Pipeline anticorrosion polyurea spraying elastomer

An elastomer and polyurea technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of unreasonable raw material allocation, high production equipment requirements, complex production processes, etc., and achieve excellent construction performance and production. The effect of low equipment requirements and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

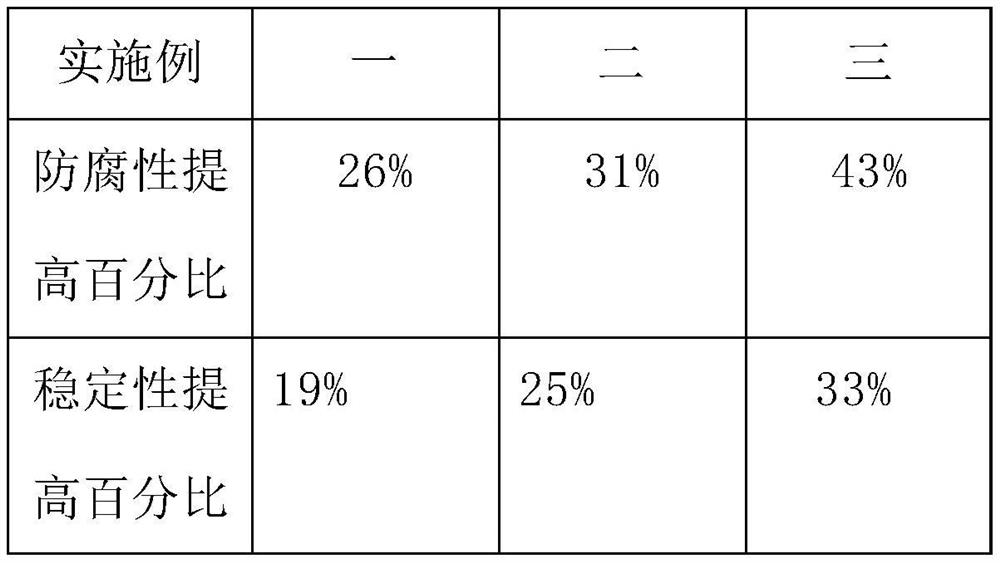

Examples

Embodiment 1

[0020] Pipeline anti-corrosion polyurea spray elastomer, including the following raw materials by weight: 10 parts of polyether polyol, 12 parts of viscosity reducer, 35 parts of flame retardant, 24 parts of mixed aromatic polyisocyanate, 35 parts of amino-terminated polyether, amine 45 parts of chain extender, 65 parts of antioxidant, 35 parts of leveling agent, 45 parts of isocyanate, 15 parts of amino-terminated alkylene oxide compound, 20 parts of diethyltoluenediamine, 10 parts of diamino, methylthio 25 parts of chlorobenzene, 35 parts of dimethylthiotoluene diamine, 20 parts of dialkyl diamine, 35 parts of dialkyl methyl diamine, 20 parts of triphosphite, 65 parts of fumed silica, fluorocarbon resin 70 parts, 65 parts of urea.

[0021] During the preparation process, first put polyether polyols, viscosity reducers, flame retardants, and mixed aromatic polyisocyanates into the disperser, then mix and stir the materials in the disperser, and after the mixing and stirring a...

Embodiment 2

[0024] Pipeline anti-corrosion polyurea spray elastomer, including the following raw materials by weight: 15 parts of polyether polyol, 20 parts of viscosity reducer, 50 parts of flame retardant, 30 parts of mixed aromatic polyisocyanate, 40 parts of amino-terminated polyether, amine 55 parts of chain extender, 70 parts of antioxidant, 40 parts of leveling agent, 55 parts of isocyanate, 20 parts of amino-terminated alkylene oxide compound, 25 parts of diethyltoluenediamine, 15 parts of diamino, methylthio 30 parts of chlorobenzene, 45 parts of dimethylthiotoluenediamine, 25 parts of dialkyldiamine, 45 parts of dialkylmethyldiamine, 30 parts of triphosphite, 70 parts of fumed silica, fluorocarbon resin 80 parts, 70 parts of urea.

[0025] During the preparation process, first put polyether polyols, viscosity reducers, flame retardants, and mixed aromatic polyisocyanates into the disperser, then mix and stir the materials in the disperser, and after the mixing and stirring are c...

Embodiment 3

[0028] Pipeline anti-corrosion polyurea spray elastomer, including the following raw materials by weight: 25 parts of polyether polyol, 38 parts of viscosity reducer, 60 parts of flame retardant, 41 parts of mixed aromatic polyisocyanate, 55 parts of amino-terminated polyether, amine 60 parts of chain extender, 80 parts of antioxidant, 45 parts of leveling agent, 65 parts of isocyanate, 35 parts of amino-terminated alkylene oxide compound, 30 parts of diethyltoluenediamine, 25 parts of diamino, methylthio 35 parts of chlorobenzene, 50 parts of dimethylthiotoluene diamine, 40 parts of dialkyl diamine, 55 parts of dialkyl methyl diamine, 40 parts of triphosphite, 75 parts of fumed silica, fluorocarbon resin 90 parts, 75 parts of urea.

[0029]During the preparation process, first put polyether polyols, viscosity reducers, flame retardants, and mixed aromatic polyisocyanates into the disperser, then mix and stir the materials in the disperser, and after the mixing and stirring ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com