Diethyltoluenediamine production device with accurate material proportioning function

A diethyltoluenediamine, production equipment technology, applied in the field of diethyltoluenediamine production equipment, can solve the problems of different flow rates, burns, inaccurate proportioning, etc., to reduce the content of impurities and reduce the time of stirring , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

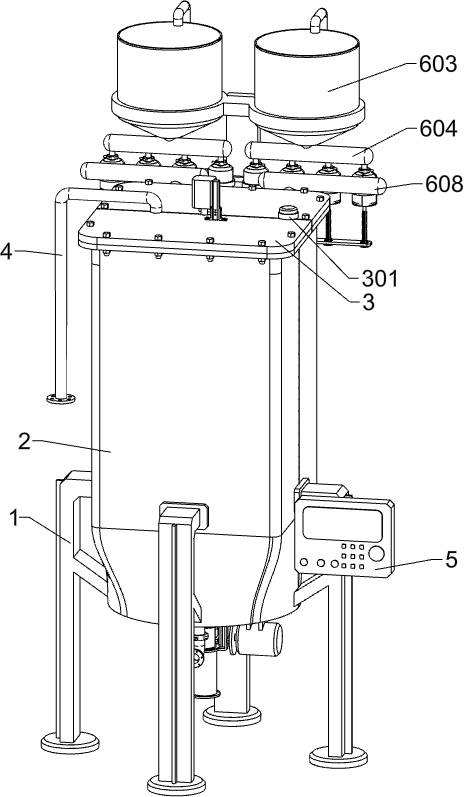

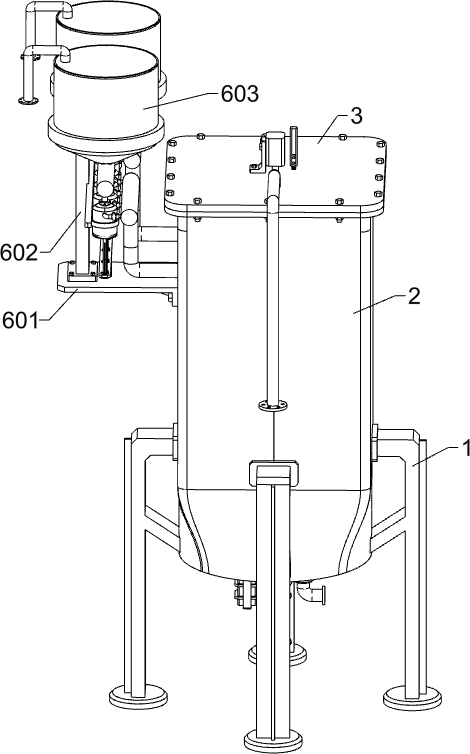

[0032] A diethyltoluenediamine production device with the function of accurate material proportioning, such as Figure 1-Figure 10 As shown, it includes a first support frame 1, and the first support frame 1 is bolted with a mixing chamber 2, the mixing chamber 2 gradually changes from a circle to a square from bottom to top, and a discharge pipe is embedded in the bottom of the mixing chamber 2. And a valve is installed on the discharge pipe of the mixing chamber 2, a top plate 3 is bolted on the upper side of the mixing chamber 2, and an intake valve 301 is embedded in the right part of the top plate 3, and the intake valve 301 enters the air to make diethyltoluene diethyl ether. The amine is quickly discharged from the mixing chamber 2 to reduce the discharge time. The left part of the top plate 3 is embedded with a water inlet pipe 4, and the right port of the water inlet pipe 4 is equipped with a nozzle for multi-angle water spraying. The nozzle on the right end of the wat...

Embodiment 2

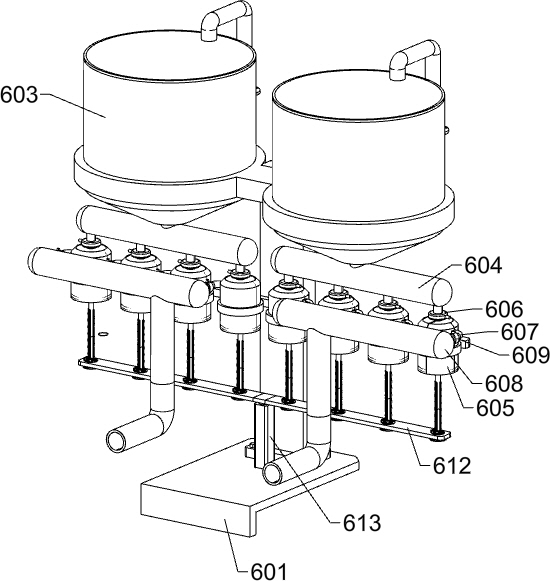

[0035] On the basis of Example 1, as Figure 3-Figure 6 As shown, the quantitative proportioning mechanism includes a second support frame 601, the second support frame 601 is bolted to the rear side of the mixing chamber 2, the upper side of the second support frame 601 is bolted with a support column 602, and the upper part of the support column 602 There are two material boxes 603 connected by bolts, and feeding pipes are embedded in the upper parts of the two material boxes 603. The liquid raw material is pumped into the two material boxes 603, so that the two material boxes 603 are always filled with liquid raw materials. The first water distribution pipes 604 communicate with each other, the lower ends of the two first water distribution pipes 604 are welded with a plurality of cylindrical shells 605, and a first solenoid valve 606 is respectively installed between the plurality of cylindrical shells 605 and the adjacent first water distribution pipes 604, The upper par...

Embodiment 3

[0045] On the basis of Example 2, as Figure 11 and Figure 12 As shown, it also includes a filter mechanism, which is used to clean the impurities in diethyltoluenediamine. The filter mechanism includes a filter shell 901, which is slidably connected to the lower part of the rotating shell 701. The shape is truncated cone, and the filter shell 901 is set in a truncated cone shape for discharging the impurities on the upper part of the mixing chamber 2, so that the impurities on the upper side of the filter shell 901 converge to the middle, and the left and right sides of the sealing plate 705 are respectively slidably connected with sliding rods 902 , a seal is installed between the two sliding rods 902 and the sealing plate 705, the upper ends of the two sliding rods 902 are respectively welded with circular plates for limiting, and the outer sides of the two sliding rods 902 are respectively sleeved with a second spring 903 , the two ends of the two second springs 903 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com