Preparation method of hollow flat plate structure type ceramic filter membrane element

A technology for filtering ceramics and membrane elements, which is applied in the field of preparation of hollow plate filter ceramic membrane elements to achieve uniform pore size distribution, good chemical stability, and narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

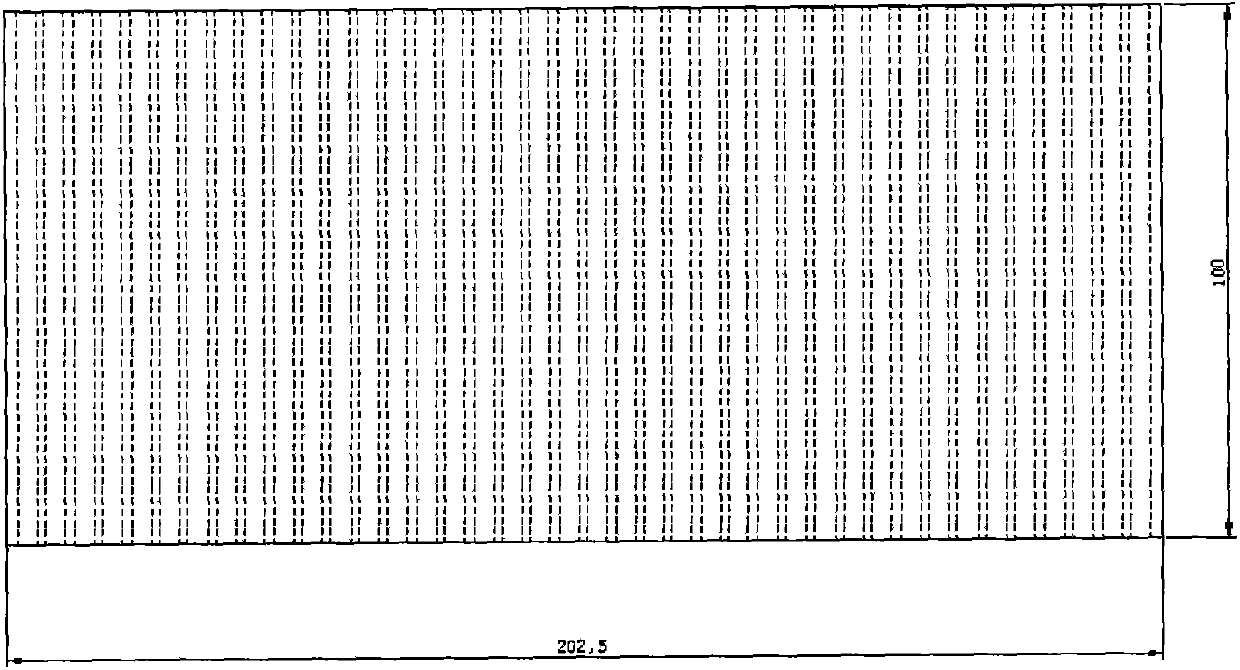

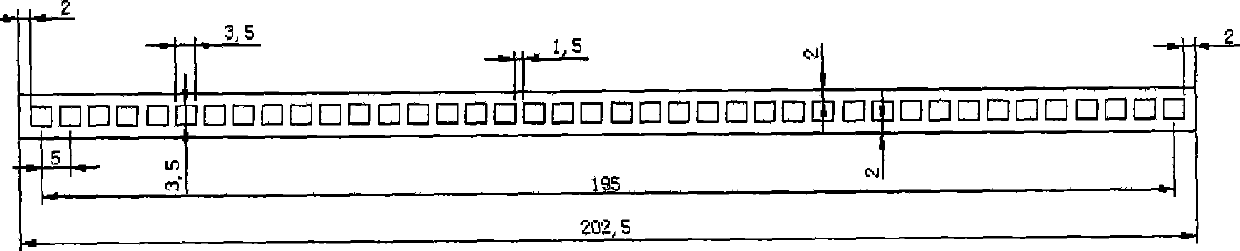

Image

Examples

Embodiment 1

[0053] (1) Preparation of ceramic membrane support body:

[0054] Calcined aluminum hydroxide (3 μm) 72wt%, starch (0.5 μm) 8wt%, gum arabic 3wt%, polyacrylamide (molecular weight 12 million) 3wt%, polyethylene glycol (molecular weight 400) 3wt% in proportion, 11wt% of water, mixed evenly, poured into a mud refining machine for mud refining, and then put it into an airtight container to stale for 20 hours. The molding process of the ceramic membrane support adopts extrusion molding, the extrusion temperature is 10°C, and the extrusion pressure is 6MPa. After molding, the green body is dried in an oven at 50°C for 4 hours, and then further dried by microwave, and the drying time is 180s. The dried green body is sintered at 1200° C. and kept warm for 2 hours to obtain a hollow flat plate filter ceramic membrane support body.

[0055] (2) Preparation of ceramic membrane:

[0056] The average particle size (D 50 ) 1μm and 0.2μm alumina powders were baked in an oven at 120°C for...

example 1

[0058] The scanning electron micrographs of the ceramic membrane element support body, cross-section and filter membrane surface made in example 1 are shown in image 3 , 4 , 5.

Embodiment 2

[0060] (1) Preparation of ceramic membrane support body:

[0061] Calcined aluminum hydroxide (3 μm) 74wt%, starch (0.5 μm) 6wt%, gum arabic 3wt%, polyacrylamide (molecular weight 12 million) 3wt%, polyethylene glycol (molecular weight 400) 3wt% in proportion, Water and 11wt% raw materials are mixed evenly, poured into a mud refining machine for mud refining, and then put into an airtight container to stale for 20 hours. The molding process of the ceramic membrane support adopts extrusion molding, the extrusion temperature is 20°C, and the extrusion pressure is 8MPa. After molding, the green body is placed in an oven at 50°C to dry for 6 hours, and then further dried by microwaves, and the drying time is 120s. The dried green body is sintered at 1250° C. and held for 3 hours to obtain a hollow flat plate filter ceramic membrane support body.

[0062] (2) Preparation of ceramic membrane:

[0063] The average particle size (D 50 ) 1 μm and 0.2 μm zirconia powders were baked i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com