Patents

Literature

49results about How to "Realize circular production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

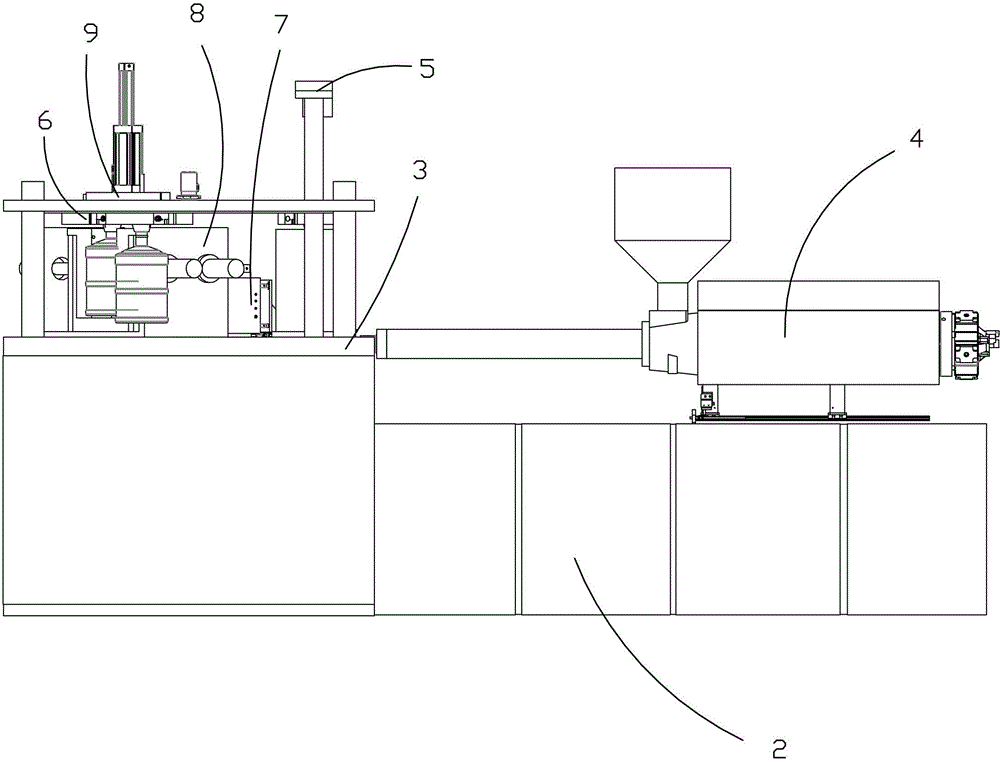

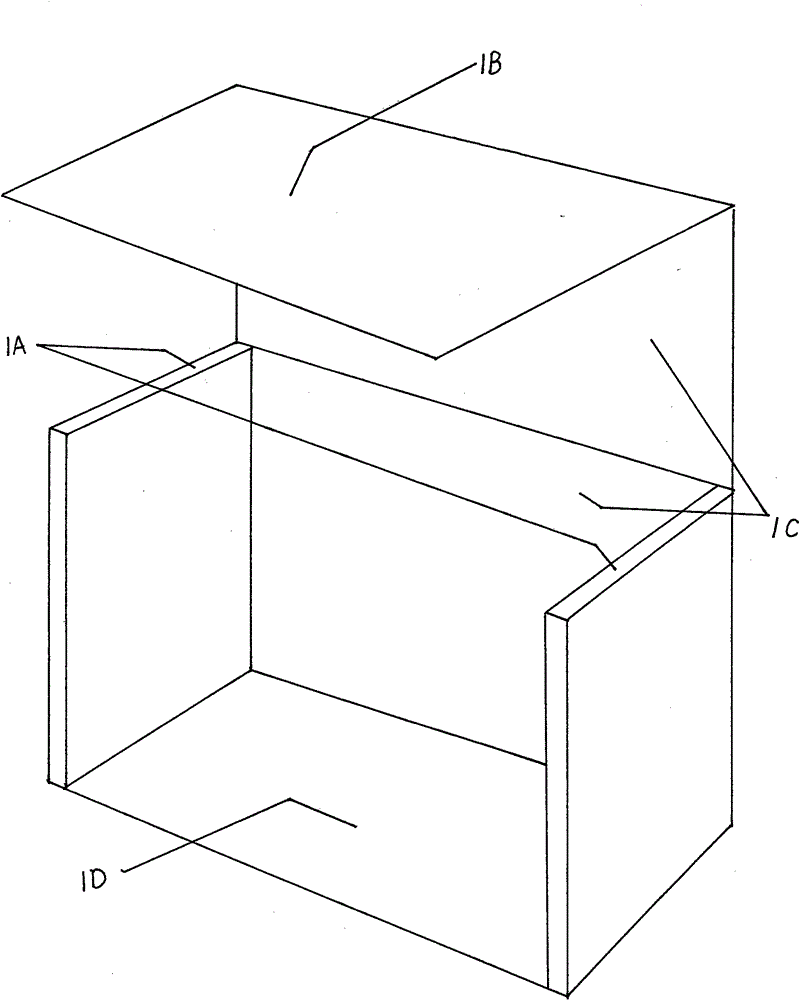

Hollow forming machine for injecting, drawing and blowing plastic by one-step method

InactiveCN101885234ARealize circular productionImprove efficiencyHollow articlesHollow formWork in process

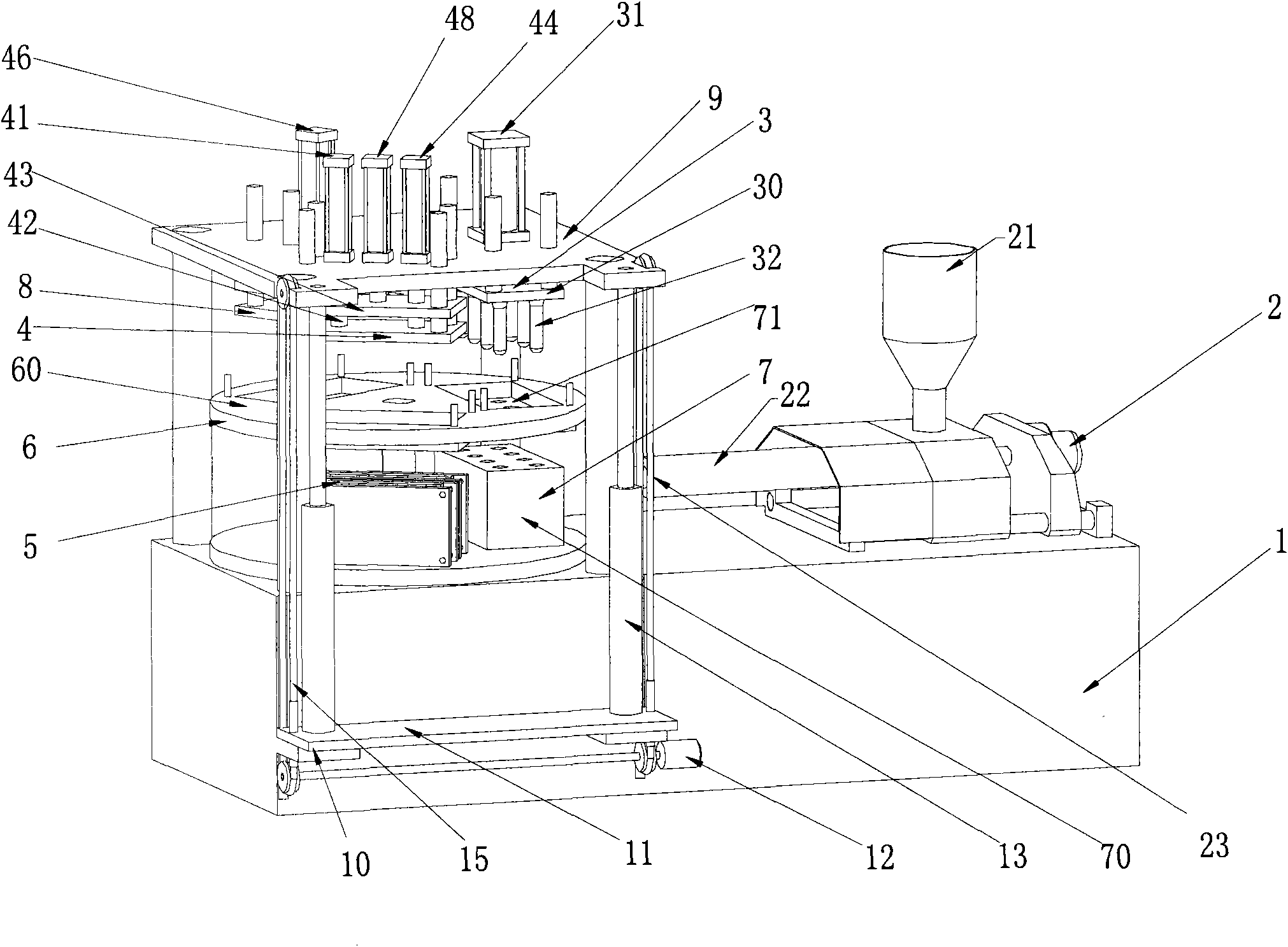

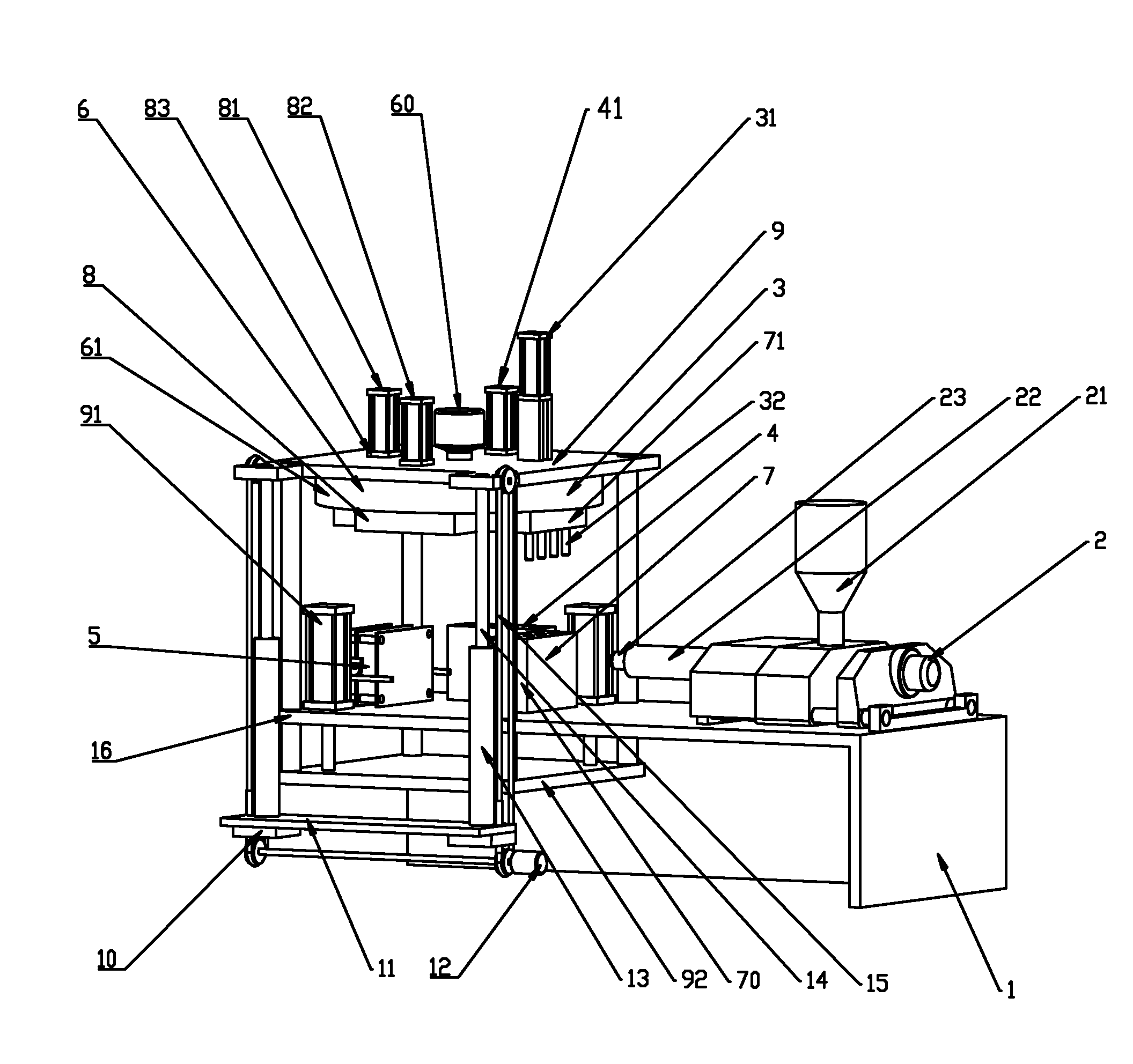

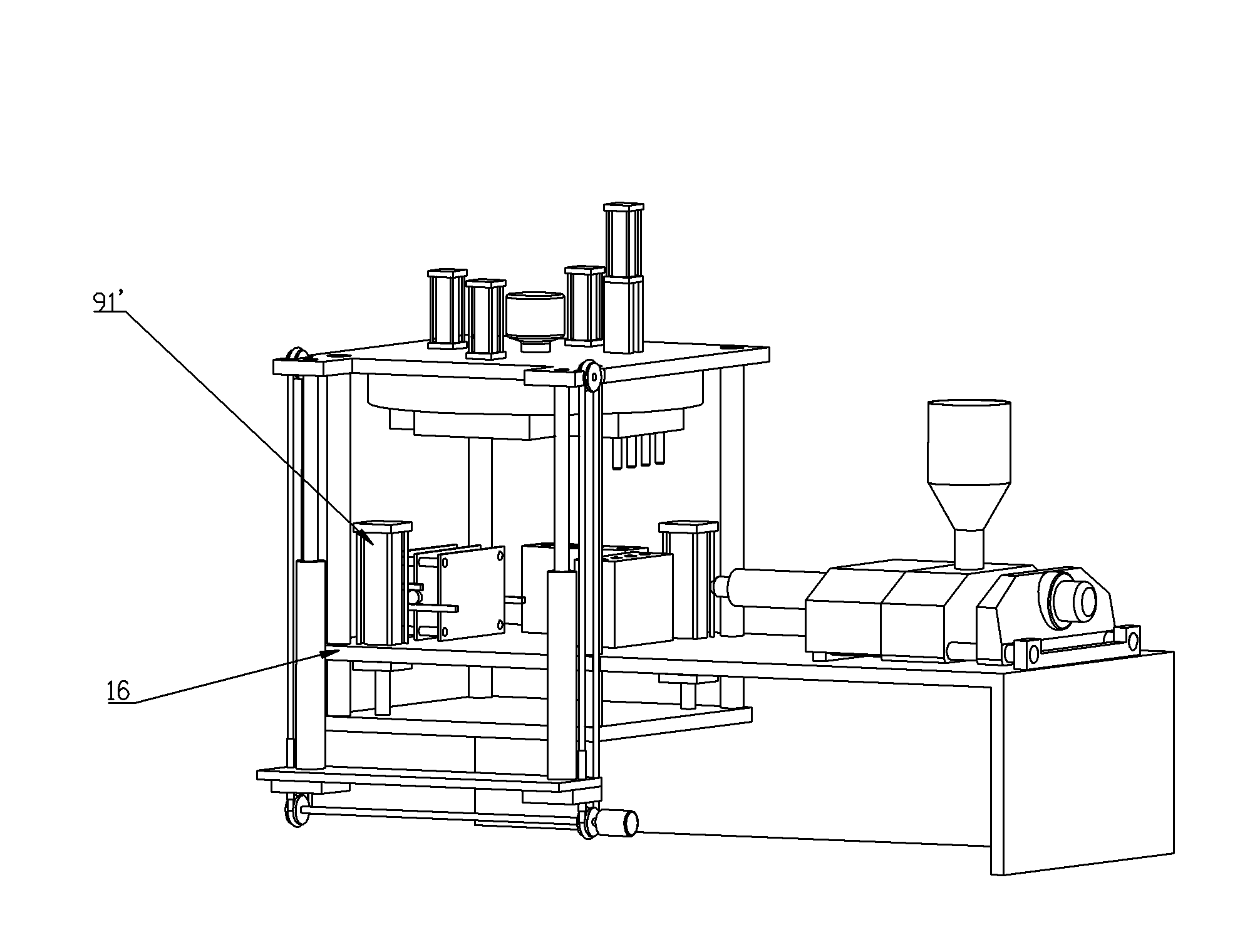

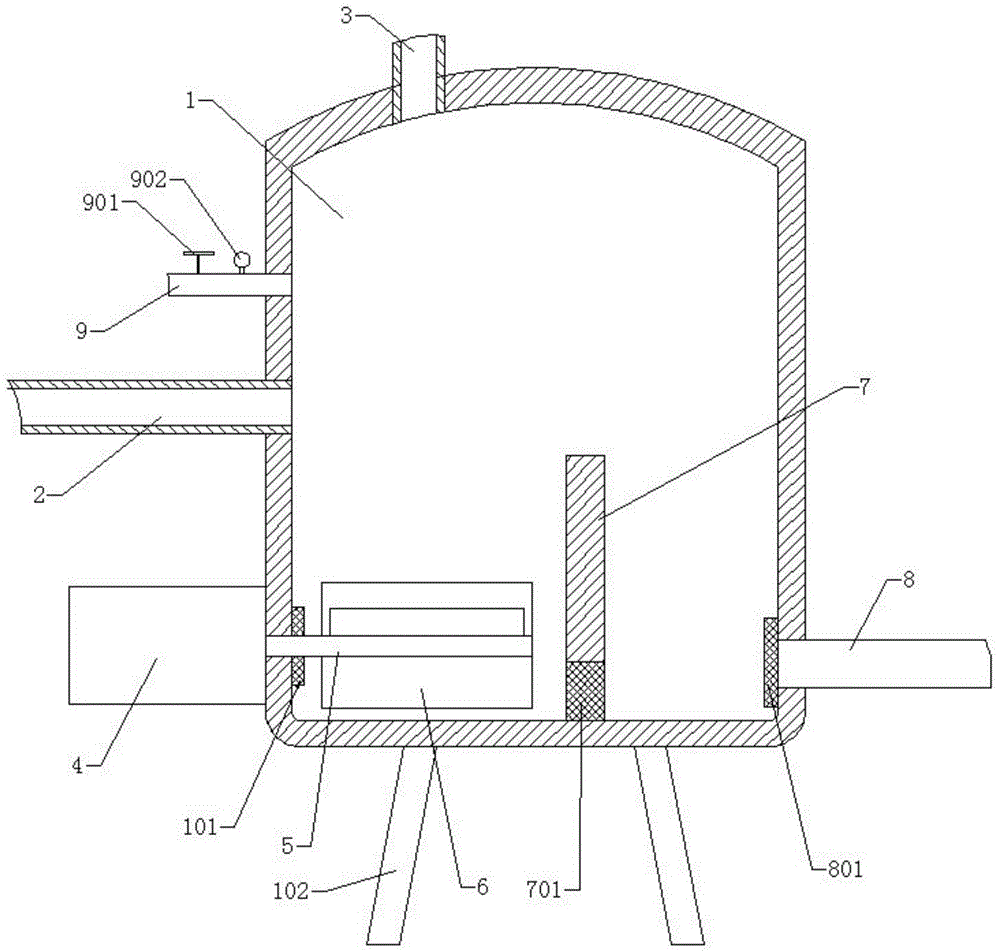

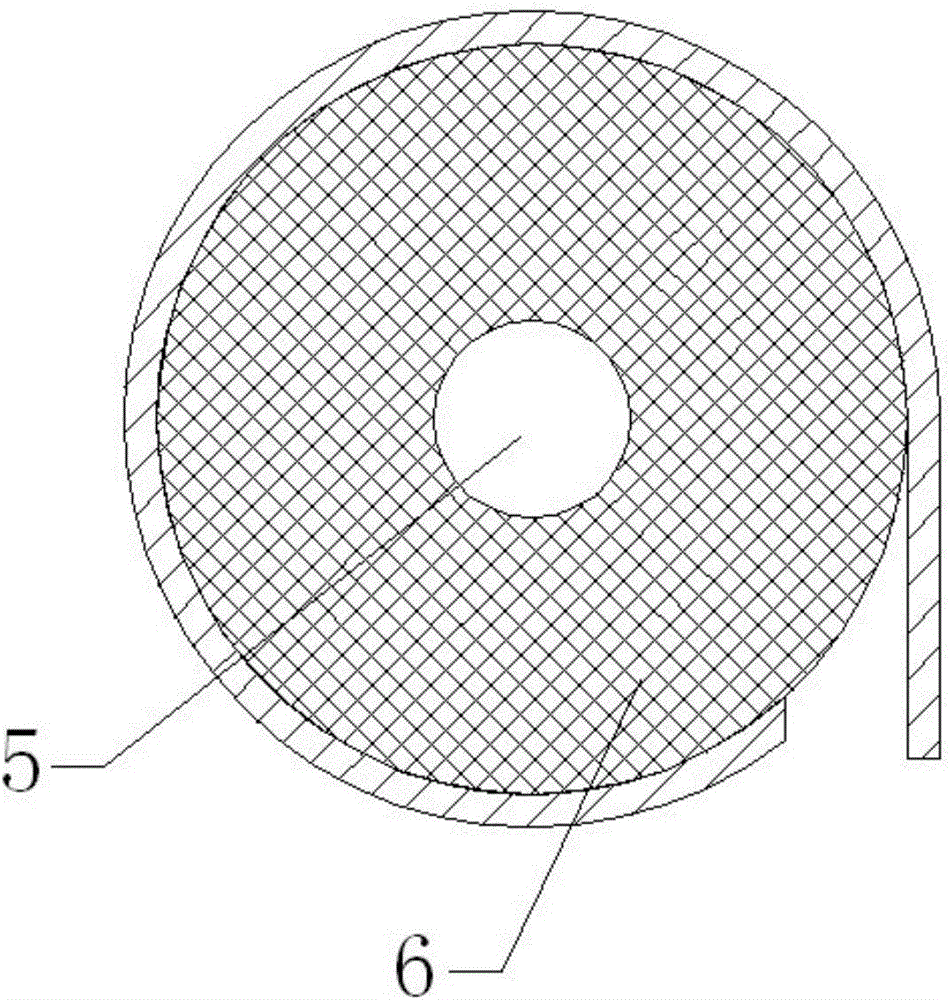

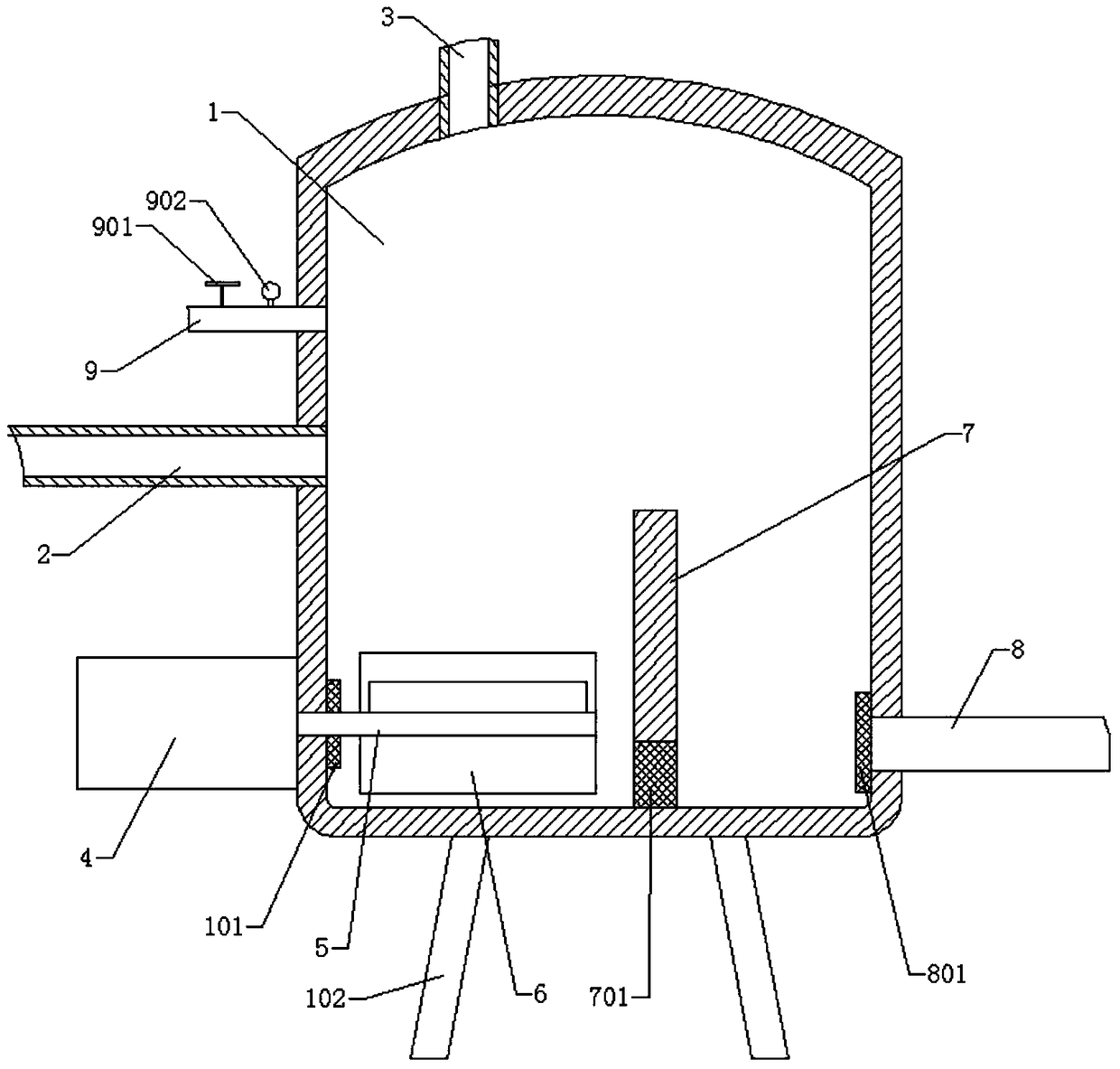

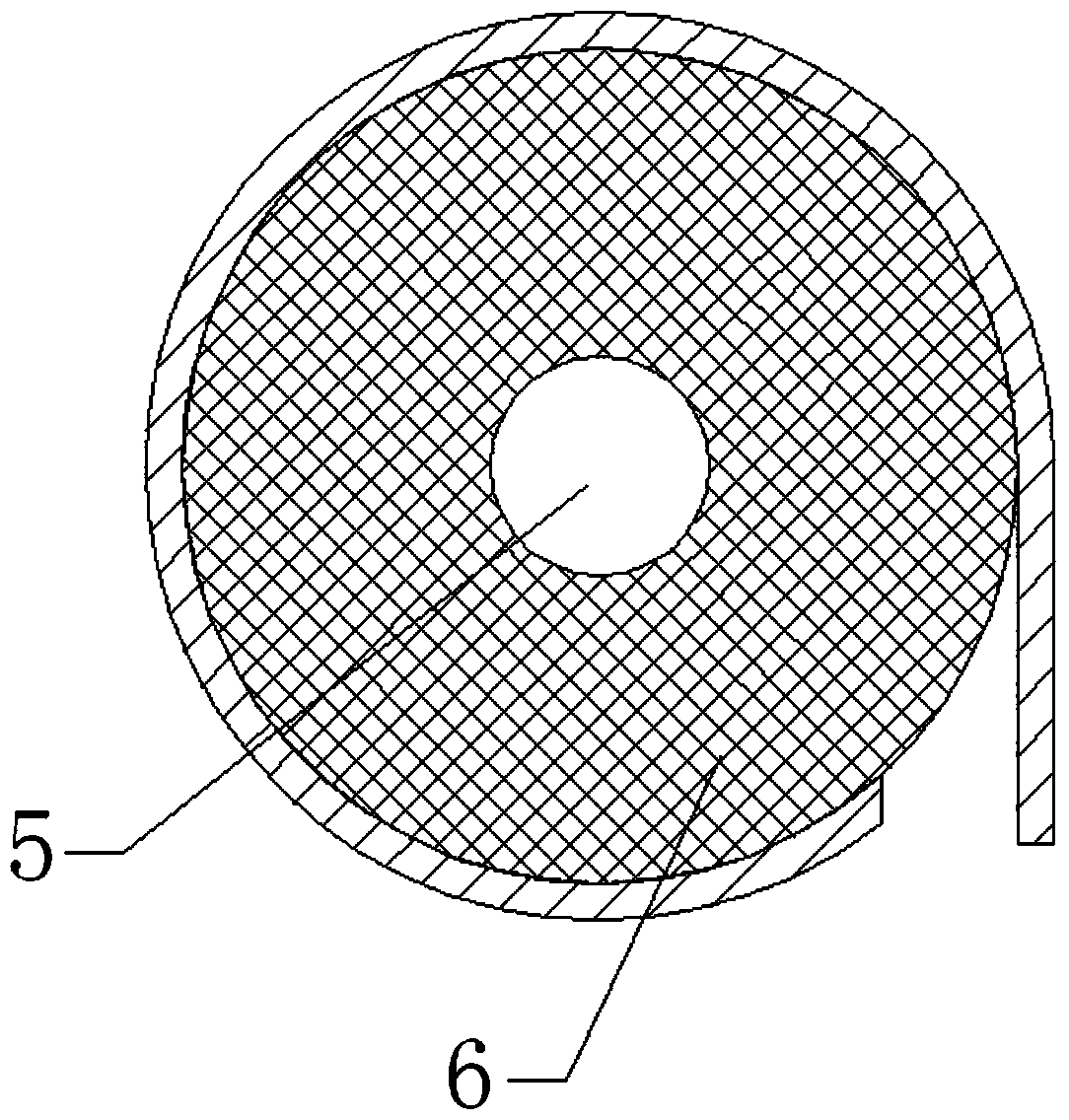

A hollow forming machine for injecting, drawing and blowing plastic by a one-step method comprises an installation machine base, an injection device, a fixed mount, an injection bottle blank component, a drawing-blowing component, a blow molding die assembly mechanism assembly, a rotary template assembly, an injection station, a product demoulding component and a quick die change mechanism, wherein the injection device is arranged at one side of the installation machine base, and the fixed mount is arranged at the other side of the installation machine seat; the injection bottle blank component is fixed on the fixed mount; the blow molding die assembly mechanism assembly is arranged on the installation machine base and is matched with the drawing-blowing component; the injection station is arranged below the injection bottle blank component and is used for placing a bottle blank die; the rotary template assembly is arranged below the injection bottle blank component; the upper of the rotary template assembly is driven by a power motor to rotate, and the lower thereof is provided with an oil cylinder; a shaped semi-finished bottle blank is injected in the injection bottle blank component; and the oil cylinder drives the rotary template assembly to go up, and then the rotary template assembly is driven by the power motor to rotate so as to drive the semi-finished bottle blank to enter into the position of a drawing-blowing die, thus the rotary template assembly goes down into the drawing-blowing die under the driving of the oil cylinder, and is drawn and blow molded into a finished bottle. The invention achieves circular production, improves production efficiency, saves energy by two thirds as compared with the existing production method, and fills domestic blank.

Owner:郝恩政

Master batch capable of fully and biologically degrading plastic film and preparation method thereof

InactiveCN102604164AReduce dependenceIn line with the construction trend of a resource-saving societyMasterbatchPlasticizer

The invention discloses a master batch capable of fully and biologically degrading a plastic film and a preparation method thereof, and belongs to the field of high molecular films. The formula of the master batch comprises the following materials in parts by weight: 100 parts of starch, 2-9 parts of coupling agent, 8-18 parts of dispersing agent, 8-25 parts of polycyclolactone, 1-50 parts of polylactic acid, 8-15 parts of poly (hydroxybutyrate-hydroxyvalerate) (PHBV), 10-25 parts of plasticizer, 0.15-1.0 part of anti-tackiness agent, 0.15-1.2 parts of pro-oxidant and 1-15 parts of chemical precipitation promoter. The preparation method of the master batch comprises the three steps of: thinning the starch; mixing; and forming. The product provided by the invention has the advantages of high starch content, being a fast-growing and renewable resource, rich resource, low unit cost, high substitutability, obvious economic benefit and ecological benefit and capabilities of reducing the content of polycyclolactone, increasing polylactic acid and poly (hydroxybutyrate-hydroxyvalerate) (PHBV), improving product performance and meanwhile reducing cost.

Owner:浙江天禾生态科技有限公司

Hollow forming machine for one-step injection, drawing and blowing of plastic

The invention discloses a hollow forming machine for one-step injection, drawing and blowing of plastic, comprising a mounting base, an injection device which is arranged at one side of the mounting base, a fixed mount which is arranged at the other side of the mounting base, a bottle embryo injection assembly which is fixed on the fixed mount, a temperature adjustment device, an blowing-drawing assembly, a blow-molding clamping mechanism assembly which is arranged on the mounting base and matched with the blowing-drawing assembly, a rotary die plate assembly, an injection station which is arranged below the bottle embryo injection assembly and used for placing a bottle embryo die, a product de-molding assembly and a rapid die change mechanism, wherein a power motor is arranged above the rotary die plate assembly and used for driving the rotary die plate assembly to rotate and a fixed mount lifting cylinder is arranged below the rotary die plate assembly; a semi-finished bottle embryois injection-molded in the bottle embryo die via the bottle embryo injection assembly; the fixed mount lifting cylinder drives the rotary die plate assembly to rise and then the power motor drives the rotary die plate assembly to rotate so that the semi-finished bottle embryo is driven to enter the position of a drawing-blowing die; and under the driving of the cylinder, the rotary die plate assembly falls into the drawing-blowing die; and drawing and blow molding are carried out by the drawing-blowing assembly so that the finished bottle is obtained.

Owner:SHENZHEN DONGCHUAN HUATE TECH CO LTD

Weighing type garbage sorting and recycling system

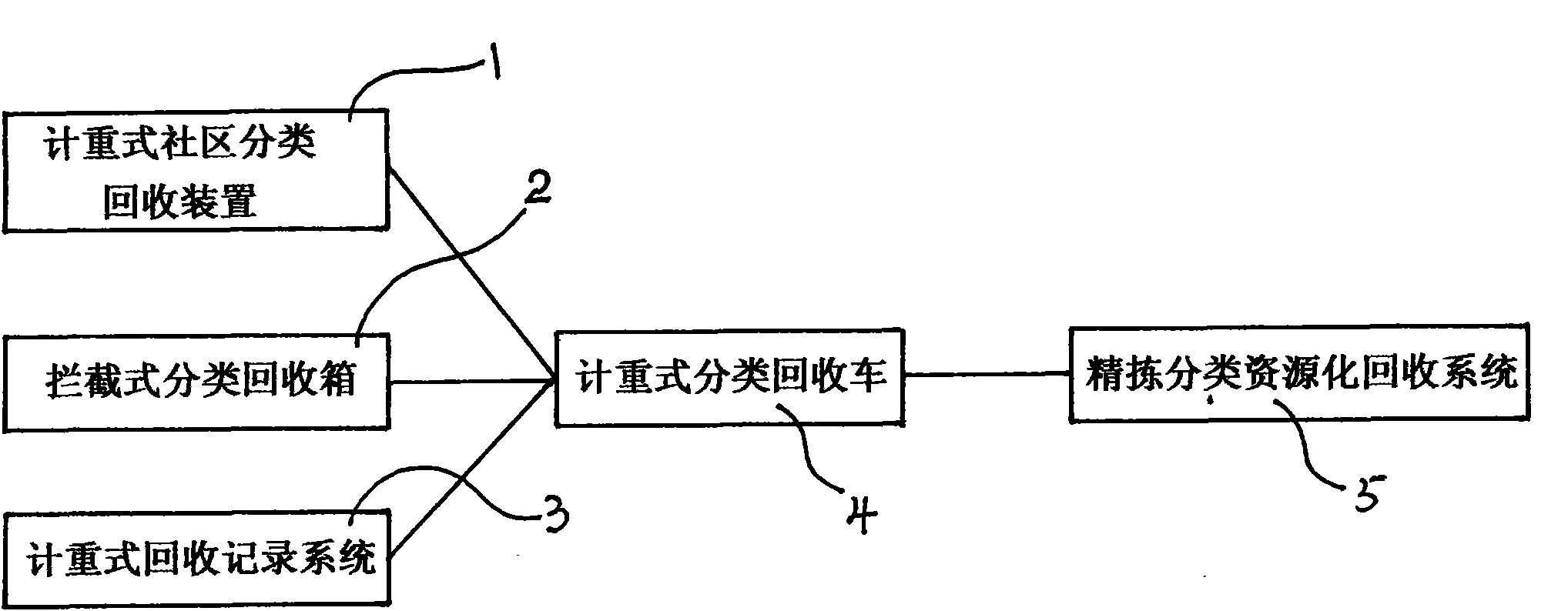

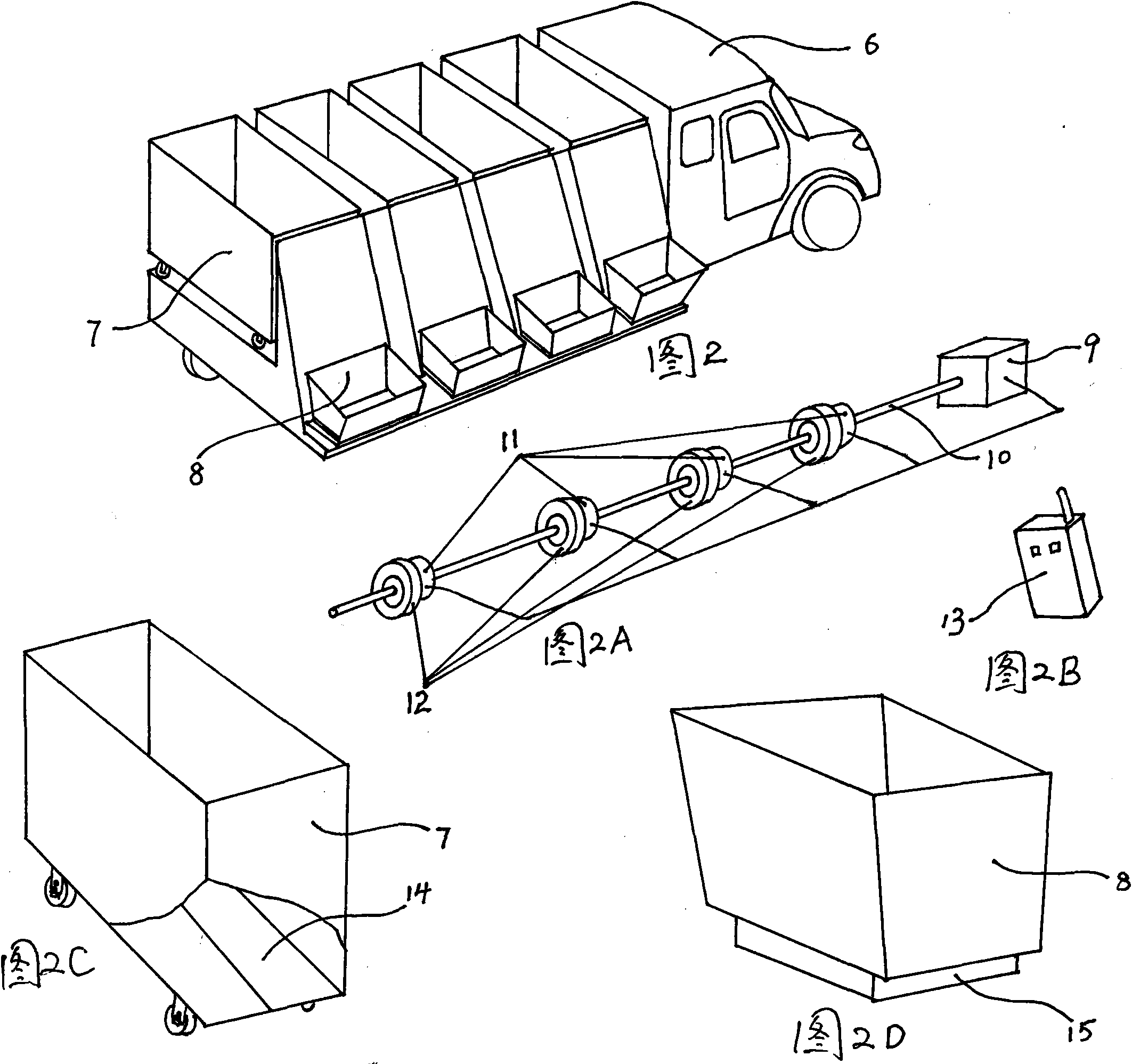

InactiveCN102464170AOvercome the embarrassing situation that cannot be classified and become a decorationThorough classificationWaste collection and transferRefuse receptaclesPaymentWaste management

The invention relates to a weighing type garbage sorting and recycling system capable of weighing, sorting and recycling garbage and recording and exciting garbage sorting recyclers. The weighing type garbage sorting and recycling system consists of a weighing type community sorting and recycling device, an interception type sorting and recycling box, a weighing type recycling and recording system, a weighing type sorting and recycling vehicle and a fine-picking sorting resource recycling system. The system can weigh and recycle various kinds of garbage so as to record recycling of the garbage and can excite the sorting recyclers by virtue of the record so as to promote consumption, protect the environment and recycle the resource by recycling the garbage for payment. Paid garbage recycling becomes the most valuable government investment. The system has the functions of enlarging employment and expanding industries and has huge social value.

Owner:倪国森

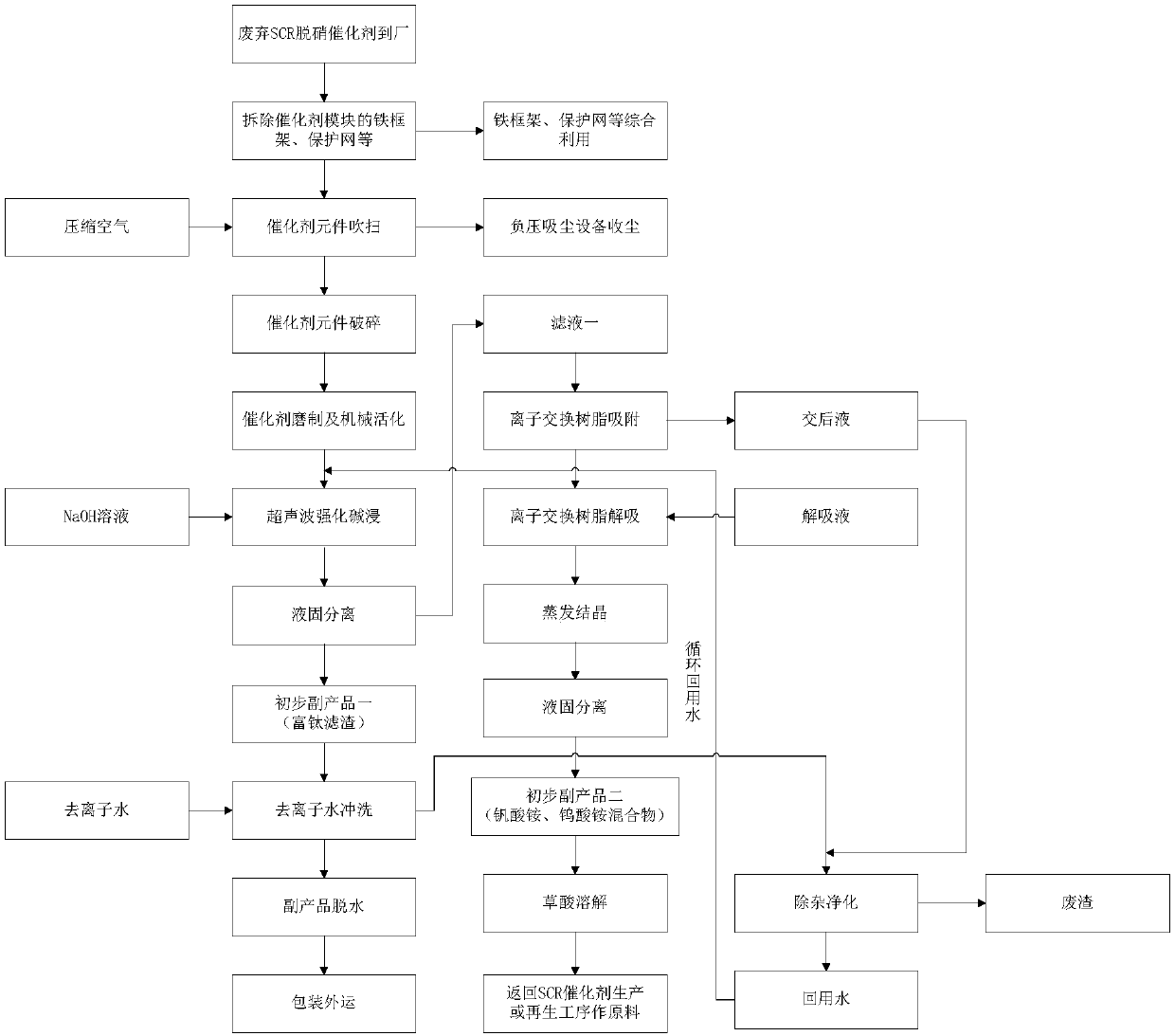

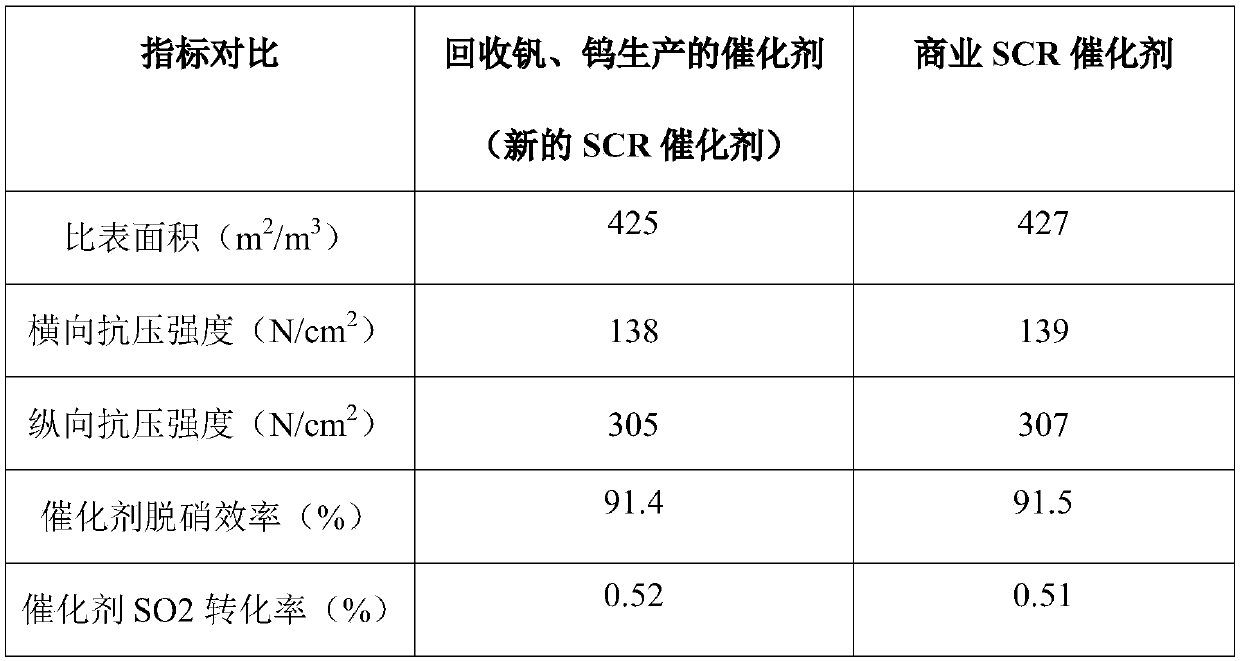

Method for recycling and circulating production of waste SCR denitration catalyst

InactiveCN109536722AShort processImprove leaching rateProcess efficiency improvementIon exchangePre treatment

The invention discloses a method for recycling and circulating production of a waste SCR denitration catalyst. According to the method, the resources of vanadium, tungsten and titanium in the waste SCR denitration catalyst are recycled and used as raw materials for producing SCR denitration catalyst or for SCR denitration catalyst active regenerating, so that the goal of forming a recycling industrial chain is achieved. The method comprises the following procedures of performing pretreating, crushing, grinding, ultrasonic enhanced alkali leaching, liquid-solid separating, impurity removing, ion exchanging, desorbing, and evaporating crystallizing of the waste SCR denitration catalyst, and then the new SCR catalyst is obtained by circulating production.

Owner:孙昕 +1

Eluting device and separation method for nitric acid type tin-stripping waste liquid

ActiveCN105439225AAchieving primary separationRealize circular productionSludge treatment by de-watering/drying/thickeningWater contaminantsFluidized bedNitrate salts

The invention discloses an eluting device for a nitric acid type tin-stripping waste liquid. The eluting device comprises a constant-temperature condensation fractionator, a collecting tank, a constant-temperature distiller, an eluting tank and a drying fluidized bed, wherein the constant-temperature distiller is provided with an eluent sample inlet, a heater and a steam outlet, the inside of the eluting tank is divided into a steam buffer chamber and an eluting chamber by a porous support, and the steam buffer chamber is formed in the lower part of the eluting tank and communicated with the steam outlet of the constant-temperature distiller; the eluting chamber is formed above the porous support, the lower part of the eluting chamber is communicated with the drying fluidized bed, and a gas outlet of the drying fluidized bed is communicated with the constant-temperature distiller; an exhaust chamber is communicated with the constant-temperature condensation fractionator which is communicated with the collecting tank. According to a separation method of the nitric acid type tin-stripping waste liquid, on the basis of the characteristic of immiscibility of ethanol and stannic acid, stannic acid, nitrate and a dilute nitric acid solution are separated in a sealed circulating elution system under the actions of eluting separation, evaporative crystallization, cooling fractionation and hot air drying, and meanwhile, recycling of an eluent, namely, ethanol, is guaranteed.

Owner:JIANGSU WANHE COATING MACHINE CO LTD

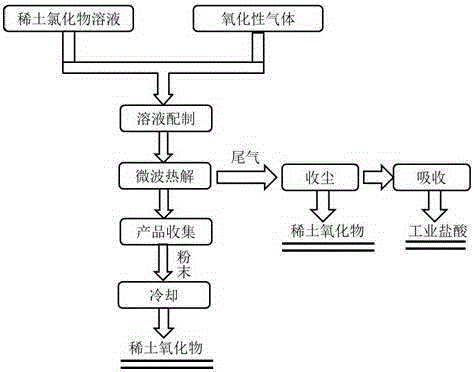

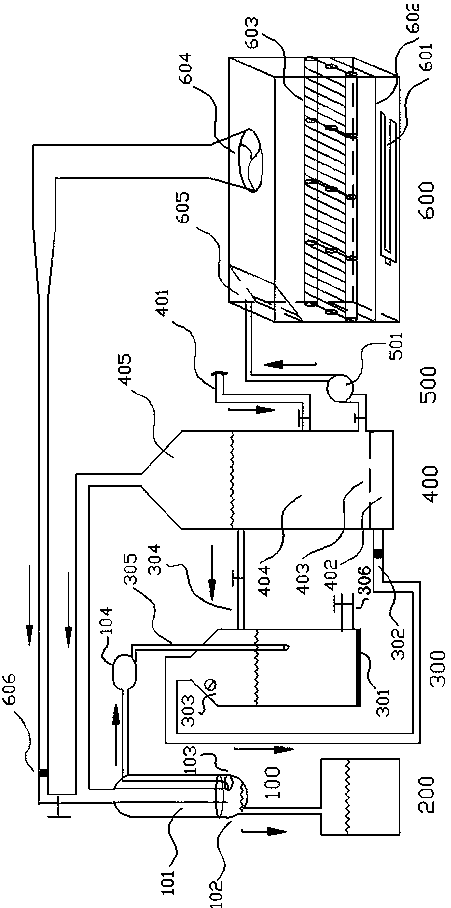

Alkali spraying system and operation method thereof

InactiveCN105396448AImprove absorption rateAvoid cloggingDispersed particle separationAgricultural engineeringSpray tower

The invention provides an alkali spraying system and an operation method thereof. The alkali spraying system comprises a spraying tower, a flushing water tank, a high-pressure water pump, an alkali spraying circulation pump and a stirrer, wherein an alkali liquor inlet in the spraying tower is communicated with the flushing water tank through a high-pressure water pipe; the high-pressure water pump is arranged on the high-pressure water pipe; the alkali spraying circulation pump is arranged on a connection pipeline between the alkali liquor inlet and an alkali liquor outlet; the blade of the stirrer is arranged at the inner bottom of the spraying tower. The alkali spraying system and the operation method adopt a stirring reaction mechanism and an alkali spraying backward flow reaction mechanism, so as to improve H2S absorption efficiency and reduce environmental pollution; moreover, blockage of the alkali spraying system can be avoided to facilitate operation of the alkali spraying system and realize circulatory production better.

Owner:宜宾海翔化工有限责任公司 +1

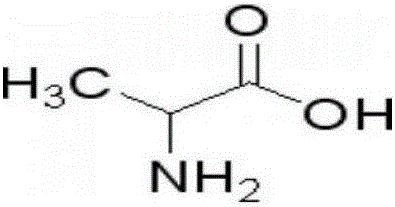

Method for preparing L-aspartic acid and L-alanine by using maleic anhydride

InactiveCN106755157ASimple processRealize circular productionFermentationHydration reactionMaleopimaric acid

The invention provides a method for preparing L-aspartic acid and L-alanine by using maleic anhydride. The method comprises the following steps: heating the maleic anhydride as the raw material to obtain a maleic acid solution through hydration reaction; adding maleate isomerase and L-aspartase; after filtering and concentrating obtained liquid of enzymatic reaction to deaminize, regulating the pH value until the isoelectric point of the L-aspartic acid is equal to 2.8 by using the maleic acid solution as an acidifying agent; crystallizing to separate out the L-aspartic acid; and converting the L-aspartic acid into the L-alanine by further using aspartate decarboxylase. The L-aspartic acid is prepared through one-step reaction by a two-enzyme method, the process is simple and convenient, the conversion ratio is high, production of malic acid as a by-product can be controlled effectively, and the quality of the product is good; and maleic acid is used as the acidifying agent to prepare the L-aspartic acid in an isoelectric point crystallization manner, crystallization mother liquor can be used as an enzyme reaction substrate and then is recycled, the discharge amount of waste water is greatly reduced, and the method conforms to the idea of environmental protection. In addition, the L-aspartic acid is further converted into the L-alanine by an enzymic method, so that products obtained by a whole process are diversified; and the market competitiveness is high.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

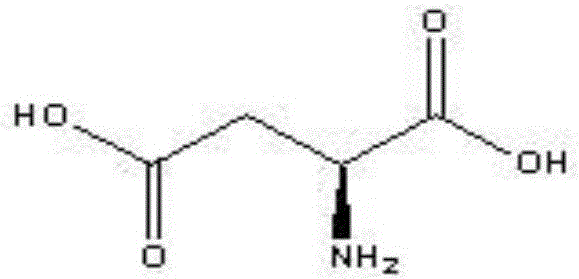

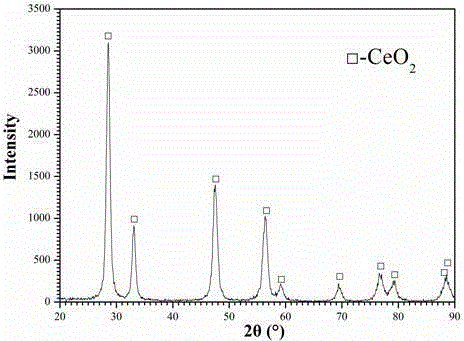

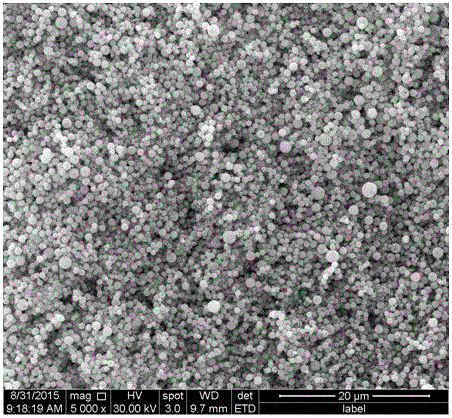

Method for preparing cerium oxide with rare earth cerium chloride

ActiveCN105271351ANo loss of purityUniform particle sizeRare earth metal compoundsMicrowave pyrolysisRare earth

The invention relates to a method for preparing cerium oxide with rare earth cerium chloride and belongs to the technical field of rare earth oxide preparation. The method comprises the steps of dissolving rare earth cerium chloride into water to form a solution with the concentration of 2-95g / L, then adding a dispersing agent of 0.3-5% of volume percentage of the solution, atomizing a mixed solution into drops, injecting from the top of a microwave reactor, supplying oxidizing gas from the bottom, carrying out microwave pyrolysis reaction at negative pressure of 100-10000Pa to form cerium oxide and exhaust gas, and obtaining technical hydrochloric acid after dust collection and absorption of the exhaust gas. The method adopts a microwave pyrolysis and solution atomization technology, the pyrolysis reaction time is very short, the quick pyrolysis is achieved, the generation of a cerium oxychloride byproduct in a rare earth cerium oxide preparation process by a rare earth cerium chloride solution roasting pyrolysis method, and the pyrolysis conversion rate and purity of rare earth cerium oxide are increased.

Owner:KUNMING UNIV OF SCI & TECH

Automatic paint filling equipment

InactiveCN109013086AAvoid contactAvoid pollutionCorrosion preventionPipe protection against corrosion/incrustationDiaphragm pumpLacquer

The invention discloses automatic paint filling equipment. The automatic paint filling equipment comprises an upper-end frame body, a middle-end frame body and a lower-end frame body, wherein a paintspraying rod capable of sliding is arranged on the upper-end frame body, a plurality of uniformly-distributed paint spraying nozzles are formed in the paint spraying rod, and a first recovery groove fixed to the upper-end frame body is formed below the paint spraying nozzles; a plurality of driven rollers, a plurality of drive rollers and a motor are arranged on the middle-end frame body; and thelower-end frame body comprises a cross brace provided with a plurality of uniformly-distributed limit rods, a flow guide sheet is arranged on the cross brace, a second recovery groove is further formed below the flow guide sheet; a paint pressing pipe is connected to one end of the paint spraying rod; a diaphragm pump is connected to one end away from the paint spraying rod, of the paint pressingpipe; the diaphragm pump is connected with a paint bucket through a paint pumping pipe, and an air compressor is further connected to the diaphragm pump through a compressed air pipe.

Owner:SHAANXI CONSTR ENG GRP CO LTD THE FIRST BUILDING

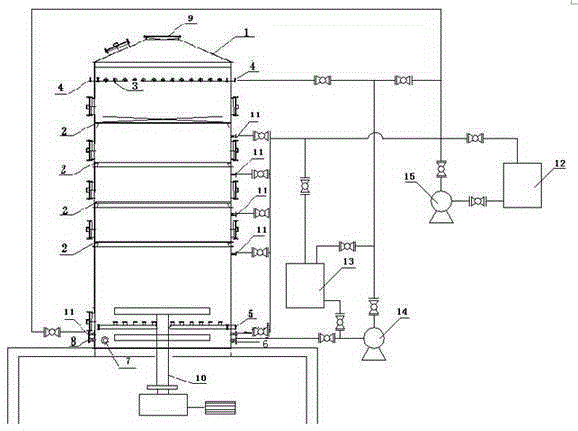

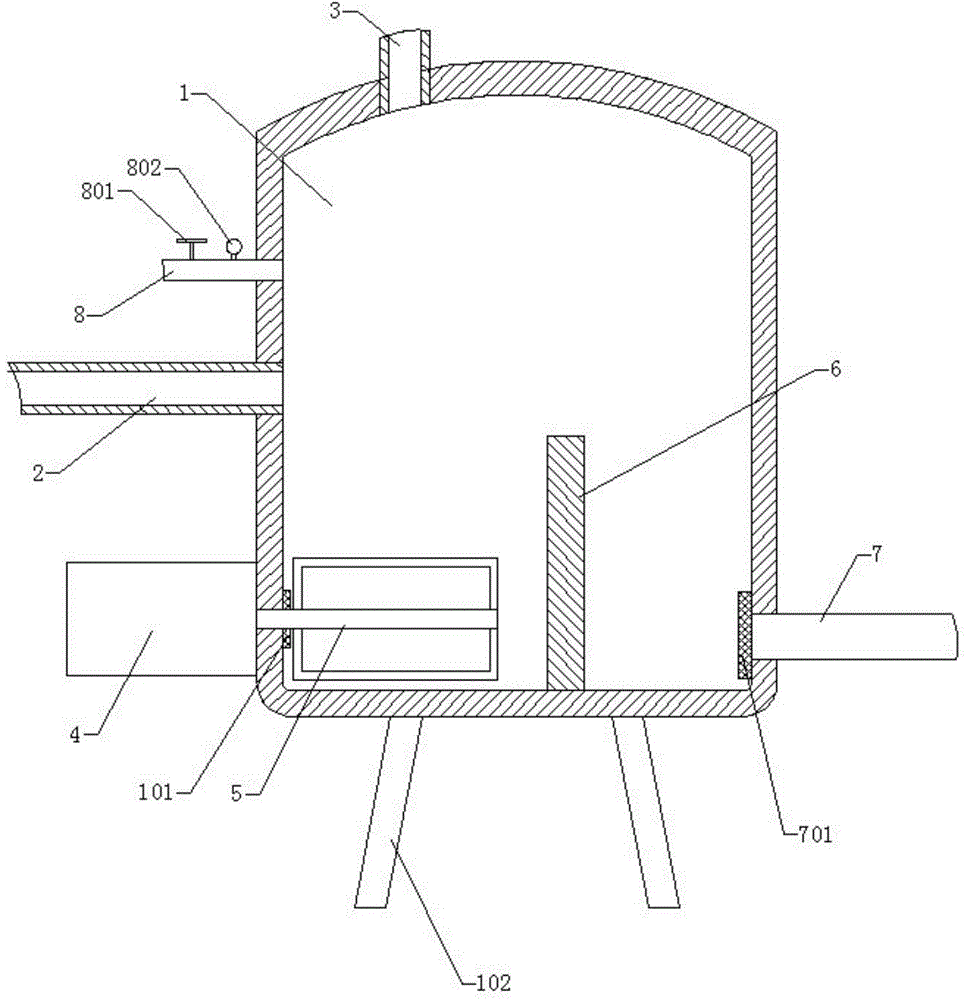

Organic silicon monomer hydrolysis device

ActiveCN104624145ACompletely hydrolyzedWell mixedChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsDistilled waterWater flow

The invention discloses an organic silicon monomer hydrolysis device which comprises a hydrolysis tank, and also comprises a water inlet pipe, an organic silicon monomer pipe, a motor, a stirrer, a partition plate, a drain pipe and a hydrochloric acid inlet pipe. Compared with the prior art, the organic silicon monomer hydrolysis device has the advantages that distilled water continuously flows into the hydrolysis tank through the water inlet pipe, an organic silicon macromonomer is continuously sent to the hydrolysis tank from the organic silicon monomer pipe, and the motor drives the stirrer to uniformly mix water with an organic silicon monomer, so that the organic silicon monomer is thoroughly hydrolyzed. The obtained organic silicon sinks to the bottom of water because the density of the organic silicon is greater than that of water, and the water flows to the other side of the hydrolysis tank when flowing over the partition plate, and is drained out of the drain pipe, so that the circulation production is realized, and the production efficiency is improved.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

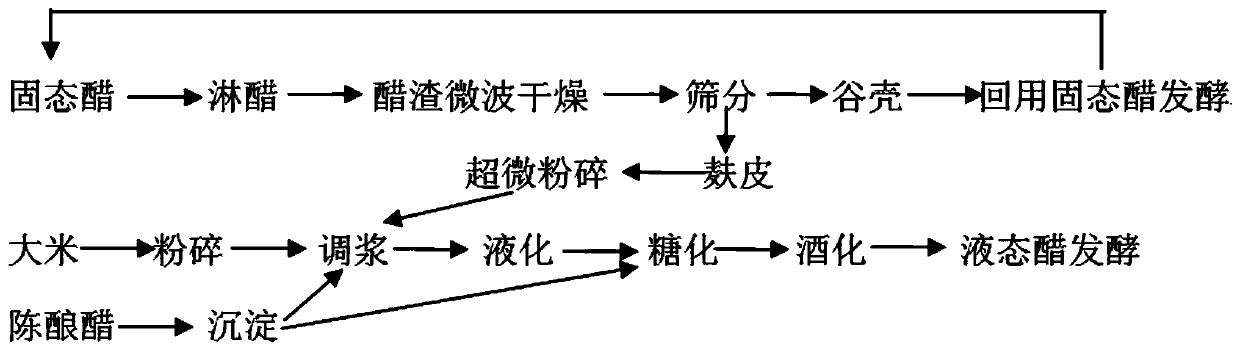

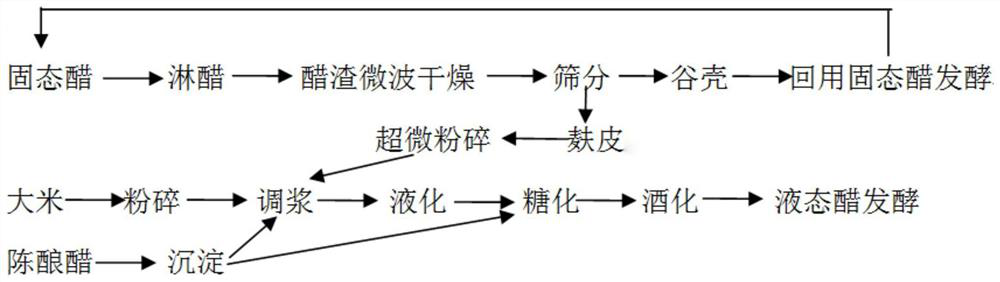

Method for utilizing vinegar residues and vinegar precipitates to brew liquid vinegar

The invention discloses a method for utilizing vinegar residues and vinegar precipitates to brew liquid vinegar. The method comprises the following steps of (1) pretreatment of rice, the vinegar residues and the vinegar precipitates; (2) liquefying, wherein the pretreated rice, the pretreated vinegar residues, the pretreated vinegar precipitates and water are blended with one another for size mixing, amylase is added for instant liquefaction at the high temperature, and then cooling is conducted for desaccharification to obtain a liquefied solution; (3) liquid vinegar fermentation, wherein thevinegar precipitates are added to adjust the pH value of the liquefied solution to be 4.0-4.5, saccharifying enzymes and cellulase are added for saccharification to obtain a saccharified liquid, andalcoholization and acetification are performed on the saccharified liquid to obtain liquid raw vinegar. Compared with the liquid vinegar fermented in the prior art, the liquid vinegar fermented through the method has more abundant nutrients, a unique flavor and a yellow and bright color, recycling of the vinegar residues and coarse precipitates is achieved at the same time, and therefore the method is more environmentally friendly and healthy.

Owner:QIANHE CONDIMENT & FOOD CO LTD

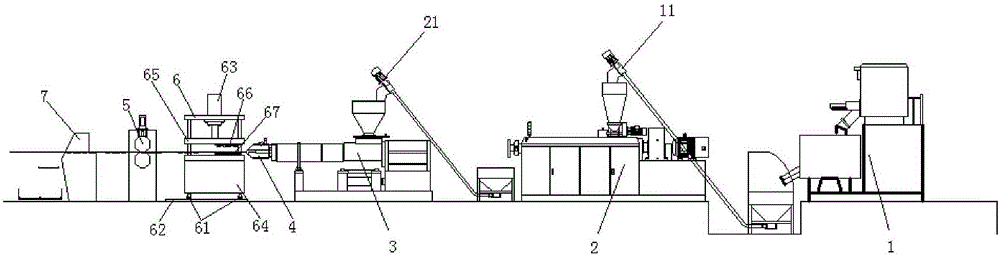

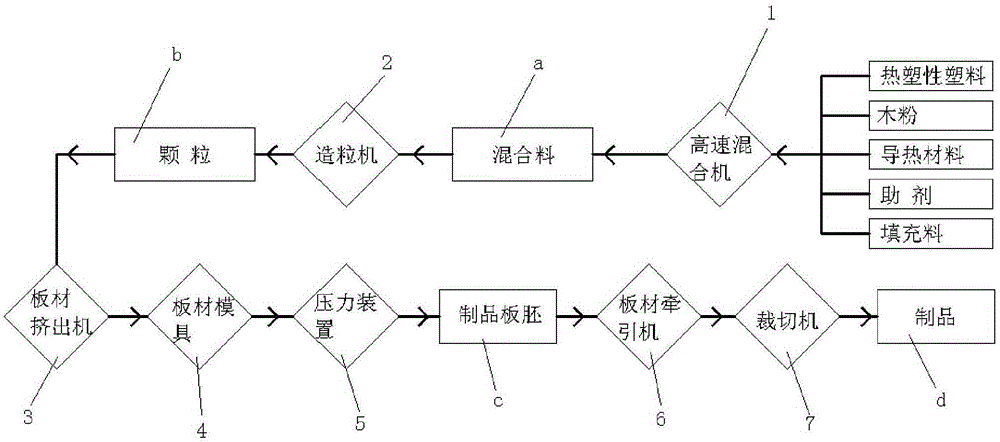

Continuous and direct compression molding forming method for thermoplastic plastic thin-wall melt

The invention discloses a continuous and direct compression molding forming method for thermoplastic plastic thin-wall melt. The method comprises the following continuously and circularly executed steps that firstly, by weight, 50% of thermoplastic plastic, 15% of wood powder, 15% of filler, 10% of heat conduction material and 10% of assistant are placed into a high-speed mixer to be manufactured into a mixture; secondly, the mixture obtained in the first step is placed in a granulator to be manufactured into particles; thirdly, the particles obtained in the second step are placed into a plate extruder, and the melt is formed through heat conduction and shearing; fourthly, the melt obtained in the third step passes a plate mold, and a melt plate blank is formed; fifthly, the melt plate blank obtained in the fourth step is pressed through a mold on a pressure device and manufactured into a product plate blank; and sixthly, the product plate blank obtained in the fifth step is dragged through a plate dragging machine to a cropping machine to be cropped and then separated, and a finished product is obtained. Continuous and circular direct compression molding forming of the thin-wall and wide melt in the molten state is achieved, and the product is high in surface hardness, accurate in size, full in shape and clear in corner angle. The production technology process is simple, the production period is short, and the production efficiency is high.

Owner:陈元文

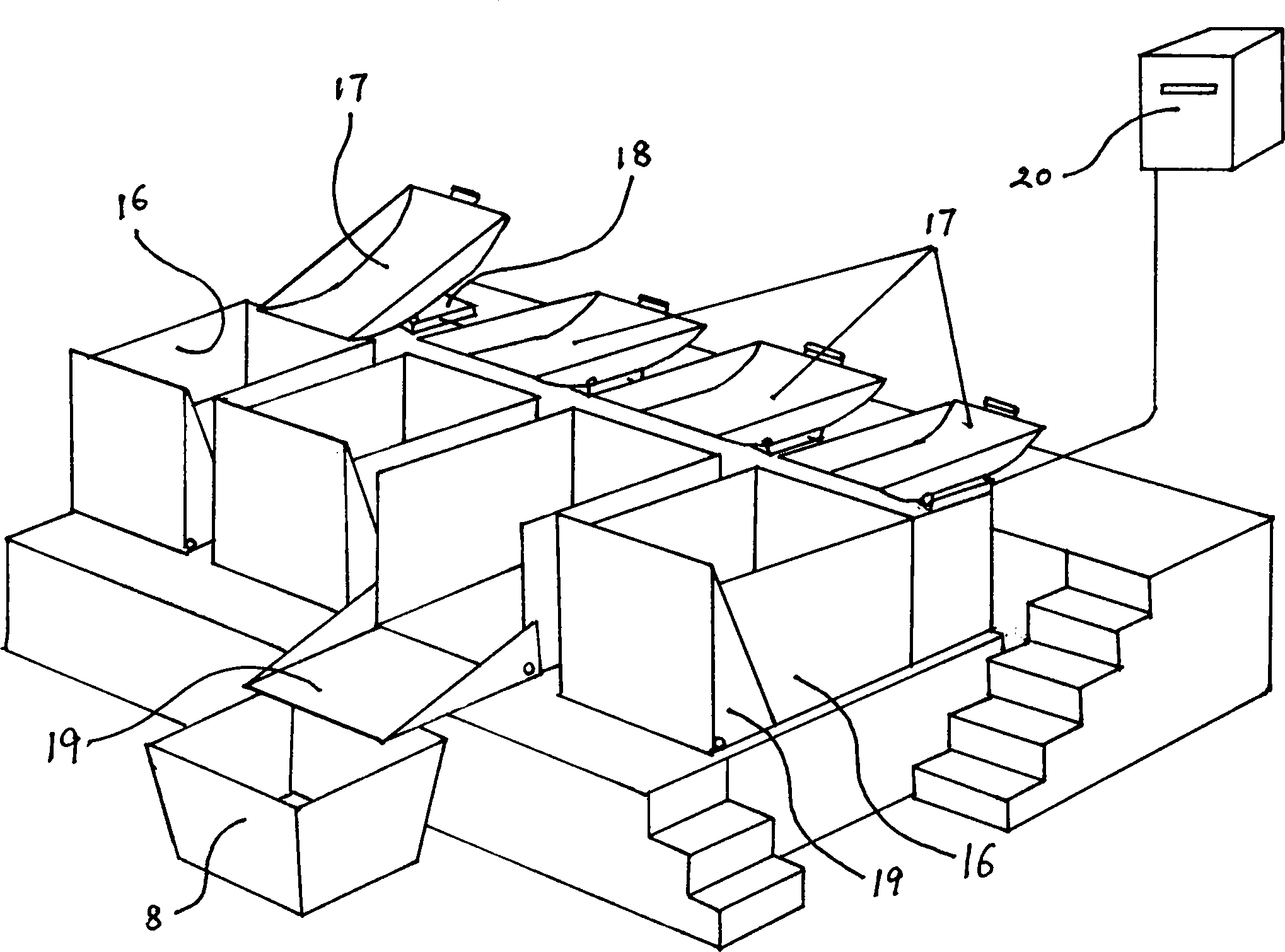

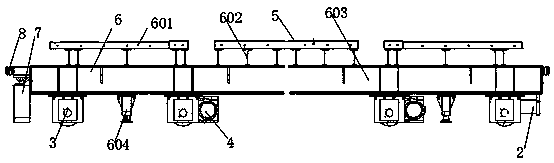

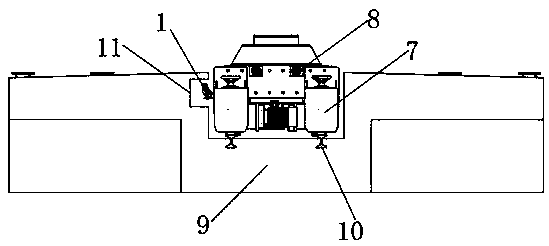

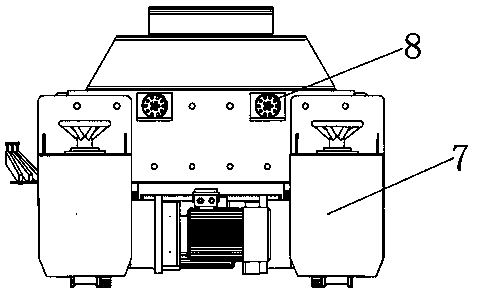

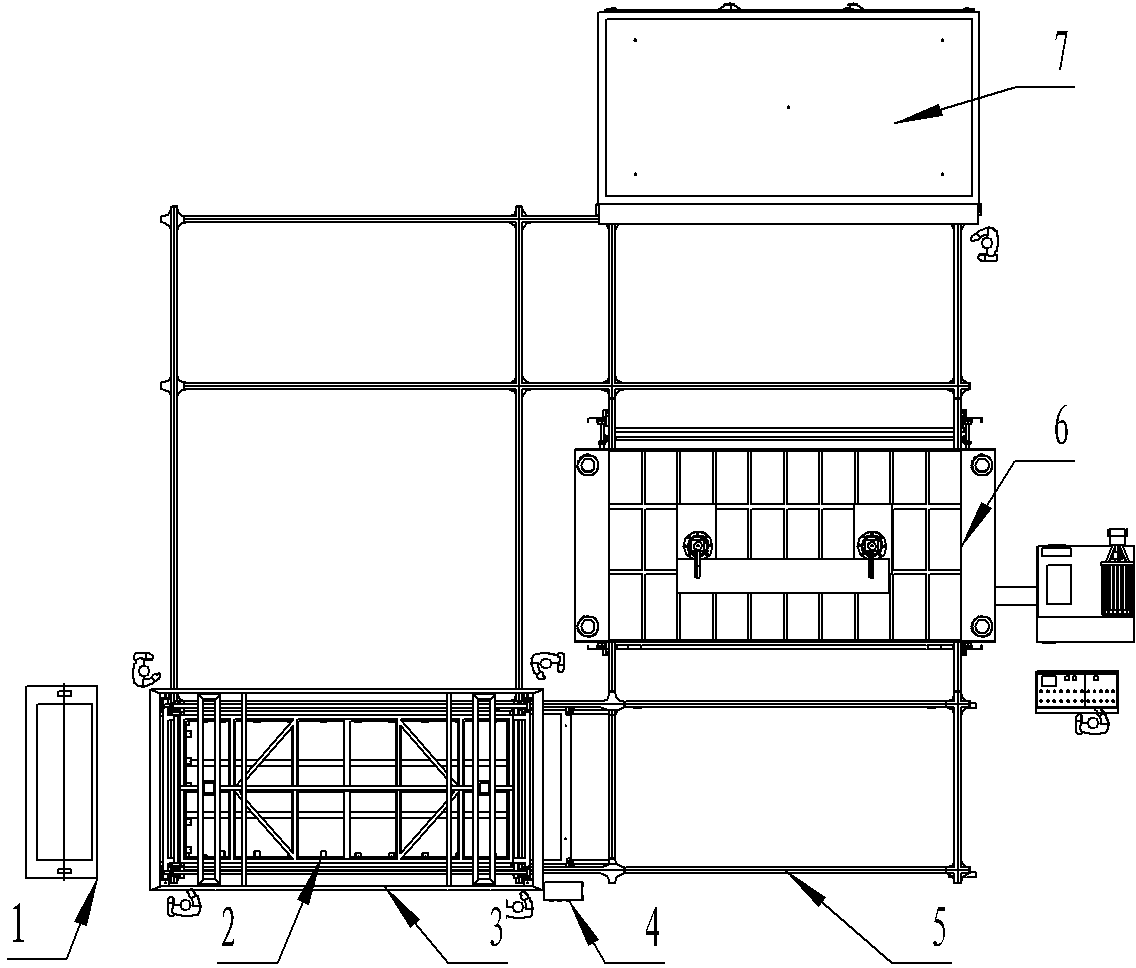

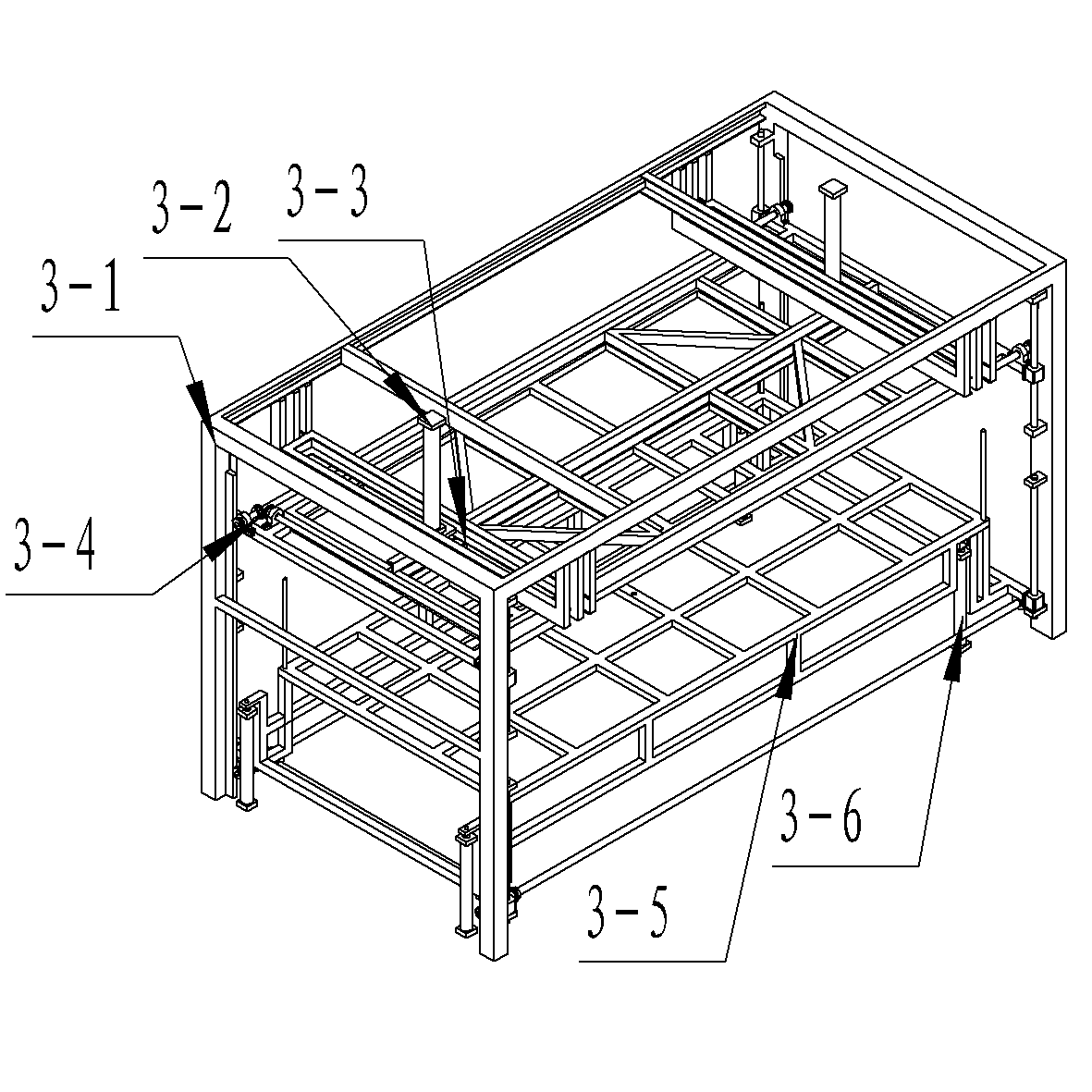

Rail movable type prefabricated beam steel pedestal

PendingCN108858737ALow efficiency of mobile operationsCross-operation safety risk is highCeramic shaping apparatusProduction rateDrive wheel

The invention discloses a rail movable type prefabricated beam steel pedestal. The pedestal comprises a main steel beam and a foundation trench, and the main steel beam is composed of a plurality of sets of bottom die support platforms, a plurality of pieces of supporting I-steel and a lower steel platform; steel bottom dies are installed at the upper end of the bottom die support platforms correspondingly, driving wheel sets are installed on the two sides of the middle of the lower surface of the lower steel platform respectively, driven wheel sets are installed on the two sides of the lowersurface of the lower steel platform respectively, and two movable supporting legs are installed at the two ends of the lower surface of the lower steel platform respectively; two basic rails are installed in the foundation trench; and a switchboard is movably installed at the end part of the other side of the lower end of the main steel beam, and buffering devices are installed at the end parts ofthe two ends of the main steel beam. According to the prefabricated beam steel pedestal, safe construction and smooth and safe transferring can be provided for construction units, in the transferringprocess, rapid installation and repeated use can be achieved, the productivity is greatly improved, and benefits are created for construction enterprises.

Owner:福建龙铁机械有限公司

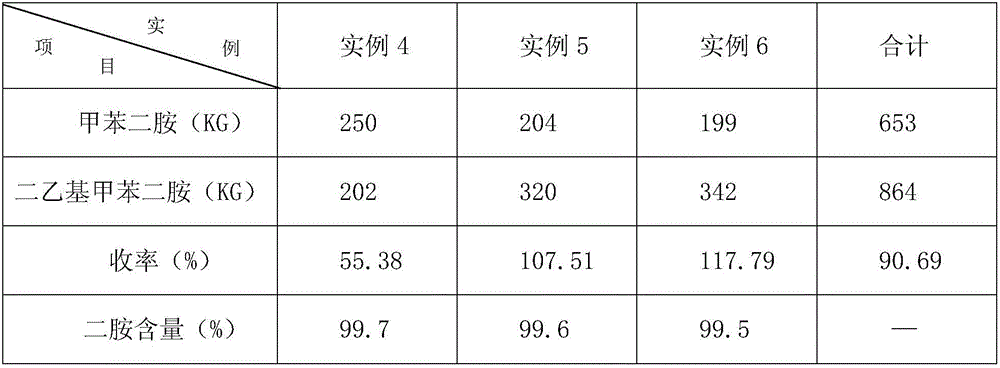

Method for synthesizing diethyltoluenediamine

ActiveCN106083605AReduce the number of timesReduce security risksAmino preparation from aminesAlkyl transferOrganic solvent

The invention discloses a method for synthesizing diethyltoluenediamine. An arylamine-aluminum catalyst system is formed with diaminotoluene under certain conditions, then, an alkylation reaction with ethylene is carried out in an autoclave, a reaction product directly enters a distillation still for distillation after the reaction ends, a front cut fraction and a remaining catalyst system directly return to the autoclave, then, the raw material diaminotoluene is put into the autoclave and is subjected to an alkylation reaction with ethylene directly, and the arylamine-aluminum catalyst system can be reused through one-time preparation. Meanwhile, a straight distillation technology is adopted, so that the consumption of organic solvents is avoided, the purity of the product can be higher, and the production process is more environmentally friendly. According to the synthesis method, the catalyst system is reused repeatedly, and the process is free of solvents and neutralizing and washing processes, so that the production cost is reduced, the production efficiency is increased, and process flows are simpler, safer and more environmentally friendly.

Owner:山东崇舜新材料科技有限公司

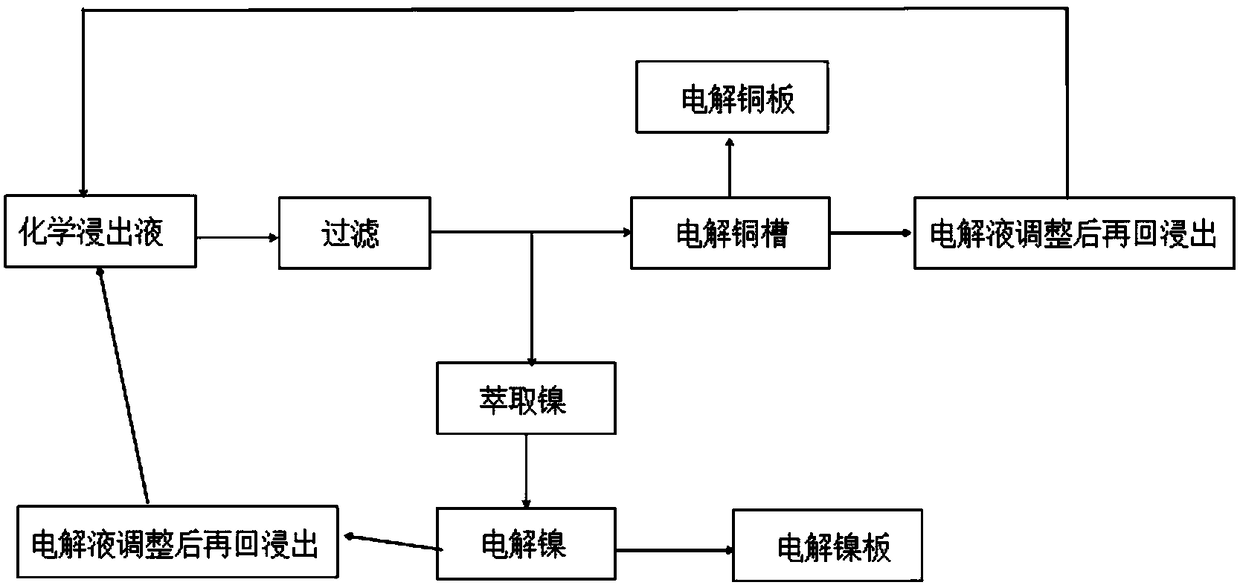

Metal recycling process for waste plastic electroplating parts

InactiveCN109161694ASimple production processAvoid impact resistance and plasticityPhotography auxillary processesProcess efficiency improvementKeroseneMetal recycling

The invention aims to propose a metal recycling process for waste plastic electroplating parts, wherein the metal recycling process is clean and environmentally friendly, high in metal recycling rate,and capable of reducing damages to a plastic substrate. The metal recycling process comprises the following steps: step A, leaching the waste plastic electroplating parts in leaching equipment, usingdilute sulfuric acid or sulfamic acid as a leaching agent to obtain chemical leachate; step B, filtering the chemical leachate to obtain nickel-copper mixed liquid, extracting the nickel-copper mixedliquid, wherein the nickel-copper mixed liquid is used as a water phase, diphosphate is used as an extracting agent, and sulfonated kerosene is used as a diluent during extraction; and step C, usingsulfuric acid as a back extractant for back extraction of an organic phase obtained after extraction, separating to obtain a copper-containing solution and a nickel-containing solution, and separatelyelectrolyzing the copper-containing solution and the nickel-containing solution into electrolytic copper and electrolytic nickel.

Owner:广东明方科技有限公司

Precast concrete production pretreatment equipment, production line and production method

InactiveCN111391106AImprove cleaning difficultyReduce labor intensityDischarging arrangementCeramic shaping plantsConstruction engineeringPrecast concrete

The embodiment of the invention provides precast concrete production pretreatment equipment, a production line and a production method, and relates to the technical field of precast concrete production. The recast concrete production pretreatment equipment provided by the embodiment of the invention comprises a mold table and a film laminating machine; the mold table is provided with a bearing face used for bearing the precast concrete, and when the mold table is used, the precast concrete in the production process is distributed on the bearing face, so that the precast concrete is driven by the mold table to move between subsequent treatment stations, thereby completing all subsequent treatment procedures. The film laminating machine is used for laminating a film on the bearing face of the mold table, so that a complete film is formed on the bearing face, and when the precast concrete is distributed on the mold table, the precast concrete is in indirect contact with the bearing face through the film, in other words, direct contact between the precast concrete and the bearing face is avoided through the film; therefore, the problem that the mold table is difficult to clean after the precast concrete is disassembled is solved, and the working efficiency is improved.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Water scale cleaning method for cooler cooling water pipeline in aluminum hydroxide production system

The invention relates to a water scale cleaning process for equipment used in aluminum hydroxide production, namely a water scale cleaning method for a cooler cooling water pipeline in an aluminum hydroxide production system. The cooling water pipeline is connected with a water supply pipeline of the production system. The cleaning process includes: a, configuring a certain amount of NaOH solution for 10% - 60% of mass fraction, placing in a container, and heating till 80 DEG C to 90 DEG C and insulating heat for standby application; b, completely placing the cooling water pipeline to the NaOH solution prepared in the step a for 4 to 8 days before taking out; c, using a drill or a steel bar to clean the inner wall of the cooling water pipeline processed in the step b along the path of the cooling water pipeline till 80% - 95% of water scale is removed for standby application; d, using water to wash the cooling water pipeline processed in the step c. According to the process, cleaning effect is fine, waste water after cleaning can be used for production circulation, and environment pollution and energy efficiency are realized.

Owner:HENAN SHENHUO NEW MATERIAL

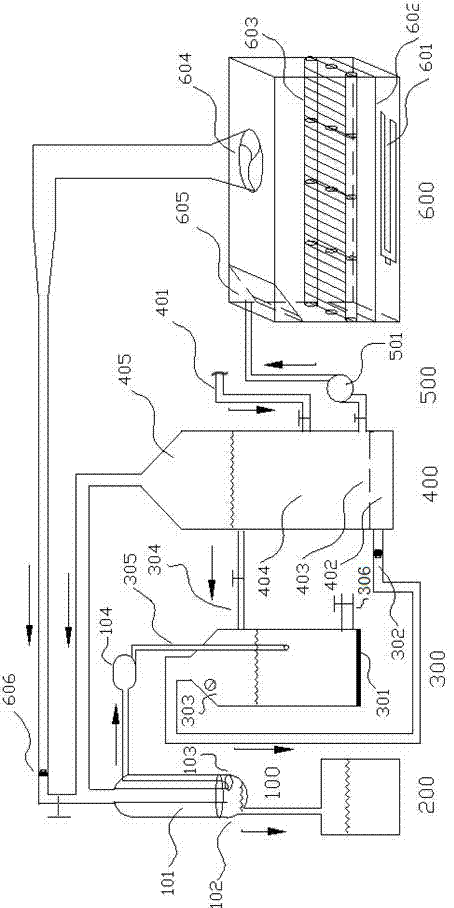

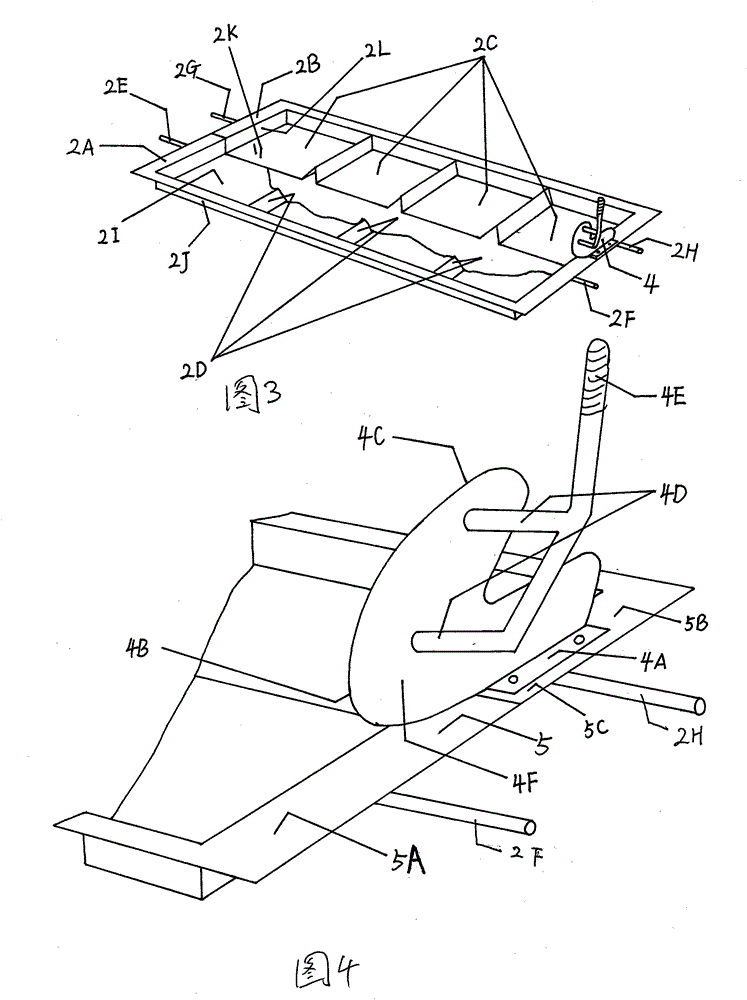

Offline and online integrated jet-printing system of printed circuit board

InactiveCN105979714AIncrease production capacityRealize on-demand production modelTypewritersConductive pattern formationPrinted circuit boardAutomation

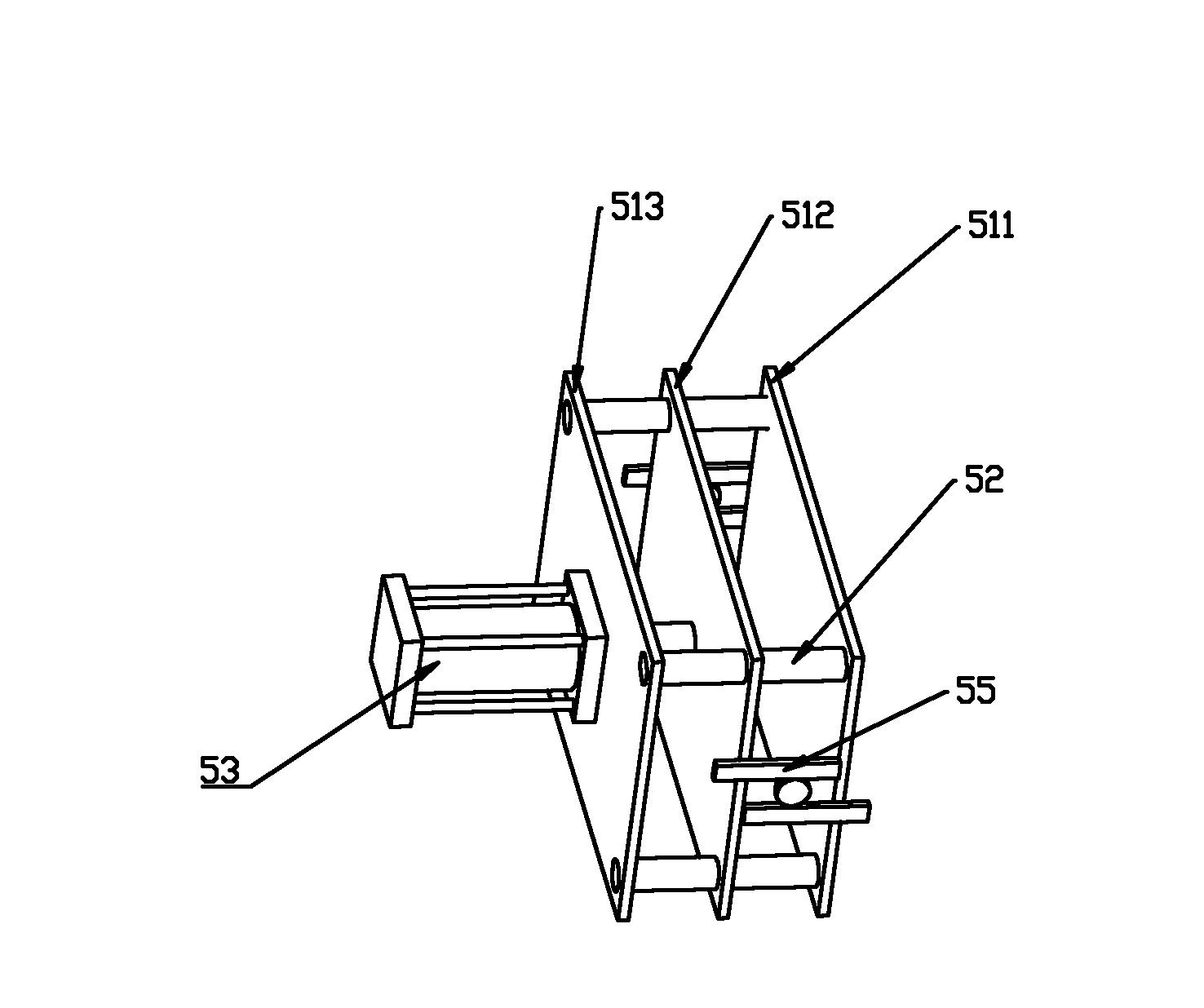

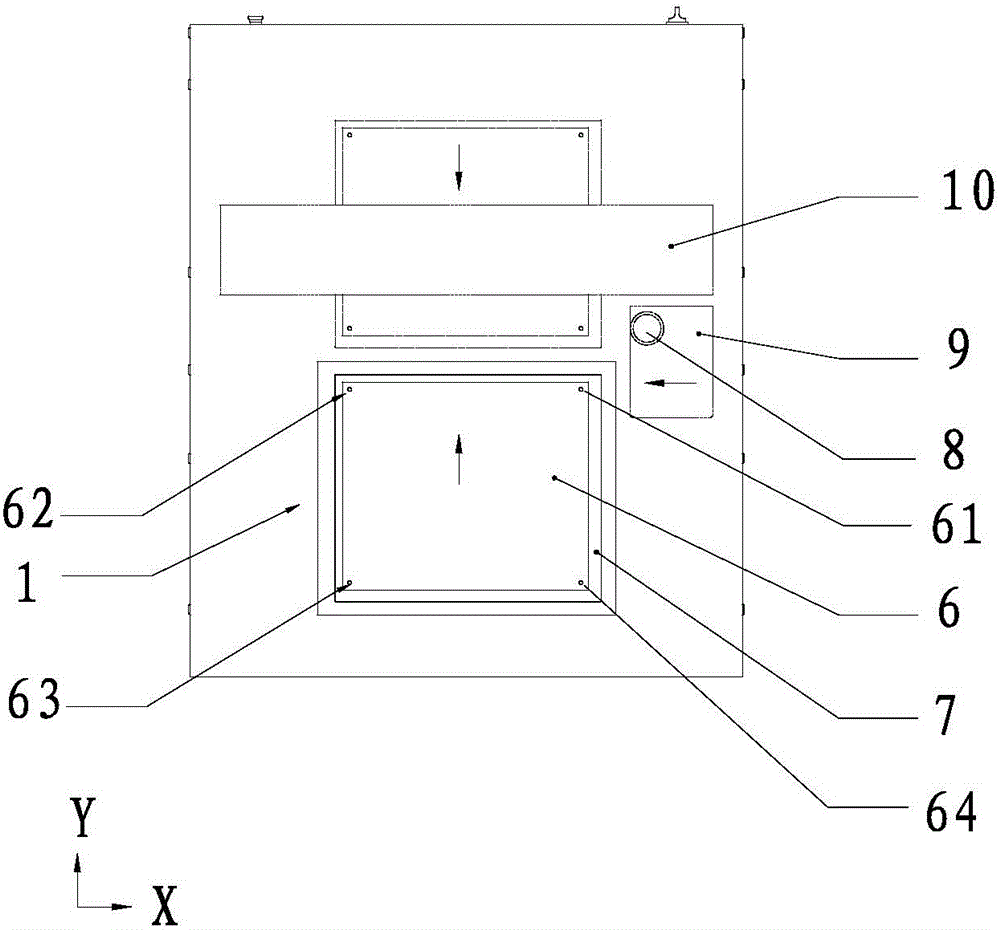

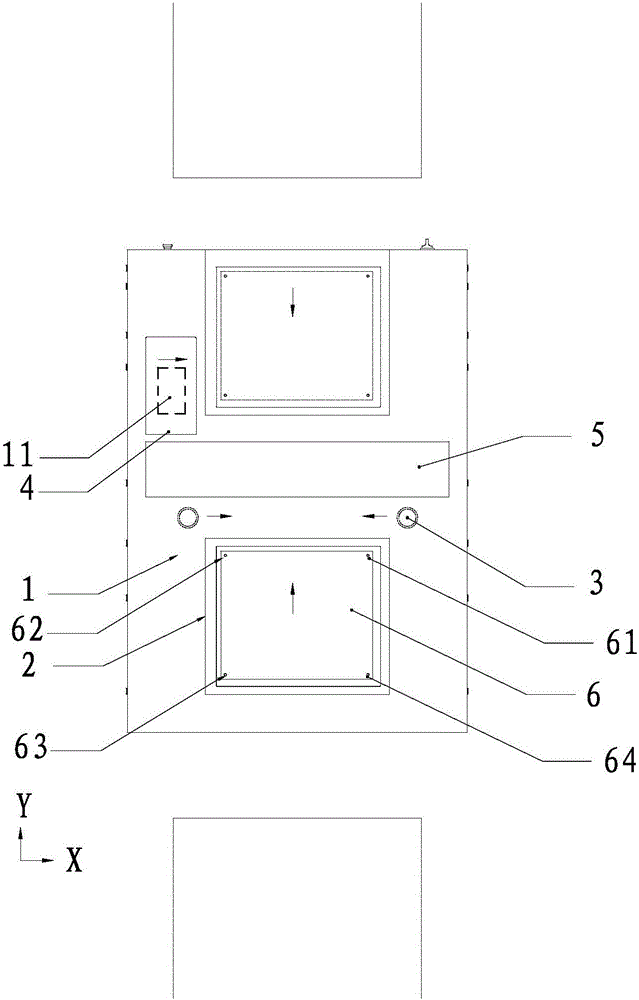

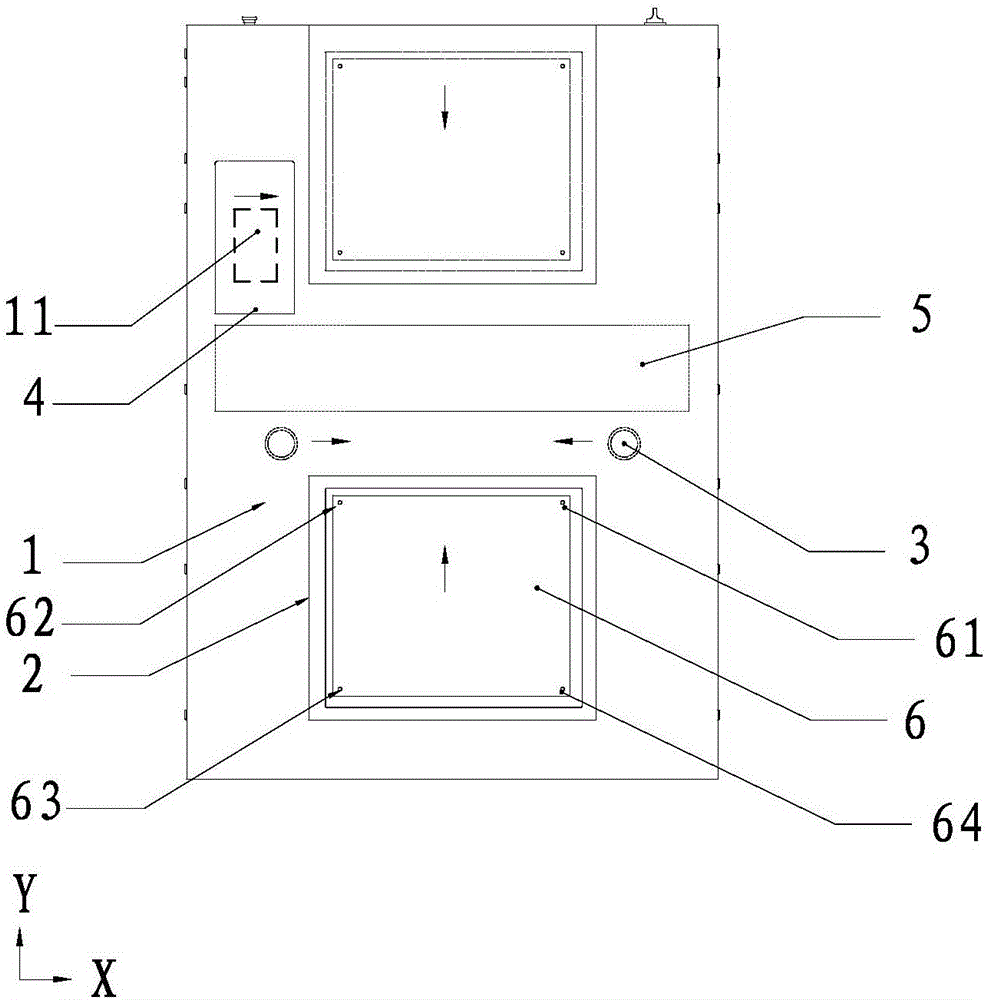

The invention relates to the field of printed circuit boards, and discloses an off-line and online integrated inkjet printing system for printed circuit boards, comprising a horizontally placed substrate (1), a mobile operating platform (2), and two image capture devices (3) , a mobile jet printing curing device (4) and a gantry (5); the mobile operating platform is movably installed on the base plate, and the moving track of the mobile operating platform is in the direction of ±Y; the gantry is fixed on the base plate , and the fixed direction of the gantry is the X direction; the front side of the gantry is provided with two image capture devices that can move independently in the ±X direction; Curing device; the X direction and the Y direction are two directions perpendicular to each other on the horizontal plane. The spray printing system of the present invention has low cost, can realize offline and online production modes, has a high degree of automation, and greatly improves work efficiency.

Owner:徐进

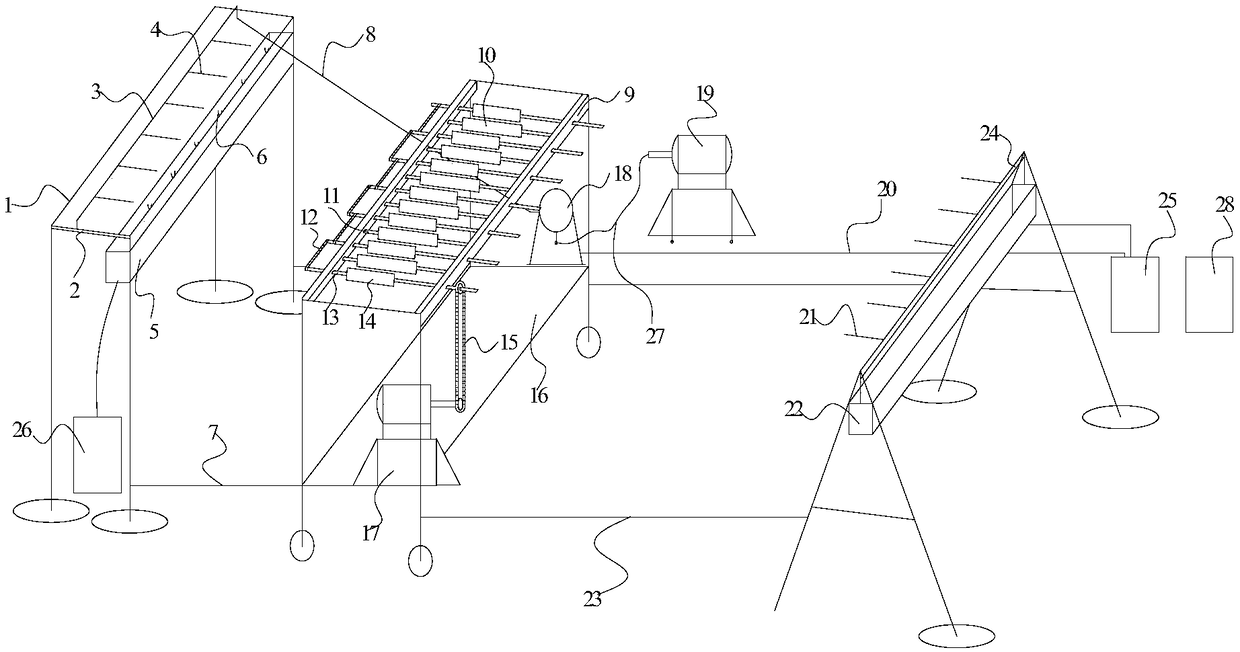

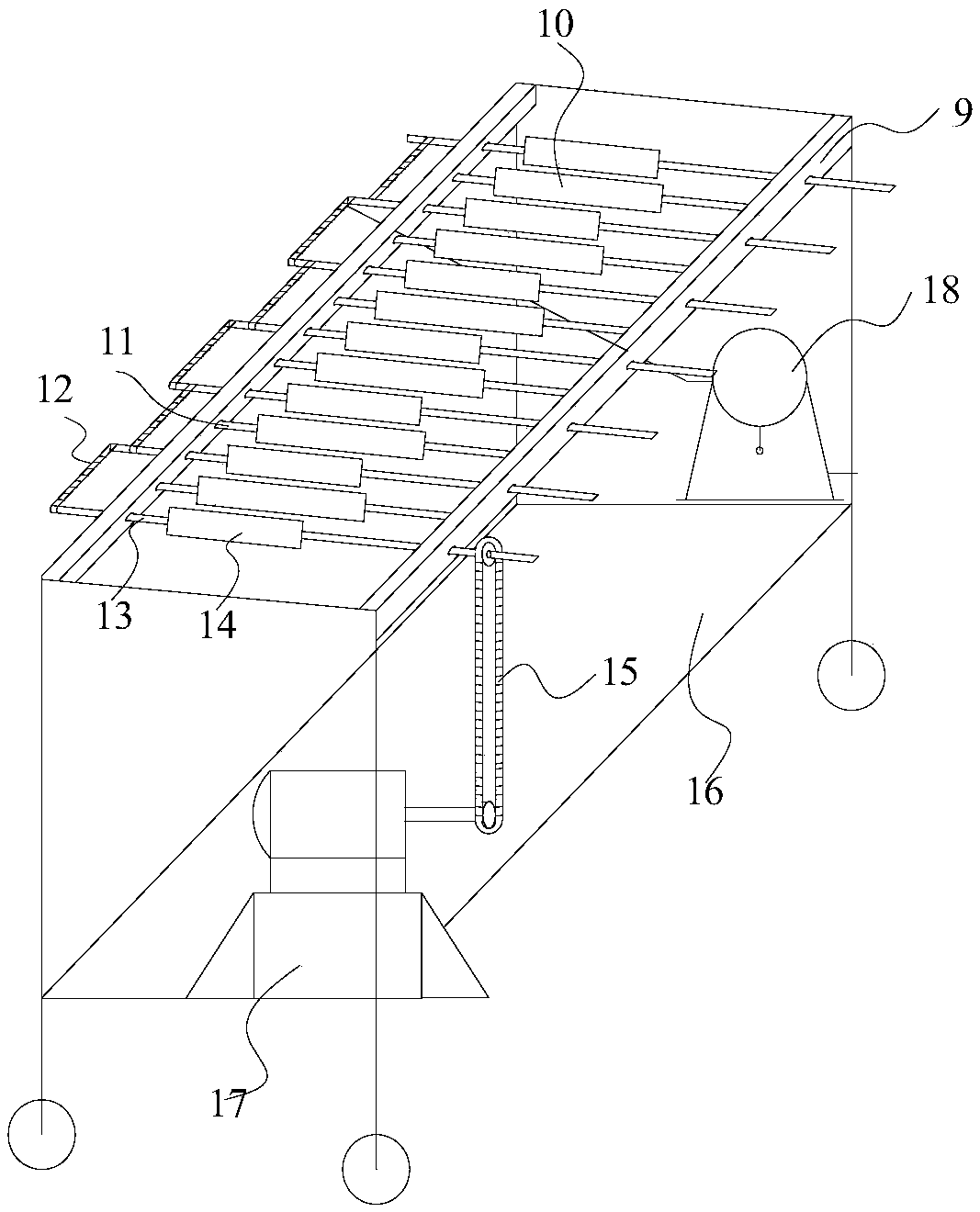

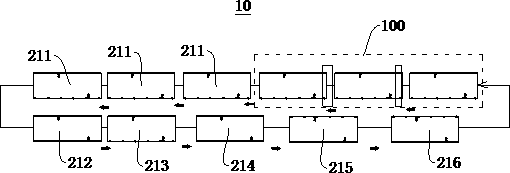

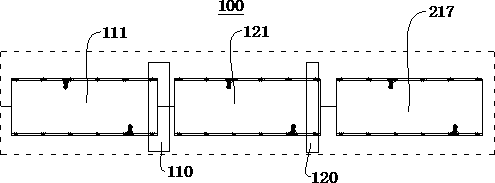

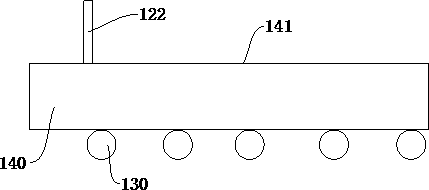

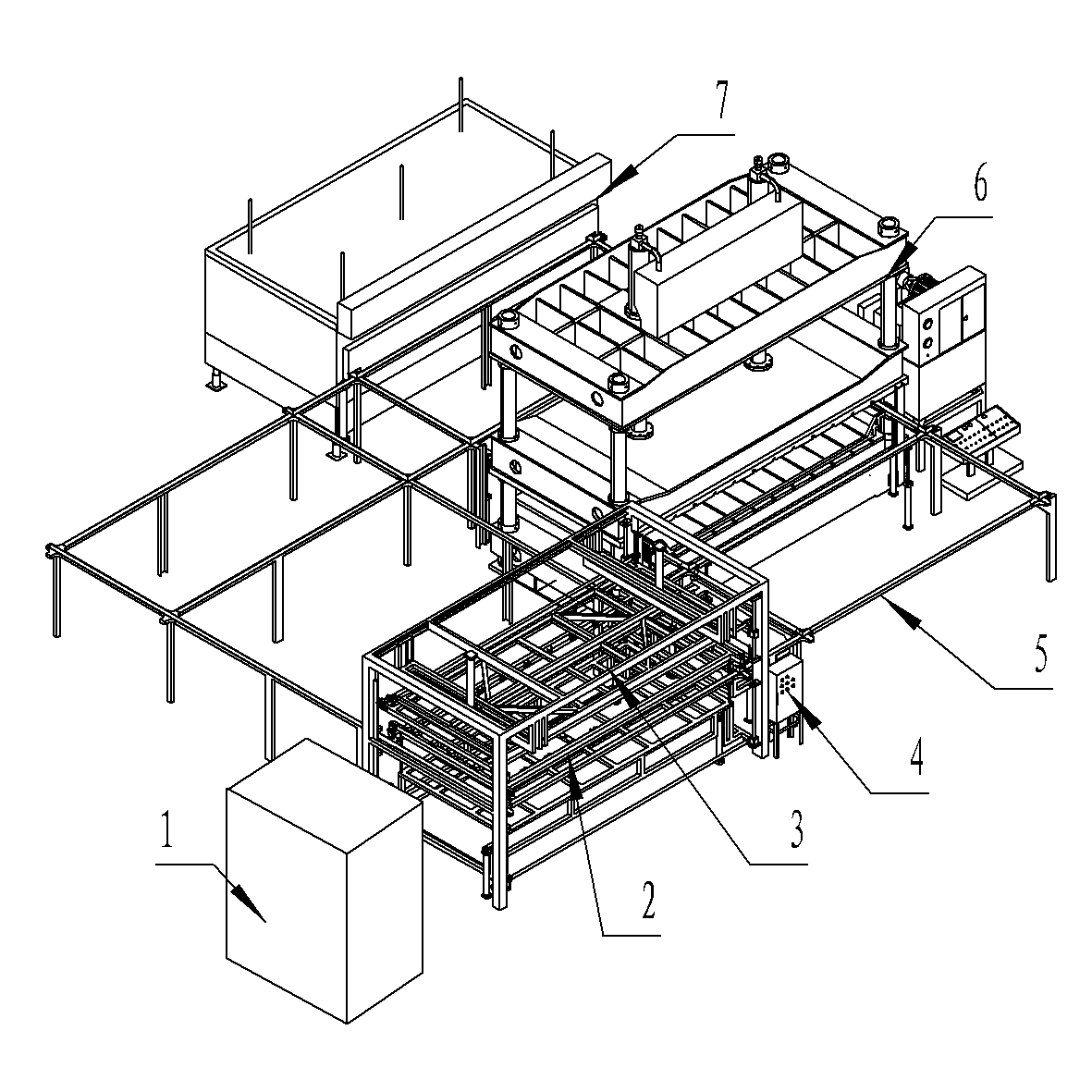

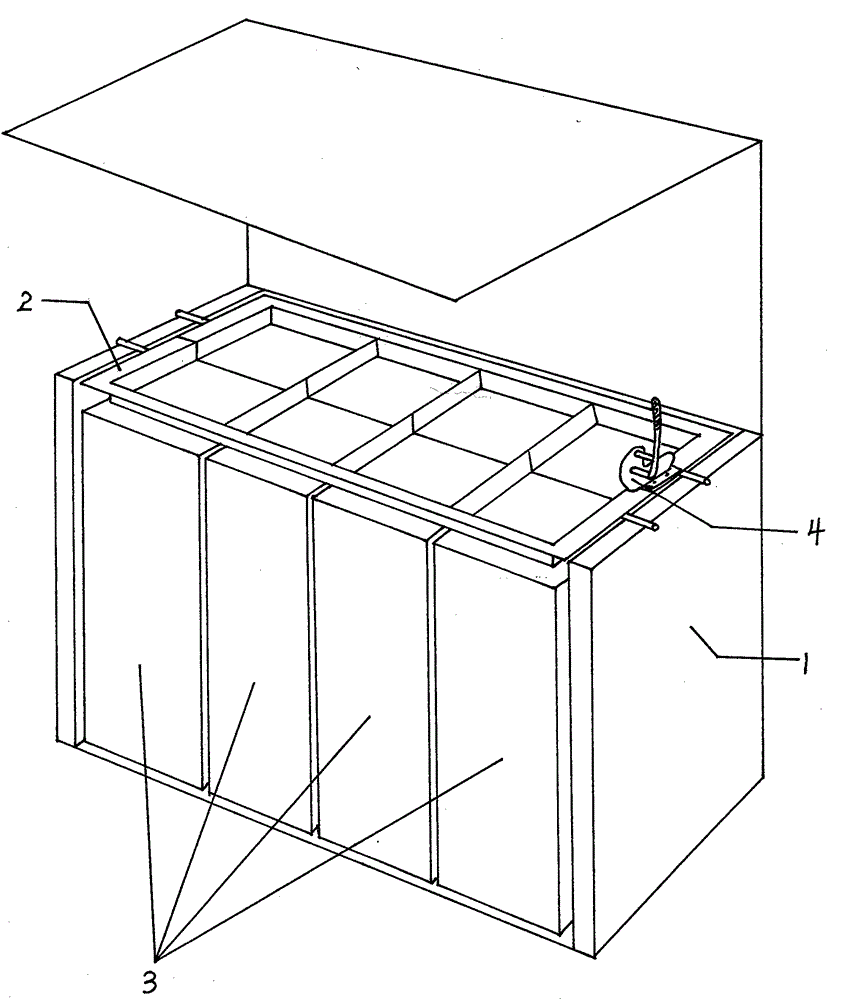

Circulatory carpet forming production line

The invention discloses a circulatory carpet forming production line, and relates to the technical field of auto part production. The circulatory carpet forming production line comprises a cutting device (1), a plurality of transshipping vehicles (2) running on guide rails (5), a drying oven (7) and a forming device (6), and further comprises a loading and unloading device (3) arranged near the forming device (6), wherein the loading and unloading device (3) is used for loading and unloading materials to and from the transshipping vehicles (2); and the guide rails (5) penetrate the loading and unloading device (3) and the forming device (6), and are arranged between the cutting device (1) and the drying oven (7) end to end in a circular manner. Compared with the prior art, the circulatory carpet forming production line can solve the problems of low production efficiency, high energy consumption and high labor intensity of the conventional auto carpet production.

Owner:四川方鑫科技有限公司

Production method of rice seedling culture/base fertilizer integrated tray

ActiveCN105830794ASimple processLess investmentGrowth substratesSewage/sludge fertilisersWet strengthOrganic fertilizer

The invention discloses a production method of a rice seedling culture / base fertilizer integrated tray. The production method comprises the following steps: (1) beating a rice straw pulp, wherein the beating degree is controlled to be 40-450SR and the wet weight is controlled to be 3.0-3.5g; (2) mixing an organic fertilizer with the rice straw pulp according to a weight ratio of 8:2, and then adding corn starch, a papermaking wet-strength agent and a paper waterproof and damp-proofing admixture; (3) injecting the material in the step (2) into a tray mold for shaping; and (4) spraying a seedling culture fertilizer to the surface of a shaped tray, and performing drying to obtain a rice seedling culture / base fertilizer integrated tray. The production method disclosed by the invention is simple in process, small in investment and quick in effect, and realizes integration of a seedling culture tray, a seedling culture fertilizer and a base fertilizer, and rice-straw-rice circulating production.

Owner:石河子市国力源环保制浆有限公司

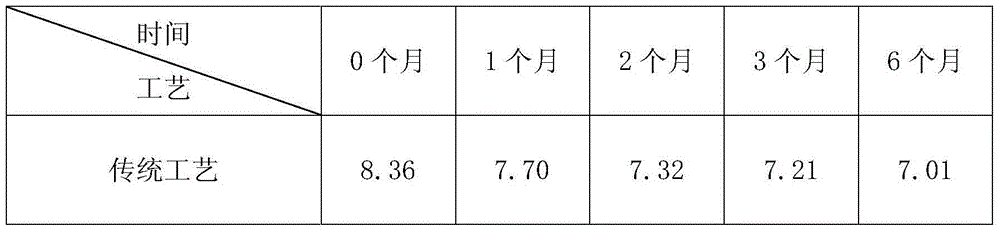

Preparation method for licorice fluid extract

The invention provides a preparation method for licorice fluid extract. The method comprises the following steps: material dissolving; dissolving with alcohol; press filtration; squeezing; concentration; blending; and filling and sealing. Compared with a traditional ternary alcohol precipitation process, the preparation method for the licorice fluid extract provided by the invention has the following advantages: a production cycle is shortened to 6 d from original 12 d, production cost is greatly reduced, and the disadvantages of decrease and instability of a pH value in the traditional process are overcome through repeated adjusting of the pH value.

Owner:BAOJI JINSEN PHARMA

Organic silicon hydrolyzer with collecting device

ActiveCN104624144ACompletely hydrolyzedWell mixedChemical/physical/physico-chemical stationary reactorsWater dischargeDistilled water

The invention discloses an organic silicon hydrolyzer with a collecting device. The organic silicon hydrolyzer comprises a hydrolysis tank, wherein the hydrolysis tank comprises a water inlet pipe, a feed pipe, a motor, a rotating shaft, a collecting net, a partition plate, a water discharge pipe and a hydrochloric acid inlet pipe. Compared with the prior art, the organic silicon hydrolyzer disclosed by the invention has the advantages that distilled water continually flows into the hydrolysis tank through the water inlet pipe, a large organic silicon monomer is continually delivered into the hydrolysis tank from the feed pipe, the organic silicon monomer is more thoroughly hydrolyzed by driving collected water to be uniformly mixed with the organic silicon monomer through the motor, organic silicon obtained through hydrolysis is automatically collected and the hydrolyzed water flows to the other side of the hydrolysis tank through the partition plate and is discharged through the water discharge pipe, thereby realizing the circulating production and improving the production efficiency.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

One-step three-station injecting, drawing and blowing plastic molding machine

InactiveCN102837417BRealize circular productionImprove efficiencyPlastic forming machineBlow molding

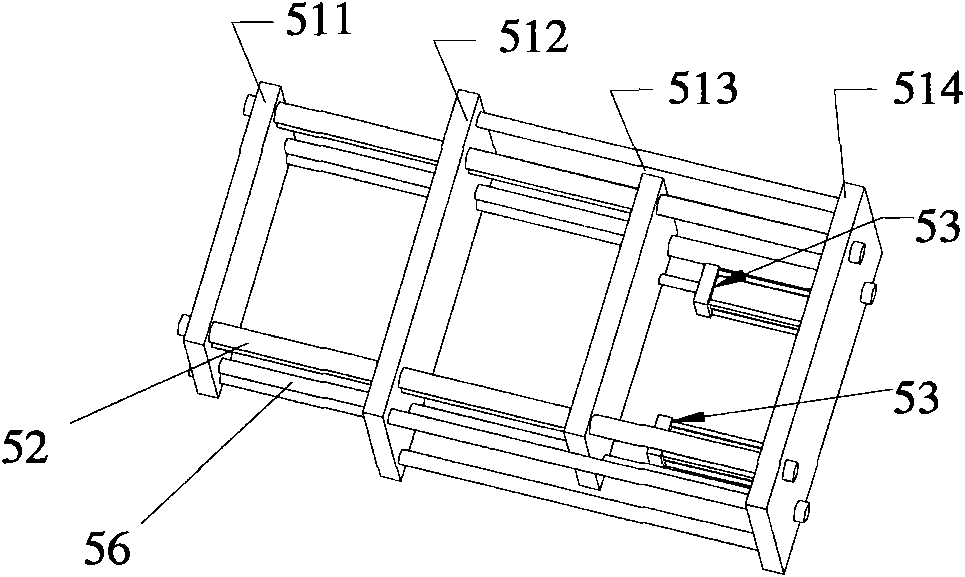

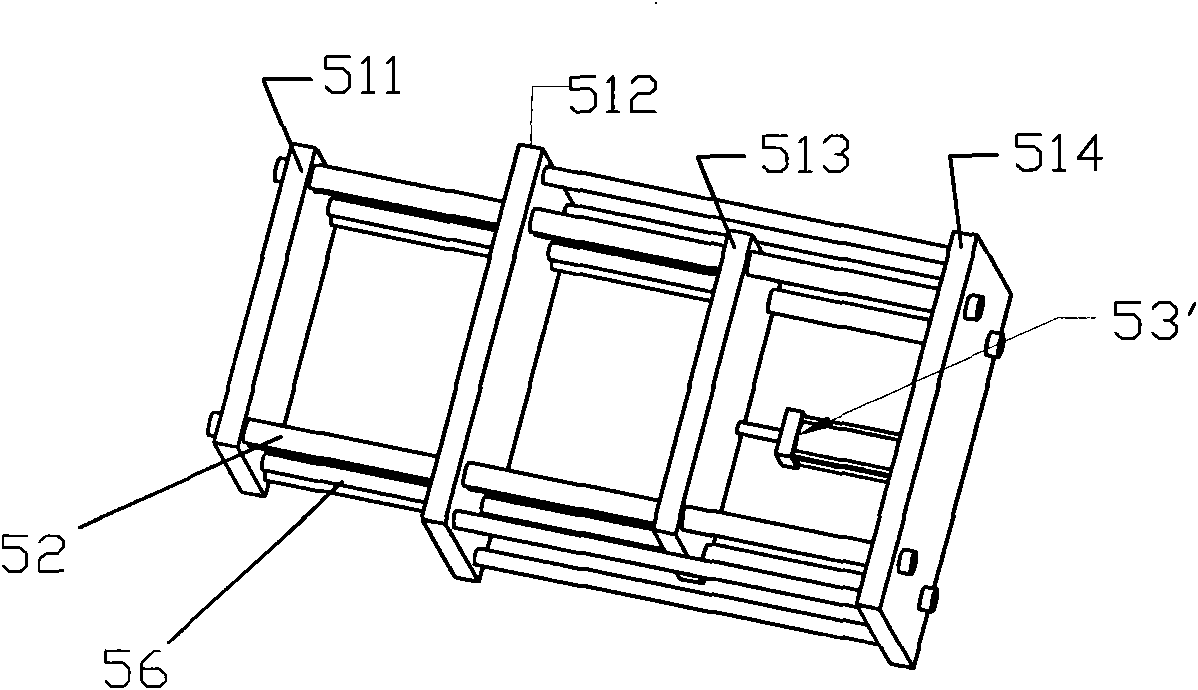

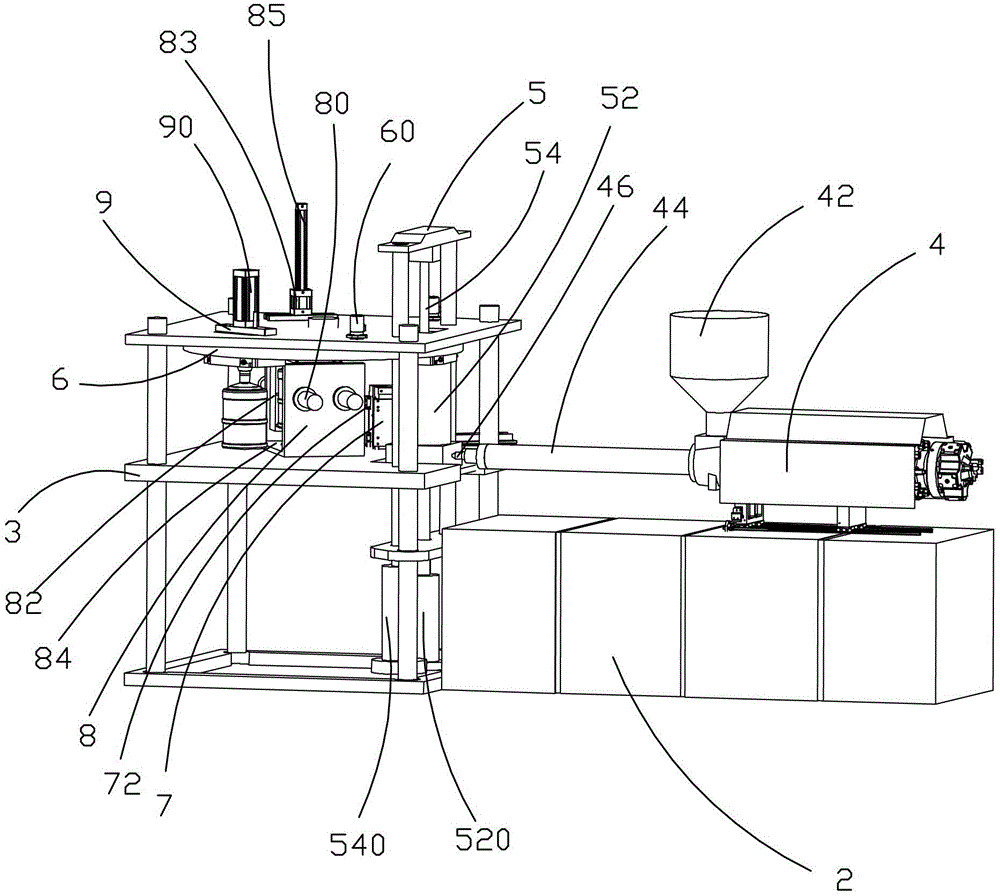

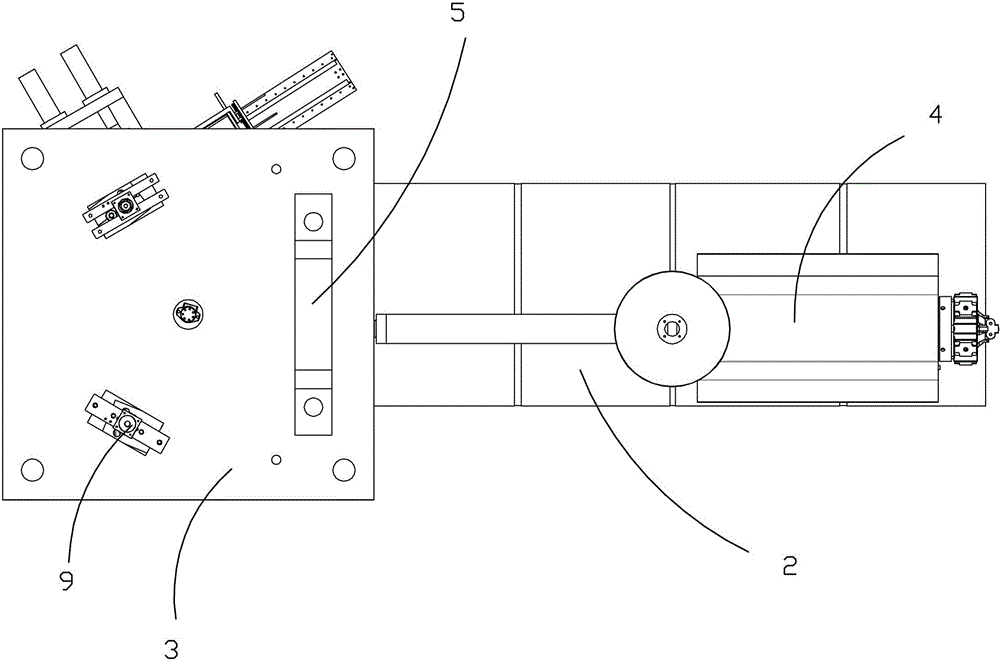

The invention provides a one-step three-station injecting, drawing and blowing plastic molding machine which comprises a mounting base, a fixing frame, an injection device, an injection bottle blank component, a rotating template assembly, a pre-blowing mould component, a drawing blowing component and a product de-molding component, wherein the fixing frame is arranged on one side of the mounting base; the injection device is arranged on the mounting base; the injection bottle blank component is fixed on the fixing frame; the rotating template assembly is fixed on the fixing frame; the pre-blowing mould component is fixed on the mounting base; the drawing blowing component is fixed on the fixing frame; the product de-molding component is fixed on the fixing frame; the injection bottle blank component is injected and molded into a semi-finished product bottle blank in an injection bottle blank mould; an injection mould core lifting cylinder is used for driving the semi-finished product bottle blank to ascend; an injection bottle blank mould lifting cylinder is used for driving the semi-finished product bottle blank to descend; and then a rotary power motor is used for driving the rotating template assembly to rotate, thereby driving the semi-finished product bottle blank to enter into a drawing blowing molding mould; and an end product is drawn, blown and molded after the temperature is adjusted by a temperature adjusting cylinder, or the pre-blowing mould component is used for adjusting the temperature and drawing, thereby obtaining a semi-finished product bottle after pre-blowing, and then the drawing blowing molding mould is used for blowing and molding, thereby forming the end product.

Owner:SHENZHEN DONGCHUAN HUATE TECH CO LTD

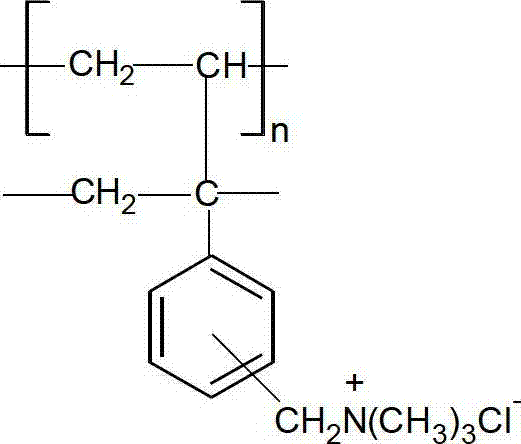

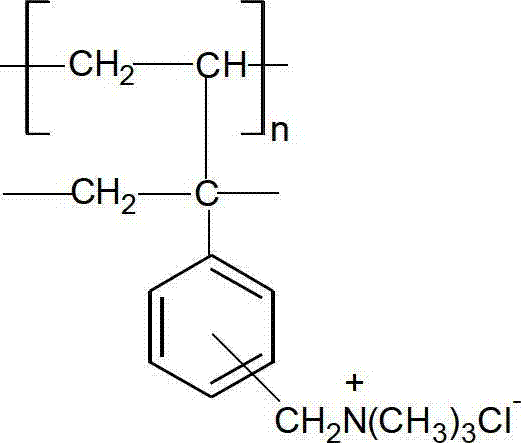

Method for separating high-concentration K2Cr2O7 from saturated NaCl solution

The invention relates to a method for separating high-concentration K2Cr2O7 from a saturated NaCl aqueous solution by using strong-base anion exchange fibers. The method comprises the following steps of: injecting a mixed solution into a separation column filled with the strong-base anion exchange fibers, so that Cr2O7<2-> in the mixed solution is adsorbed on the strong-base anion exchange fibers, and the obtained filtrate is a saturated NaCl solution containing KCl; and performing evaporative crystallization on the filtrate, and thus obtaining pure NaCl and KCl solid. By the method, the separation process is easy and convenient, the device is simple, and separation of the high-concentration K2Cr2O7 and the saturated NaCl solution can be finished in the fixed bed ion exchange column.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Stopping type sorting garbage can with linked skip hopper

InactiveCN104029955ASimple structureEasy to useWaste collection and transferRefuse receptaclesLitter

Owner:倪国森

Elution device and separation method for nitric acid type tin stripping waste liquid

ActiveCN105439225BAchieving primary separationRealize circular productionSludge treatment by de-watering/drying/thickeningWater contaminantsLiquid wasteFluidized bed

Owner:JIANGSU WANHE COATING MACHINE CO LTD

A method for brewing liquid vinegar using vinegar residue and vinegar precipitation

The invention discloses a method for brewing liquid vinegar by using vinegar residue and vinegar precipitation, which comprises the following steps: (1) pretreatment of rice, vinegar residue, and vinegar precipitation; (2) liquefaction: the pretreated rice, vinegar residue, Vinegar precipitation is mixed with water for pulping, amylase is added for high-temperature instant liquefaction, and then cooled to desaccharify to obtain liquefied liquid; (3) Liquid vinegar fermentation: add vinegar precipitation to adjust the pH of the liquefied liquid to 4.0-4.5, add glucoamylase and cellulase Carry out saccharification to obtain a saccharification solution, and the saccharification solution is subjected to alcoholization and vinegarization to obtain liquid raw vinegar. Compared with the liquid vinegar fermented by the existing technology, the liquid vinegar fermented by the method has richer nutrition, unique flavor and bright yellow color, realizes the reuse of vinegar residue and coarse sediment, and is more environmentally friendly and healthy.

Owner:QIANHE CONDIMENT & FOOD CO LTD

An organosilicon hydrolyzer with a collecting device

ActiveCN104624144BCompletely hydrolyzedWell mixedChemical/physical/physico-chemical stationary reactorsWater dischargeDistilled water

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

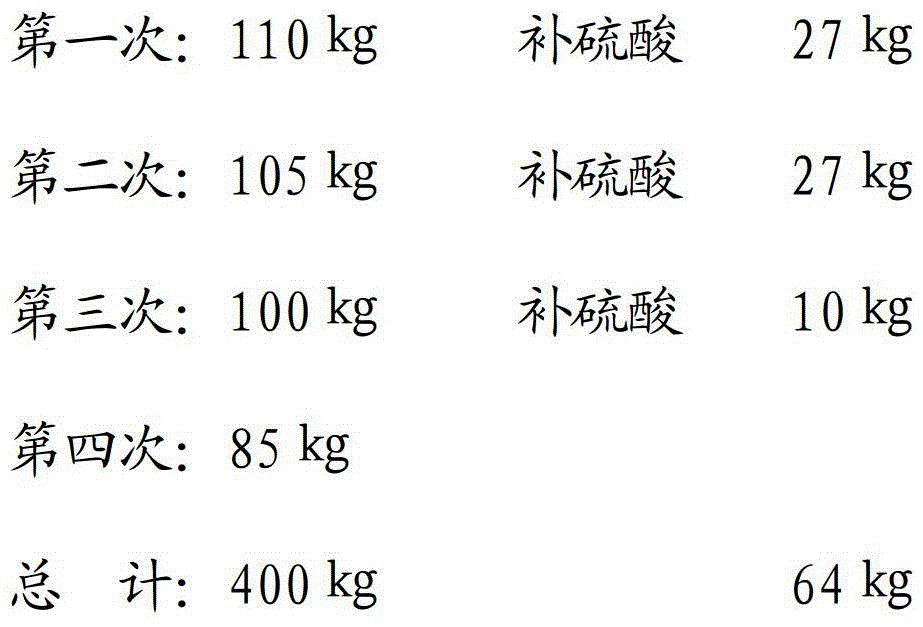

A kind of method for synthesizing clean production of metronidazole crude drug

ActiveCN104177297BReduce pollutionRealize cleaner productionOrganic chemistryWater/sewage treatment by neutralisationOrganic synthesisSewage treatment

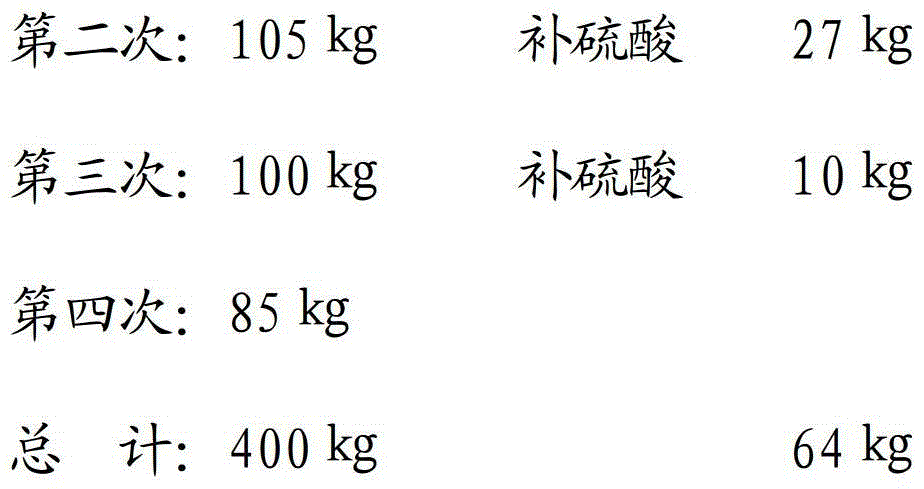

The invention relates to a clean production method for synthesizing metronidazole, and belongs to the field of the organic synthesis of drugs. The method comprises the following steps: 1, utilizing a neutralizing second mother liquor (with the pH value of 10.5-11.0) in a metronidazole synthesis process to substitute a 30% sodium hydroxide solution to be used in a neutralization reaction of a metronidazole hydroxylation liquid; and 2, carrying out concentrated recovery on the above finally obtained metronidazole production mother liquor before emission, neutralizing the mother liquor by sulfuric acid until the pH value is 5.0-6.0, allowing the neutralized solution to stand for above 6h, centrifuging to obtain a nitro substance, and sending the recovered mother liquor to a sewage treatment station. About 200kg of the 30% sodium hydroxide solution is saved each batch, the emission of the neutralizing second mother liquor (with the pH value of 10.5-11.0) is reduced, cycle production is formed, the environmental protection throughput is reduced, and the production cost is reduced. The wet product of the recovered nitro substance in each batch is about 18kg, so the production cost is reduced, and the environmental protection throughout is reduced.

Owner:DONGGANG HONGDA PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com