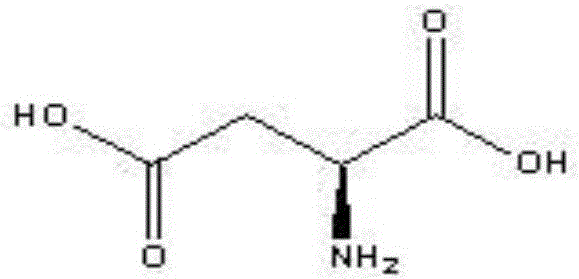

Method for preparing L-aspartic acid and L-alanine by using maleic anhydride

A technology of aspartic acid and alanine, applied in the direction of fermentation, can solve the problems of inability to further reduce costs, high production costs and high technical requirements, and achieve the effects of product diversification, good product quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 L-aspartic acid

[0041] 1) Maleic anhydride and pure water were stirred and dissolved in a 60°C water bath, and prepared into a maleic acid solution with a concentration of 60% for later use.

[0042] 2) Add the maleic acid solution obtained in step 1) into a 50L enzyme reaction kettle, adjust the reaction temperature to 40°C, adjust the pH value with 30% ammonia water, and control it at 7.0-9.0, as the reaction substrate. Calculated according to the volume of the reaction substrate, add 8% maleate isomerase enzyme solution and 10% L-aspartase enzyme solution to react, react at 40°C for 12h, and heat the conversion solution at the end of the reaction to 80°C Keep it for 30min.

[0043] 3) The enzyme reaction liquid obtained in step 2) is filtered with a ceramic membrane with a pore size of 0.05-0.2 μm, the membrane inlet pressure is 0.3 MPa, the membrane outlet pressure is 0.15 MPa, and the operating temperature is 60° C., and the filtr...

Embodiment 2

[0049] The preparation of embodiment 2 L-aspartic acid

[0050] 1) Maleic anhydride and pure water were stirred and dissolved in a water bath at 60°C, and prepared into a maleic acid solution with a concentration of 15% for later use.

[0051] 2) Add the maleic acid solution obtained in step 1) into a 50L enzyme reaction kettle, adjust the reaction temperature to 40°C, adjust the pH value with 30% ammonia water, and control it at 7.0-9.0, as the reaction substrate, calculated according to the volume of the reaction substrate, Calculated according to the volume of the reaction substrate, add 10% maleate isomerase enzyme solution and 15% L-aspartase enzyme solution respectively for reaction, react at 40°C for 10h, and heat the conversion solution at the end of the reaction to 105°C. Keep for 30min to inactivate.

[0052] 3) The enzyme reaction solution obtained in step 2) is filtered with a ceramic membrane with a pore size of 0.05-0.2 μm, the membrane inlet pressure is 0.2 MPa...

Embodiment 3

[0058] The preparation of embodiment 3 L-aspartic acid

[0059] 1) Maleic anhydride and pure water were stirred and dissolved in a 60°C water bath, and prepared into a maleic acid solution with a concentration of 60% for later use.

[0060] 2)) Add the maleic acid solution obtained in step 1) into a 50L enzyme reactor, adjust the reaction temperature to 40°C, adjust the pH value with 30% ammonia water, and control it at 7.0-9.0, as the reaction substrate, calculated according to the volume of the reaction substrate According to the volume of the reaction substrate, add 8% maleate isomerase enzyme solution and 10% L-aspartase enzyme solution to react, react at 40°C for 16h, and heat the conversion solution at the end of the reaction to 90°C And maintain 60min inactivation.

[0061] 3) The enzyme reaction solution obtained in step 2) is filtered with a ceramic membrane with a pore size of 0.05-0.2 μm, the membrane inlet pressure is 0.3 MPa, the membrane outlet pressure is 0.2 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com