Method for recycling and circulating production of waste SCR denitration catalyst

A denitrification catalyst and catalyst technology, applied in the direction of improving process efficiency, can solve problems such as rising costs, poor bargaining power of buyers, unfavorable cost control, etc., and achieve the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

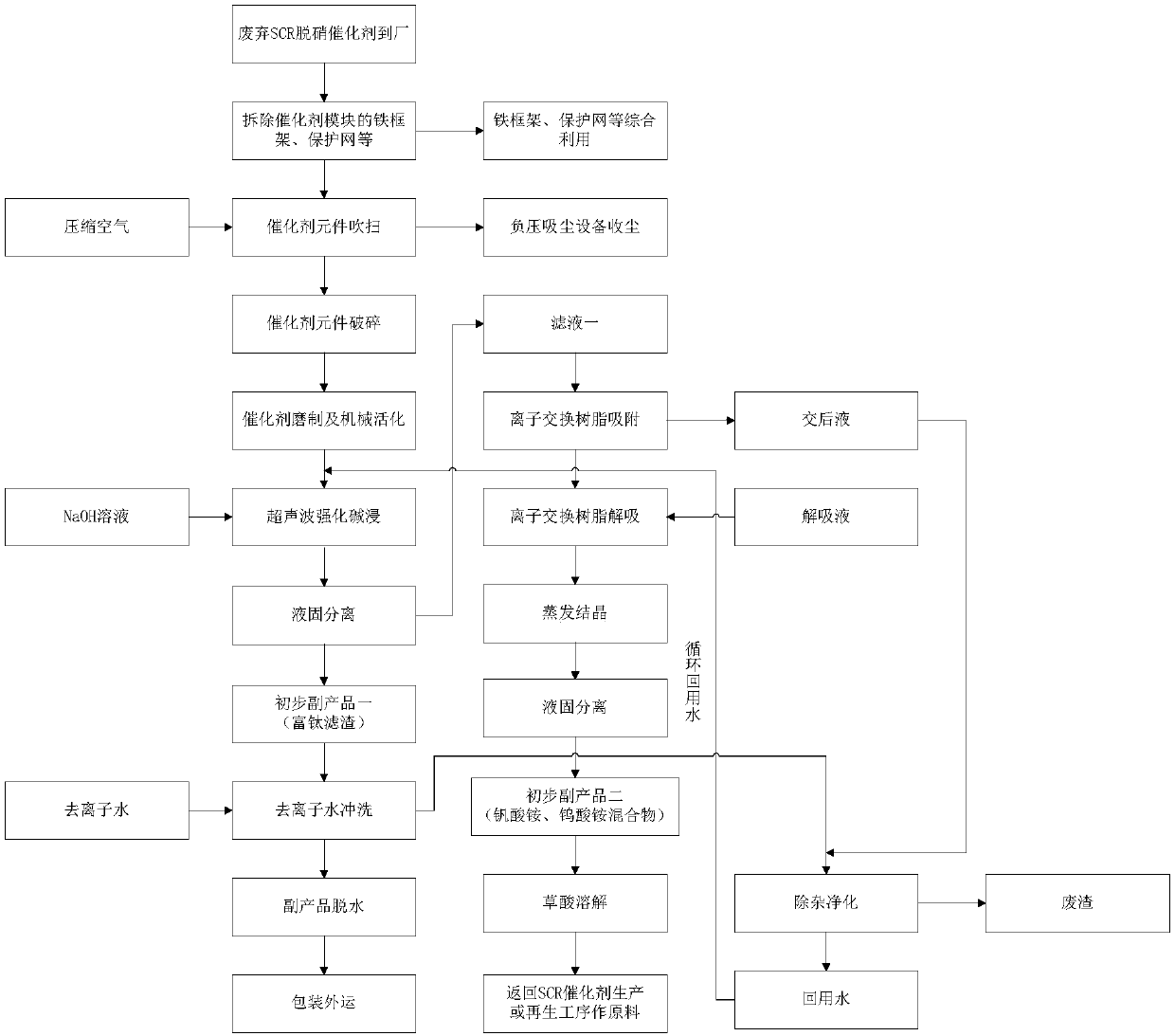

Method used

Image

Examples

Embodiment 1

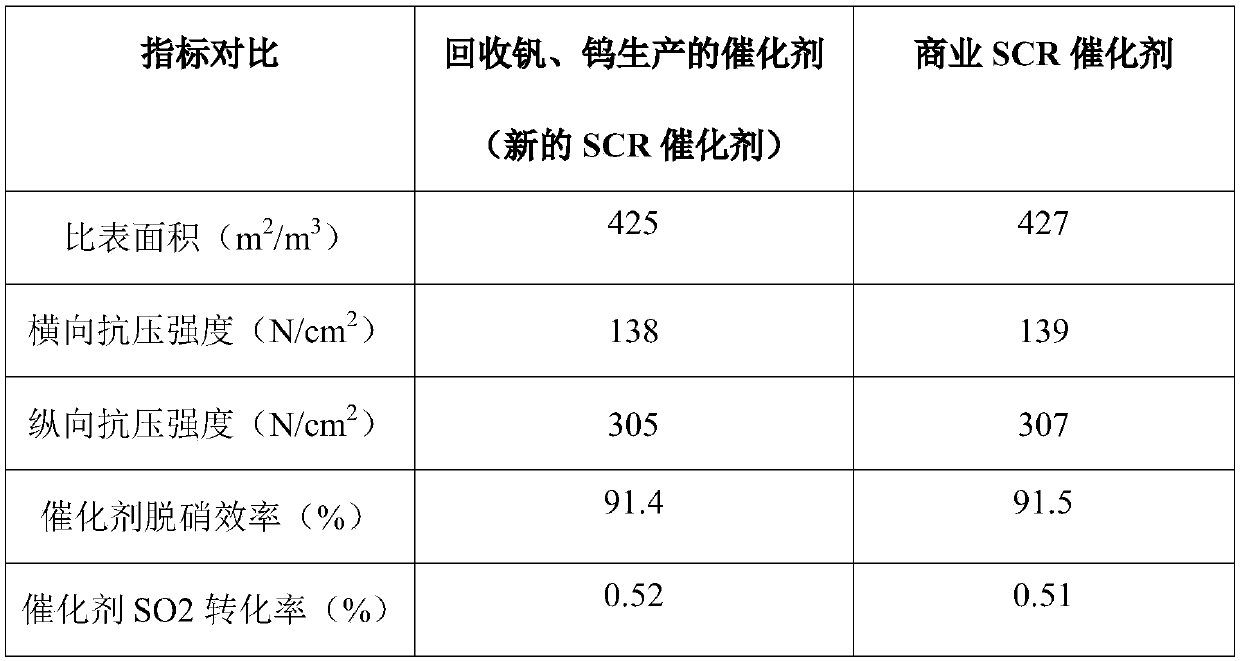

[0028] Take 500g of discarded SCR catalyst, remove, crush, and grind it into a 60-micron powder, add it to 3.5L NaOH solution with a concentration of 1.0mol / L, control the leaching temperature at 80°C, and leaching time for 0.5h. The pressure is controlled at 0.5MPa, the frequency of ultrasonic waves is controlled at 50kHz, and then liquid-solid separation is carried out. Vanadium, tungsten and other impurities enter the liquid in the form of ions, and the pH value of the filtrate is adjusted between 8.5 and 10.5. After stirring fully, let it stand for 6 hours. Liquid-solid separation and impurity removal. Use a strong basic large channel anion exchange resin to adsorb vanadium and tungsten ions, and then add a mixed solution of ammonia water and ammonium chloride for desorption, in which NH 4 The concentration of Cl is 4mol / L, NH 4 The concentration of OH is 2mol / L, and the desorption temperature is 50°C; the desorption liquid is crystallized, and the crystallization tempera...

Embodiment 2

[0030] Take 500g of discarded SCR catalyst, remove, crush, and grind it into a 60-micron powder, add it to 3.5L NaOH solution with a concentration of 1.0mol / L, control the leaching temperature at 80°C, and leaching time for 0.5h. The pressure is controlled at 0.5MPa, and the ultrasonic frequency is controlled at 50kHz. Then carry out liquid-solid separation, vanadium, tungsten and other impurities enter the liquid in the form of ions, adjust the pH value of the filtrate between 8.5 and 10.5, stir fully and let it stand for 5 hours, liquid-solid separation and removal of impurities. Use a strong basic large channel anion exchange resin to adsorb vanadium and tungsten ions, and then add a mixed solution of ammonia water and ammonium chloride for desorption, in which NH 4 The concentration of Cl is 5mol / L, NH 4 The concentration of OH is 1mol / L, and the desorption temperature is 50°C; the desorption liquid is crystallized, and the crystallization temperature is 90°C. 62.4 g of ...

Embodiment 3

[0032]Take 500g of discarded SCR catalyst, remove, crush, and grind it into a 60-micron powder, add it to 3.5L NaOH solution with a concentration of 1.0mol / L, control the leaching temperature at 80°C, the leaching time is 1h, and the leaching pressure Controlled at 0.5MPa, ultrasonic frequency controlled at 50kHz. Then carry out liquid-solid separation, vanadium, tungsten and other impurities enter the liquid in the form of ions, adjust the pH value of the filtrate between 8.5 and 10.5, stir fully and let it stand for 4 hours, liquid-solid separation and removal of impurities. Use a strong basic large channel anion exchange resin to adsorb vanadium and tungsten ions, and then add a mixed solution of ammonia water and ammonium chloride for desorption, in which NH 4 The concentration of Cl is 5mol / L, NH 4 The concentration of OH is 1mol / L, and the desorption temperature is 60°C; the desorption solution is crystallized, and the crystallization temperature is 90°C. 60.4 g of obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com