Anticorrosive coating for solar water storage tank and preparation method of anticorrosive coating

A technology of anti-corrosion coatings and water storage tanks, applied in the field of solar energy materials, can solve problems such as coating failure, loss of wet adhesion, corrosion under the film, etc., achieve good impact resistance, good corrosion resistance, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

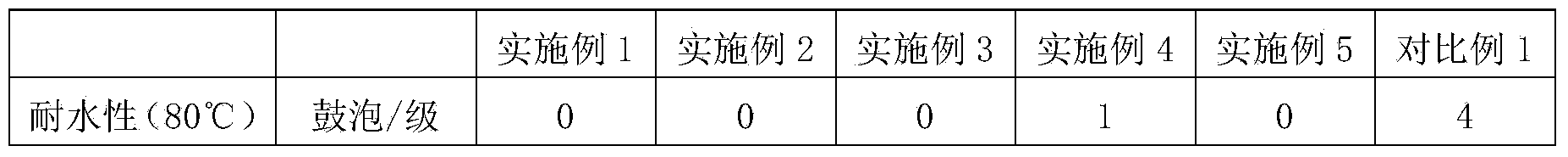

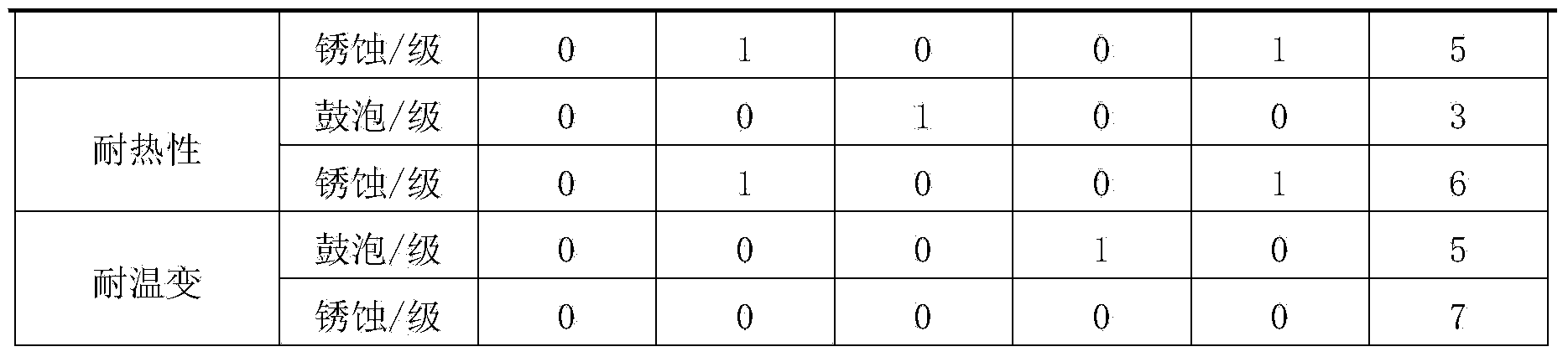

Examples

Embodiment 1

[0019] A kind of anticorrosion coating for solar water storage tank, raw material comprises by weight: 3 parts of polyvinyl acetate resin, 1 part of thermosetting acrylic resin, 2 parts of bisphenol A type epoxy resin, 2,4-dimethyl benzoic acid ethyl ester 4 parts, 2 parts of silica sol, 3 parts of iron powder, 2 parts of tetraethoxysilane, 1 part of methyltriethoxysilane, 3 parts of diethyltoluenediamine, 1 part of dimethylaminoethyl methacrylate 2 parts of boron nitride, 1 part of carbon black, 3 parts of glass flakes, 2 parts of organic acid salts, 1 part of pigment, 3 parts of xylene, and 5 parts of n-butanol.

[0020] The particle size of the iron powder is 0.5 μm; the organic acid salt is zinc naphthenate; the pigment is aluminum dihydrogen tripolyphosphate.

[0021] The preparation method of the anticorrosion coating for the above-mentioned solar water storage tank comprises the following steps:

[0022] Step 1, mix polyvinyl acetate resin, thermosetting acrylic resin,...

Embodiment 2

[0026] An anticorrosion coating for a solar water storage tank, the raw materials include in parts by weight: 6 parts of polyvinyl acetate resin, 3 parts of thermosetting acrylic resin, 4 parts of bisphenol A epoxy resin, 2,4-dimethylbenzoate ethyl 5 parts, 4 parts of silica sol, 5 parts of iron powder, 3 parts of tetraethoxysilane, 2 parts of methyltriethoxysilane, 4 parts of diethyltoluenediamine, 2 parts of dimethylaminoethyl methacrylate 4 parts of boron nitride, 2 parts of carbon black, 4 parts of glass flakes, 3 parts of organic acid salts, 2 parts of pigments, 5 parts of xylene, and 7 parts of n-butanol.

[0027] The particle size of the above-mentioned iron powder is 2.4 μm, the organic acid salt is zinc isozincate; the pigment is zinc phosphate.

[0028] The preparation method of the anticorrosion coating for the above-mentioned solar water storage tank comprises the following steps:

[0029] Step 1, mix polyvinyl acetate resin, thermosetting acrylic resin, ethyl 2,4...

Embodiment 3

[0033] An anticorrosion coating for a solar water storage tank, the raw materials include in parts by weight: 9 parts of polyvinyl acetate resin, 7 parts of thermosetting acrylic resin, 8 parts of bisphenol A epoxy resin, 2,4-dimethylbenzoate ethyl 10 parts, 9 parts of silica sol, 9 parts of iron powder, 8 parts of tetraethoxysilane, 6 parts of methyltriethoxysilane, 8 parts of diethyltoluenediamine, 5 parts of dimethylaminoethyl methacrylate 8 parts of boron nitride, 6 parts of carbon black, 7 parts of glass flakes, 7 parts of organic acid salts, 5 parts of pigments, 9 parts of xylene, and 10 parts of n-butanol.

[0034] The particle size of the iron powder is 1.8 μm; the organic acid salt is zinc naphthenate; the pigment is micaceous iron oxide.

[0035] The preparation method of the anticorrosion coating for the above-mentioned solar water storage tank comprises the following steps:

[0036] Step 1, mix polyvinyl acetate resin, thermosetting acrylic resin, ethyl 2,4-dimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com