Aluminum oxide ceramic and preparation method thereof

An alumina ceramic and alumina technology, which is applied in the field of ceramics, can solve the problems of inability to meet the requirements of semiconductor equipment, low density of alumina ceramics, and low mechanical strength of ceramics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

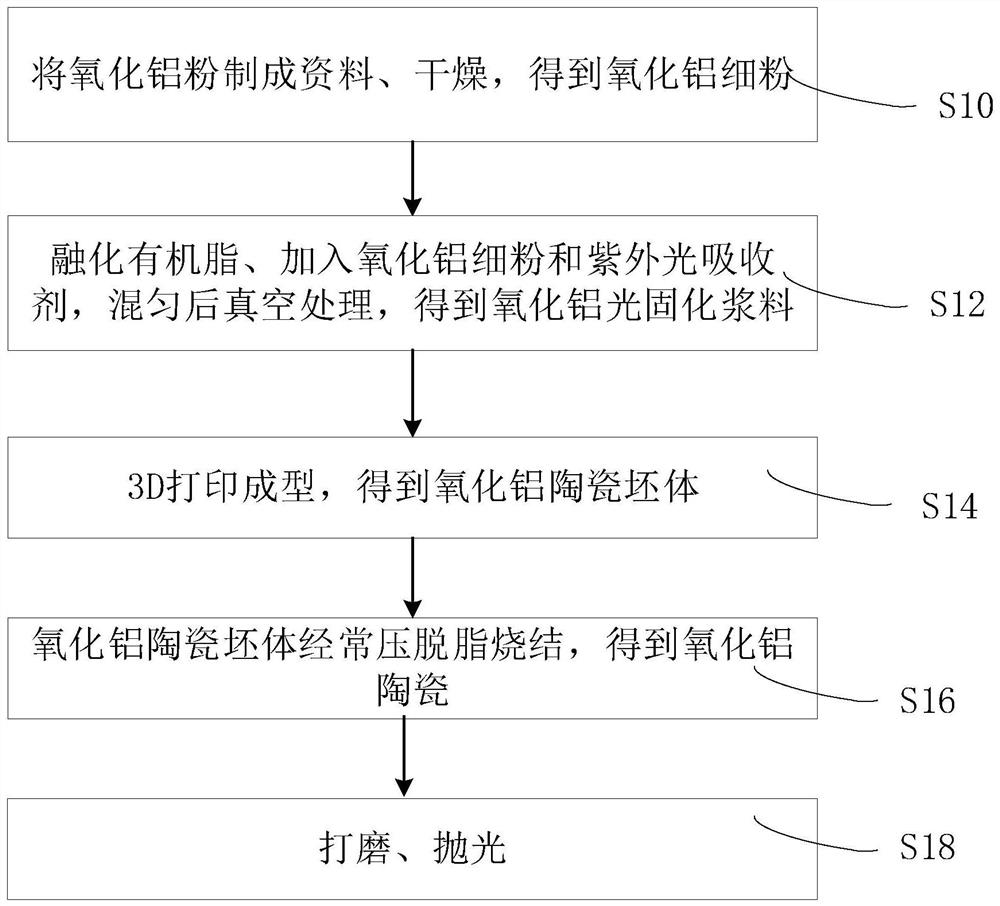

[0029] One embodiment of the present invention provides a method for preparing an alumina ceramic sintered body, such as figure 1 As shown, the following steps S10-S18 are included.

[0030] S10, making the alumina powder into slurry and drying to obtain alumina fine powder.

[0031] Specifically, alumina powder with an alumina content ≥ 99 wt % is made into a slurry to obtain an alumina slurry with a particle size D90 ≤ 0.8 μm, and then dried to obtain a fine alumina powder.

[0032] In some embodiments, the alumina content in the alumina powder is ≥99.99wt%, the D50 is 0.3μm-0.6μm, and the BET (specific surface area) is 10m 2 / g~20m 2 / g.

[0033] D90 means the particle size at which the particle cumulative distribution is 90%, that is, the volume content of particles smaller than this particle size accounts for 90% of all particles. D50 represents the particle size at which the particle cumulative distribution is 50%, also known as the median particle. A D50 of 0.3 μm ...

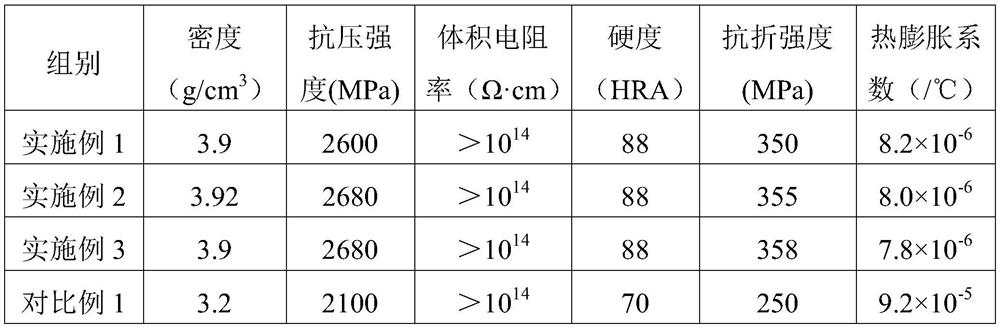

Embodiment 1

[0060] Raw materials: high-purity alumina powder: alumina purity over 99.99%, particle size D50: 0.4μm, BET: 13m 2 / g.

[0061] 1) Weigh 2000g of pure water from the grinding medium, weigh 20g of polyvinyl alcohol dispersant, add the dispersant to the pure water, stir and disperse evenly, and make a premix.

[0062] 2) Add 2000g of high-purity alumina powder to the premix, stir and disperse it into a slurry, and mill it for 5 hours in a high-speed sand mill to prepare an alumina slurry with a narrow particle size distribution and a small particle size. Its D90 is measured <0.8μm.

[0063] 3) The alumina slurry is dried in a spray dryer at an air inlet temperature of 280°C, an air outlet temperature of 120°C, and an atomization disc rotation speed of 10,000 rpm to prepare spherical alumina superfine powder .

[0064] 4) Weigh 250g of polyacrylic acid resin and melt it in an oil bath at 190°C. When the polyacrylic acid resin particles are completely melted into a liquid state...

Embodiment 2

[0069] Raw materials: high-purity alumina powder: alumina purity over 99.99%, particle size D50: 0.3μm, BET: 15m 2 / g.

[0070] 1) Weigh 2000g of pure water from the grinding medium, weigh 20g of polyvinyl alcohol dispersant, add the dispersant to the pure water, stir and disperse evenly, and make a premix.

[0071] 2) Add 2,000g of high-purity alumina powder to the premix, stir and disperse it into a slurry, and mill it with a high-speed sand mill for 4 hours to prepare an alumina slurry with a narrow particle size distribution and a small particle size, and its D90<0.8 μm.

[0072] 3) The alumina slurry is dried in a spray dryer at an air inlet temperature of 280°C, an air outlet temperature of 120°C, and an atomization disc rotation speed of 10,000 rpm to prepare spherical alumina superfine powder.

[0073] 4) Weigh 200g of polyacrylic acid resin and melt it in an oil bath at 190°C. When the polyacrylic acid resin particles are completely melted into a liquid state, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com