Anticorrosive paint for stainless steel decorating plate and preparation method of anticorrosive paint

A technology of anti-rust coating and decorative board, applied in the direction of coating, etc., can solve the problems of anti-rust, anti-yellowing and anti-corrosion, poor high temperature resistance, etc., and achieve excellent anti-rust effect, good protection effect, and excellent high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

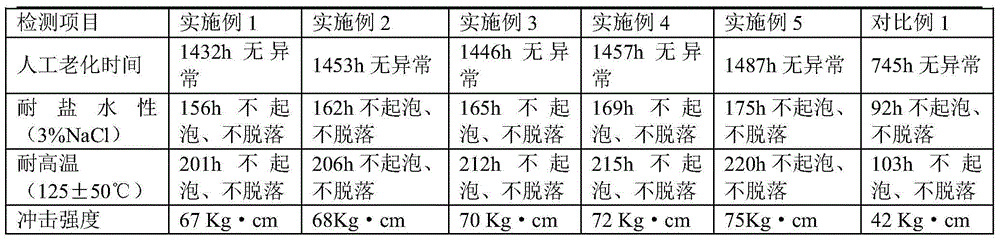

Examples

Embodiment 1

[0018] An antirust coating for stainless steel decorative panels, which contains the following components in parts by mass: 33 parts of white latex, 2 parts of iron oxide red, 1 part of chromium oxide green, 0.3 parts of mica magnesium oxide, 5 parts of aluminum tripolyphosphate, chromic acid 2 parts of zinc, 1 part of polyvinyl acetal, 0.8 parts of zinc oxide, 6 parts of zirconia, 1 part of cobalt naphthenate, 0.5 parts of polyvinylsiloxane, 0.7 parts of tripropylene glycol diacrylate, diethylene glycol 0.1 part of methyl toluenediamine, 1 part of sodium nitrite, 0.3 part of phenolic resin, 12 parts of purified water.

[0019] A preparation method for antirust paint for stainless steel decorative panels, the preparation steps of the method are as follows:

[0020] Step 1: Add pure water into the dispersing barrel with stirring device, heat the pure water to 80°C, then add white latex, iron oxide red, chromium oxide green, mica magnesium oxide, aluminum tripolyphosphate, Zinc...

Embodiment 2

[0024] An antirust coating for stainless steel decorative panels, containing the following components in parts by mass: 44 parts of white latex, 10 parts of iron oxide red, 4 parts of chromium oxide green, 1.5 parts of mica magnesium oxide, 15 parts of aluminum tripolyphosphate, chromic acid 8 parts of zinc, 7 parts of polyvinyl acetal, 4 parts of zinc oxide, 18 parts of zirconia, 5 parts of cobalt naphthenate, 1.8 parts of polyvinylsiloxane, 2.2 parts of tripropylene glycol diacrylate, diethylene glycol 0.6 parts of methyl toluene diamine, 5 parts of sodium nitrite, 1.6 parts of phenolic resin, 24 parts of purified water.

[0025] A preparation method for antirust paint for stainless steel decorative panels, the preparation steps of the method are as follows:

[0026] Step 1: Add pure water into the dispersing barrel with stirring device, heat the pure water to 100°C, then add white latex, iron oxide red, chromium oxide green, mica magnesium oxide, aluminum tripolyphosphate, ...

Embodiment 3

[0030] An antirust coating for stainless steel decorative panels, which contains the following components in parts by mass: 35 parts of white latex, 4 parts of iron oxide red, 1.5 parts of chromium oxide green, 0.5 parts of mica magnesium oxide, 7 parts of aluminum tripolyphosphate, chromic acid 3 parts of zinc, 2 parts of polyvinyl acetal, 1 part of zinc oxide, 8 parts of zirconia, 2 parts of cobalt naphthenate, 0.7 parts of polyvinyl siloxane, 1 part of tripropylene glycol diacrylate, diethylene glycol 0.2 parts of methyl toluenediamine, 1.8 parts of sodium nitrite, 0.5 parts of phenolic resin, and 14 parts of purified water.

[0031] A preparation method for antirust paint for stainless steel decorative panels, the preparation steps of the method are as follows:

[0032] Step 1: Add pure water into the dispersing barrel with stirring device, heat the pure water to 90°C, then add white latex, iron oxide red, chromium oxide green, mica magnesium oxide, aluminum tripolyphospha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com