Method for synthesizing diethyltoluenediamine

A technology of diethyltoluenediamine and diaminotoluene, which is applied in the field of synthesizing diethyltoluenediamine, can solve the problems of catalysts not being reused, increasing the pressure of environmental protection, reaction temperature, high pressure, etc., and achieve the realization of recycling The effect of streamlining production, saving energy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] ①Add 1500g of diaminotoluene and catalyst (30g of aluminum powder, 14g of zinc powder, 45g of anhydrous aluminum trichloride, 0.5g of diethylaluminum chloride) into a 5L reactor, protect it with dry nitrogen, and slowly raise the temperature to 180°C And maintain the reaction at 180-200°C for 1.5 hours.

[0024] ② Use ethylene to drive out the hydrogen and nitrogen in the kettle and pressurize to 1.0MPa. When the temperature rises to 267°C, the pressure begins to drop and the alkylation reaction begins. Control the ethylene pressure at 4.0MPa through a pressure reducing valve and a flow meter. The temperature is controlled between 270-290°C. After 4.6 hours of reaction, the temperature stabilizes and drops slightly, and the ethylene pressure no longer drops, and the reaction is considered to be over.

[0025] ③After the pressure is released, put it into a retort for distillation. After cutting off about 10% of the front fraction, distill 1200g of the main fraction with ...

example 2

[0030] ①Put 250KG of raw material diaminotoluene (TDA) into a 500L kettle, add 5.0KG of aluminum powder, 1.50KG of zinc powder, and 7.5KG of anhydrous aluminum trichloride, and react at 114-200°C for 2.5 hours.

[0031] ②Press dry nitrogen into a 500L high-pressure reactor, replace it with ethylene three times, pressurize to 1.0MPa, start to heat up, and the pressure in the autoclave starts to drop at 261°C, and the alkylation reaction starts, adjust the ethylene flow rate to control the inside of the reactor The pressure was 4.0 MPa, the reaction temperature was 265-275°C, after 3.5 hours of reaction, the pressure stopped dropping and remained for 0.5 hours, the temperature stabilized and dropped slightly, and the alkylation reaction ended.

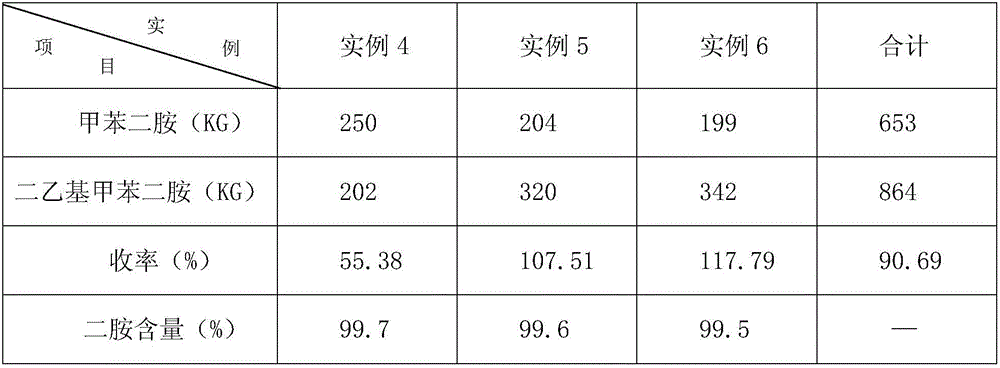

[0032] ③Unload and recover ethylene, until the pressure in the kettle drops to 0.4MPa, the material enters the still still for distillation, and the main fraction of 202KG is distilled, with a diamine content of 99.7%, and the fraction be...

Embodiment 3

[0037] The catalytic system residue generated by the final application of Example 1 and Example 2 is washed with a polar solvent and separated. The organic phase is polyamine, which is used as a curing agent in the bottom material of the PU track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com