Alkali spraying system and operation method thereof

An operation method, alkali spraying technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as easy blockage, lime milk is difficult to dissolve in water, etc., improve absorption efficiency, prevent system blockage, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

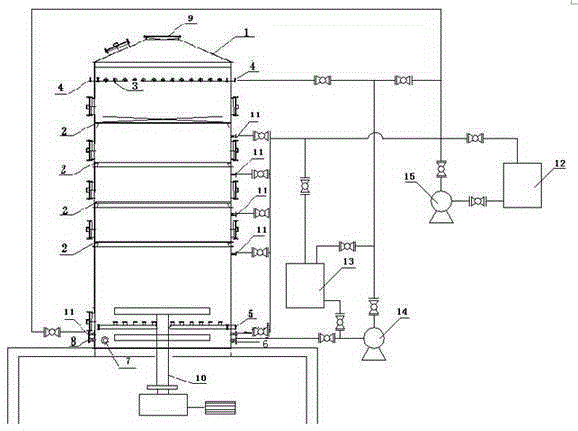

[0036] An alkali spray system, comprising a spray tower, a flushing water tank, a high-pressure water pump, an alkali spray circulation pump and an agitator, the alkali liquor inlet of the spray tower is connected to the flushing water tank through a high-pressure water pipe, and the high-pressure water pump is arranged at a high pressure On the water pipe, an alkali spray circulating pump is arranged on the connecting pipe between the alkali liquor inlet and the alkali liquor outlet, and the blades of the agitator are arranged at the bottom of the spray tower.

Embodiment 2

[0038] An alkali spray system, comprising a spray tower, a flushing water tank, a high-pressure water pump, an alkali spray circulation pump and an agitator, the alkali liquor inlet of the spray tower is connected to the flushing water tank through a high-pressure water pipe, and the high-pressure water pump is arranged at a high pressure On the water pipe, an alkali spray circulating pump is arranged on the connecting pipe between the alkali liquor inlet and the alkali liquor outlet, and the blades of the agitator are arranged at the bottom of the spray tower.

[0039] The agitator is a double-layer three-blade back-swept agitator, the upper blades are arranged above the air inlet of the spray tower, and the lower blades are arranged below the air inlet of the spray tower.

Embodiment 3

[0041] An alkali spray system, comprising a spray tower, a flushing water tank, a high-pressure water pump, an alkali spray circulation pump and an agitator, the alkali liquor inlet of the spray tower is connected to the flushing water tank through a high-pressure water pipe, and the high-pressure water pump is arranged at a high pressure On the water pipe, an alkali spray circulating pump is arranged on the connecting pipe between the alkali liquor inlet and the alkali liquor outlet, and the blades of the agitator are arranged at the bottom of the spray tower.

[0042] The agitator is a double-layer three-blade back-swept agitator, the upper blades are arranged above the air inlet of the spray tower, and the lower blades are arranged below the air inlet of the spray tower.

[0043] The lower blades are installed at 0.5 meters from the bottom of the tower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com