Offline and online integrated jet-printing system of printed circuit board

A printed circuit board, integrated technology, applied in the direction of printed circuit, printed circuit manufacturing, printing, etc., can solve the problems of low degree of automation, long time consumption, and inability to clean nozzles at the same time, so as to improve work efficiency and high degree of automation , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

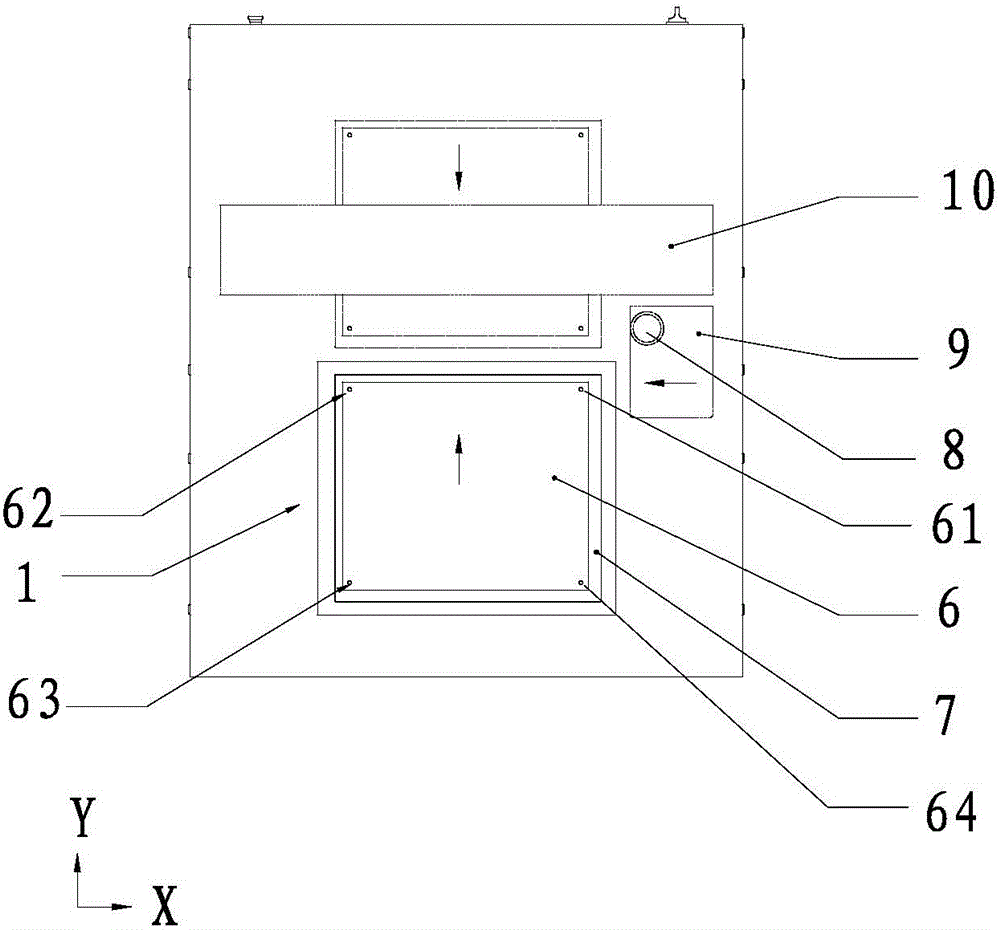

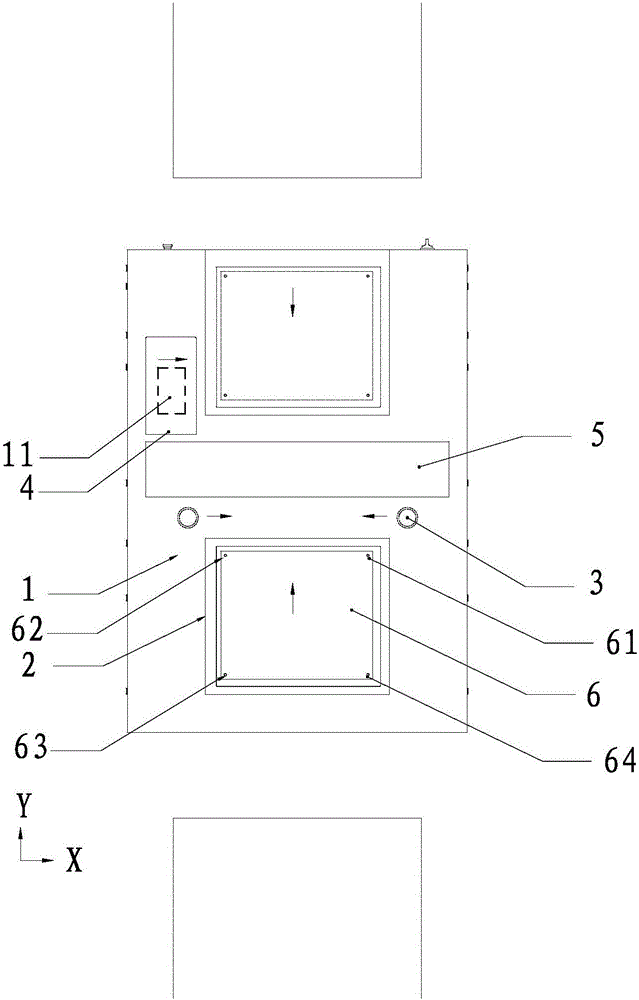

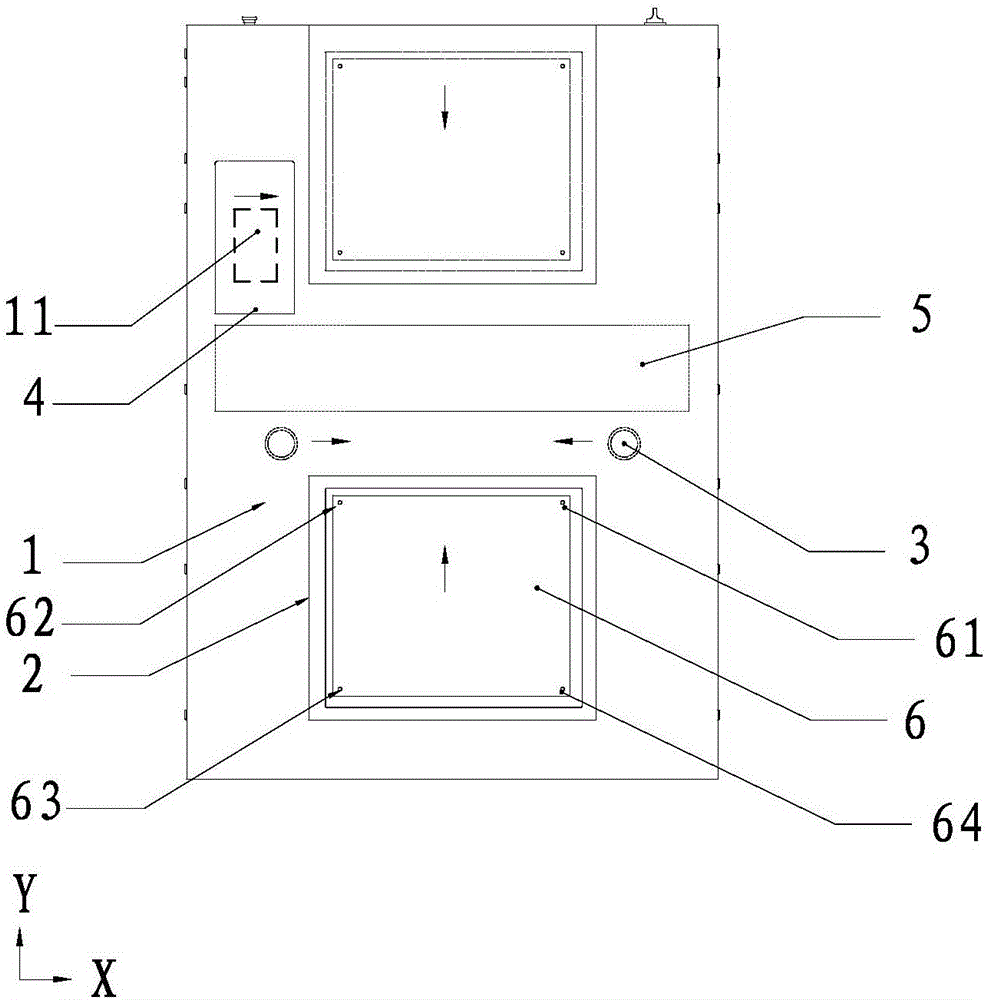

[0024] like figure 2 , image 3 As shown, an off-line and on-line integrated printing system for printed circuit boards includes a horizontally placed substrate 1, a mobile operating platform 2, two image capture devices 3, a mobile printing curing device 4, and a nozzle cleaning device 11 and Longmen 5.

[0025] The mobile operating platform is movably installed on the base plate, and the moving track of the mobile operating platform is ±Y direction; the gantry is fixed on the base plate, and the gantry fixing direction is X direction, and the gantry is fixed on the mobile The motion trajectory of the operating platform is on the line. The front side of the gantry is provided with two image capture devices that can move independently in ±X directions, and the position of the image capture devices is higher than the mobile operating platform. The rear side of the gantry is provided with a mobile jet printing curing device that can move independently in the ±X direction. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com