Automobile tail gas purification catalyst carrier and preparation method thereof

A technology for purifying catalysts and automobile exhaust gas, applied in the field of materials, can solve the problems of reduced specific surface area, pore volume oxygen storage and release capacity, failure to meet exhaust emission standards, poor mechanical mixing method, etc. Low impurity composition and good oxygen storage and release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

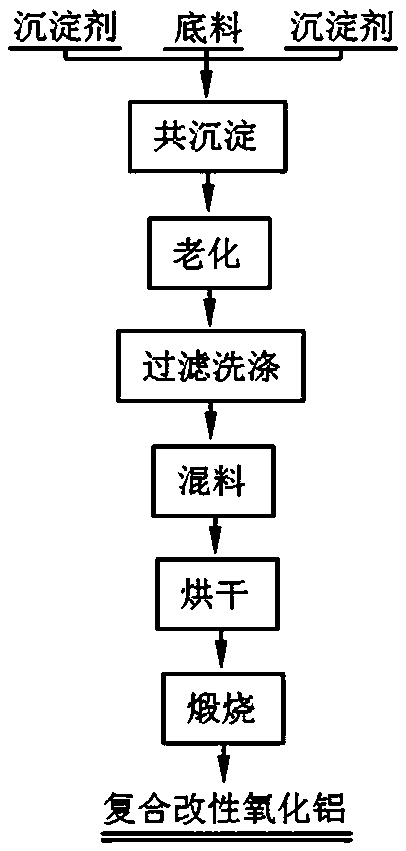

[0026] The preparation method of the vehicle exhaust gas purification catalyst carrier of the present invention is a two-step precipitation method, which specifically includes the following steps:

[0027] A. Using sodium aluminate or potassium aluminate as raw materials, nitric acid, modifier and surfactant as auxiliary materials, through co-precipitation, aging, filtration and washing to obtain modified aluminum hydroxide, and then drying, calcining and pulverizing to obtain modified aluminum hydroxide Alumina;

[0028] B. The modified aluminum hydroxide or modified alumina prepared in step A is used as the raw material, the modified aluminum hydroxide or alumina slurry containing the surfactant and the oxidant is used as the bottom liquid, and the precipitant and the modifier are sprayed together The precipitation temperature is -20 ℃ ~ 90 ℃, and the pH value of the precipitation is 7.0 ~ 12.5; after precipitation, the compound modified target is prepared by aging, filtrati...

Embodiment 1

[0038] 1) Prepare Al(OH) according to the patented catalyst carrier and preparation method (patent number: 201710094079.2) 3 :La 2 O 3 :Pr 6 O 11 =153:8:6 modified aluminum hydroxide;

[0039] 2) Prepare Al(OH) with a solid content of 40% 3 :La 2 O 3 :Pr 6 O 11 =153:8:6 modified aluminum hydroxide primer, with composite modified aluminum oxide (Al 2 O 3 :La 2 O 3 :Pr 6 O 11 : CeO2 :ZrO 2 =50:4:3:31:12) Add 8% of the mass of the surfactant ammonium polyacrylate into the primer, and add the oxidant H to 50% of the mass of the composite modified alumina 2 O 2 into the bottom material;

[0040] 3) Prepare CeO according to the ratio of composite modified alumina 2 :ZrO 2 = 72:28 rare earth modifier nitrate solution;

[0041] 4) Precipitate as Me(OH) by rare earth nitrate x 1.2x OH required - Ammonia solution is prepared according to the quantity, wherein the volume of rare earth nitrate solution is equal to the volume of precipitant solution;

[0042] 5) The ...

Embodiment 2

[0050] 1) Prepare Al according to the patented catalyst carrier and preparation method (patent number: 201710094079.2) 2 O 3 :ZrO 2 :Y 2 O 3 =95.5:3.3:1.2 modified alumina;

[0051] 2) Prepare Al with a solid content of 40% 2 O 3 :ZrO 2 :Y 2 O 3 = 95.5:3.3:1.2 modified alumina primer, compound modified alumina (Al 2 O 3 :ZrO 2 :Y 2 O 3 : CeO 2 =70:2.4:0.9:26.7) 8% by mass of PEG-2000 and 2% of cetyltrimethylammonium bromide, add oxidant H at 40% of the mass of composite modified alumina 2 O 2 into the bottom material;

[0052] 3) Prepare 26.7% CeO according to the ratio of composite modified alumina 2 The rare earth modifier nitrate solution;

[0053] 4) Precipitate as Me(OH) by rare earth nitrate x 1.2x OH required - The volume of the rare earth nitrate solution is equal to the volume of the precipitant solution;

[0054] 5) The modifier solution and the precipitant solution are sprayed into the primer in parallel, the precipitation temperature is 50 °C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com