A method for brewing liquid vinegar using vinegar residue and vinegar precipitation

A technology of vinegar residue and liquid state, which is applied in the field of vinegar preparation technology, can solve problems such as environmental pollution and solid waste treatment difficulties, and achieve the effects of reducing production costs, bright yellow color, and strong competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

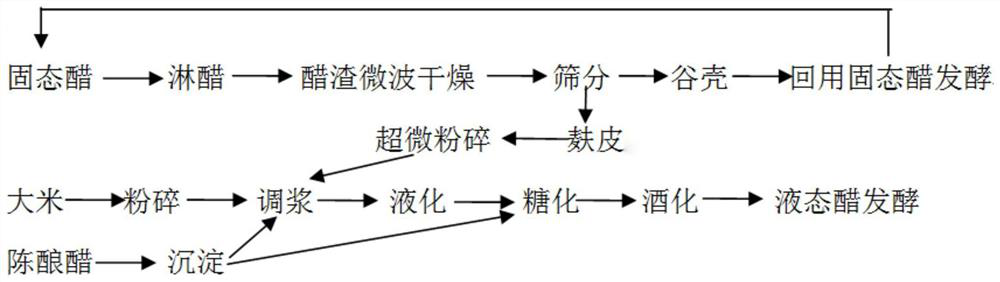

[0034] Such as figure 1 Shown, a kind of method of the present invention utilizes vinegar dregs, vinegar precipitation to brew liquid vinegar, comprises the following steps:

[0035] 1. Raw material processing: the first is the treatment of vinegar residue: after the fermentation of solid-state vinegar, the vinegar in the vinegar residue is drenched with water first, and the residue is dried at 120° C. for 20 seconds by a tunnel-type continuous microwave drier until the moisture is 50% (moisture is too high). Vibrating sieve in the high-impact stage separates chaff and bran), and then sieves bran and chaff through a vibrating sieve, and the bran is pulverized by an ultrafine pulverizer to a fineness of 300 mesh (the purpose of pulverization is to make the bran particles smaller and the fiber Tissue is destroyed, easy to liquefy), and then go to pulp and liquefy, and the chaff returns to ferment again; the second is aging solid vinegar precipitation treatment: after aging solid...

Embodiment 2

[0042] Such as figure 1 Shown, a kind of method of the present invention utilizes vinegar dregs, vinegar precipitation to brew liquid vinegar, comprises the following steps:

[0043] 1. Raw material processing: the first is the treatment of vinegar residue: after the fermentation of solid-state vinegar, the vinegar in the vinegar residue is drenched with water first, and the residue is dried at 120° C. for 20 seconds by a tunnel-type continuous microwave drier until the moisture is 50% (moisture is too high). Vibrating sieve in the high-impact stage separates the chaff and bran), and then sieves the bran and chaff through a vibrating sieve, and the bran is pulverized by an ultrafine pulverizer to a fineness of 400 mesh (the purpose of pulverization is to make the bran particles smaller and the fiber Tissue is destroyed, easy to liquefy), and then go to pulp and liquefy, and the chaff returns to ferment again; the second is aging solid vinegar precipitation treatment: after agi...

Embodiment 3

[0050] Such as figure 1 Shown, a kind of method of the present invention utilizes vinegar dregs, vinegar precipitation to brew liquid vinegar, comprises the following steps:

[0051] 1. Raw material processing: the first is the treatment of vinegar residue: after the fermentation of solid-state vinegar, the vinegar in the vinegar residue is drenched with water first, and the residue is dried at 120° C. for 20 seconds by a tunnel-type continuous microwave drier until the moisture is 50% (moisture is too high). The high-impact post-stage vibrating sieve separates the chaff and bran), and then sieves the bran and chaff through a vibrating sieve. Tissue is destroyed, easy to liquefy), and then go to pulp and liquefy, and the chaff returns to ferment again; the second is aging solid vinegar precipitation treatment: after aging solid vinegar, first extract the upper 98% of the clear liquid, and the remaining 2% of the sediment (PH3.0, total acid 6.0g / 100ml) for subsequent use; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com