Chip type oxygen sensor

An oxygen sensor, a chip technology, applied in the field of sensors, can solve the problems of inability to detect the oxygen content of automobile exhaust, serious environmental pollution, and insufficient sensor sensitivity, etc., to achieve improved heterogeneous combination, high sensitivity, and thermal conductivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

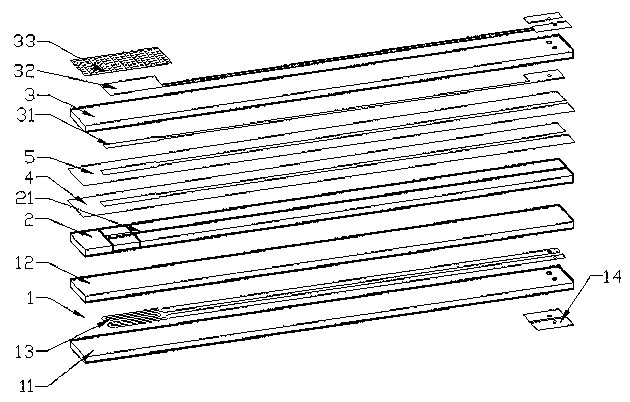

[0014] Such as figure 1 As shown, in this embodiment, the present invention includes three parts: a ceramic heater 1 , an alumina substrate 2 and a zirconia substrate 3 , which are sequentially stacked from bottom to top. A reference air channel 21 is provided on the alumina substrate 2, and an inner working electrode 31 and an outer working electrode 32 are respectively pasted on the upper and lower surfaces of the zirconia substrate 3, and the outer working electrode 32 is printed with There is a porous protective layer 33 . The material of the porous protective layer 33 is generally aluminum spinel powder. An alumina printing layer 4 and a zirconia printing layer 5 are printed between the alumina substrate 2 and the zirconia substrate 3, and the alumina printing layer 4 is printed on the upper side of the alumina substrate 2, so The zirconia printing layer 5 is printed on the lower side of the zirconia substrate 3 . The inner working electrode 31 and the outer working el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com