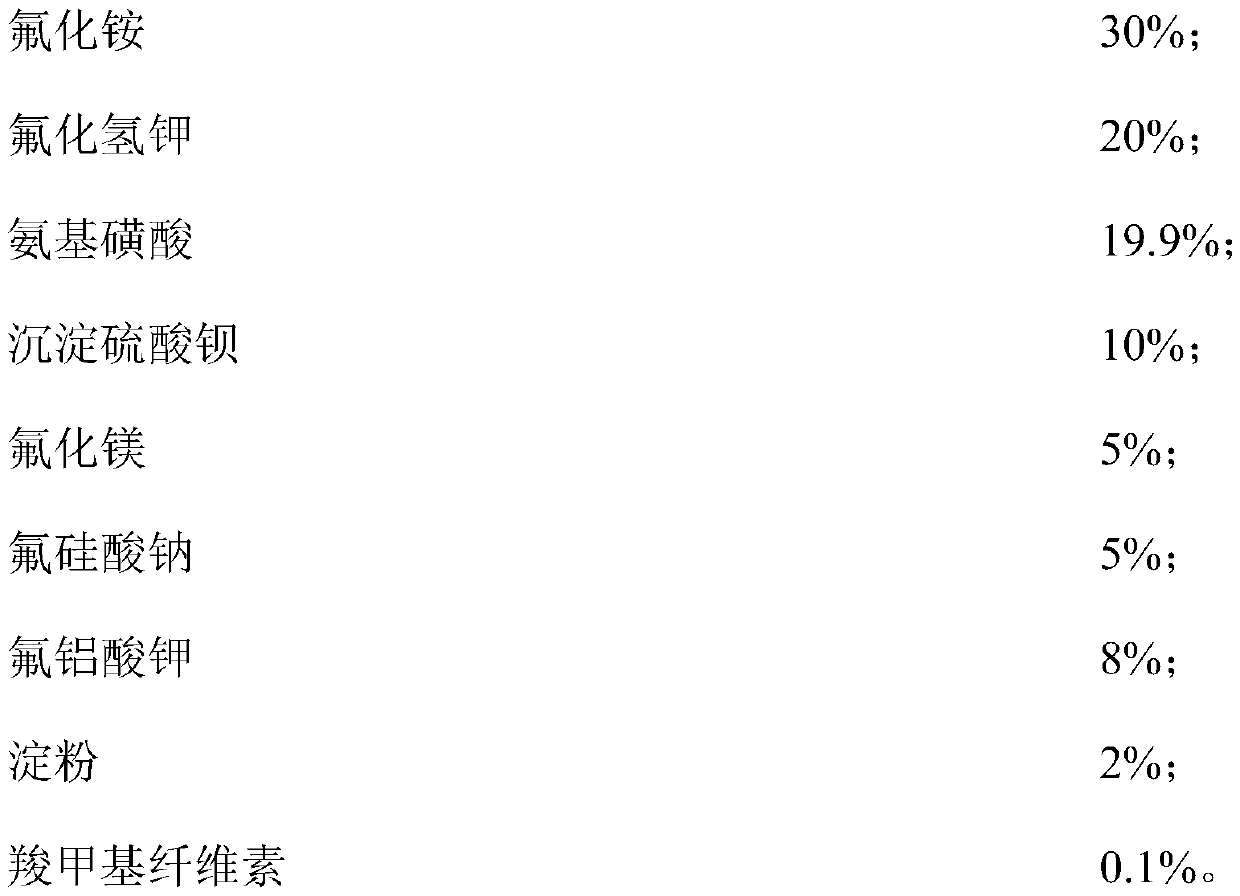

[0062] This embodiment provides a high-alumina glass frosting powder, and the high-alumina glass frosting powder includes the following components according to mass percentage:

[0063]

[0064] The high-alumina glass frosting powder is used for the frosting operation of Corning GG6 high-alumina glass workpieces. The specific use method includes the following steps:

[0065] (1) The high-alumina glass frosting powder and water are mixed according to the mass ratio of 1:0.2, and then aged at 40° C. for 48 hours to obtain a high-alumina glass frosting liquid;

[0066] (2) Adopt the mode of showering sand, carry out frosting with the high-alumina glass frosting solution described in step (1) to be frosted Corning GG6 type high-alumina glass workpiece, wherein the temperature of controlling frosting is 30 ± 2 ℃, Sand time is 60s.

[0067] The glass surface roughness Ra of the Corning GG6 high-alumina glass workpiece obtained in this example is 0.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com