Coating film and production method of coated controlled-release fertilizer

A production method and technology of controlled-release fertilizers, which are applied in layered/coated fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of inability to release fertilizer nutrients, environmental pollution, and inability to cover fertilizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

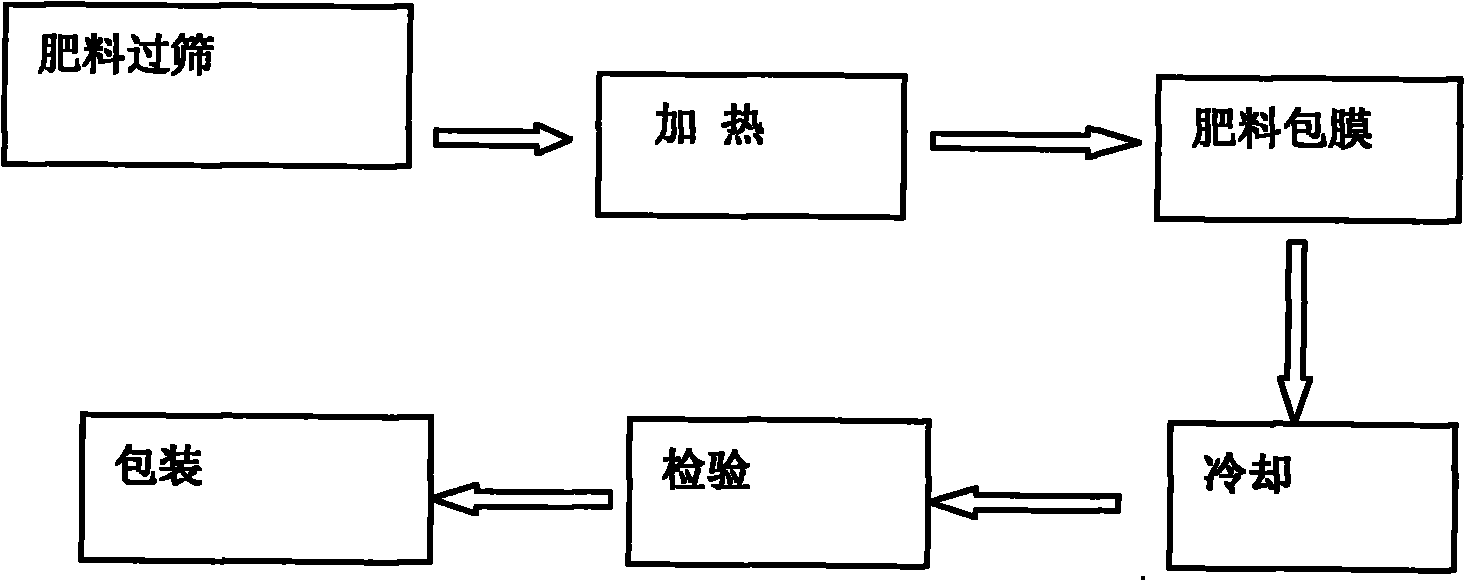

[0026] As shown in Figure 1, the method of the present invention is carried out according to the following steps.

[0027] 1: The coating material raw materials A1: polyester polyol, A2: soybean oil polyol, A3: castor oil, A4: diethyltoluenediamine (DETDA) according to 20-30%, 40-50%, 20- 30% and 5-10% are mixed as material A, and material B is polymethylene polyphenyl isocyanate (PAPI). The ratio of material A to material B is about 6-7:3-4. The material A of this formula uses vegetable oil polyol and easily hydrolyzed polyester polyol. The polyurethane film produced by this method is easy to degrade, so as to ensure that the film is easy to degrade and not pollute soil and environment. Generally, other companies use polyether polyols. The membranes produced by this method are difficult to degrade in soil and water, and cause relatively large environmental pollution.

[0028] 2: Sieving: Sieve the fertilizer that needs to be coated, sift out the fertilizer with a particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com