Method for separating high-concentration K2Cr2O7 from saturated NaCl solution

A k2cr2o7, high-concentration technology, applied in the direction of chromate/dichromate, etc., to achieve the effect of good separation, simple device and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

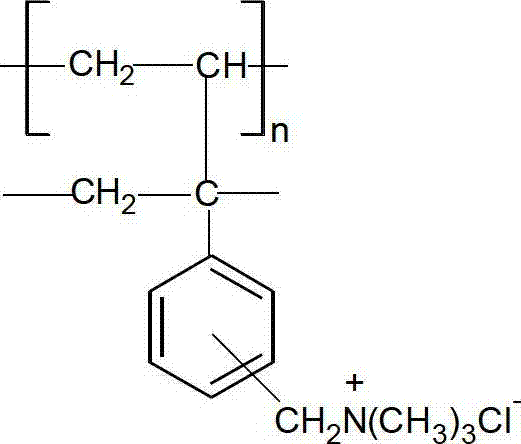

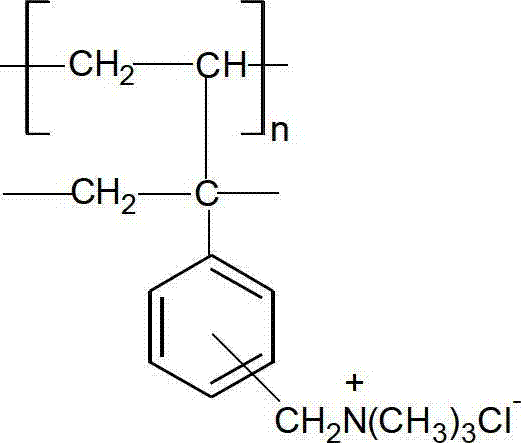

Image

Examples

Embodiment 1

[0021] Before separation, the strongly basic anion exchange fiber is transformed by soaking in a solution for a soaking time ≥ 6 hours; the solution is a 0.5-10mol / L HCl solution.

[0022] Will K 2 Cr 2 o 7 - The mixed solution of NaCl passes through the strong basic anion exchange fiber column at a flow rate of 0.4300mL / min (10.0BV / h). In the mixed solution, K 2 Cr 2 o 7 The concentration of NaCl is 2.148g / L, NaCl is a saturated solution, and the pH value is adjusted to 2.06; the column is equipped with a strong basic anion exchange fiber with a dry weight of 0.50g, and the column is wet-packed. The column diameter is 10.0mm and the height is 3.2cm.

[0023] At the start of the separation, the effluent was a saturated NaCl solution containing KCl. When the volume of the effluent was 17.08mL, the concentration of Cr(VI) in the column effluent was still 0g / L, and the penetration rate of Cr(VI) was 0. With the increase of the volume of effluent, the concentration of Cr(Ⅵ)...

Embodiment 2

[0025] Before separation, the strongly basic anion exchange fiber is transformed by soaking in a solution for a soaking time of ≥6 hours; the solution is a 0.5-10mol / L NaCl solution.

[0026] Will K 2 Cr 2 o 7 - The mixed solution of NaCl passes through the strong basic anion exchange fiber column at a flow rate of 0.4300mL / min (10.0BV / h). In the mixed solution, K 2 Cr 2 o 7 The concentration of NaCl is 3.866g / L, NaCl is a saturated solution, and the pH value is adjusted to 4.06; the column is equipped with strong basic anion exchange fibers with a dry weight of 0.50g, and the column is wet-packed. The column diameter is 10.0mm and the height is 3.2cm.

[0027] At the beginning of the separation, the effluent was a saturated solution of NaCl containing KCl. When the volume of the effluent is 6.76 mL, the concentration of Cr(VI) in the column effluent is 0 mg / L, and the penetration rate of Cr(VI) is 0. As the volume of the effluent increases, the concentration of Cr(VI) ...

Embodiment 3

[0029]Before separation, the strongly basic anion exchange fiber is transformed by soaking in a solution for a soaking time of ≥6 hours; the solution is a 0.5-10mol / L NaCl solution.

[0030] Will K 2 Cr 2 o 7 - The mixed solution of NaCl passes through the strong basic anion exchange fiber column at a flow rate of 1.005mL / min (10.0BV / h). In the mixed solution, K 2 Cr 2 o 7 The concentration of NaCl is 4.912g / L, NaCl is a saturated solution, and the pH is adjusted to 1.00; the column is equipped with a strong basic anion exchange fiber with a dry weight of 1.00g, and the column is wet-packed. The column diameter is 10.0mm and the height is 8.0cm.

[0031] At the beginning of the separation, the effluent was a saturated solution of NaCl containing KCl. When the volume of the effluent is 24.00 mL, the concentration of Cr(VI) in the column effluent is 0 mg / L, and the penetration rate of Cr(VI) is 0. As the volume of the effluent increases, the concentration of Cr(Ⅵ) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com