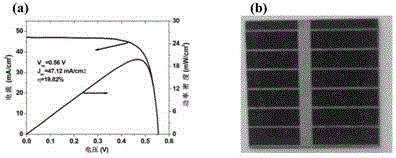

Perovskite-silicon integral cascading and overlapped solar cell and manufacturing method thereof

A technology of stacked solar and solar cells, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve problems such as low efficiency, and achieve the goal of accelerating promotion, reducing capital cost investment and resource waste, and efficient distribution and utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

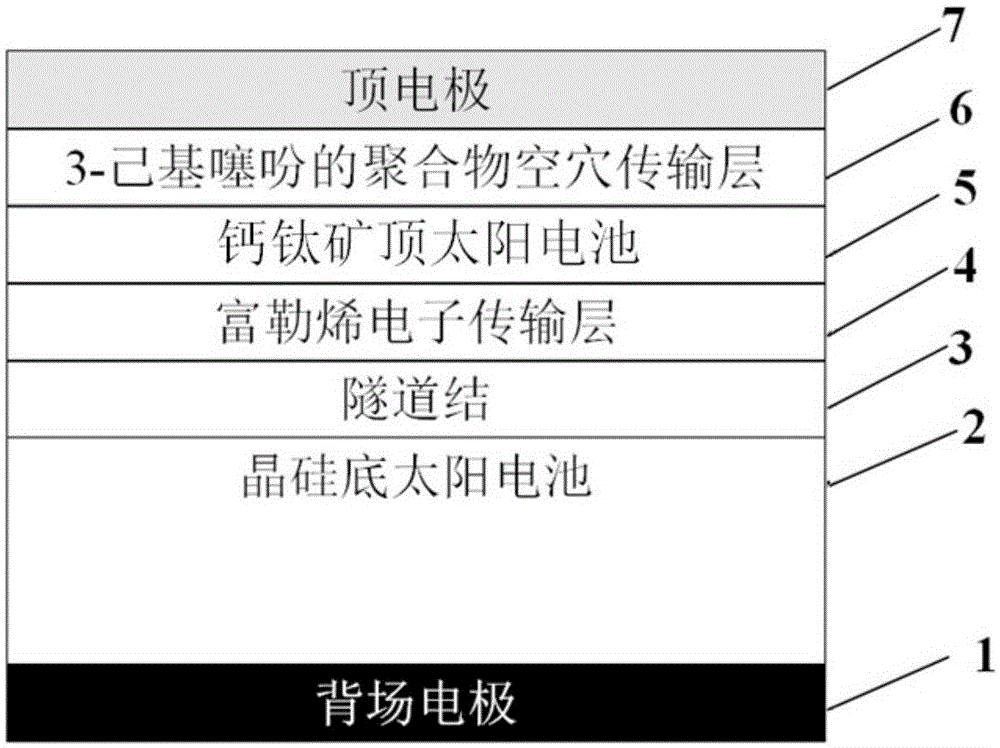

[0037] The structure, characteristics and device preparation process of the present invention will be further described below in conjunction with the detailed description of the accompanying drawings and examples.

[0038] 1. The preparation of crystalline silicon bottom solar cell 2 comprises the following steps:

[0039] 1) Texturing the surface of monocrystalline silicon

[0040] Thickness of 180±10μm, single crystal silicon wafer of size 15mm×15mm was put into 5% sodium citrate solution, and reacted at 90°C for 5min to preliminarily remove dirt and damage on the surface of the silicon wafer.

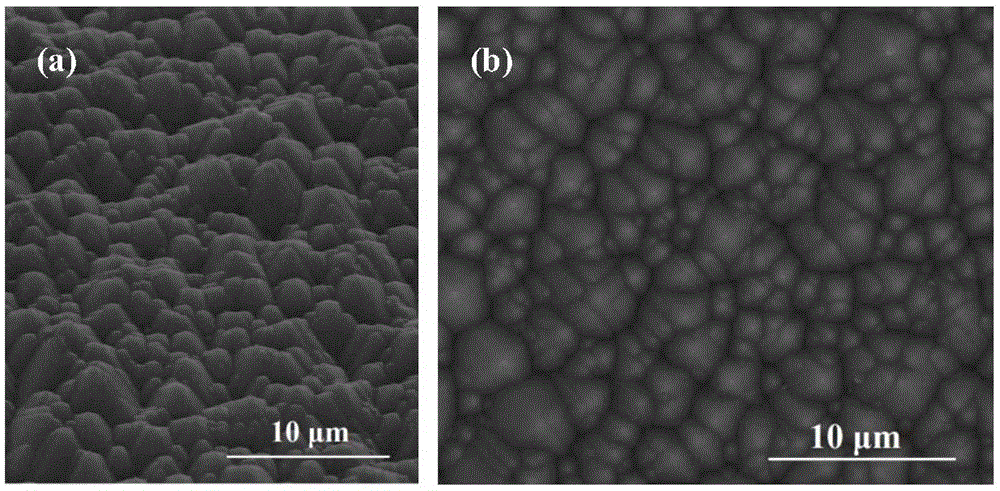

[0041] Put the cleaned silicon wafer into a mixed solution of KOH and isopropanol, wherein the concentration of KOH is 3%, and the volume concentration of isopropanol is 8%, react at 85°C for 30min, and form a uniform pyramid structure, such as figure 2 shown.

[0042] It is important to emphasize that figure 2 Figures (a) and (b) are for the preparation of Si 3 N 4 Scanning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com