Method for synthesizing diethyltoluenediamine through alkylation of toluenediamine catalyzed by ionic liquid

A technology of diethyltoluenediamine and catalyzed toluenediamine alkane, which is applied in the preparation of amino compounds from amines and organic chemistry. It can solve the problems of expensive catalysts, potential safety hazards, and easy coking of materials, and achieve short reaction times. , reduce potential safety hazards, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

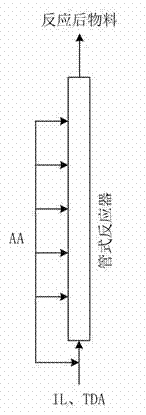

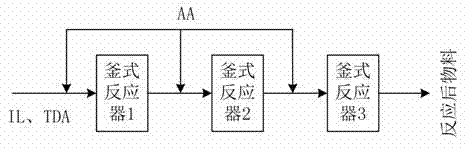

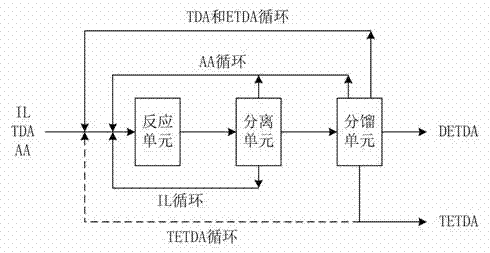

Method used

Image

Examples

Embodiment 1

[0044] Triethylamine hydrochloride ([(C 2 h 5 ) 3 NH]Cl) and aluminum trichloride (AlCl 3 ) are mixed at a molar ratio of 1:2, stirred at room temperature for 30-40 minutes, then raised to about 100°C, and stirred continuously at this temperature for about 4-6 hours to form an ionic liquid. cooling, that is, the base ionic liquid (([(C 2 h 5 ) 3 NH]Cl) / AlCl 3 ). Collected in a desiccator for later use.

Embodiment 2

[0046] Triethylamine hydrochloride ([(C 2 h 5 ) 3 NH]Cl) and ferric chloride (FeCl 3 ) in a molar ratio of 1:2 and stirred at room temperature for 30-40 minutes. Then the temperature was raised to about 100° C., and stirring was continued at this temperature for about 4 to 6 hours to form an ionic liquid. cooling, that is, the base ionic liquid (([(C 2 h 5 ) 3 NH]Cl) / FeCl 3 ). Collected in a desiccator for later use.

Embodiment 3

[0048] In the basic ionic liquid of embodiment 1, add the second metal compound CuCl 2 , CuCl 2 with AlCl 3 The molar ratio is 1:8, continue to raise the temperature to about 100-200°C, and stir for about 5-6 hours until the metal compound (CuCl 2 ) also fully participates in the reaction (CuCl 2 Solid completely disappears and transforms into liquid), promptly obtains composite ionic liquid (([(C 2 h 5 ) 3 NH]Cl) / AlCl 3 / CuCl 2 ). Collected in a desiccator for later use.

[0049] Synthesis

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com