Fly ash low-temperature wet activating treatment method

An activation treatment, fly ash technology, applied in the direction of alumina/aluminum hydroxide, solid waste removal, etc., can solve the problems of high energy consumption of grinding and sintering, poor prospects, air pollution, etc., to reduce energy consumption and equipment investment, reduce raw material costs, good environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

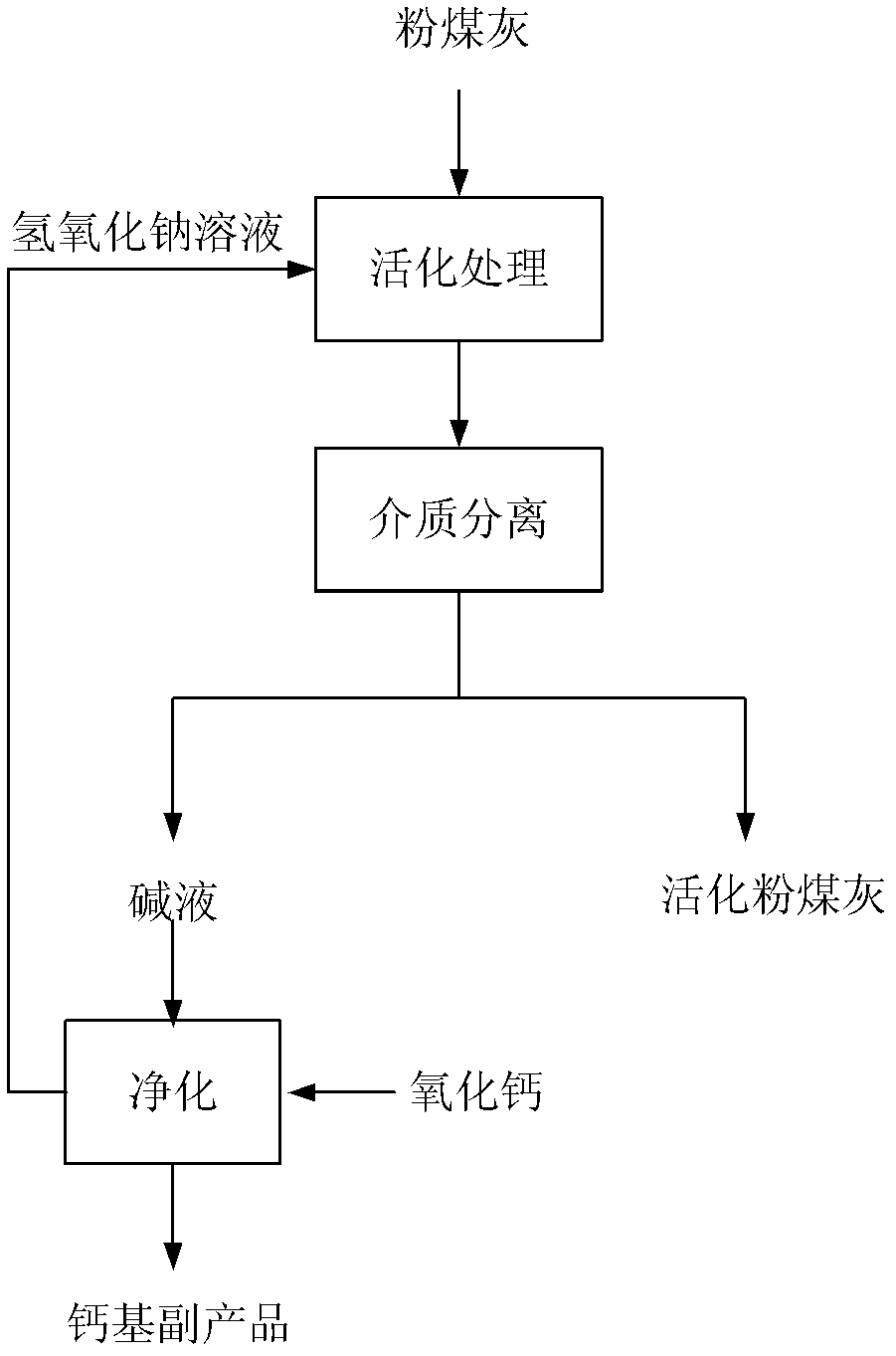

Method used

Image

Examples

Embodiment 1

[0029] This embodiment uses fly ash containing Al 2 o 3 41.41%, SiO 2 39.54%, is a kind of white or gray powder substance similar to volcanic ash collected from flue gas after pulverized coal is burned at high temperature in pulverized coal furnace.

[0030] 1) Ingredients: mix the fly ash and the alkali solution whose NaOH concentration is 300g / l and add them into the activation reactor, the volume-mass ratio of the alkali solution to the fly ash is 5:1 (ml / g);

[0031] 2) Activation: Activate the material obtained in step 1) in a reactor, the activation temperature is 180°C, the activation time is 2h, and the reaction slurry is obtained after the activation is completed;

[0032] 3) separation: the slurry obtained in step 2) is subjected to liquid-solid separation to obtain crude lye and activated fly ash;

[0033] 4) Purification: add calcium oxide to the crude lye after dilution and react at 100°C for 3 hours, and obtain calcium-containing slag and lye after liquid-soli...

Embodiment 2

[0036] This embodiment uses fly ash containing Al 2 o 3 32.43%, SiO 2 41.77%, is a white or gray powder substance similar to volcanic ash that is collected from the flue gas after the pulverized coal is burned at a high temperature in a circulating fluidized bed.

[0037] 1) Ingredients: the fly ash and the NaOH alkali solution with a NaOH concentration of 700g / l are mixed together and added to the activation reactor, and the volume-mass ratio of the alkali solution to the fly ash is 20:1 (ml / g);

[0038] 2) Activation: The material obtained in step 1) is activated in a reactor, the activation temperature is 130°C, the activation time is 5h, and the reaction slurry is obtained after the activation is completed;

[0039] 3) Separation: after diluting the slurry obtained in step 2), liquid-solid separation is obtained to obtain crude lye and activated fly ash;

[0040] 4) Purification: add calcium oxide to the crude lye after dilution and react at 80°C for 5 hours. After liqu...

Embodiment 3

[0043] This embodiment uses fly ash containing Al 2 o 3 41.41%, SiO 2 39.54%, is a kind of white or gray powder substance similar to volcanic ash collected from flue gas after pulverized coal is burned at high temperature in pulverized coal furnace.

[0044] 1) Ingredients: mix the fly ash and the alkali solution with a NaOH concentration of 550g / l and add them into the activation reactor, the volume-to-mass ratio of the alkali solution to the fly ash is 20:1 (ml / g);

[0045] 2) Activation: The material obtained in step 1) is activated in a reactor, the activation temperature is 175°C, the activation time is 0.5h, and the reaction slurry is obtained after the activation is completed;

[0046] 3) Separation: separating the liquid and solid of the slurry obtained in step 2) to obtain crude lye and activated fly ash;

[0047] 4) Purification: the crude lye is diluted and then added with calcium oxide to react at 120°C for 1 hour, and the obtained slurry is separated from liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com