Circulatory carpet forming production line

A production line and carpet technology, applied in carpets and other directions, can solve the problems of high energy consumption and low carpet production efficiency, and achieve the effects of improving production efficiency, flexible use and reducing waiting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing implementation:

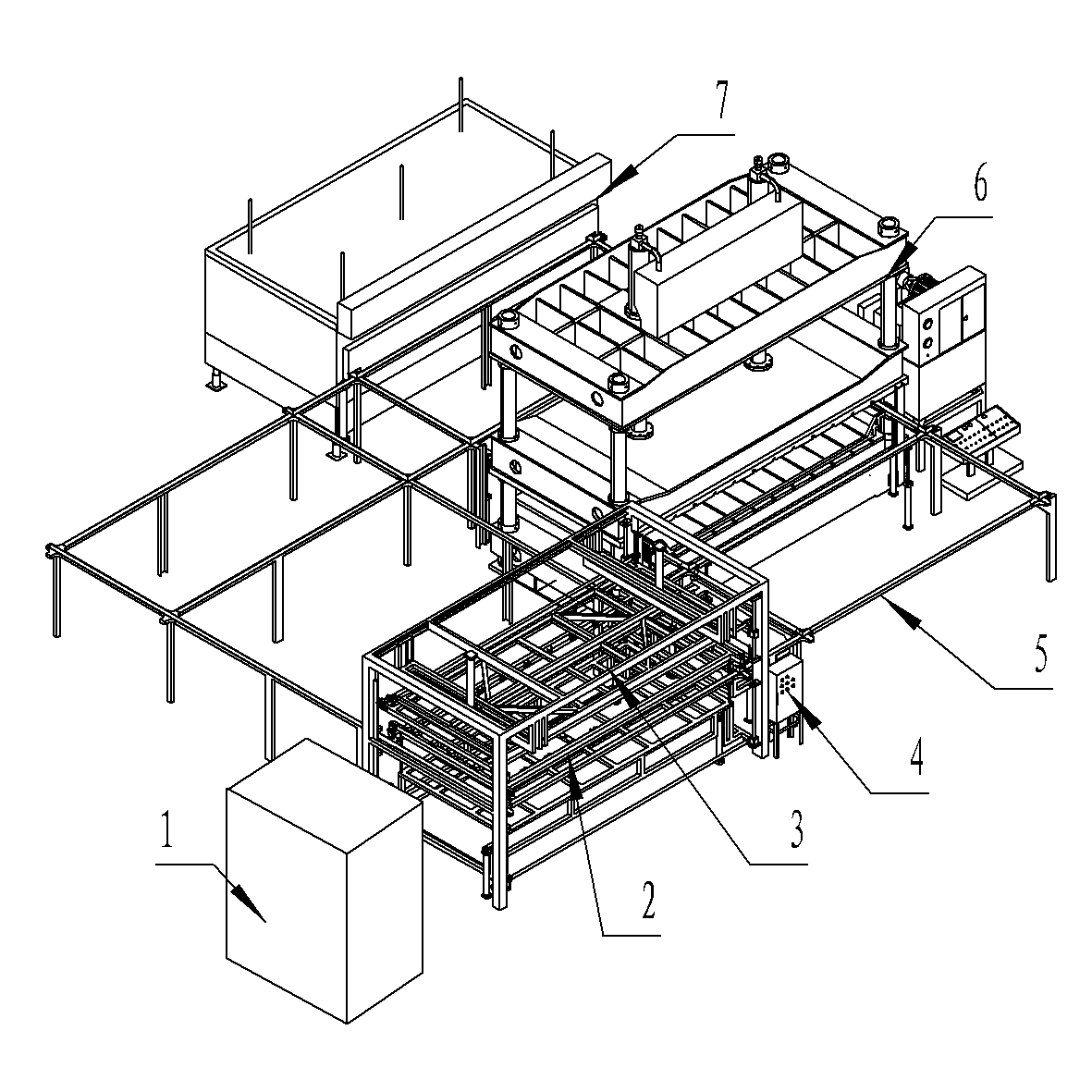

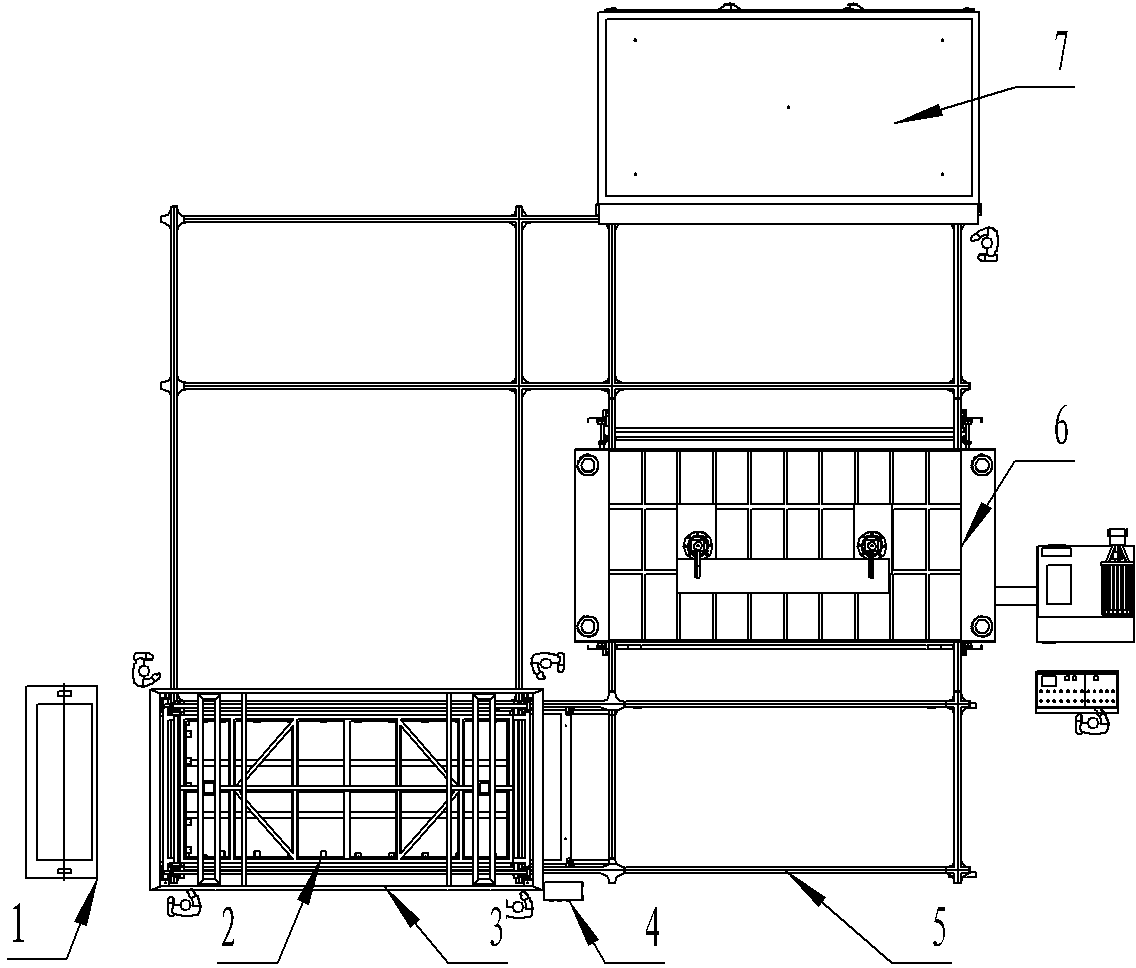

[0015] Figure 1 to Figure 4 The carpet forming cycle production line shown includes a cutting device 1, an oven 7 and a forming device 6, and three transfer vehicles 2 running on guide rails 5. In the figure, only one transfer vehicle 2 is shown in the production line and it is in a loading state. There is also a loading and unloading device 3 arranged beside the cutting device 1 for loading and unloading materials of the transfer vehicle 2; the guide rail 5 passes through the loading and unloading device 3 and the forming device 6; the forming device 6 is a four-column hydraulic press; 1 and oven 7.

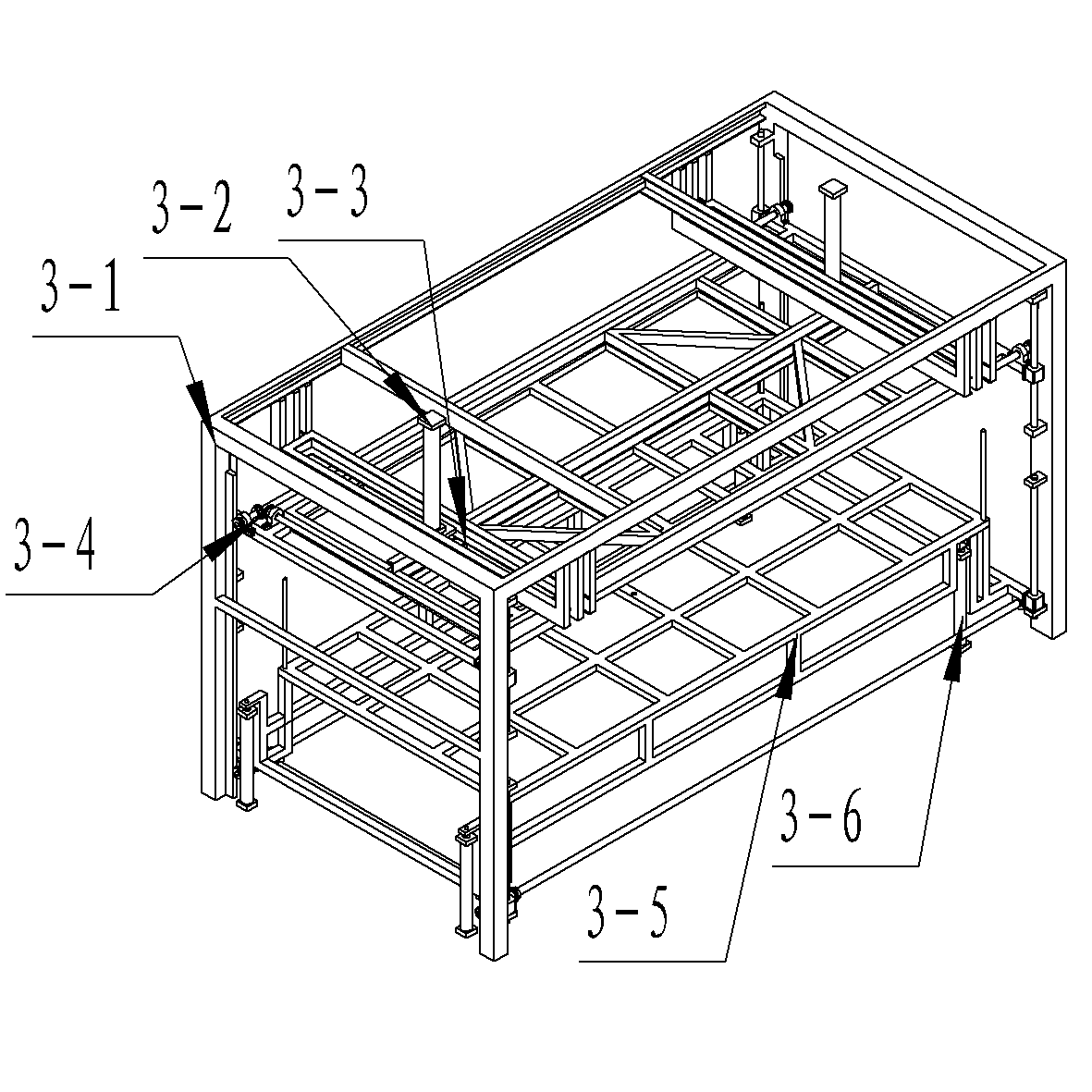

[0016] The loading and unloading device 3 includes an upper pressing frame 3-3 that is movably installed on the top of the skeleton main body 3-1 and a lower pressing frame 3-5 installed on the lower part of the skeleton main body 3-1; the upper pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com