Heating-free non-alkali liquid accelerator for jetting concrete and preparation method of heating-free non-alkali liquid accelerator

A sprayed concrete, heating-free technology, applied in the preparation of the liquid accelerator, non-heating non-alkali liquid accelerator for shotcrete, non-alkali liquid accelerator field, can solve the problem of not giving guidance, strength Reduced ratio, high alkali content, etc., to achieve the effect of no change in use effect, reduced possibility, and good cement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

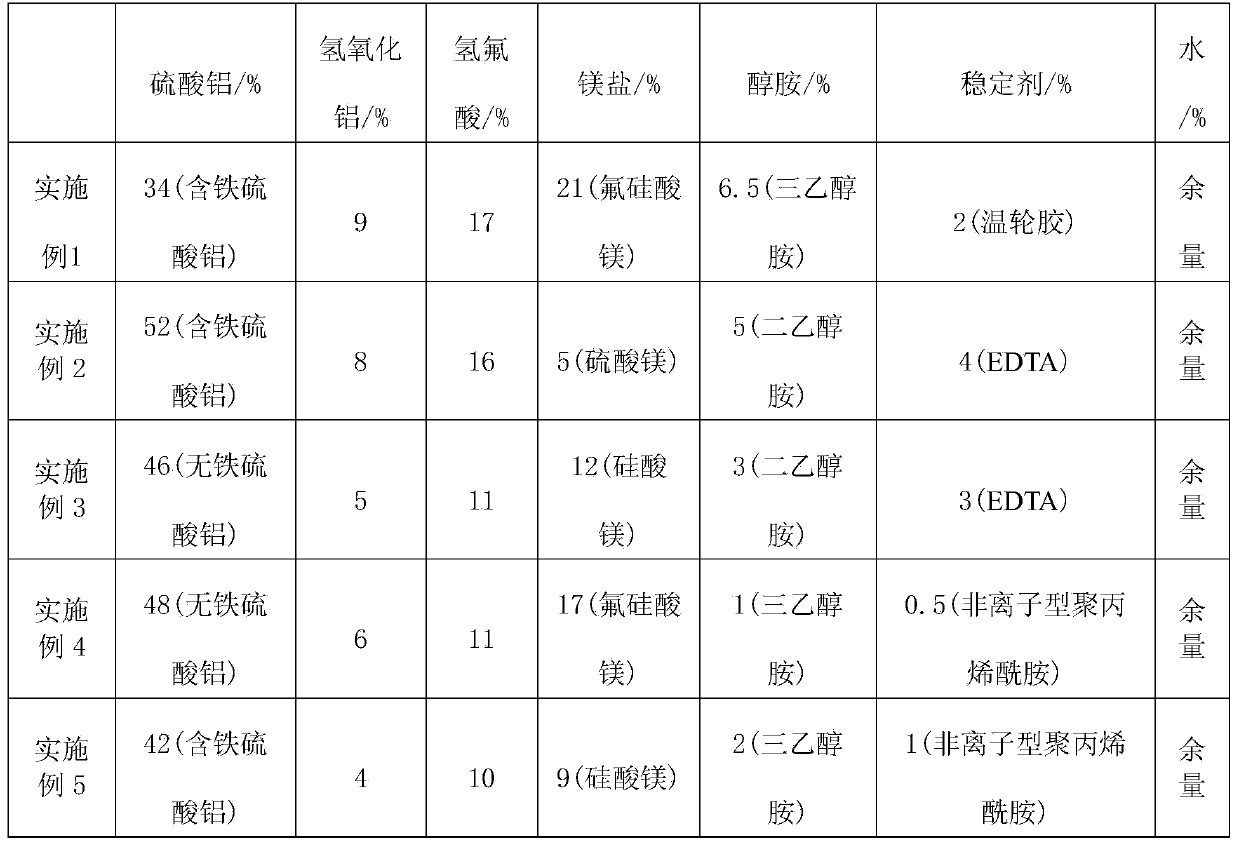

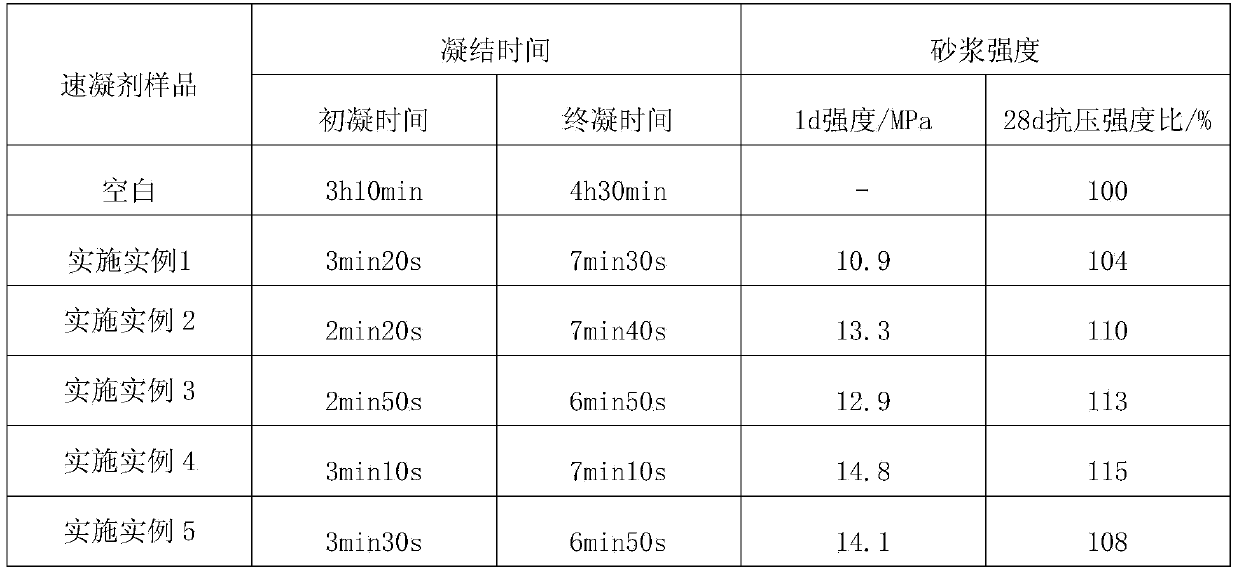

[0022] Embodiment 1: liquid quick-setting agent of the present invention (heat-free non-alkali liquid quick-setting agent for shotcrete) is made by the raw material of component described in table 1 and mass proportion (mass percentage), and table 1 is this The raw material ratio (raw material formula) of the inventive embodiments 1-5 is as shown in Table 1, and the percentages are mass percentages.

[0023] Table 1 Raw material ratio of Examples 1-5

[0024]

[0025] The preparation method of liquid quick-setting agent (embodiment 1) of the present invention comprises following processing steps:

[0026] Weigh 90g of aluminum hydroxide according to the above mass percentage, place it in the reactor, add 10g of water (accounting for 9.5% of the total water) in the reactor, stir the aluminum hydroxide into a paste, and then mix 170g of hydrofluoride Add the acid slowly and keep stirring during the adding process. Since the reaction is exothermic, add aluminum sulfate in bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com