Patents

Literature

54results about How to "Reduce equipment energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

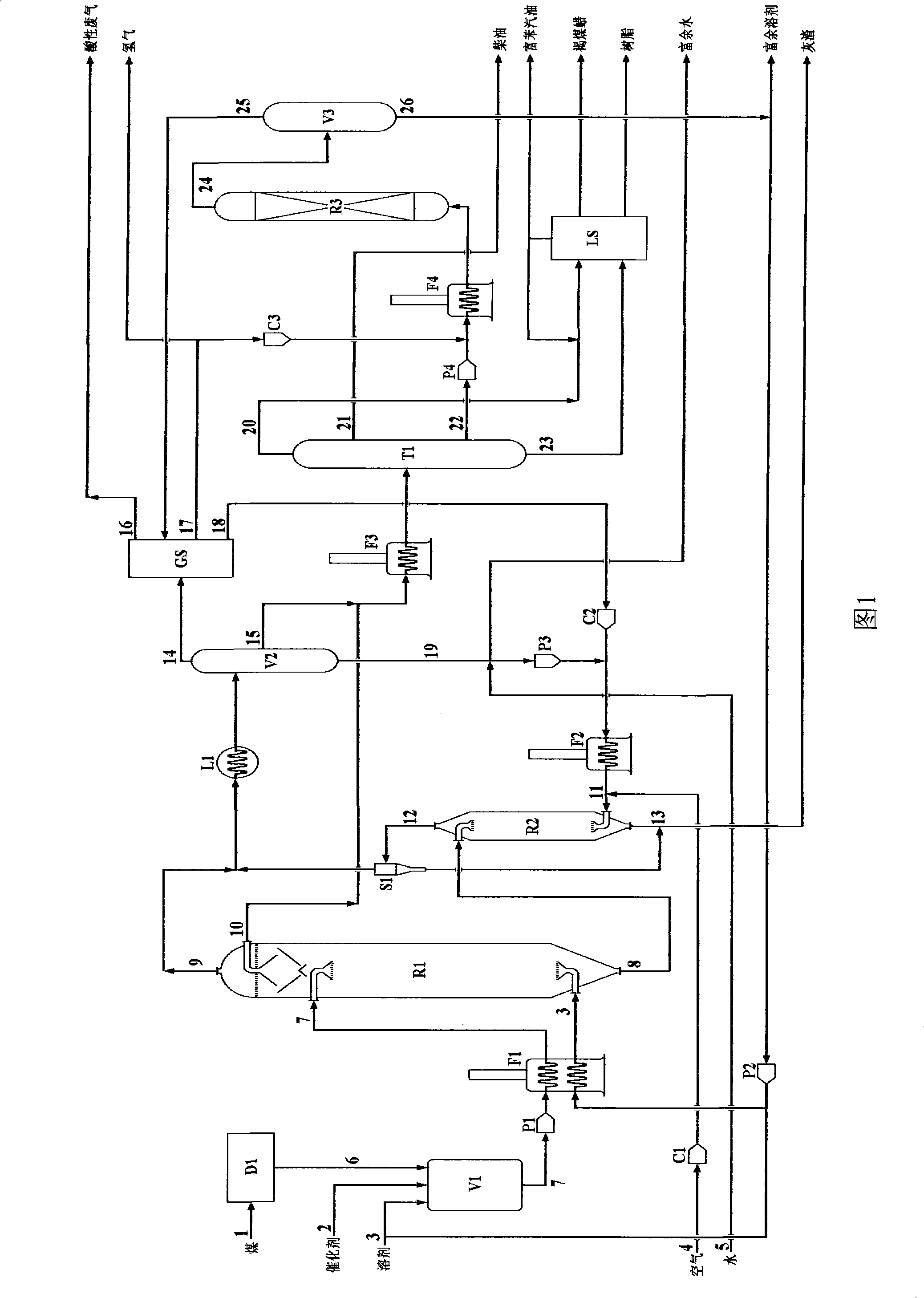

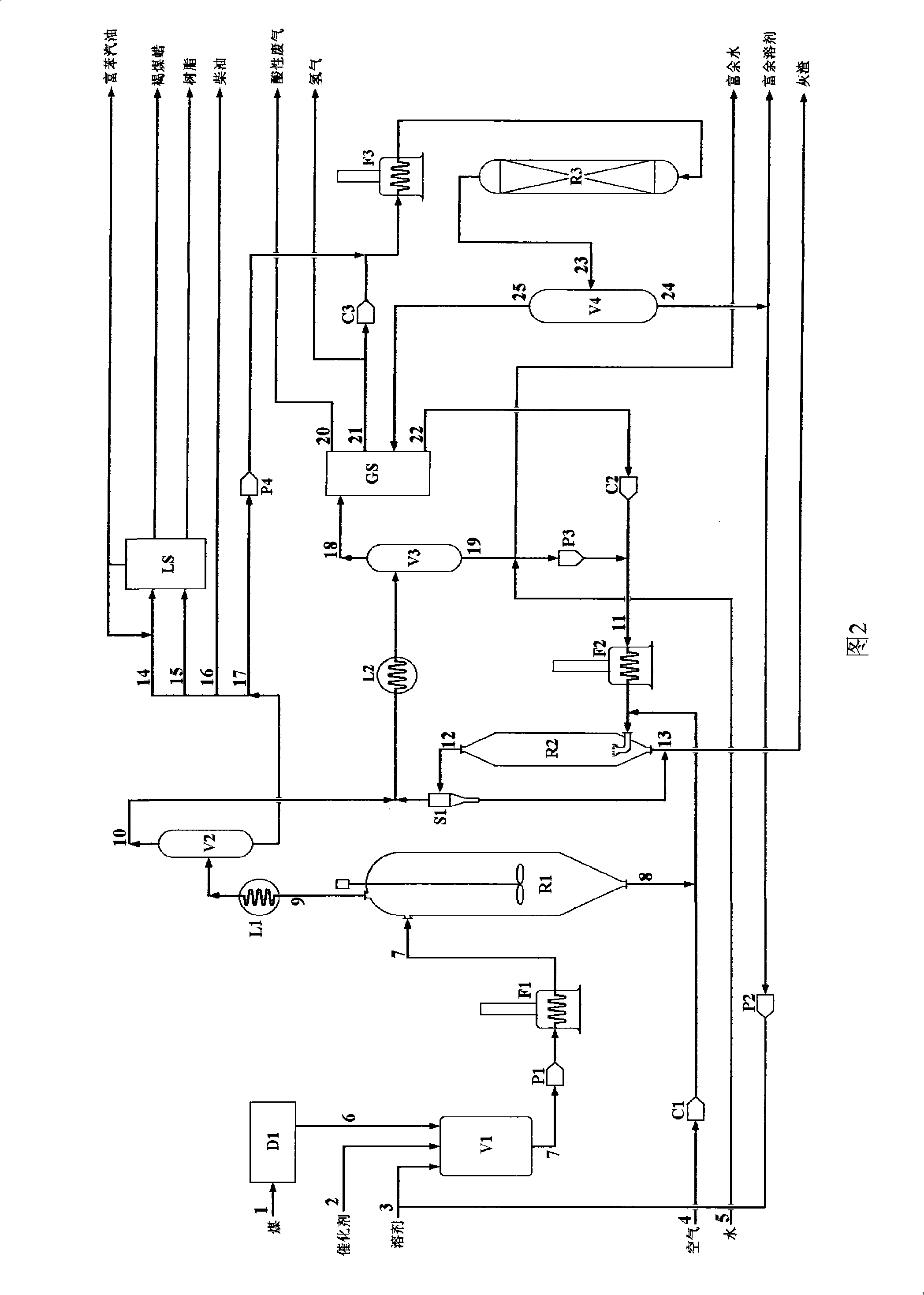

Method for direct liquefaction and comprehensive utilization of ravens

ActiveCN101280207AImprove resource utilization efficiencyLow equipment requirementsHydrogenLiquid hydrocarbon mixture productionLiquid productHydrogen

The invention discloses a method of direct liquefaction of the lean coal and comprehensive utilization. The method includes that under mild condition, proper catalyst and hydrogen-donor solvent are used; the feed coal is processed with liquefaction reaction under the situation that the gas hydrogen is not adopted; the main product is liquid fuel and the by products include montan wax, resin and organic compounds with high values; meanwhile, the liquefaction generation water, the generation gas and the non-transformed residual coal can be used to produce liquid products; the liquid products can be processed with hydro-grading to obtain needed hydrogen; the method of direct liquefaction of the lean coal and comprehensive utilization not only can reduce the device requirement and the energy consumption of the coal liquefaction technique, but also can improve the resource utilization benefits of the lean coal greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

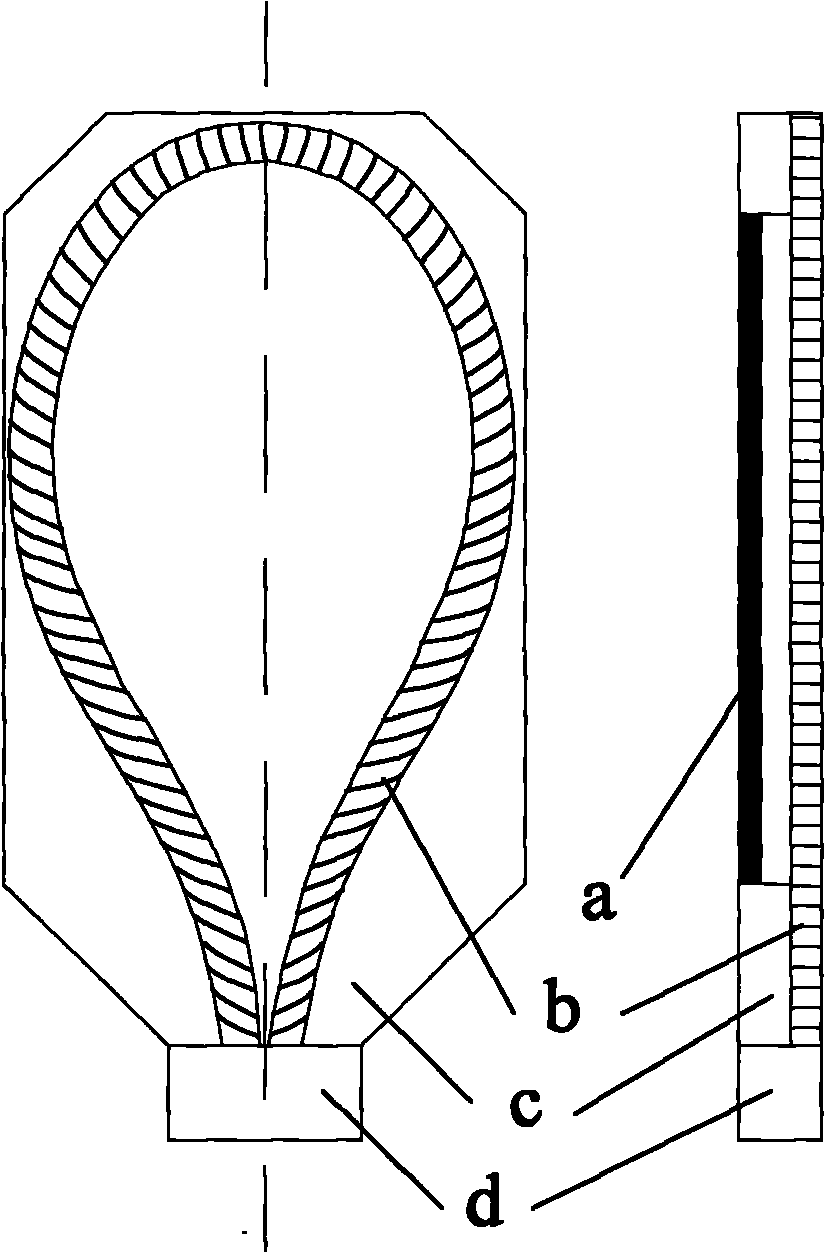

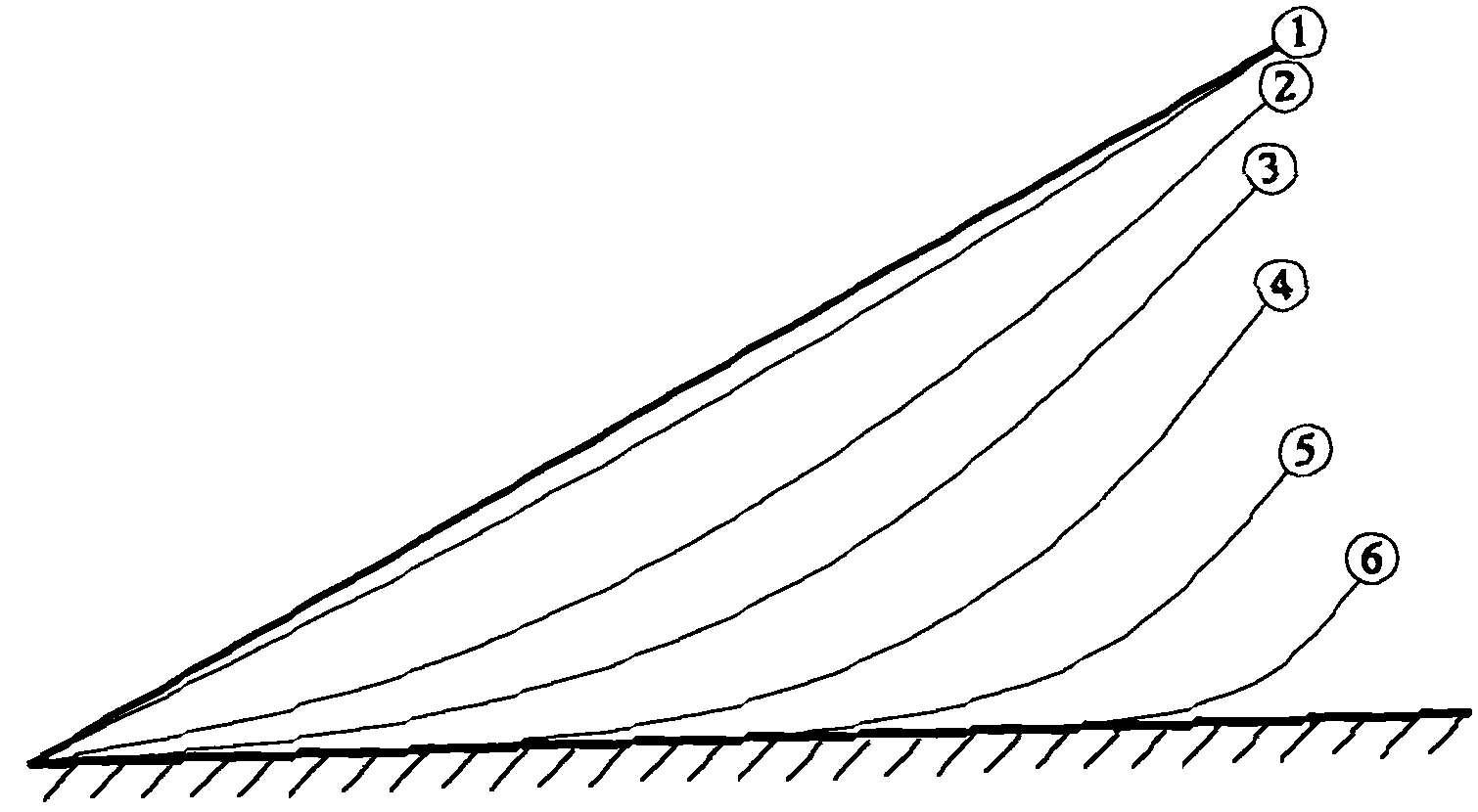

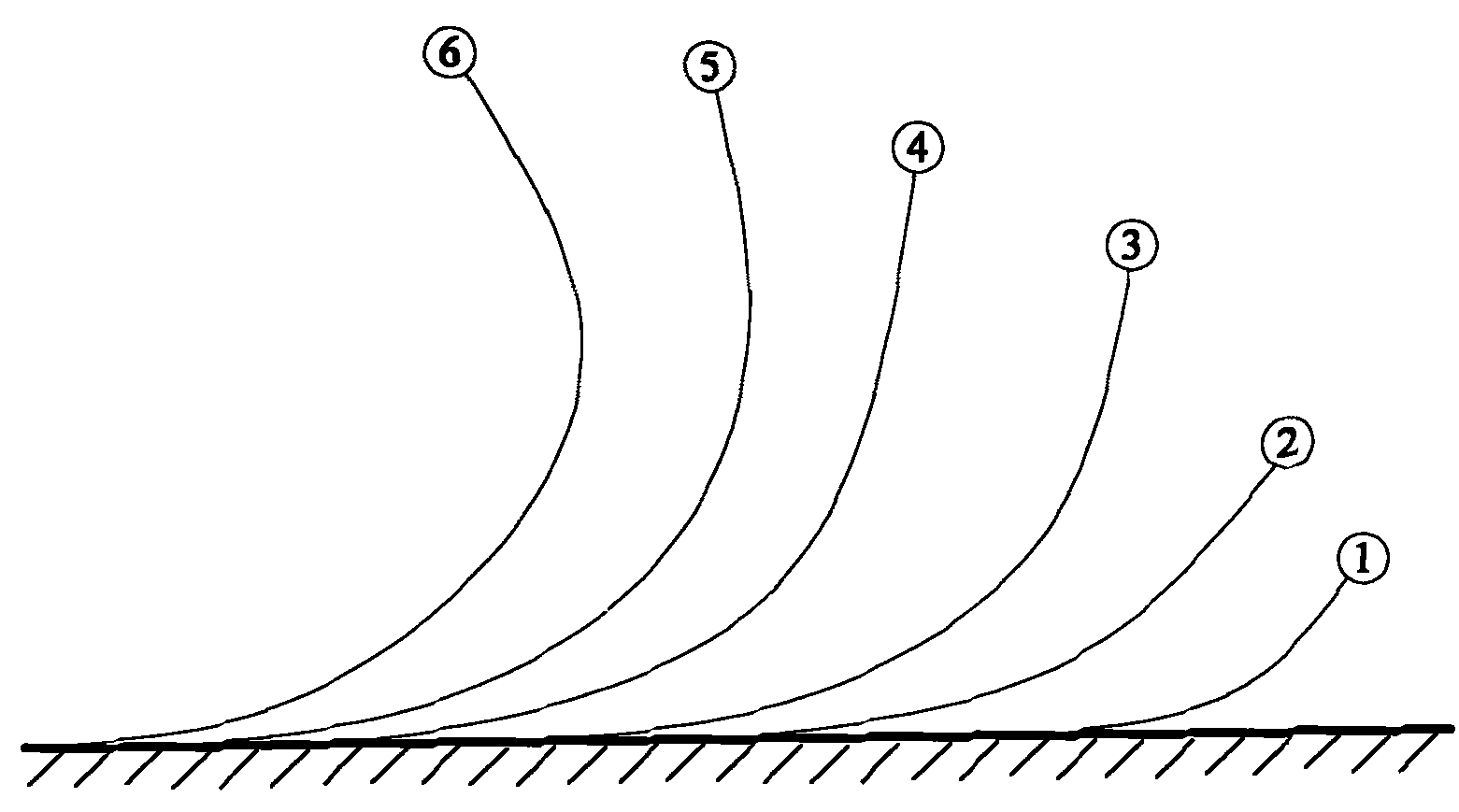

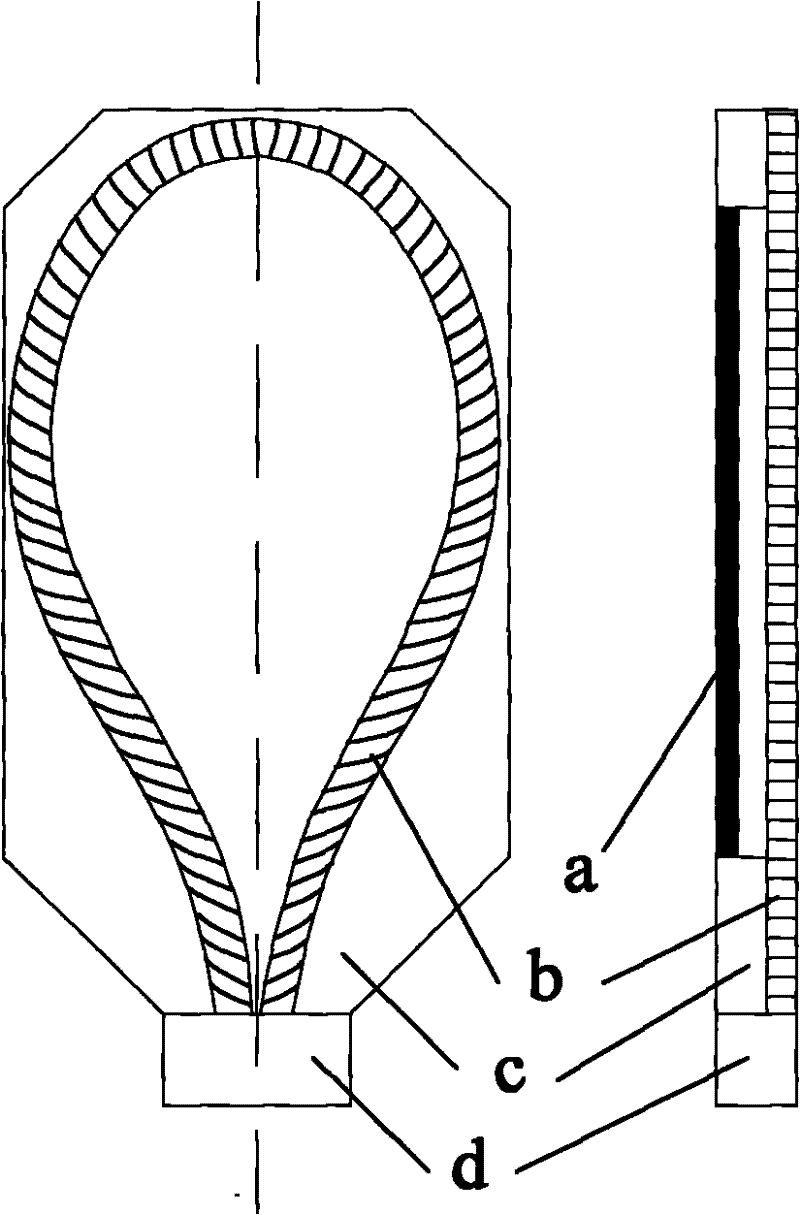

Adhesive toe for gecko robot and movement method thereof

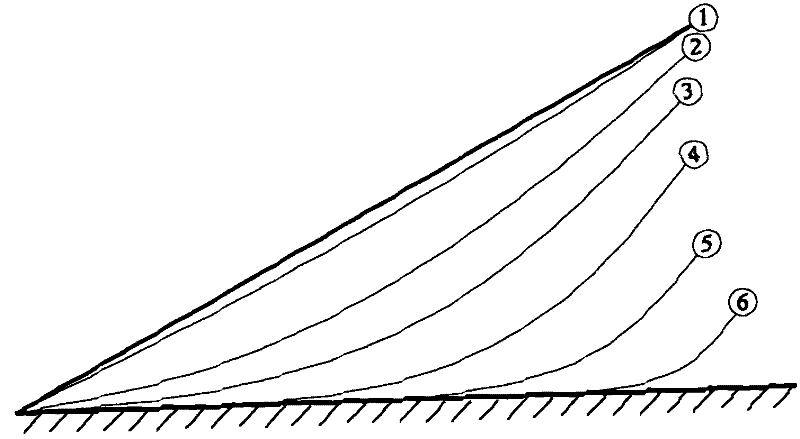

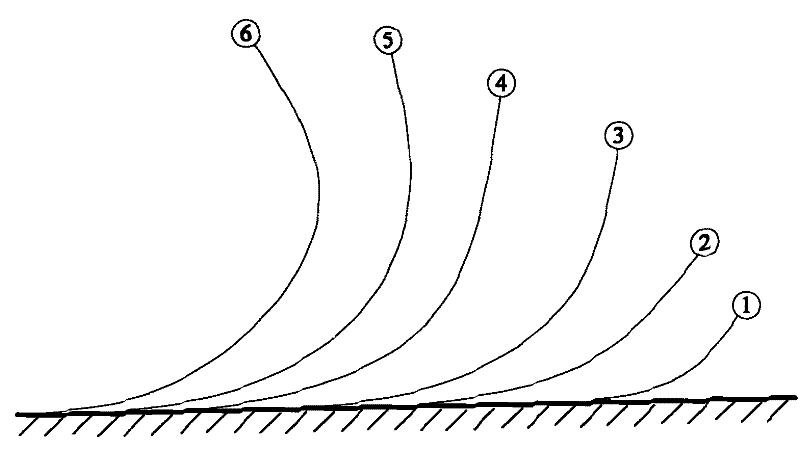

The invention relates to an adhesive toe for a gecko robot and a movement method thereof and belongs to the field of technical application of biomorphic robots. The toe comprises a flexible material toe base (c) and a sticky material layer (a) which is embedded into the flexible material toe base (c), wherein the height of the lower bottom surface of the sticky material layer (a) is equal to that of the flexible material toe base (c); and a spring layer (b) is also formed on the flexible material toe base (c). The toe has three specific structures, namely flat-shaped, semi-arc and arched stereo structures with bending of 180 degrees. According to the characteristic of a special cantilever type structure, the driven mode is adopted, so that the characteristics that the toe has the larger adhesion in one direction and the smaller desorption force in the negative direction are provided, and the mechanical anisotropy characteristics that a gecko has the larger adhesion in the one direction and the smaller desorption force in the negative direction can be simulated fully and are applied to the gecko robot.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

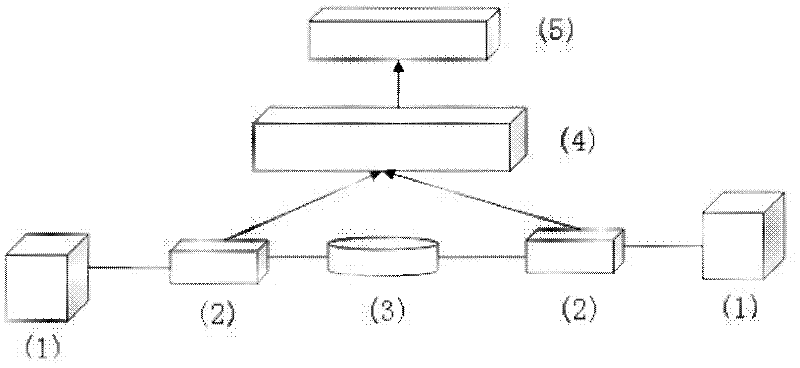

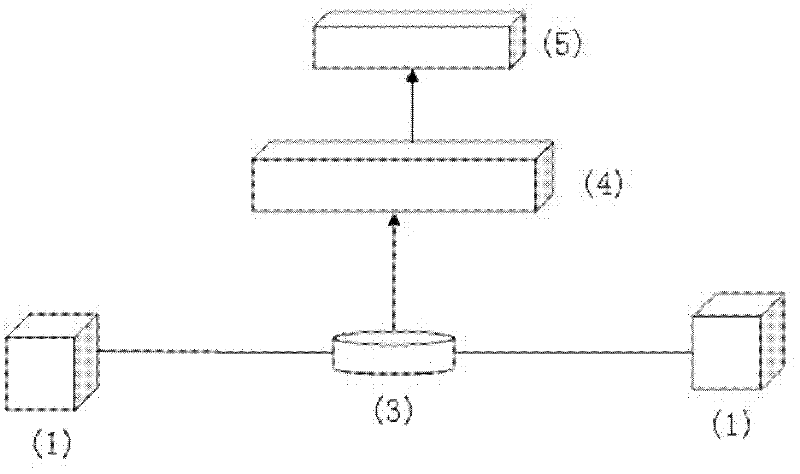

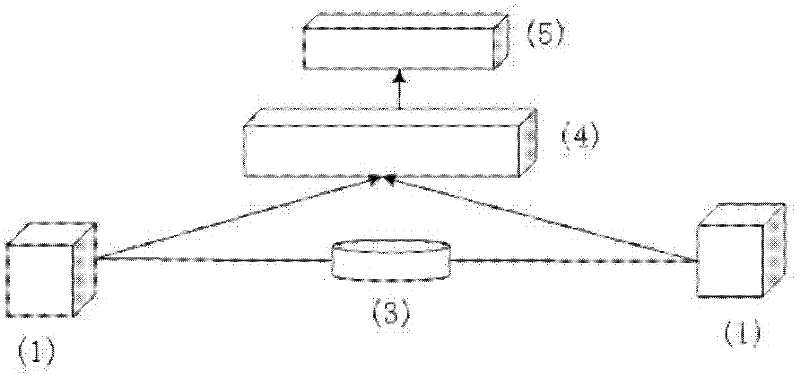

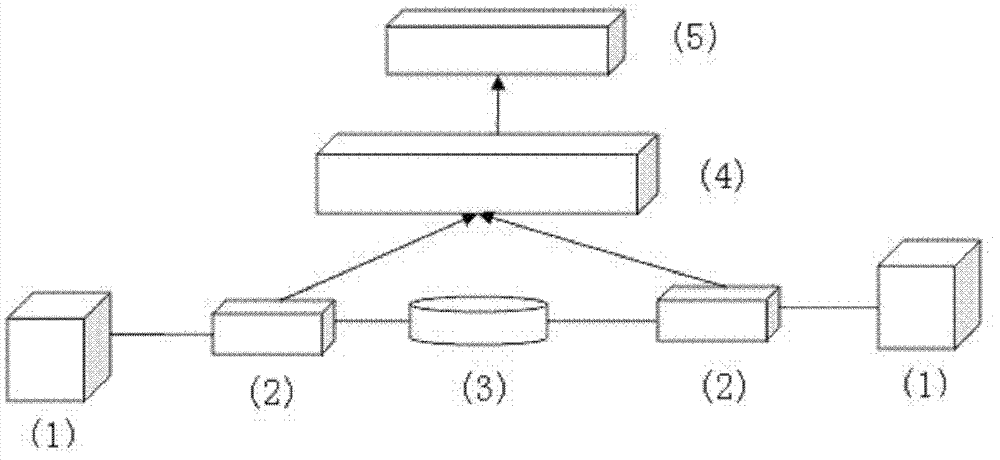

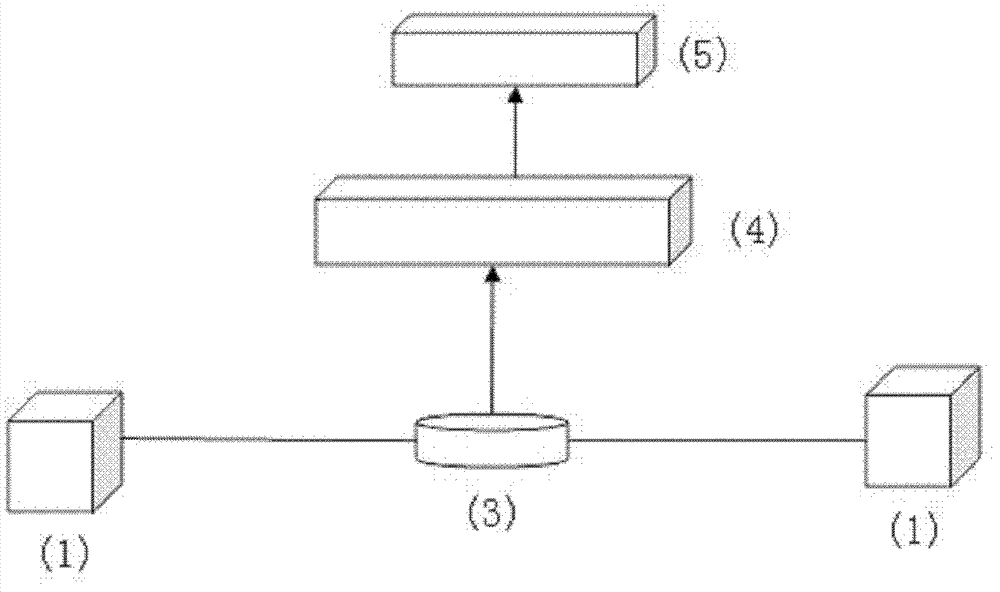

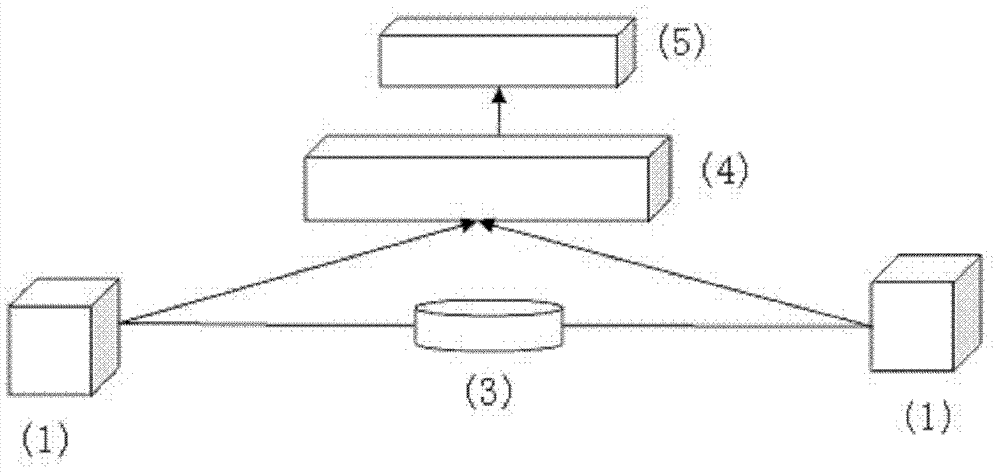

Method and application of compound network monitoring packet

InactiveCN102255770AReduce the number of timesReduce the number of transfersData switching networksOperational systemNetwork packet

The invention relates to the technical field of data frame definition and usage of a network monitoring packet, in particular to a method and an application of a compound network monitoring packet. A TAP branching unit is serially connected between a server and an IP (Internet Protocol) switcher or router connected to the server, wherein a branch of the TAP branching unit is connected to a data collecting device; the data collecting device is connected to a follow-up processor; the TAP branching unit is used for copying various packets sent by the server at real time and sending the packets to the data collecting device; the packets collected by the data collecting device are original packets; the data collecting device is used for defining the data frames of the original packets; an operation system is used for storing the original packets; and the collected original packets on the data collecting device are combined and merged, thereby forming the compound network monitoring packet; and the compound network monitoring packet is sent to the follow-up processor and is subjected to the follow-up processing. The method and the application of the compound network monitoring packet provided by the invention are used for obviously reducing the load capacities of the data collecting device and the follow-up processor and reducing the energy consumption of the device.

Owner:EWANIT IND DEV SHANGHAI

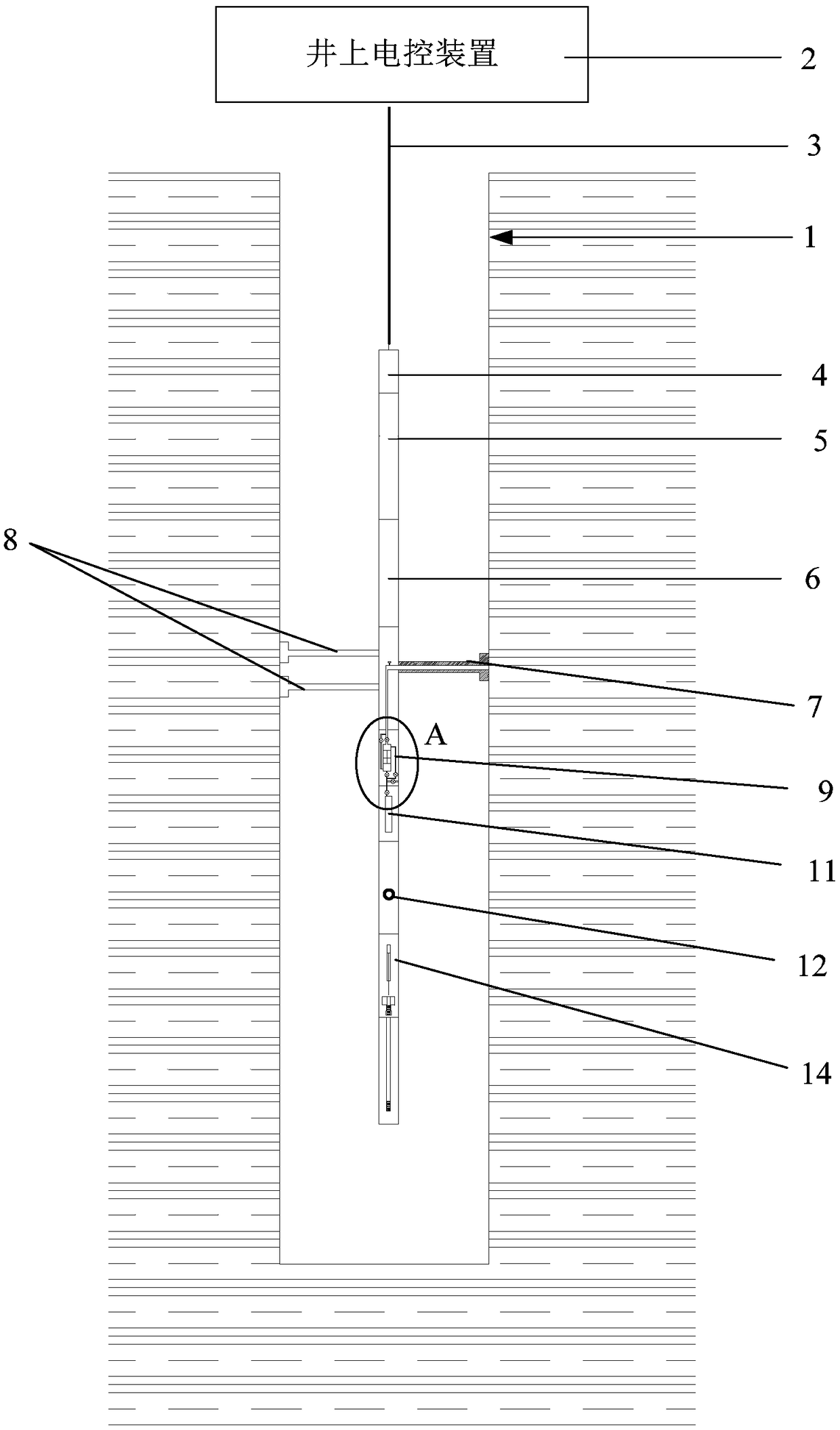

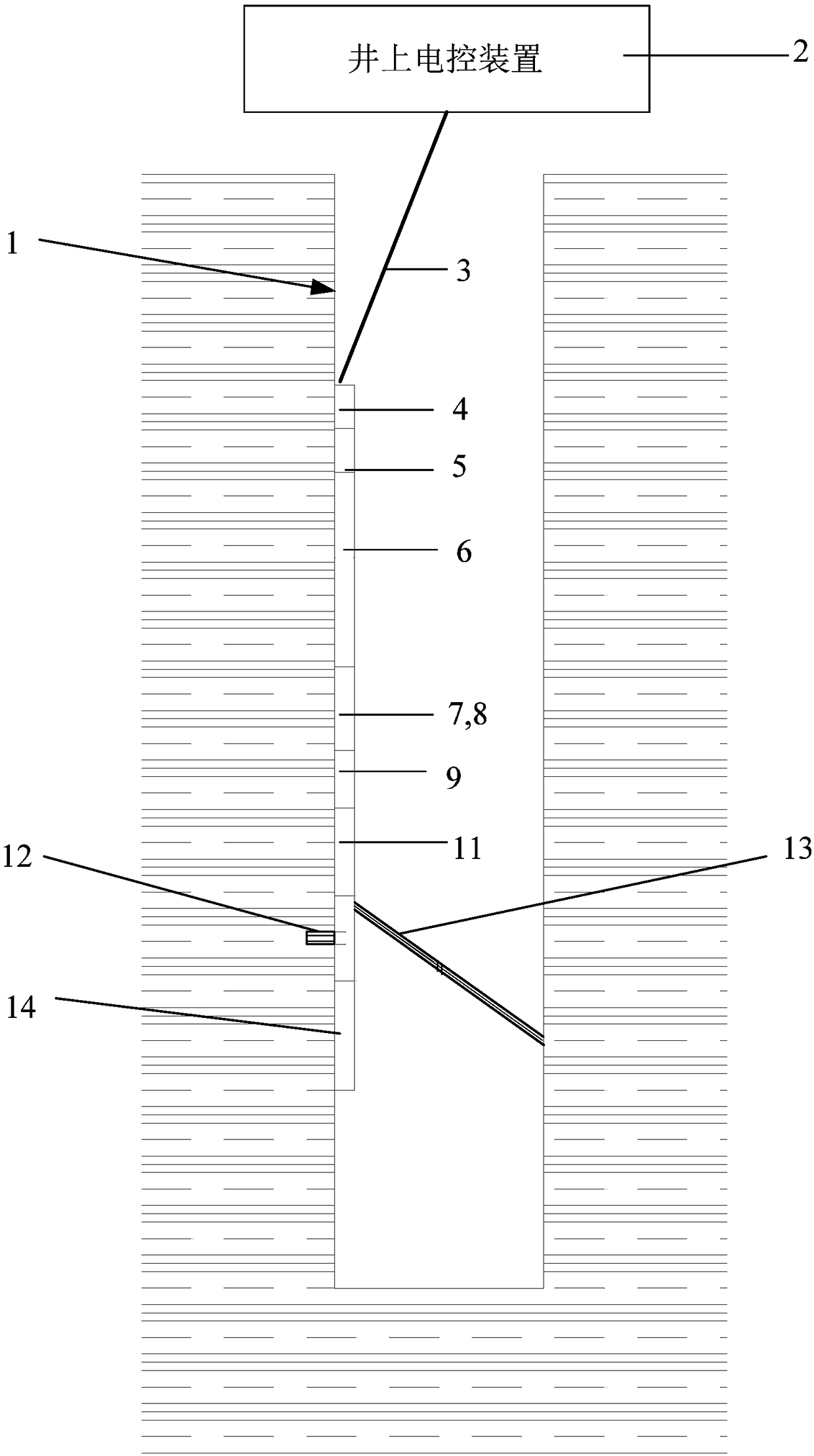

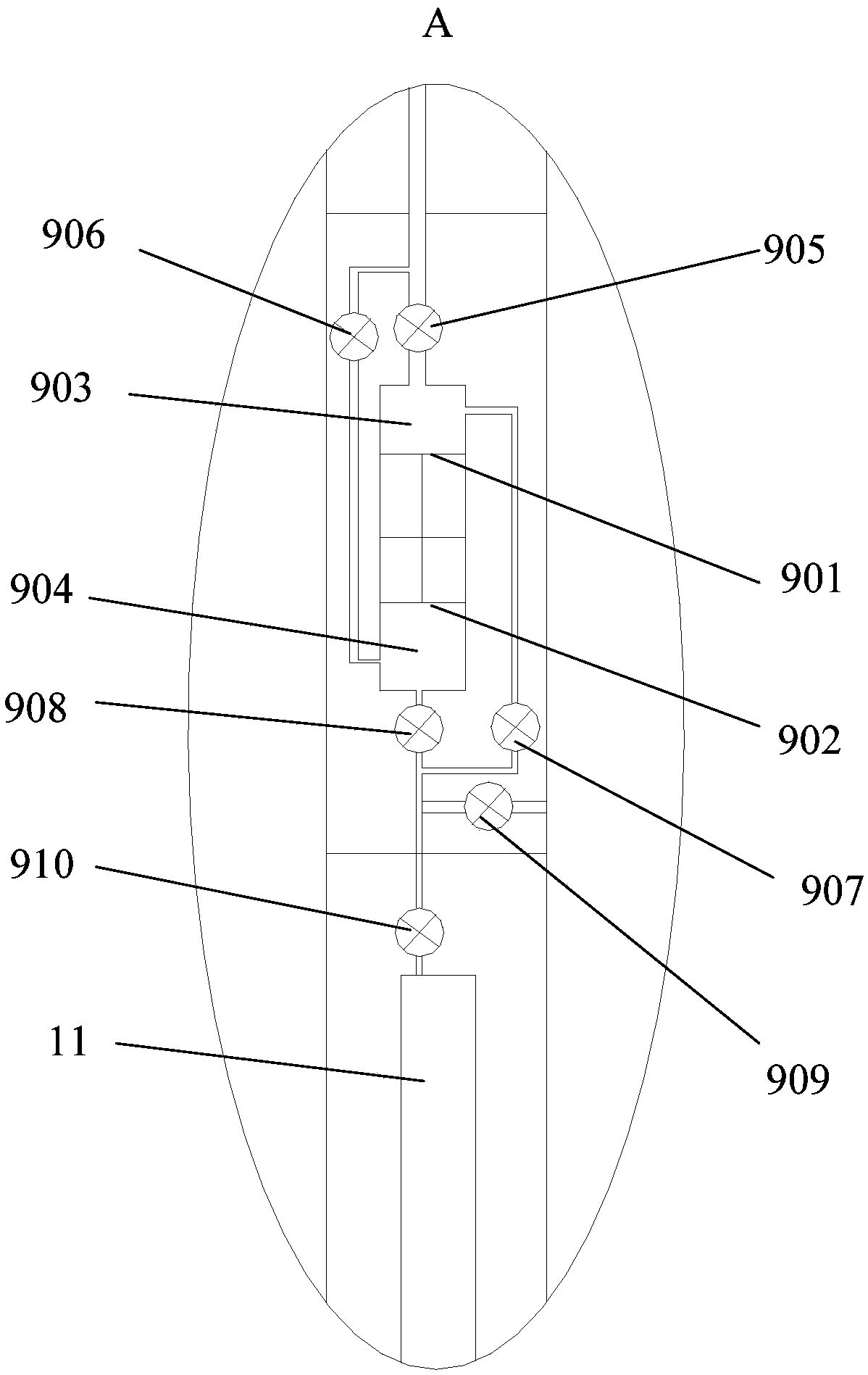

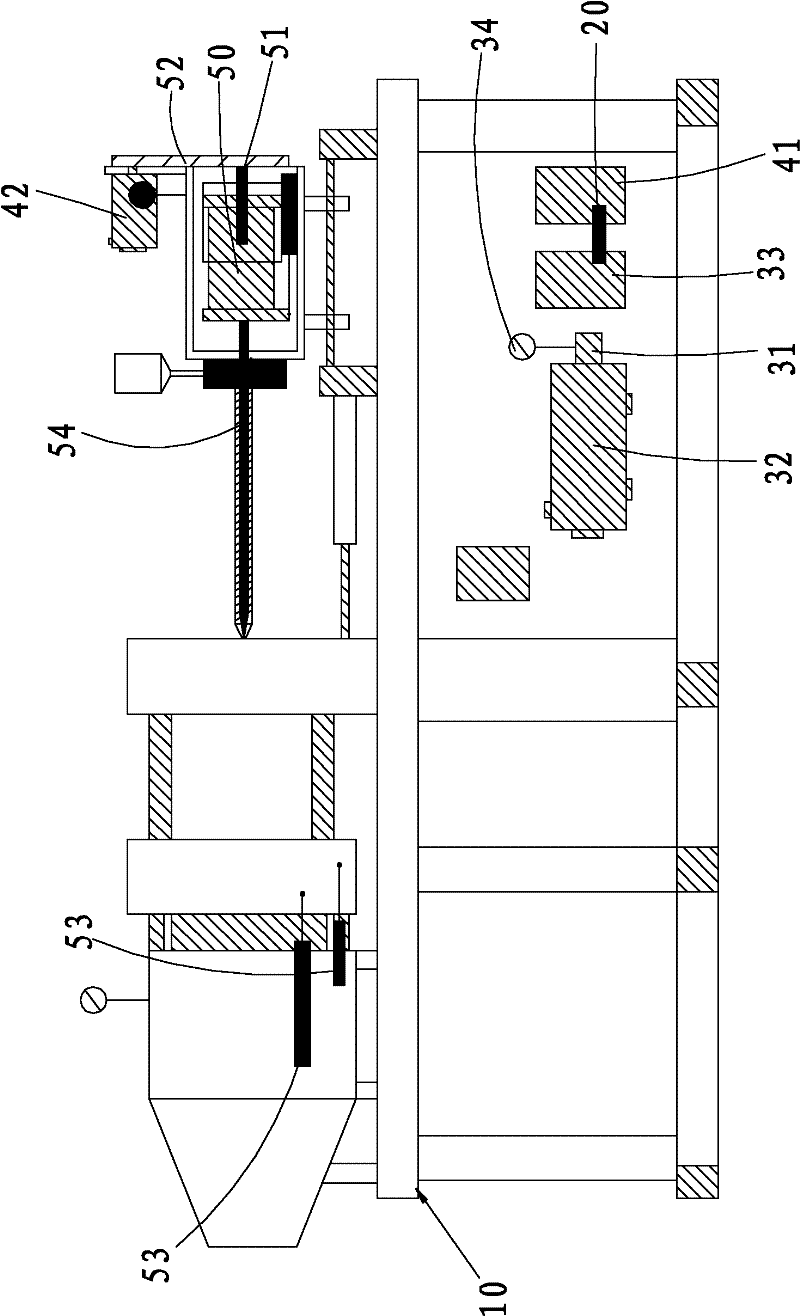

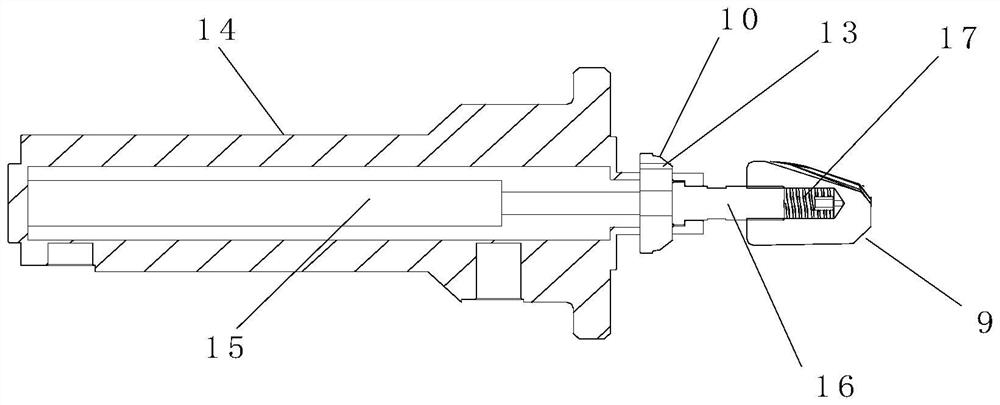

Logging equipment and coring and sampling method

ActiveCN108756874AFlexible connectionReduce wellhead timeBorehole/well accessoriesCore removalCoringInstrumentation

The invention provides logging equipment and a coring and sampling method. The logging equipment comprises a main body, a sampling mechanism, a coring mechanism and an electronic control device. The sampling mechanism comprises a probe and a first push and backup arm retractably arranged on the two opposite sides of the main body. The coring mechanism comprises a coring drilling bit and a second push and backup arm retractably arranged on the two opposite sides of the main body. The electronic control device is used for controlling the main body, the sampling mechanism and the coring mechanismto carry out the sampling and coring operations, wherein the second push and backup arm can be used as a reverse push and backup arm of the sampling mechanism, and the first push and backup arm can be used as a reverse push and backup arm of the coring mechanism. According to the logging equipment and the coring and sampling method, the logging equipment which can complete coring and sampling operations at the same time by going down to a well once is achieved, and the first push and backup arm and the second push and backup arm can be correspondingly used for carrying out reverse push and backup operations, and the self-clamping-removal operation in the coring and sampling process is realized respectively. The logging equipment is easy and convenient to operate, the logging efficiency iseffectively improved, and the cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

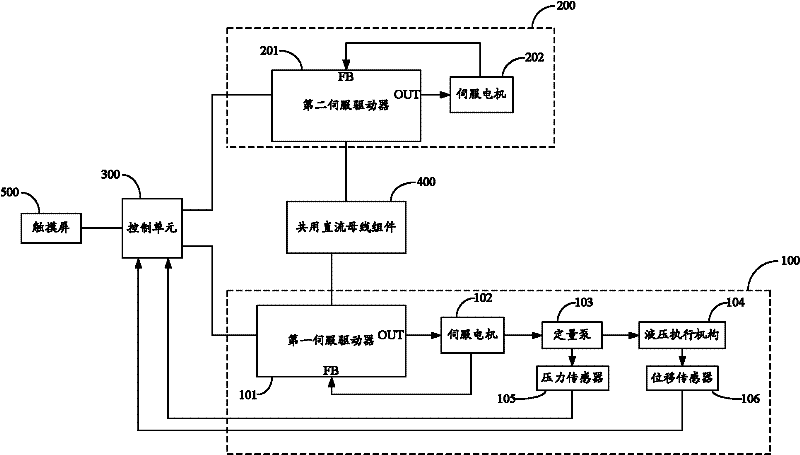

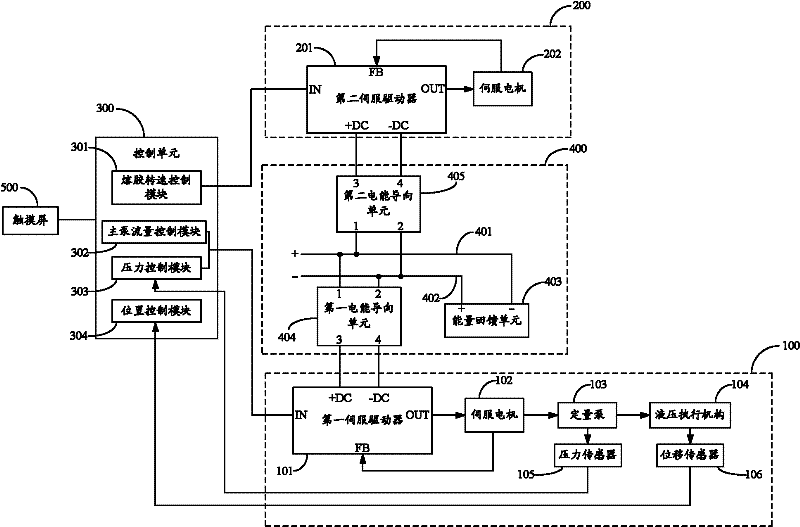

Double-servo control system and energy-saving injection molding machine comprising same

ActiveCN102358019AGood energy saving effectReduce equipment energy consumptionEnergy lossElectricity

The invention is applied in the field of electromechanical control, and discloses a double-servo control system and an energy-saving injection molding machine comprising the same. The double-servo control system comprises first and second servo control systems connected through a shared direct current bus assembly to mutually utilize the braking energy. The energy-saving injection molding machine comprises a frame; and mechanisms, electricity, liquid and the double-servo control system are arranged on the frame. The first servo control system provides power for operations of mechanisms of die opening and closing, rubber injection, advance and retreat of an injection table, ejection and the like; and the second servo control system drives a rubber melting mechanism. According to the double-servo control system and the energy-saving injection molding machine provided by the invention, on the one hand, overflow energy loss of the traditional hydraulic injection molding machine is eliminated by tracking and control matching of a load, and the braking energy of the first and second servo control systems is complementary by using a common direct current bus technology; and on the other hand, synchronization of rubber melting operation and other process operations is realized, so that the rubber injection period is greatly shortened, the energy consumption is effectively reduced and the work efficiency is improved.

Owner:SHENZHEN UNIV

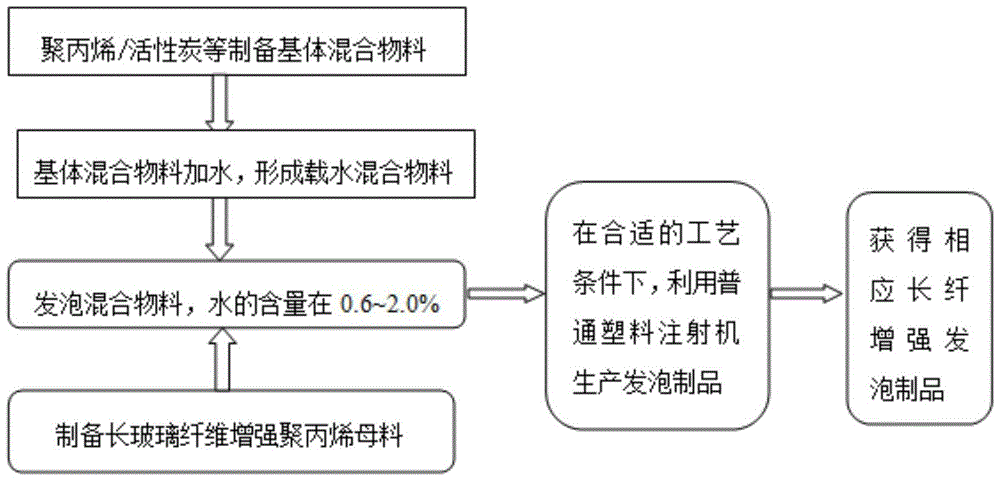

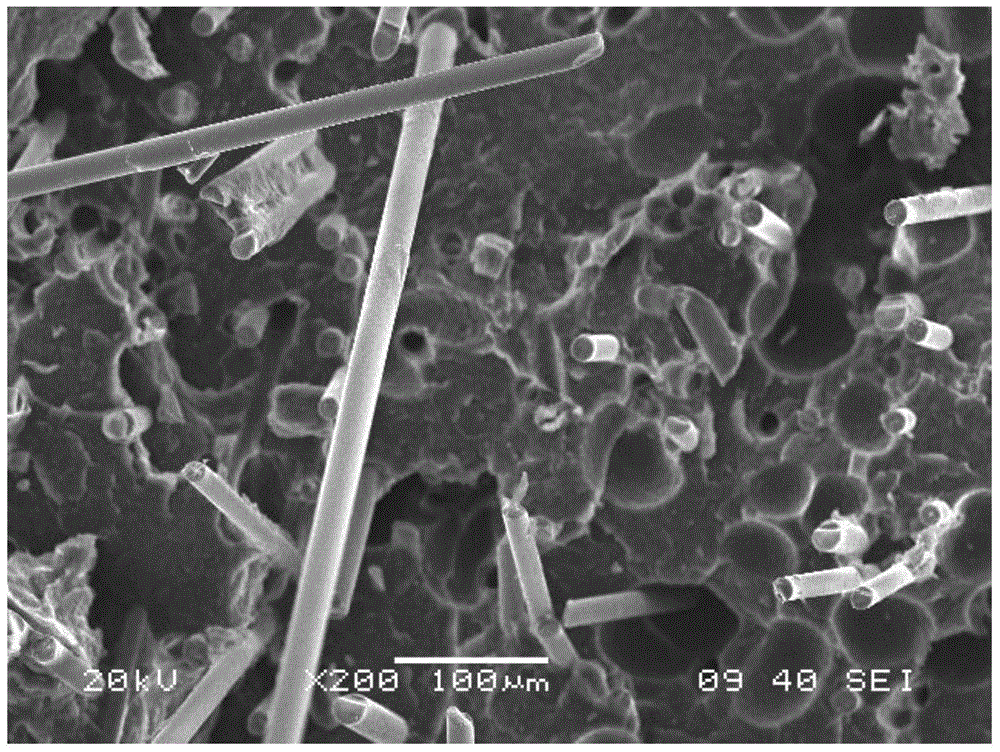

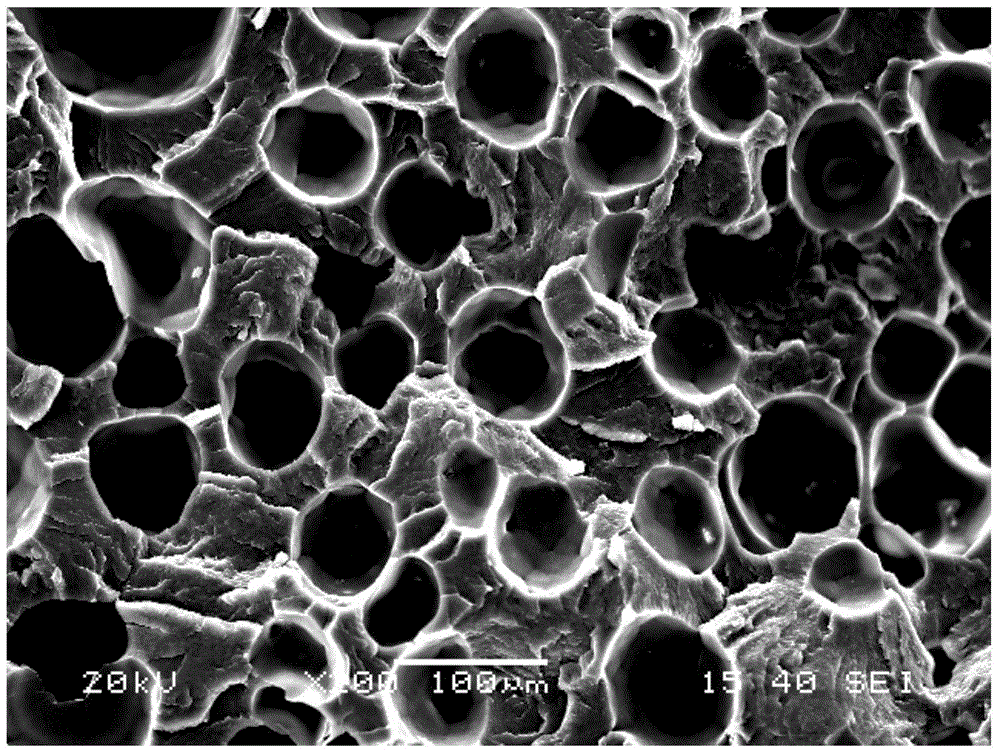

Method for producing long-glass-fiber-reinforced polypropylene foaming injection product by using water as foaming agent

The invention discloses a method for producing a long-glass-fiber-reinforced polypropylene foaming injection product by using water as a foaming agent. The method comprises the following steps: (1) drying raw materials; (2) impregnating by an extruder to prepare a long-glass-fiber-reinforced polypropylene master batch; (3) preparing a matrix mixture; (4) spraying distilled water onto the matrix mixture to form a water-carrying material; (5) mixing the long-glass-fiber-reinforced polypropylene master batch with the water-carrying material to prepare a long-glass-fiber-reinforced polypropylene foaming material; and (7) adding the long-glass-fiber-reinforced polypropylene foaming material into a plastic injection machine to produce the foaming injection product. The method disclosed by the invention utilizes the water as the foaming agent to perform preparation and injection on the long-glass-fiber-reinforced polypropylene foaming material; and the water is easy to acquire, and thus, the water quantity can be easily controlled, thereby easily controlling the foaming degree, and greatly reducing the fiber ruptures. Therefore, the product has the characteristics of excellent properties, environment friendliness, high economy, wide applicability and the like, and is simple and convenient.

Owner:宁海县第一注塑模具有限公司

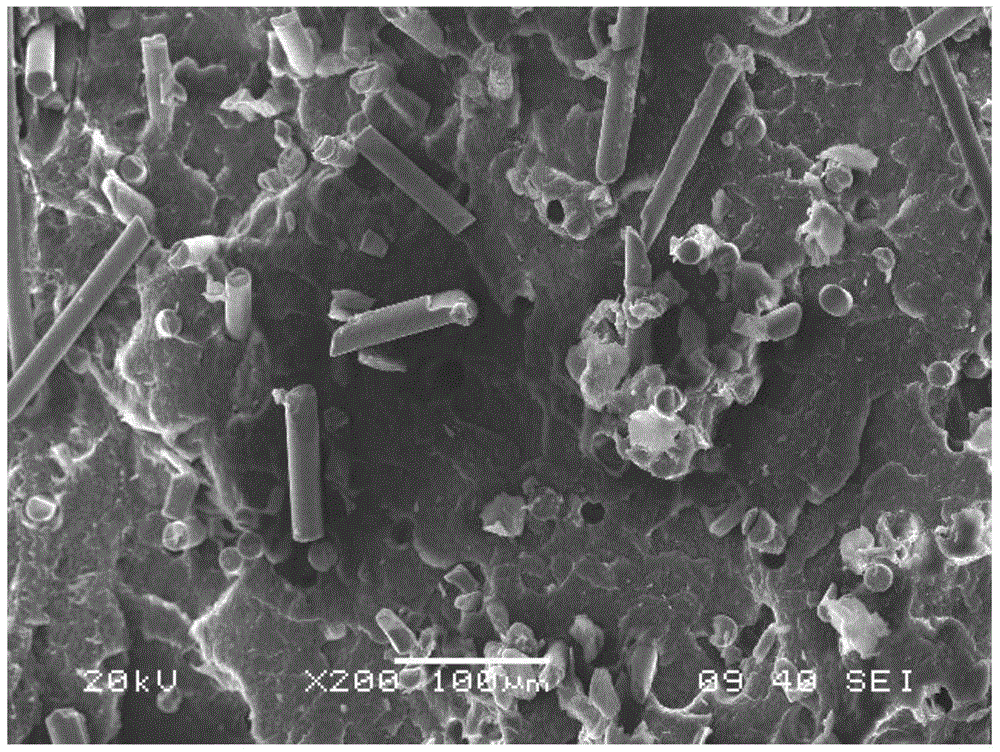

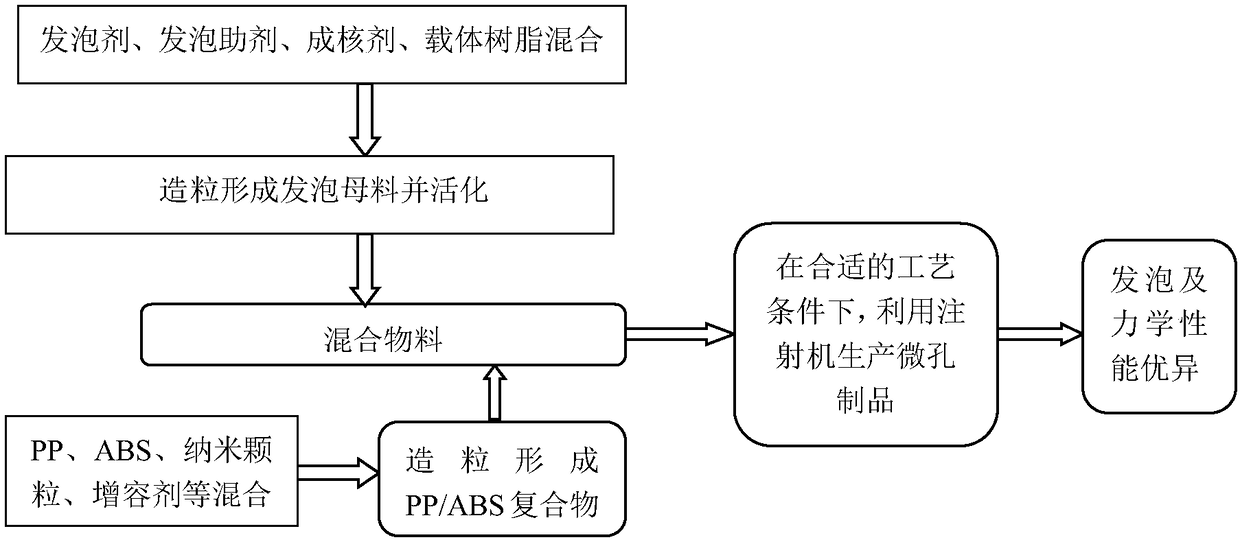

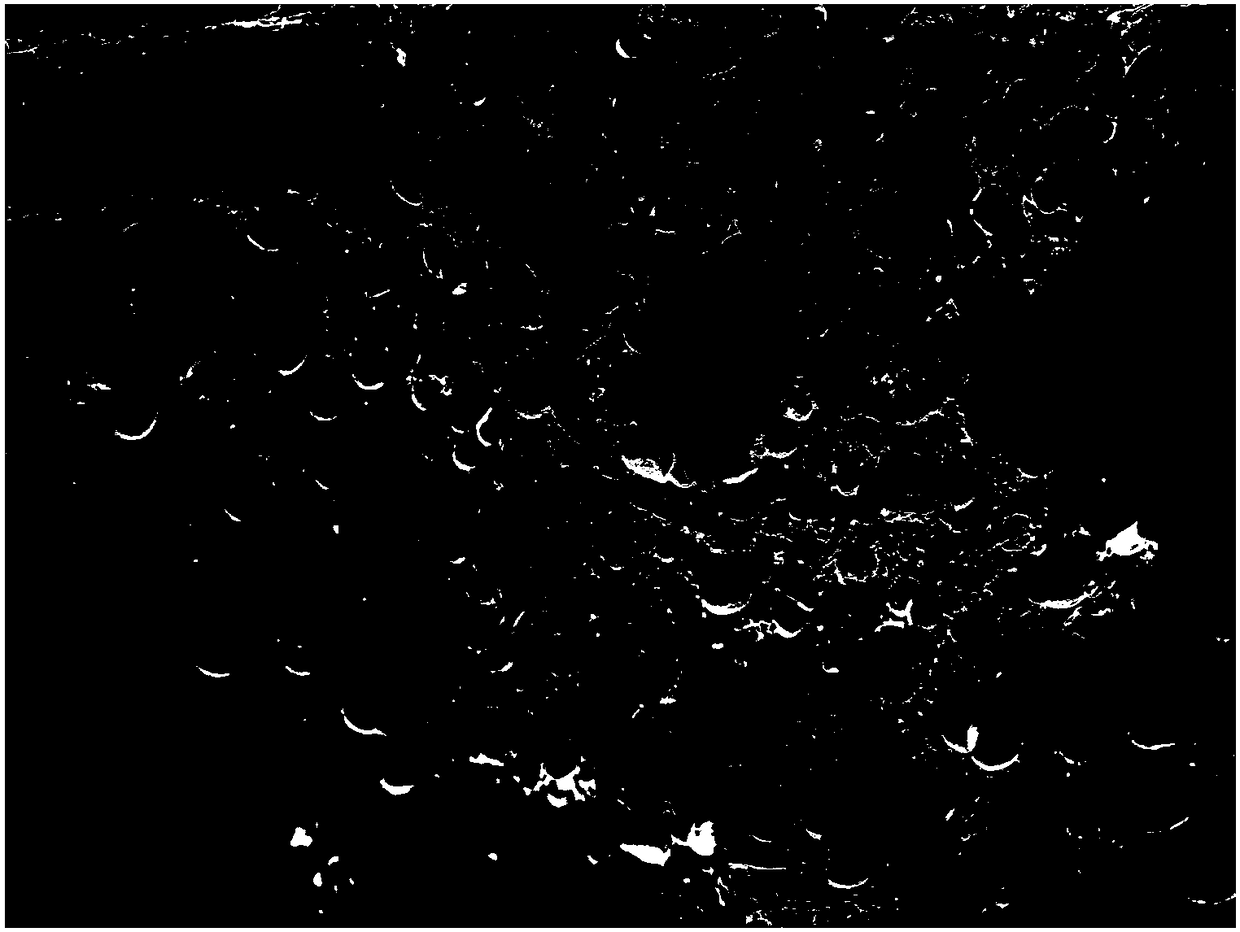

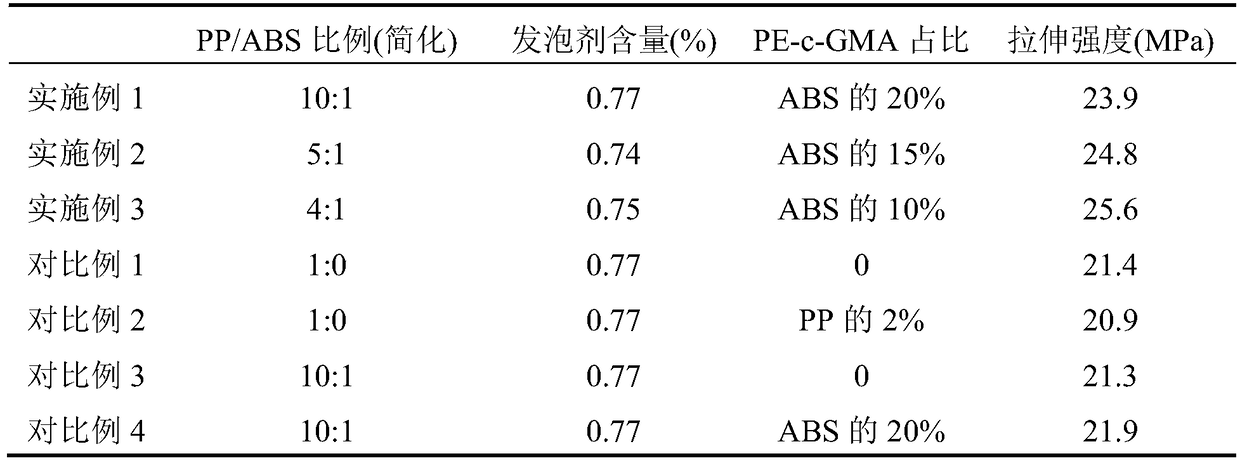

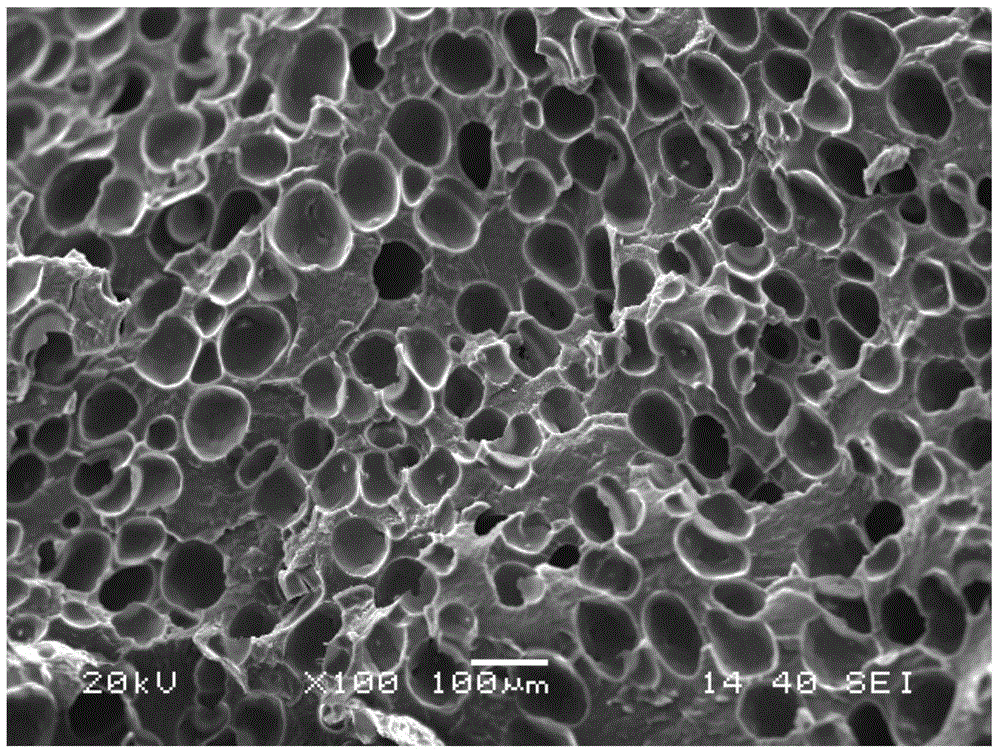

Preparation method of PP/ABS micro-foaming material

The invention discloses a preparation method of a PP / ABS micro-foaming material. The method comprises the following steps that (1) a foaming agent, a foaming auxiliary agent, a nucleating agent and the like are mixed with a carrier resin and then be made into foaming master batch through a twin-screw extrusion mechanism; (2) PP, ABS, nanoparticles and compatibilizer are uniformly mixed to preparea PP / ABS mixture; (3) the PP / ABS mixture of step (2) is melted, extruded, and granulated through a twin-screw extruder to prepare a uniform composite; (4) the foaming master batch of step (1) is activated and mixed with the composite prepared in step (3) to form a mixed material; (5) a PP / ABS microporous product can be produced by adding the mixed material into an injection molding machine. The preparation method of the PP / ABS micro-foaming material has the advantages that on one hand, the micro-foaming performance of the PP / ABS can be effectively improved, the uniform density of cells is high, and the size is small, on the other hand, the influence of the incompatibility between PP and ABS on mechanical properties of the PP / ABS composite material is avoided, the cost is low, and the processing and production are convenient.

Owner:ZHENGZHOU UNIV

Method for preparing heavy metal ion adsorbent using maleic acylation wood fibers at room temperature

ActiveCN103506087ARealize the comprehensive utilization of all componentsSimple processOther chemical processesFiberSorbent

The invention discloses a method for preparing a heavy metal ion adsorbent using maleic acylation wood fibers at room temperature and belongs to the field of biomass chemistry and renewable resource utilization. The method disclosed by the invention comprises the following steps: completely dissolving ball-milled wood fiber powder in a room-temperature solvent system, adding maleic anhydride for reaction at room temperature, performing precipitation, washing and freeze-drying after the reaction is completed, so as to obtain a heavy metal ion adsorbent containing wood fiber derivatives. According to the adsorbent preparation method used in the invention, the wood fiber dissolution and modification procedures are both performed at room temperature without heating, so as to reduce the equipment requirement and energy consumption. The prepared adsorbent can effectively adsorb heavy metal ions in a solution, and has an important scientific value and practical significance in development and utilization of wood fiber biomass and other renewable resources.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing graphene filled master batch with low energy consumption and large scale

ActiveCN107603131AReduce equipment costsReduce equipment energy consumptionCvd grapheneDecomposition

The invention provides a method for preparing graphene filled master batch with low energy consumption and large scale. The method comprises the following steps: adsorbing graphene with porous resin microspheres having high compatibility with matrix resin; dissolving a foaming agent H in an organic solvent; atomizing to remove the organic solvent; depositing the foaming agent H on the surfaces ofthe porous resin microspheres, and encapsulating and coating; separating by a centrifuge and pulverizing to obtain the functional master batch. The scheme provided by the invention overcomes the technical defects of complicated technology, high equipment cost and high energy consumption caused by adopting a screw extruder; extrusion equipment is not required to prepare master batch; the equipmentcost and the energy consumption are reduced, and large-scale production is facilitated; furthermore, due to the high compatibility between the porous resin microspheres and the matrix resin, the graphene dispersing effect is improved; when the master batch is in use, the graphene is uniformly and slowly released into the resin along with the decomposition of the foaming agent, the graphene dispersing effect is improved, and porous resin microspheres are prevented from agglomerating again during fusion of the matrix resin.

Owner:济宁三荷塑料制品有限公司

High-toughness silicon carbide ceramic and low-temperature sintering technology thereof

The invention discloses high-toughness silicon carbide ceramic and a low-temperature sintering technology thereof. The high-toughness silicon carbide ceramic comprises, by weight, 100 parts of alpha-silicon carbide, 0.3-1.2 parts of boron carbide and 3-10 parts of YAG powder, wherein the granularity D50 of the YAG powder is smaller than or equal to 6.0 micrometers. Silicon carbide potteries obtained through the sintering technology are good in structural compactness, high in fracture toughness and lower in sintering temperature compared with the prior art, so that better operability and production convenience are achieved, the production cost of products is lowered, and production energy consumption is saved.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

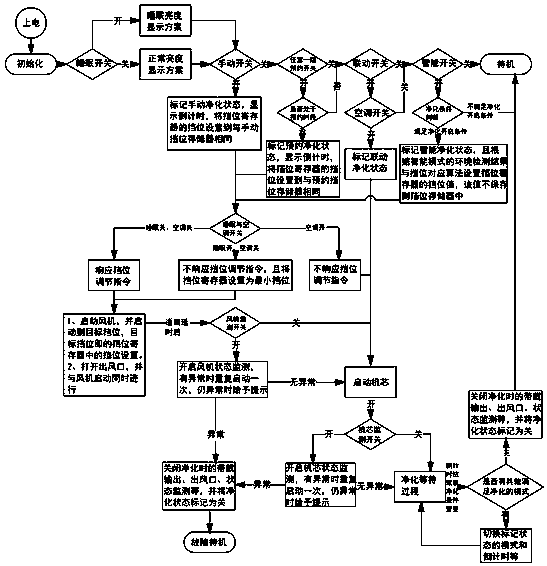

Control method of fresh air purification system

InactiveCN109682031AImprove sleep environmentIntelligent controlMechanical apparatusSpace heating and ventilation safety systemsFresh airEngineering

The invention discloses a control method of a fresh air purification system and belongs to the technical field of fresh air purification system control methods. The control method comprises the stepsthat the on / off states of a sleep switch and an air conditioning switch of the fresh air purification system are judged, when the sleep switch and the air conditioning switch are both in the off state, a gear adjustment command is responded, then, a fan is started, and a gear registered in a gear register is started; and when the sleep switch is in the on state and the air conditioning switch is in the off state, the gear adjustment command is not responded, the gear register is set to be at the minimum gear, then, the fan is started, and the gear registered in the gear register is started. The fresh air purification system has multiple purification modes; automatic purification matched with the sleeping mode can be conducted when the different purification modes are implemented, users feel at ease to a greater extent in the sleeping state, and higher humanization and intelligentization are achieved; and in addition, the operation states of the fan and a fan core can be monitored and prompted automatically, and intelligentized control is achieved.

Owner:成都好空气科技发展有限公司

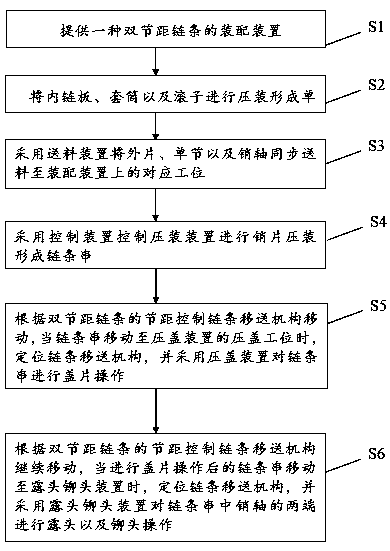

Assembly method for double-pitch chain

InactiveCN109396323AImprove work efficiencyReduce labor intensityMetal chainsChain transferMechanical engineering

The invention provides an assembly method for a double-pitch chain. The assembly method comprises the following steps of: providing an assembly device for the double-pitch chain; press-fitting an inner chain plate, a sleeve and a roller to form a single pitch; synchronously feeding an outer sheet, the single pitch and a pin roll to a corresponding station on the assembly device through a feeding device; controlling a press-fitting device to perform pin sheet press-fitting, thereby forming a chain string; controlling a chain transfer mechanism to move according to pitches of the double-pitch chain, and performing sheet covering operation on the chain string; and controlling the chain transfer mechanism to continuously move according to pitches of the double-pitch chain, and performing head-exposing and head-riveting operation on the two ends of the pin roll in the chain string. The assembly method can solve the problems that chain assembly quality is not high, assembly efficiency is low, work is complex, labour power is wasted, and the like in the prior art.

Owner:东华链条兴化有限公司

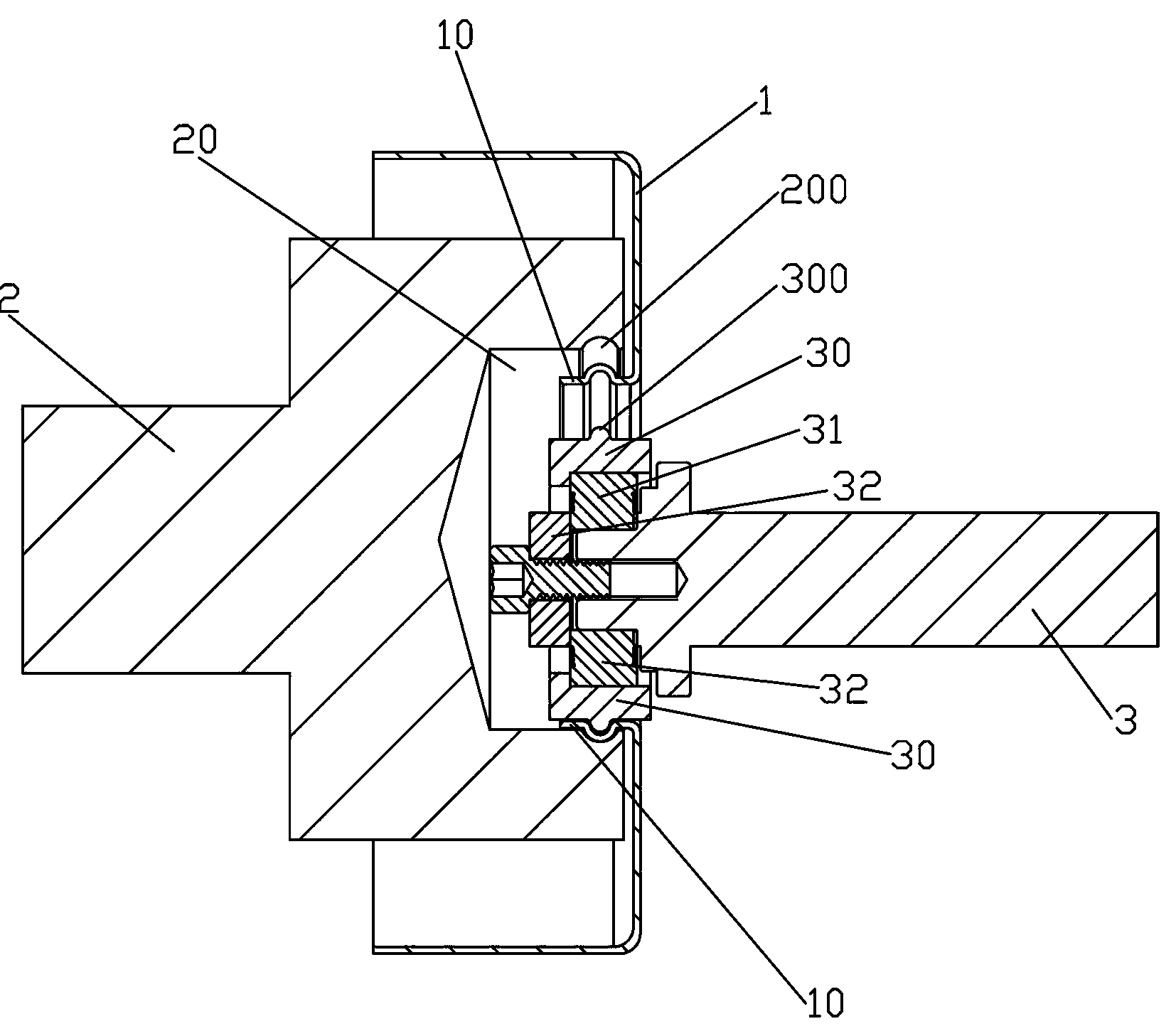

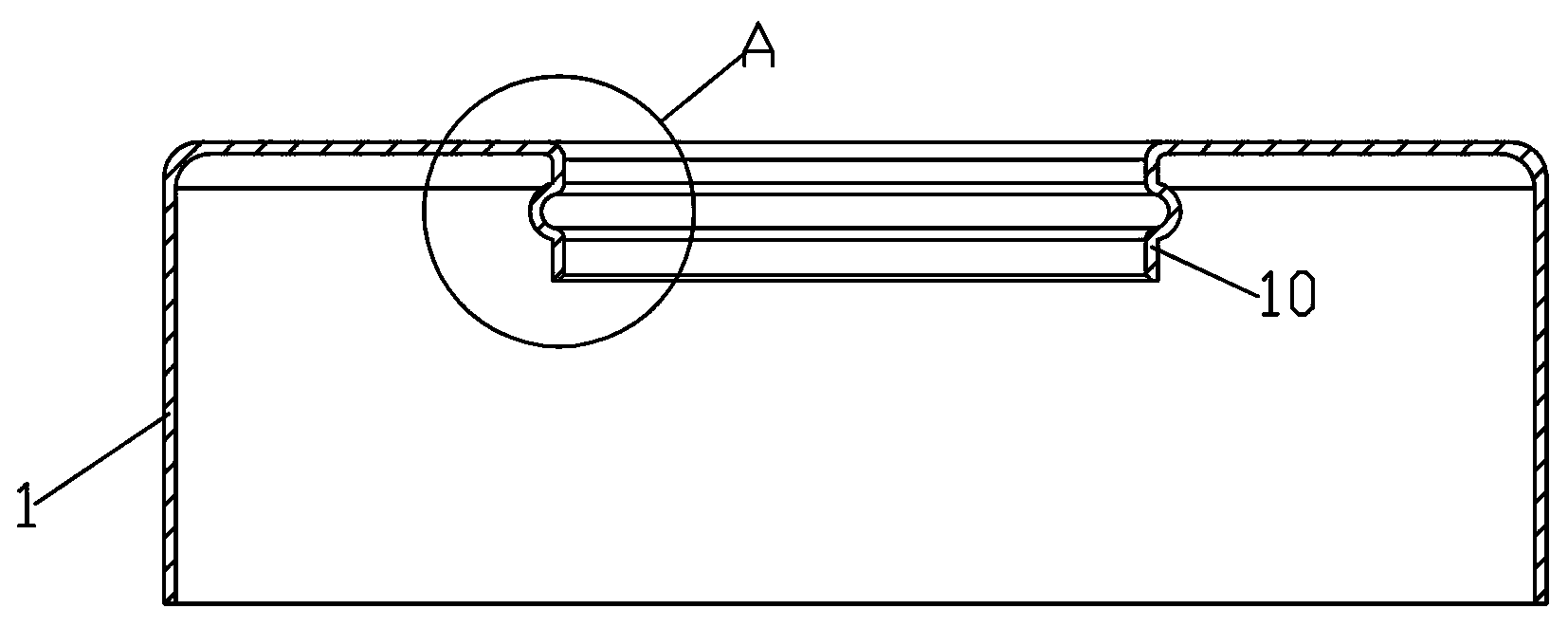

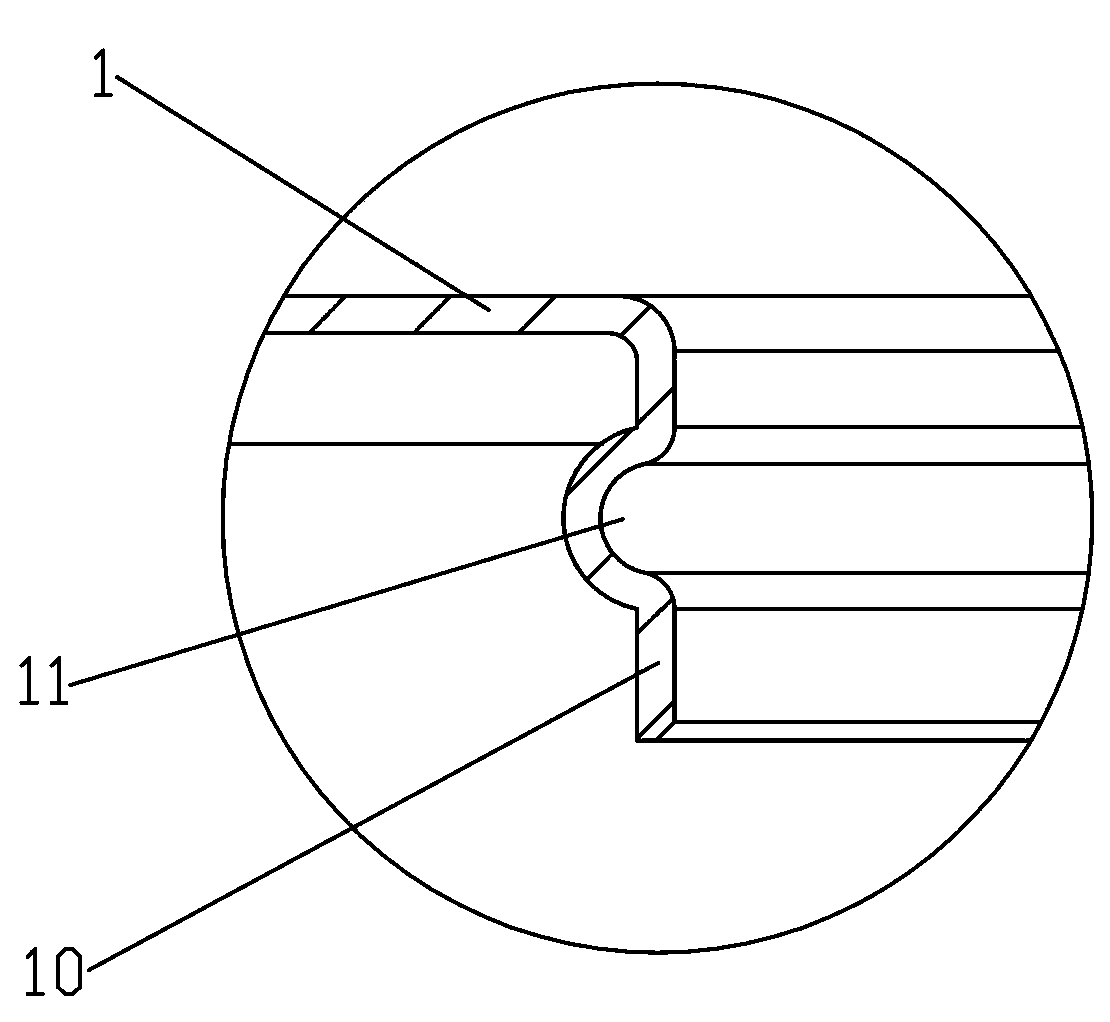

Roll groove forming die used for stretching panel

InactiveCN103658278AEasy to operateReduce equipment energy consumptionSurface plateEnergy consumption

The invention discloses a roll groove forming die used for a stretching panel. The roll groove forming die comprises a roll groove fixing base used for fixedly installing the stretching panel. An installation groove is formed in the side wall of one end of the roll groove fixing base and can enable a concave stretching part of the stretching panel to be installed inside the roll groove fixing base in an embedded mode and to be connected with the inner side wall of the roll groove fixing base in an abutting-against mode. A forming roll groove is formed in the side wall of the installation groove, a forming cutter rod is further arranged on one side of the installation groove and can extend into the installation groove, a forming roll shaft is arranged at the end, extending into the installation groove, of the forming cutter rod and can be matched with the forming roll groove, and circular arc protrusions are arranged on the outer side wall of the forming roll shaft and can be pressed into the forming roll groove. By the adoption of the roll groove forming die, people only need to install the roll groove forming die on a common machine tool, so that rolling forming is performed on the stretching panel, the roll groove forming die has the advantages of being easy to operate and low in equipment energy consumption, the technology is easy to control, energy is greatly saved, and labor intensity is greatly relieved.

Owner:JODEN INC

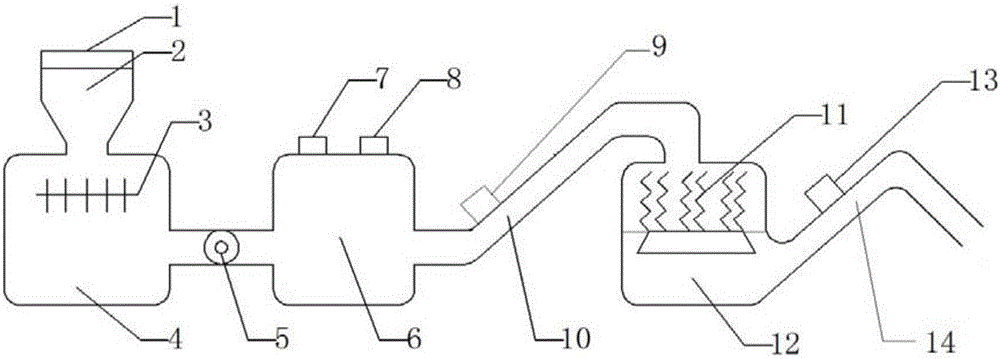

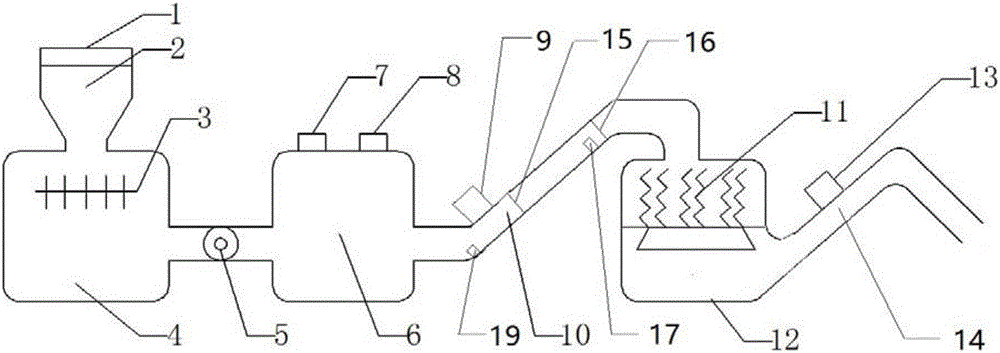

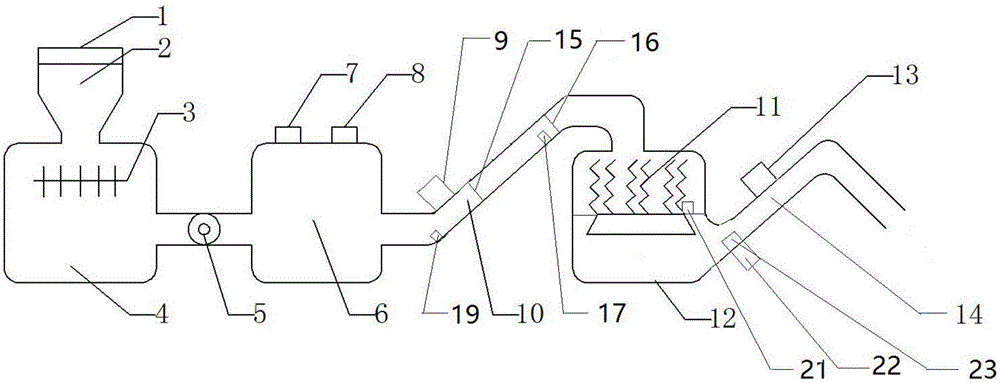

Equipment for producing biochar from rice straw and technology for producing biochar

ActiveCN106479536ASimple production processReduce equipment energy consumptionBiofuelsSpecial form destructive distillationSpecific gravityRice straw

The invention discloses equipment for producing biochar from rice straw. The equipment comprises a feeding box, a pulverizator, a reaction vessel, a discharge delivery pipe, a pyrolysis box, a heating stove, a first cooler and a second cooler. Meanwhile, the invention discloses a technology for producing the biochar. The method comprises steps as follows: firstly, the rice straw enters the feeding box through a feed inlet and then enters the pulverizator for pulverization; the pulverized rice straw enters the reaction vessel through a discharge valve and is processed, the processed rice straw is cooled by the first cooler, is sent to the pyrolysis box through the discharge delivery pipe for high-temperature pyrolysis and then is conveyed to the heating stove for carbonization, and the carbonized rice straw is discharged from a discharge port after cooled by the second cooler. The production technology is simple, the energy consumption of the equipment is low, and the cost is lower than that of other methods by 8% or more; the production cycle is short, the controllability of a production process is high, and apparent specific gravity of the obtained biochar is high.

Owner:CAPITAL NORMAL UNIVERSITY

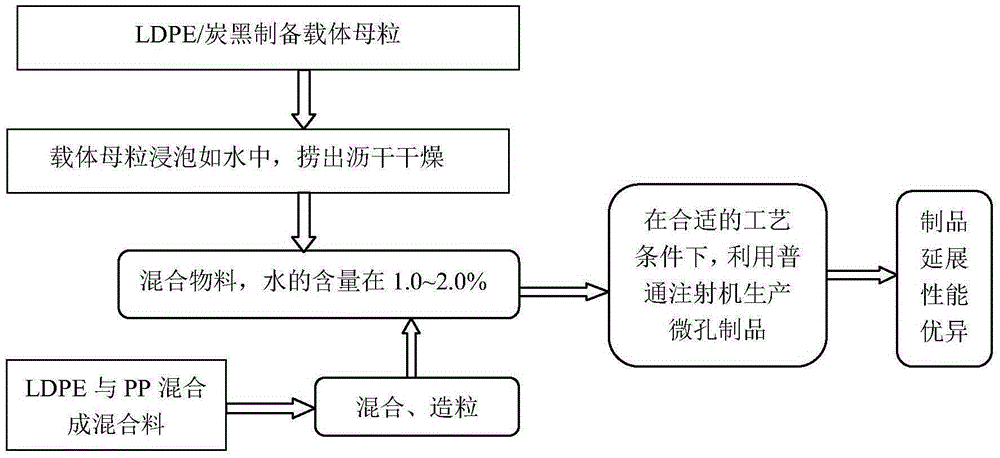

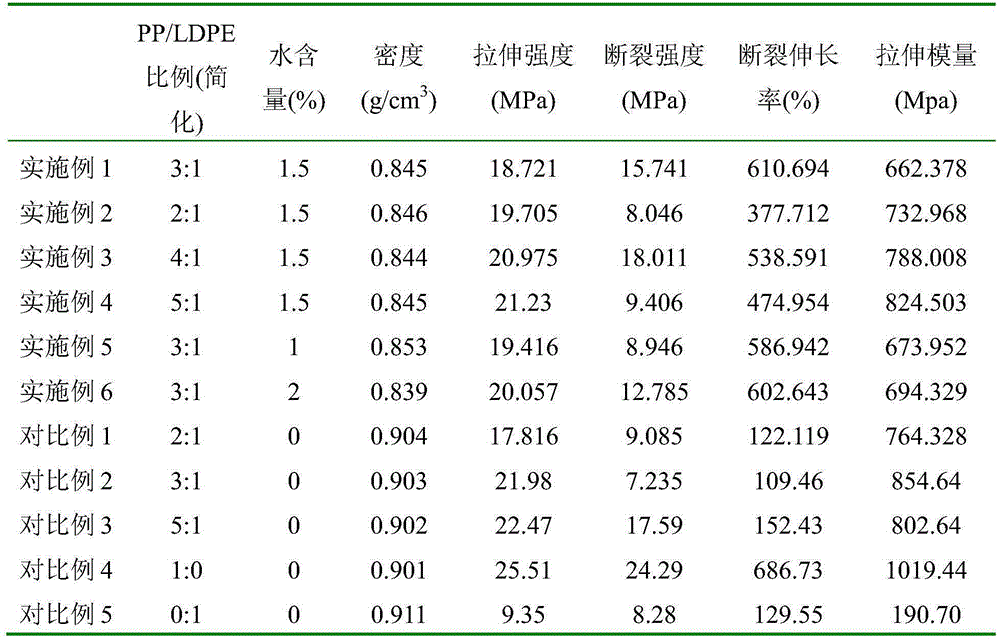

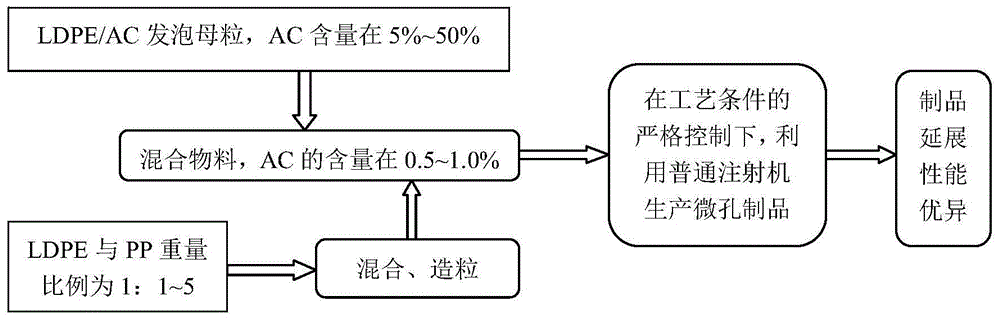

Water foaming injection molding method for PP/LDPE ultra-extension product

The invention discloses a water foaming injection molding method for a PP / LDPE ultra-extension product. The water foaming injection molding method includes the following steps that firstly, activated carbon and LDPE raw materials are mixed and then pass through a common plastic extruder, and carrier master batches are manufactured; secondly, PP and LDPE are mixed evenly, and a PP / LDPE compound material is formed; thirdly, the PP / LDPE compound material in the second step is melted, extruded and diced through the common plastic extruder, and an even compound is obtained; fourthly, the carrier master batches prepared in the first step are soaked into water, and the carrier master batches are taken out after several hours and properly dried; fifthly, the carrier master batches in the fourth step and the mixture prepared in the third step are evenly mixed to form a mixed material; and sixthly, the mixed material is added to a common horizontal injection molding machine, and therefore a PP / LDPE micropore product can be produced. According to the water foaming injection molding method for the PP / LDPE ultra-extension product, the ductility of the prepared product is three or more times that of a common injection part, the elongation at break of the product is over 370%, water serves as a foaming agent and is easy to obtain, cost is low, and storing and adding are easy to implement.

Owner:WENZHOU XINTAI NEW MATERIALS CO LTD

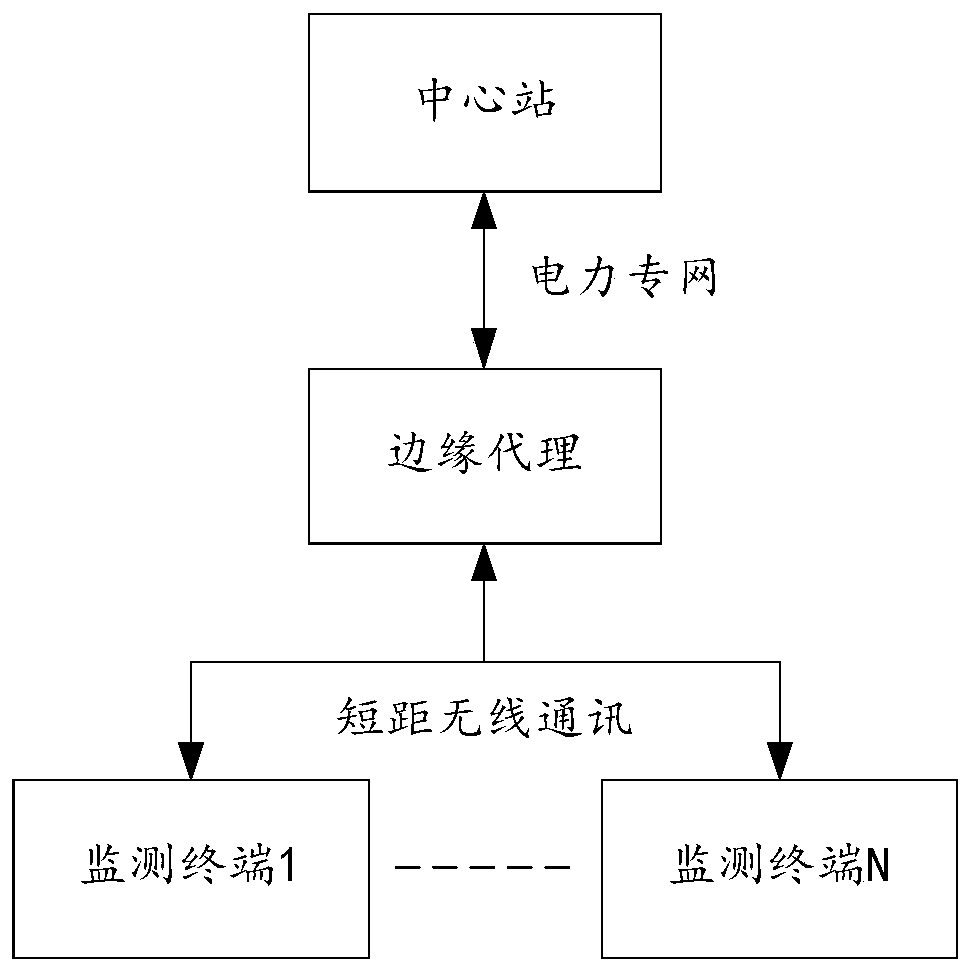

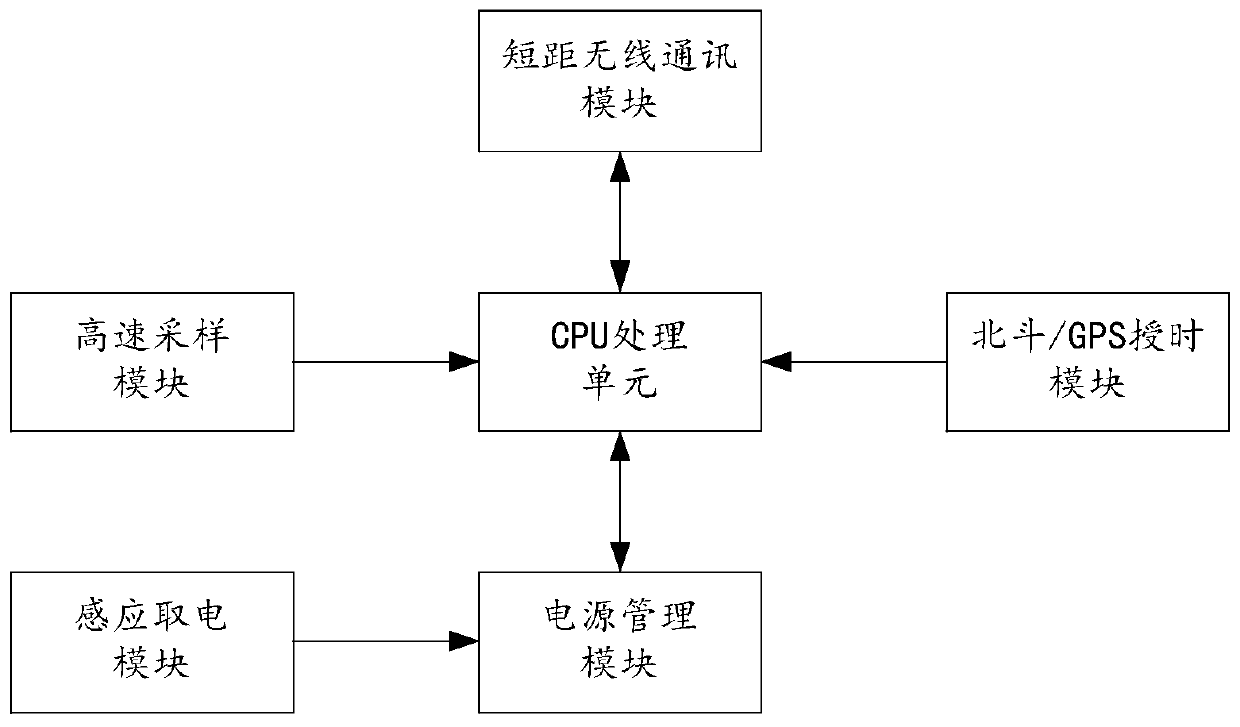

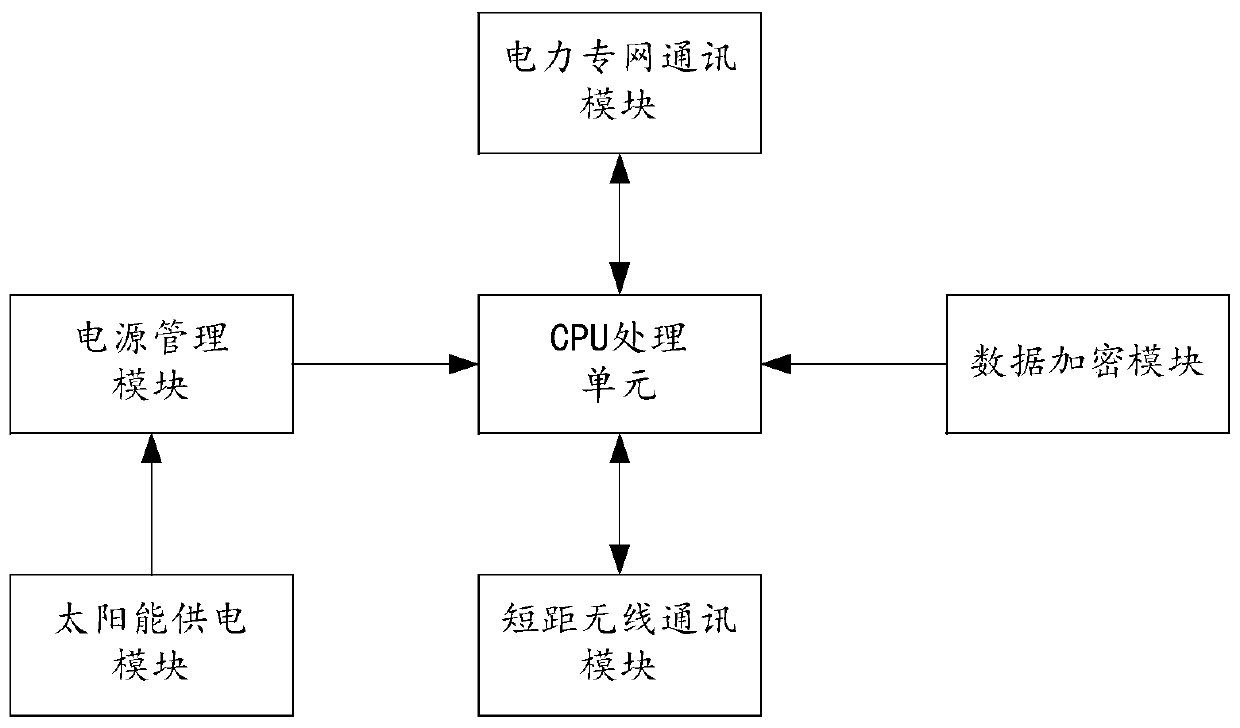

Power transmission line distributed fault diagnosis system suitable for power Internet of things

InactiveCN110749786AReduce equipment energy consumptionEnsure online rate and battery lifeTransmission systemsParticular environment based servicesInternet of ThingsReal-time computing

The invention discloses a power transmission line distributed fault diagnosis system suitable for the power Internet of things. The system comprises a monitoring terminal, an edge agent module and a central station system, wherein the monitoring terminal is used for acquiring power transmission line data, and the data comprises traveling wave current, power frequency electric quantity and wire temperature in a wire; the edge agent module is used for encrypting the received power transmission line data and outputting the encrypted data; the central station system is used for receiving the encrypted data and performing calculation processing to realize fault early warning and diagnosis; and the monitoring terminal performs data interaction with the edge agent module through short-distance wireless communication, and the edge agent module performs data interaction with the central station system through a power private network. The system can reduce energy consumption, improve safety, reduce equipment volume, widen the application range and reduce the operation cost.

Owner:NARI TECH CO LTD +1

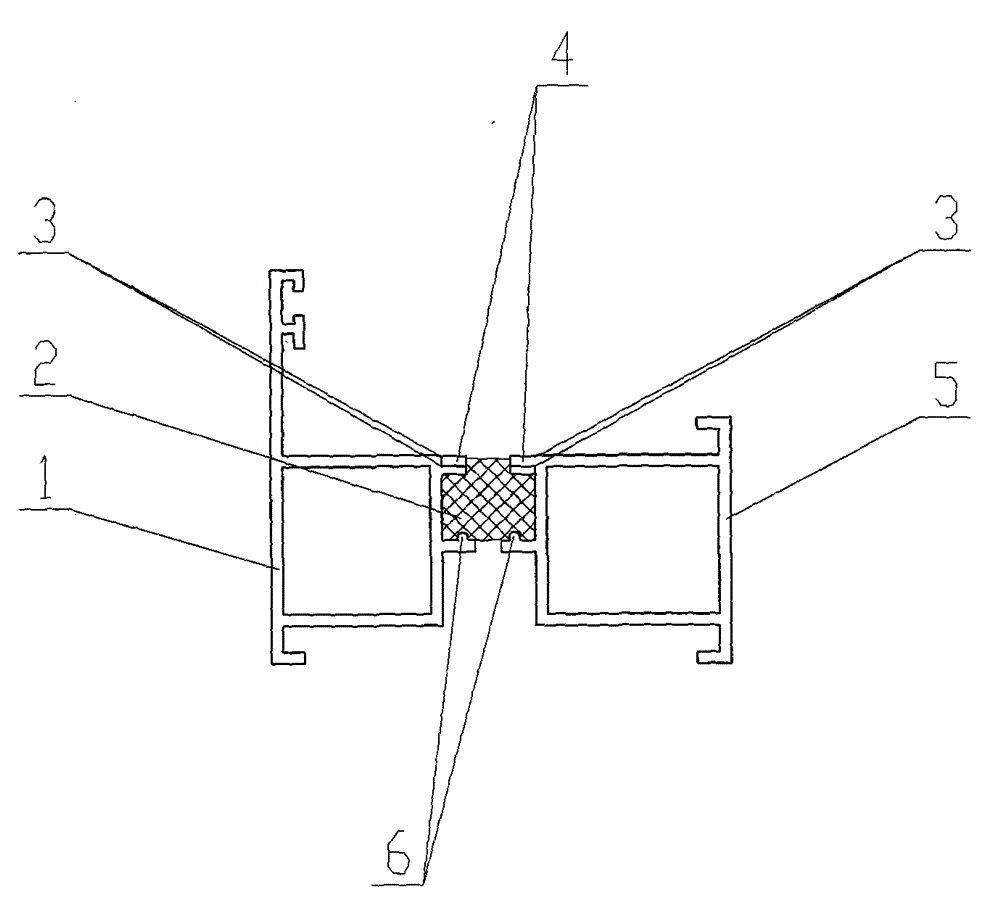

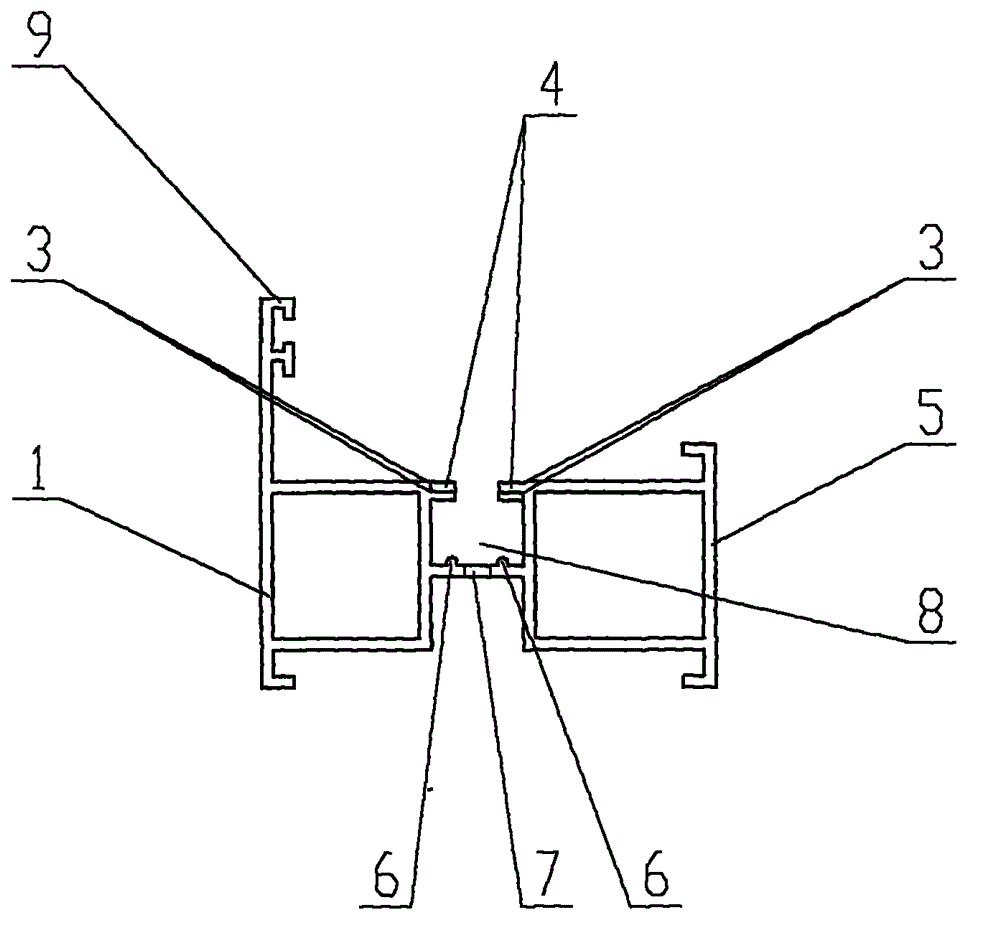

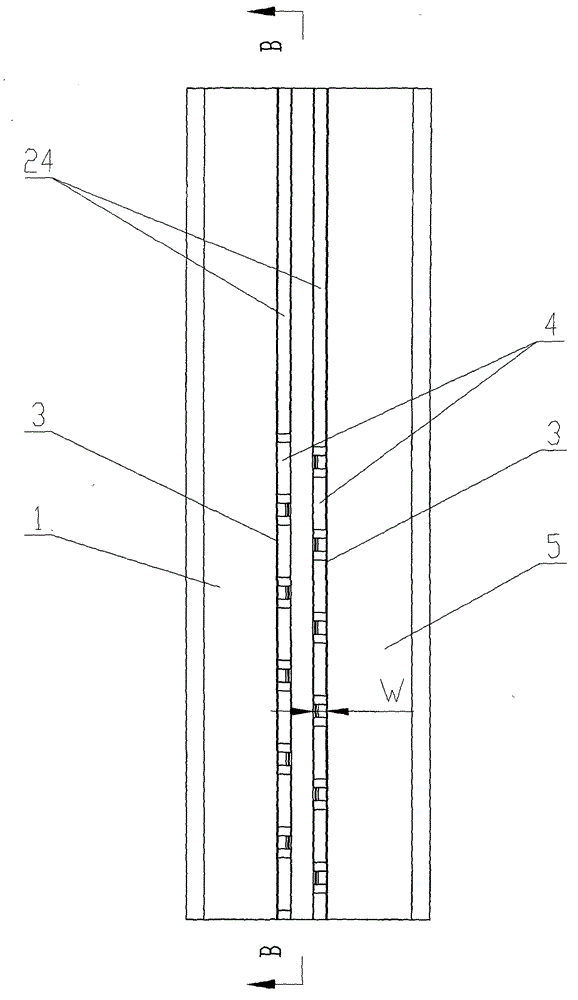

Tooth punching equipment for carrying out tooth punching on heat insulation aluminium section by pouring process

ActiveCN104690128AHigh bond strength and shear strengthReduce equipment energy consumptionElongated constructional elementsAluminiumEngineering

The invention discloses tooth punching equipment for carrying out tooth punching on a heat insulation aluminium section by a pouring process, relates to the heat insulation aluminium section, and belongs to the field of aluminium section processing, aluminium section door and window processing and curtain wall aluminium section processing. The aluminium section consists of a left aluminium section, a polyurethane strip and a right aluminium section; the tooth punching equipment for carrying out tool punching on the heat insulation aluminium section by the pouring process comprises a rack, a supporting wheel, left and right guide wheels, an upper pressure wheel, a lower guide roller, a shaft seat, a power source, a spindle, a sliding seat, a guide disk, rolling disks and the like; the rolling disks roll two convex strips on the upper surface of a pouring rabbet; tooth tops of both left and right rolling disks roll triangular grooves or rectangular grooves of the left aluminium section and the right aluminium section; the left and right convex strips are disconnected with the positions of the tooth tops of the rolling disks and the positions of the triangular grooves or the rectangular grooves at the same time so as to form rolled lock points. The rolled lock points increase an adhesive force of the heat insulation polyurethane and aluminium section and improve shearing intensity; the heat insulation aluminium section processed by the tooth punching equipment is a new variety of heat insulation aluminium section; the novel tooth punching equipment is provided.

Owner:DALIAN HUAGONG INNOVATION TECH

Method and application of compound network monitoring packet

InactiveCN102255770BReduce the number of timesReduce the number of transfersData switching networksOperational systemNetwork packet

The invention relates to the technical field of data frame definition and usage of a network monitoring packet, in particular to a method and an application of a compound network monitoring packet. A TAP branching unit is serially connected between a server and an IP (Internet Protocol) switcher or router connected to the server, wherein a branch of the TAP branching unit is connected to a data collecting device; the data collecting device is connected to a follow-up processor; the TAP branching unit is used for copying various packets sent by the server at real time and sending the packets to the data collecting device; the packets collected by the data collecting device are original packets; the data collecting device is used for defining the data frames of the original packets; an operation system is used for storing the original packets; and the collected original packets on the data collecting device are combined and merged, thereby forming the compound network monitoring packet; and the compound network monitoring packet is sent to the follow-up processor and is subjected to the follow-up processing. The method and the application of the compound network monitoring packet provided by the invention are used for obviously reducing the load capacities of the data collecting device and the follow-up processor and reducing the energy consumption of the device.

Owner:EWANIT IND DEV SHANGHAI

Adhesive toe for gecko robot and movement method thereof

InactiveCN101890988BImprove adhesionSmall desorption forceVehiclesMechanical engineeringFuture of robotics

The invention relates to an adhesive toe for a gecko robot and a movement method thereof and belongs to the field of technical application of biomorphic robots. The toe comprises a flexible material toe base (c) and a sticky material layer (a) which is embedded into the flexible material toe base (c), wherein the height of the lower bottom surface of the sticky material layer (a) is equal to thatof the flexible material toe base (c); and a spring layer (b) is also formed on the flexible material toe base (c). The toe has three specific structures, namely flat-shaped, semi-arc and arched stereo structures with bending of 180 degrees. According to the characteristic of a special cantilever type structure, the driven mode is adopted, so that the characteristics that the toe has the larger adhesion in one direction and the smaller desorption force in the negative direction are provided, and the mechanical anisotropy characteristics that a gecko has the larger adhesion in the one direction and the smaller desorption force in the negative direction can be simulated fully and are applied to the gecko robot.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

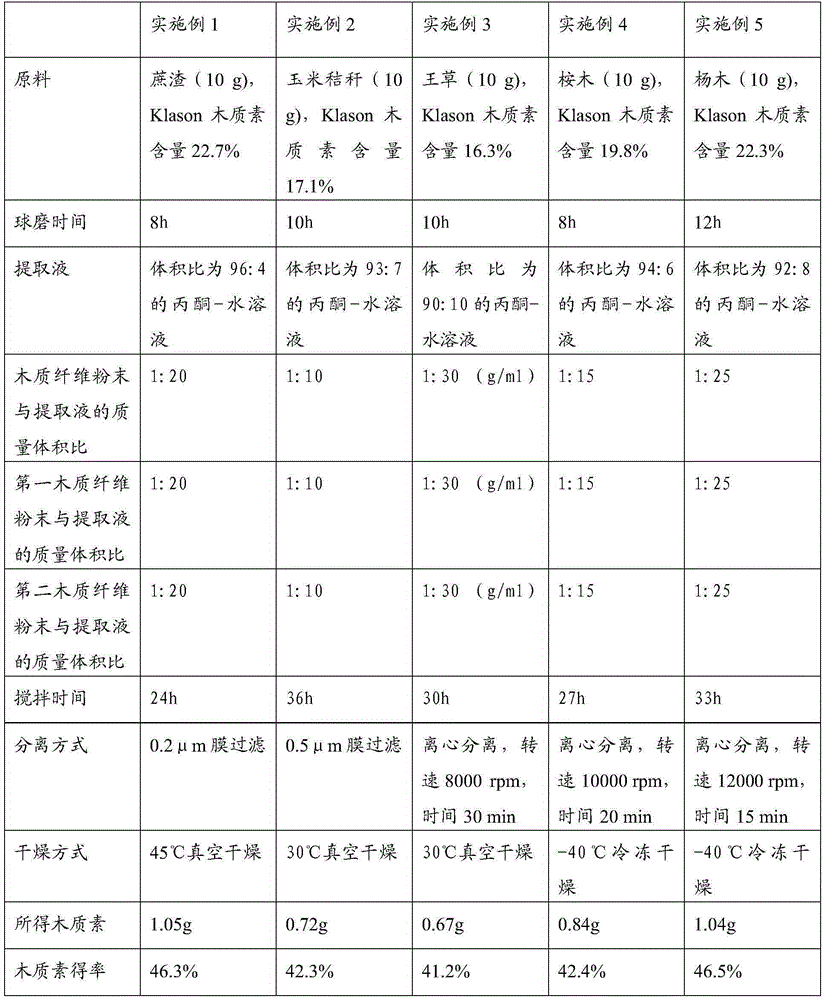

Method for extracting lignin from wood fiber cell walls

InactiveCN105256631ALow equipment requirementsReduce equipment energy consumptionPaper material treatmentRotary evaporatorFreeze-drying

The invention discloses a method for extracting lignin from wood fiber cell walls. The method comprises the following steps: 1, crushing a wood fiber raw material, and extracting wood fiber powder by using a benzene-ethanol solution to obtain extract-free wood fiber powder; 2, carrying out ball milling on the obtained extract-free wood fiber powder for 8-12h through a ball mill, dispersing the ball milled powder in an extract liquid to obtain a suspension, stirring at normal temperature in a closed container for 24-36h, and filtering and separating, or centrifuging and separating to obtain wood fiber powder and a solution; and 3, carrying out rotary evaporation on the solution at a temperature being lower than 45DEG C through a rotary evaporator to obtain solid extract, and carrying out vacuum drying or freeze drying to obtain the lignin. The method reduces the temperature in the rotary evaporation process, reduces the lignin denaturation possibility, improves the rotary evaporation efficiency, reduces the production cost, and is of great scientific significance to identify the structure of wood fibers.

Owner:SOUTH CHINA AGRI UNIV

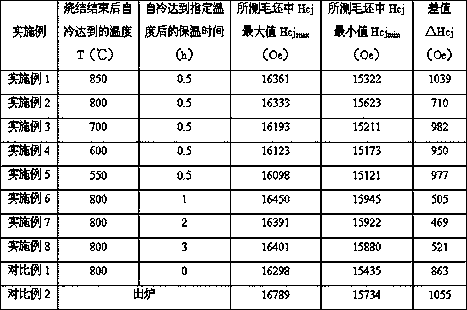

Heat treatment method for improving consistency of intrinsic coercive force of neodymium iron boron blank

InactiveCN108907203AReduce temperature differenceReduce generationMagnetic materialsNitrogenIntrinsics

The invention discloses a heat treatment method for improving the consistency of the intrinsic coercive force of neodymium iron boron blank. The method includes the following steps: step one, putting,in a glove box filled with nitrogen, the formed neodymium iron boron pressing blank into a stone mill box, adding a cover on the stone mill box, and pushing the stone mill box into a vacuum sinteringfurnace for sintering; step two, after sintering, self-cooling the magnetic body to 550-850 DEG C, keeping warm for 0.5-3 hours, and then heating into a first-grade aging stage; step three, after thefirst-grade aging stage, cooling the magnetic body to 75-85 DEG C by wind, and then heating into a second-grade aging stage; and step four, after the second-grade aging stage, cooling the magnetic body to 75-85 DEG C by the wind and taking the magnetic body out off the furnace, taking off the cover on the stone mill box, cooling the magnetic body to 35-45 DEG C by a fan, and acquiring the neodymium iron boron blank. The consistency of the intrinsic coercive force of the neodymium iron boron blank from the same furnace made by the heat treatment method is improved obviously, and meanwhile, themethod can effectively shorten the heat treatment time of the blank, so that the production cost and equipment energy consumption are reduced.

Owner:CHINA JILIANG UNIV

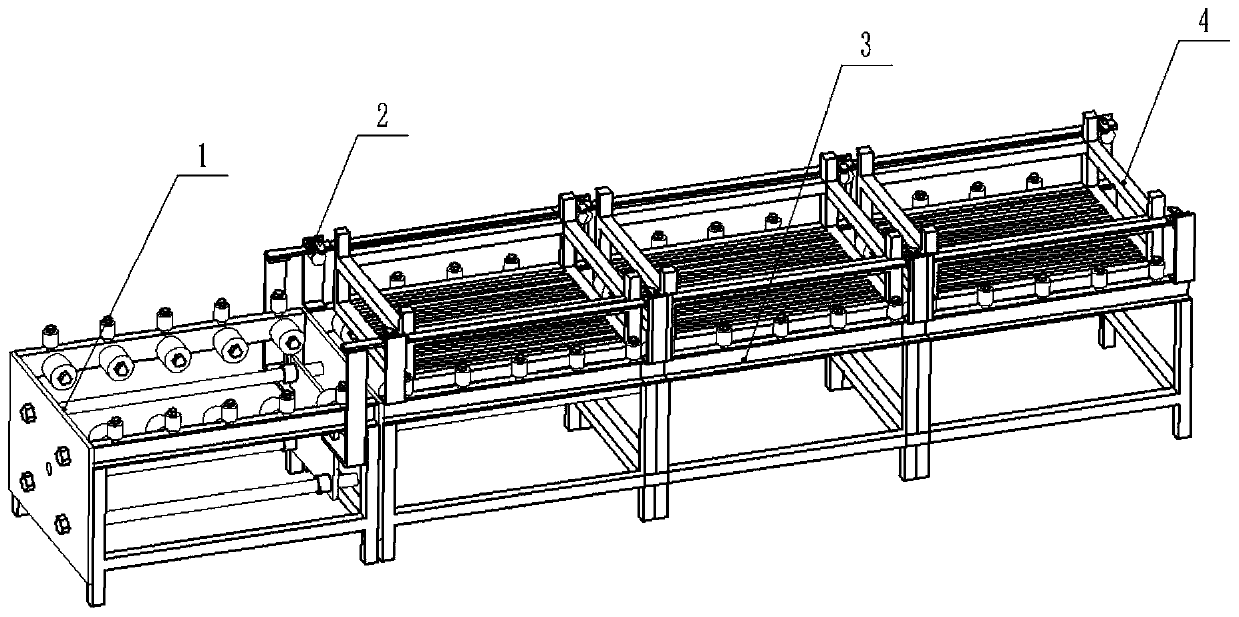

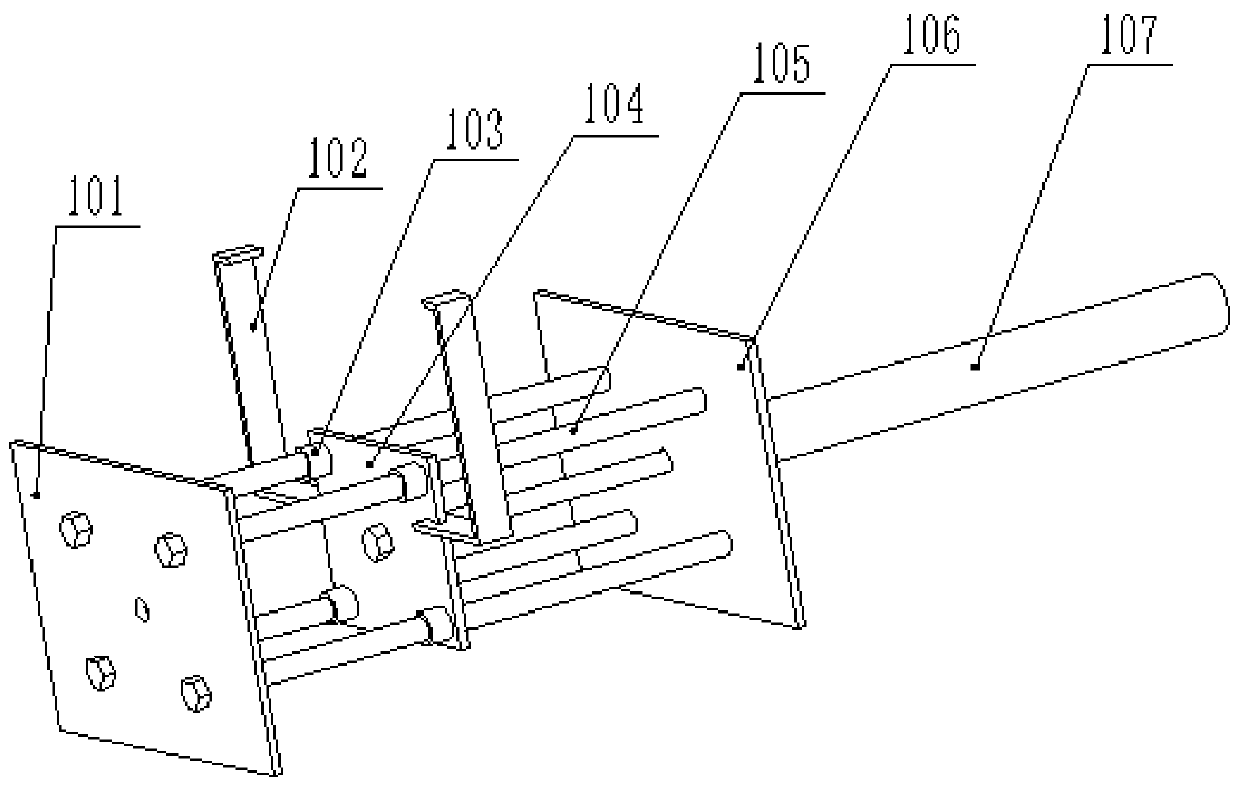

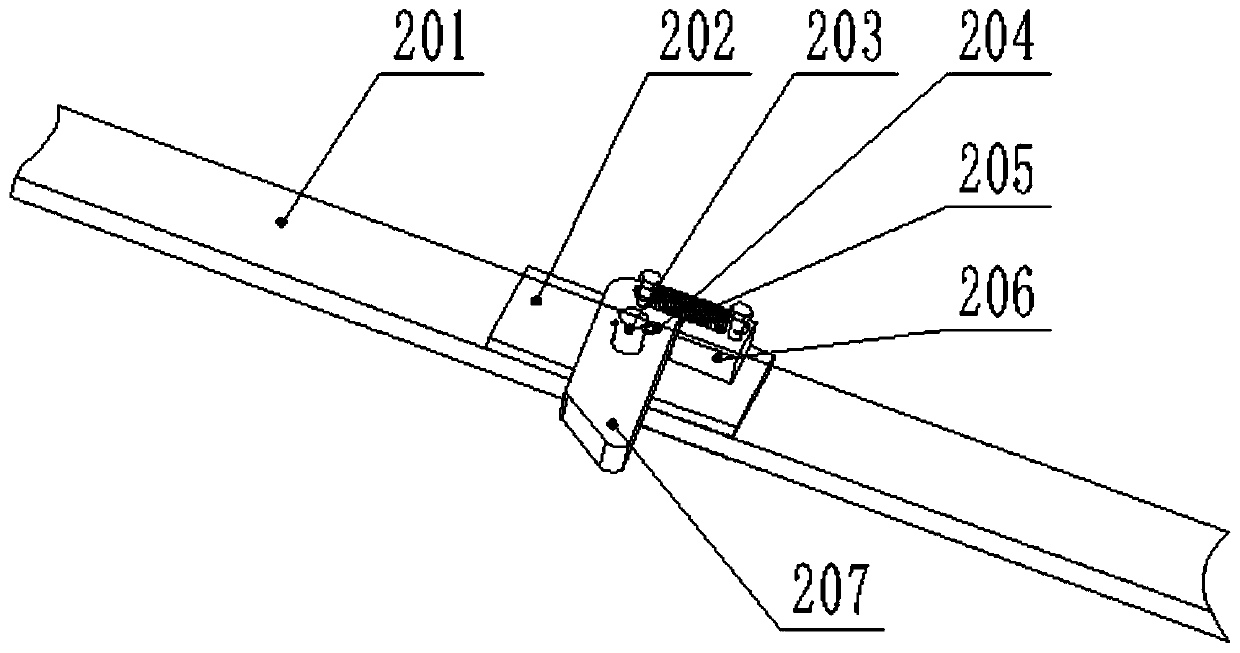

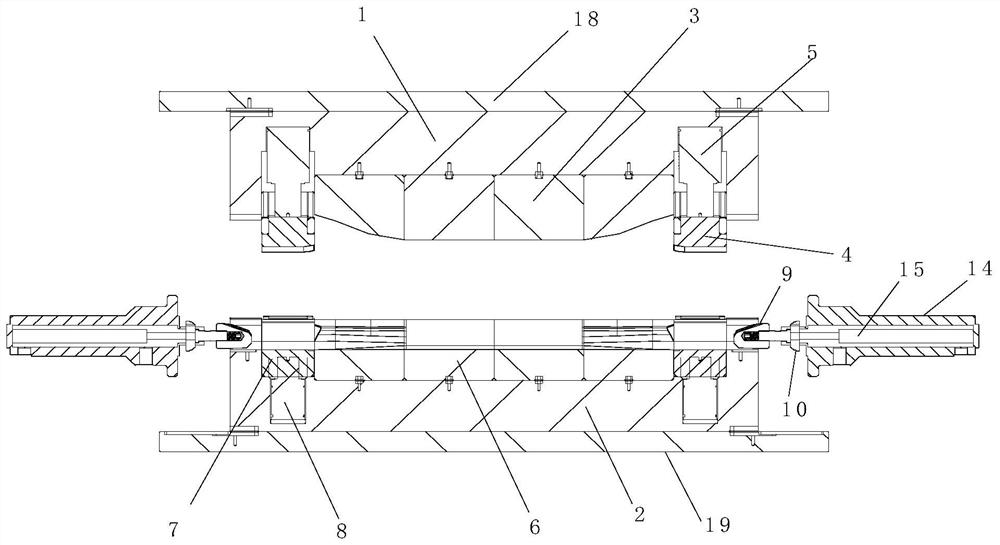

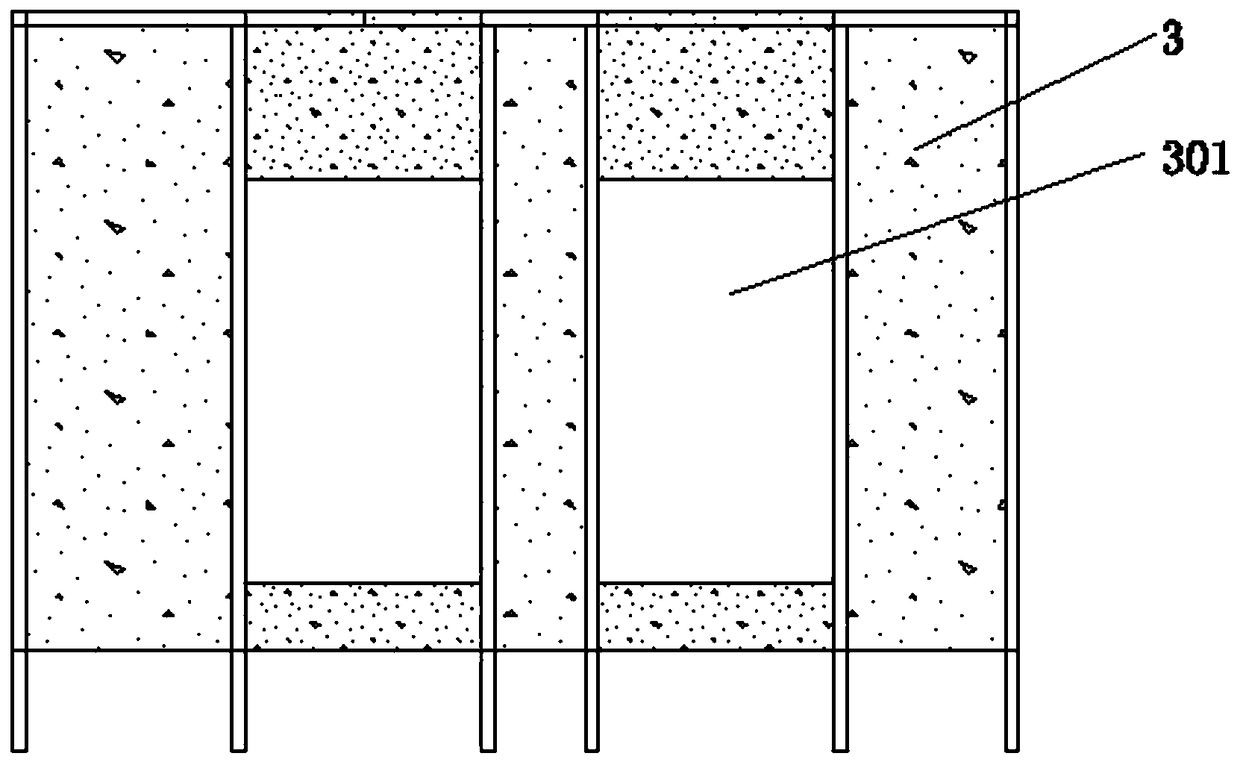

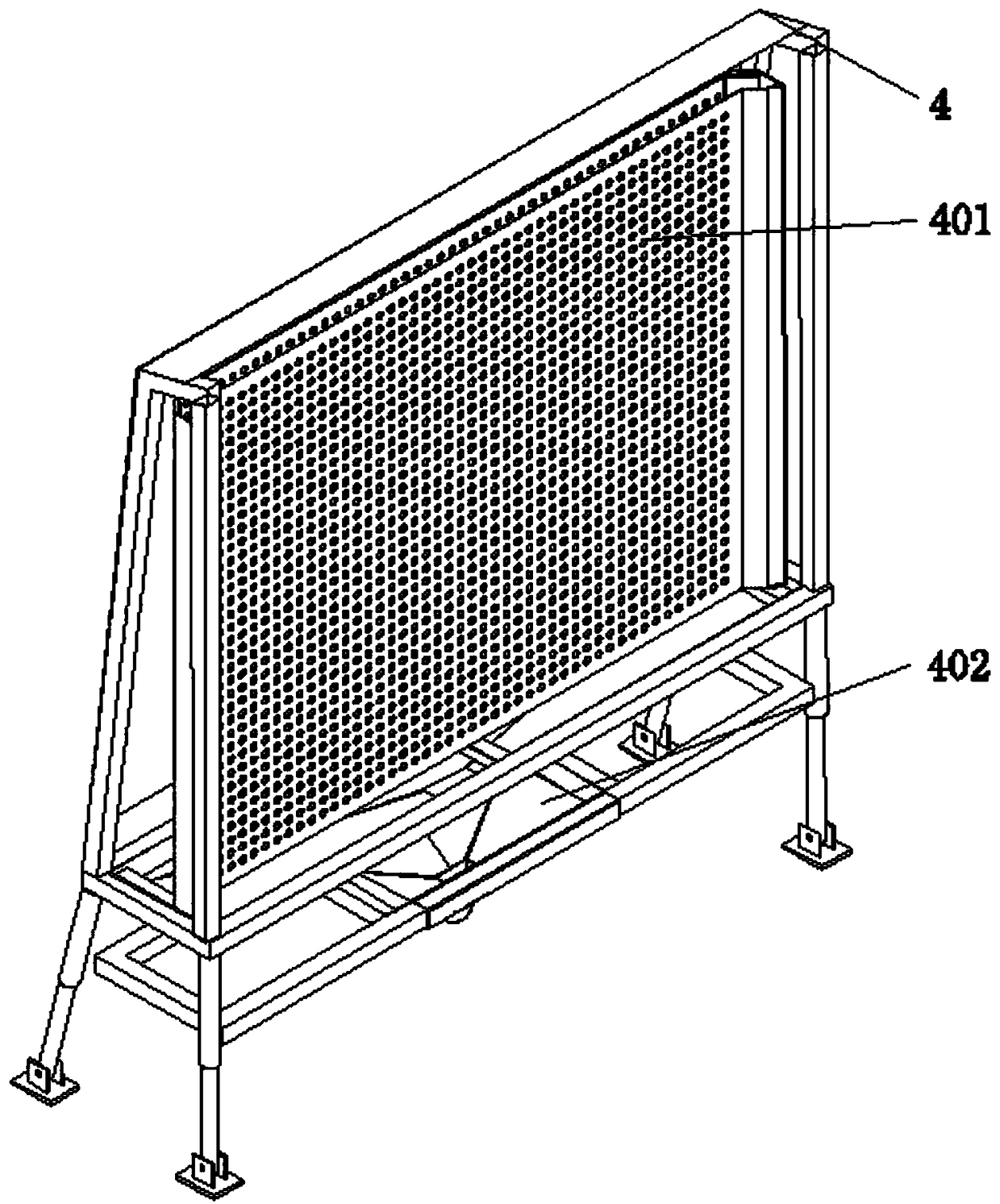

Multi-station conveying facility

PendingCN110683289AReduce manufacturing costReduce equipment energy consumptionConveyorsSupporting framesReciprocating motionControl engineering

The invention relates to a multi-station conveying facility. The multi-station conveying facility comprises a driving device, a transmission engaging device and a station combination device. The station combination device comprises multiple conveying station mechanisms (3) which are arranged in sequence in the mode of corresponding to multiple stations. A material frame (4) is suitable for being placed and supported on each conveying station mechanism. The driving device can drive the multiple material frames on the multiple conveying station mechanisms to synchronously move through the transmission engaging device. The transmission engaging device comprises at least one pulling belt and shifting fork mechanism (2). The pulling belt and shifting fork mechanisms are driven by the driving device to conduct reciprocating movement, and the material frames are driven to simultaneously advance. An electrical system and a mechanical system in an existing conveying mechanism are simplified, the manufacturing cost of the facility and the energy consumption of the facility are reduced, the number of fault points is reduced, and the working efficiency is improved by the simultaneous and synchronous conveying operation.

Owner:CITIC DICASTAL

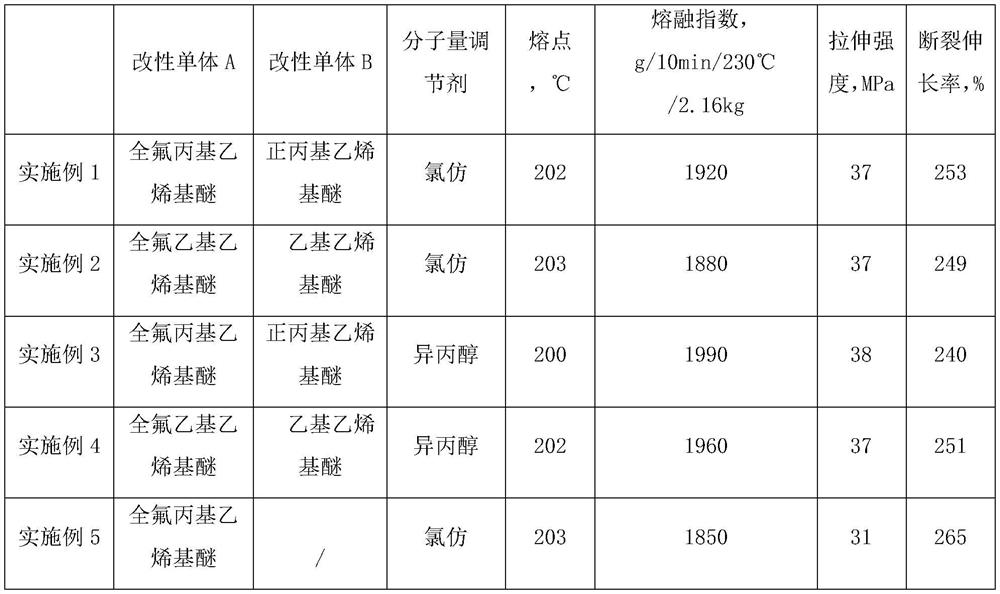

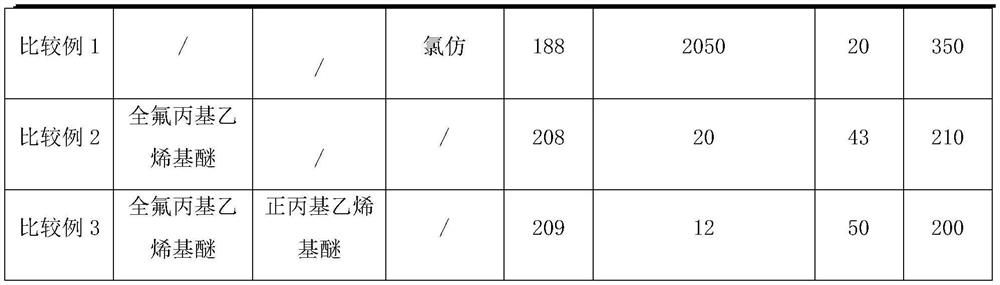

Ethylene-chlorotrifluoroethylene copolymer for melt blowing and preparation method thereof

PendingCN114349888ALower melting temperatureImprove melt indexMonocomponent synthetic polymer artificial filamentNon-woven fabricsPolymer scienceMelt flow index

The invention discloses an ethylene-trifluorochlor oethylene copolymer for melt blowing, comonomers of the ethylene-trifluorochlor oethylene copolymer comprise ethylene, trifluorochlor oethylene and a modified monomer A, and the modified monomer A is RX-(CF2) m-O-CF = CF2. The invention also discloses a preparation method of the ethylene-trifluorochlor oethylene copolymer for melt blowing. The ethylene-trifluorochlor oethylene copolymer disclosed by the invention has good mechanical strength, lower melting temperature and ultrahigh melt index, can be used for preparing melt-blown non-woven fabrics, and is suitable for filter elements for industrial filtration.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

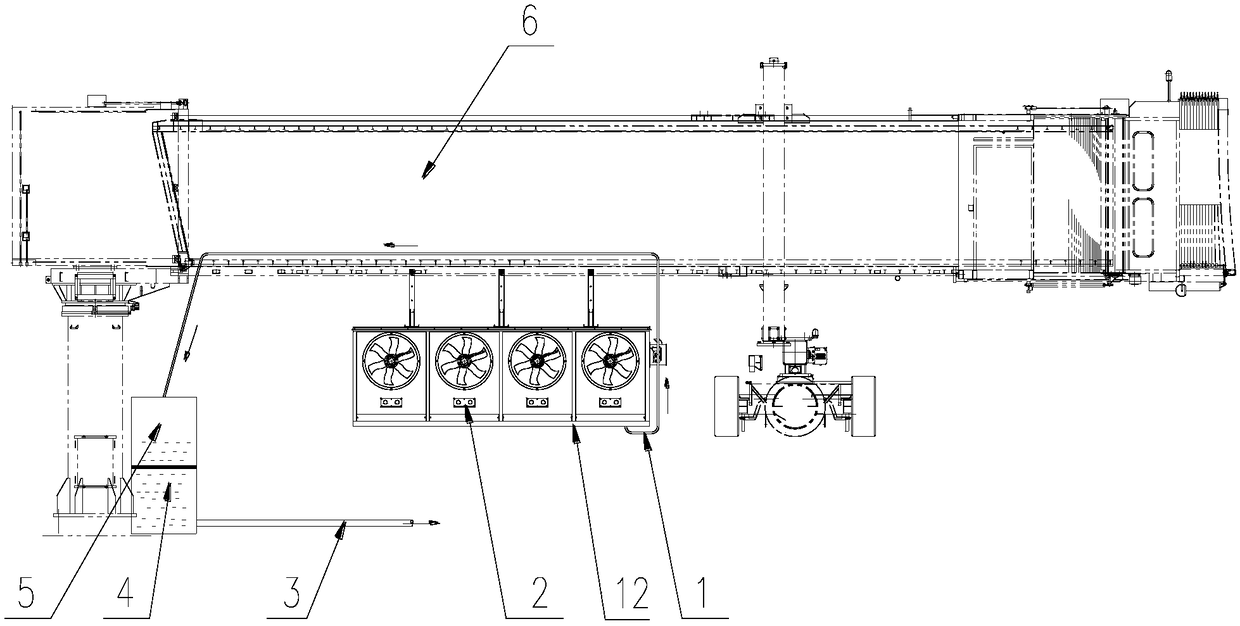

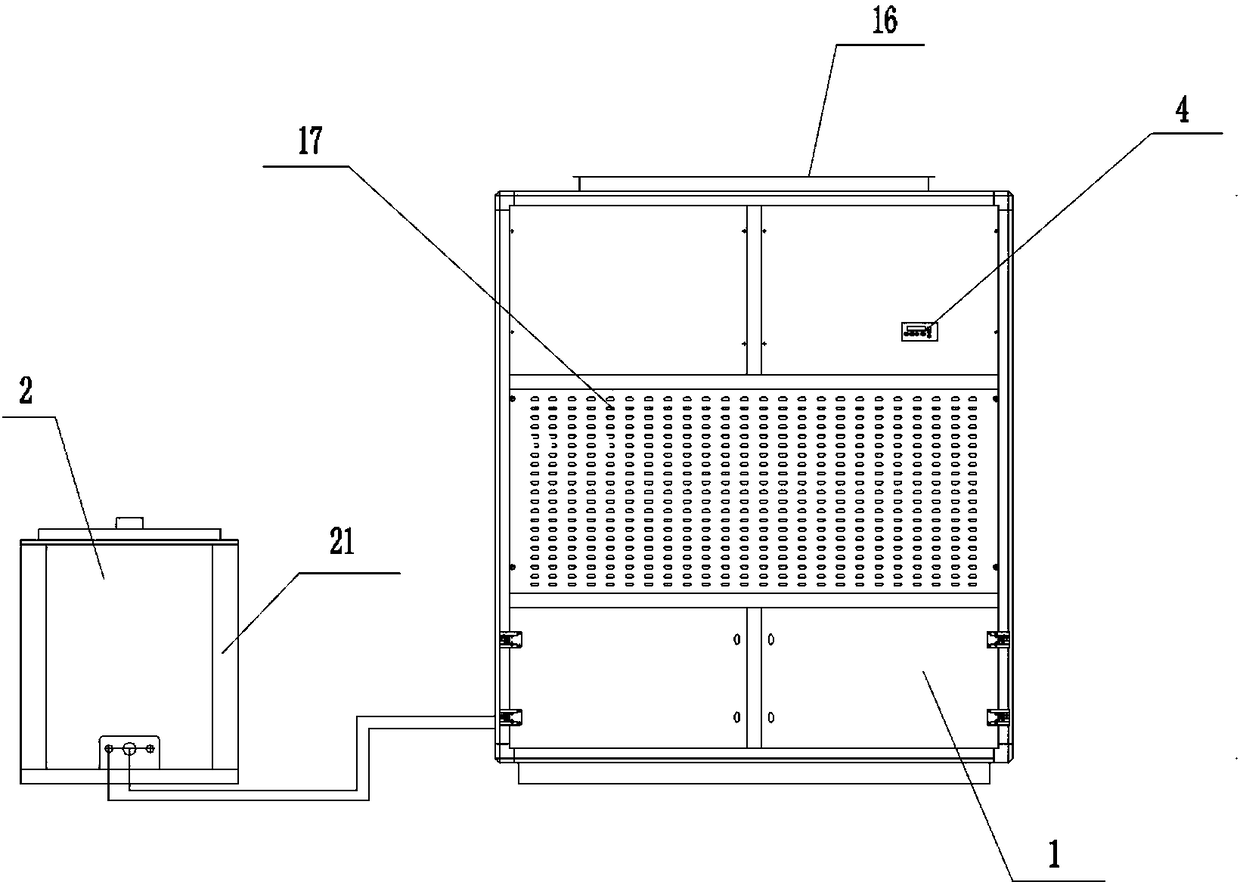

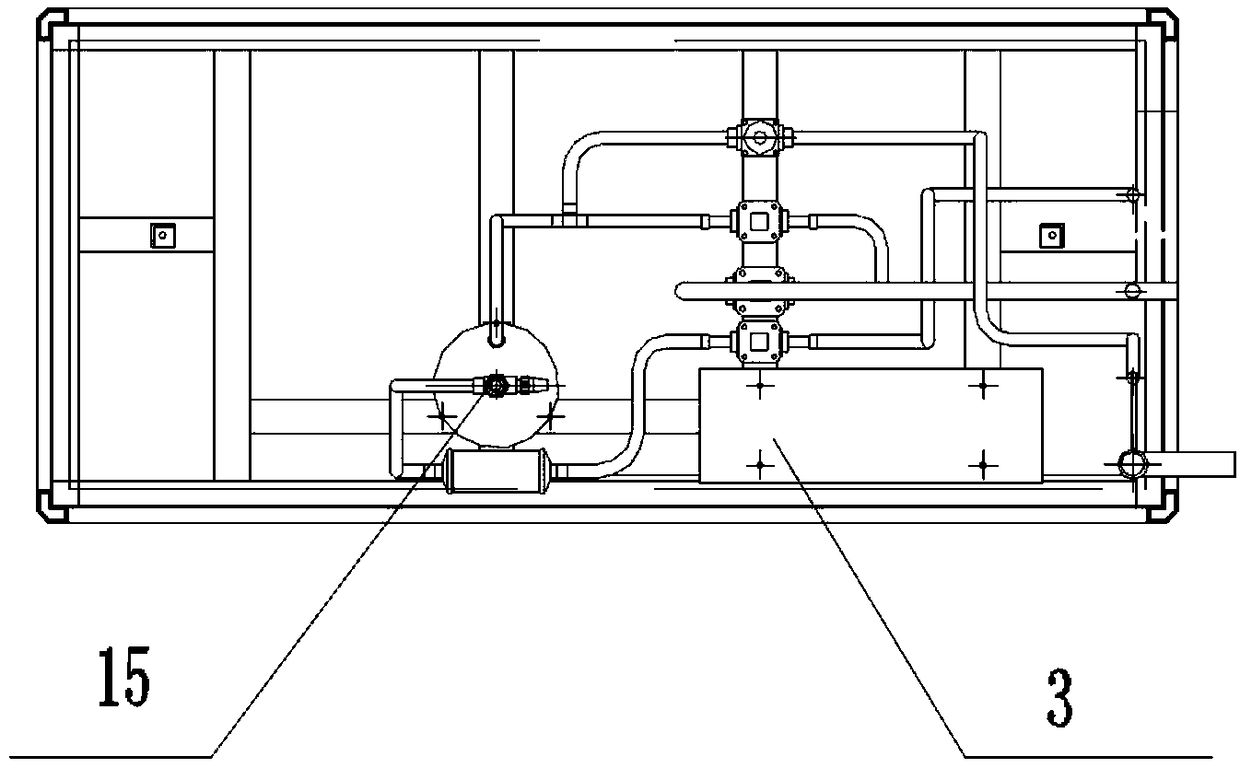

Comprehensive utilization system for condensate water of aircraft air conditioner

PendingCN108163221ALow costReduce equipment energy consumptionWater contaminantsWater/sewage treatment by ion-exchangeCondensed waterWater pipe

The invention discloses a comprehensive utilization system for condensate water of an aircraft air conditioner. The system comprises the aircraft air conditioner, a condensate water collecting tray, afiltering device, a water storage device, an aircraft water supplementing pipe, a condenser water pipe and a spraying device. According to the system, condensed water generated by the aircraft air conditioner is intensively recycled, stored, purified and filtered; when an aircraft stops at a boarding bridge, a water pump is used for injecting water into an aircraft water tank for drinking and living use; compared with a traditional mode of injecting water by means of clear water trunks, the system has the advantages that the manual cost of purchasing the clear water trunks and matched devicesfor airports can be saved, partial condensed water passes through the spraying device to conduct heat dissipation on a condenser at the same time, the equipment energy consumption is reduced, the effects of saving energy and reducing emission are achieved, the waste of water resources is avoided, and the working environment around the aircraft air conditioner is improved.

Owner:四川华盛强环控系统设备有限公司

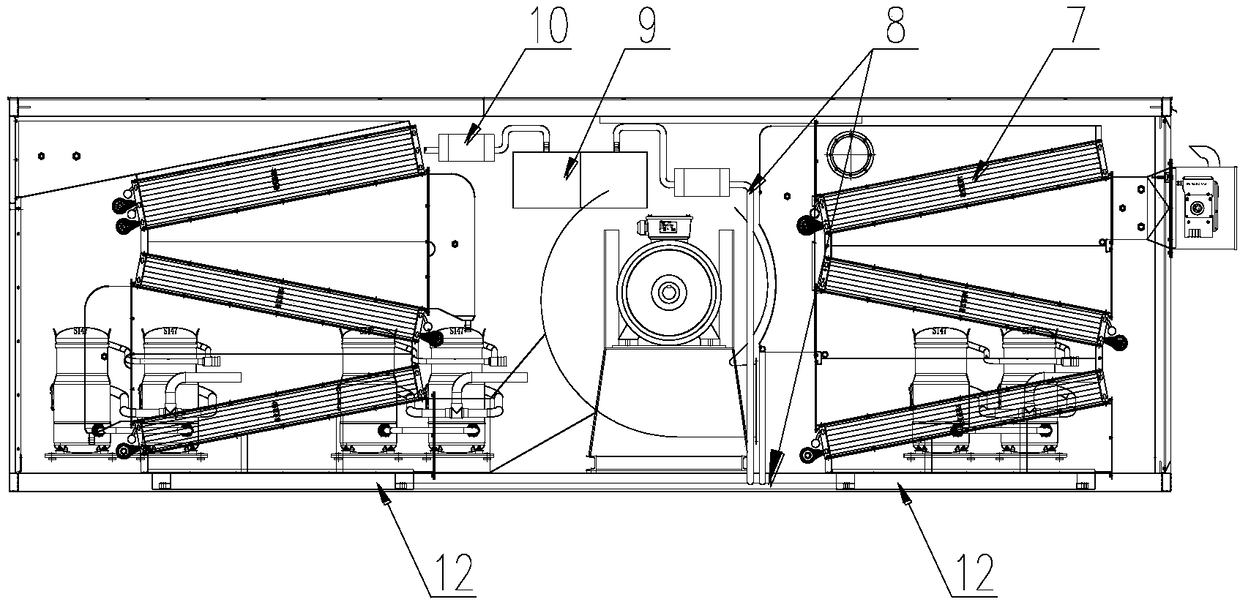

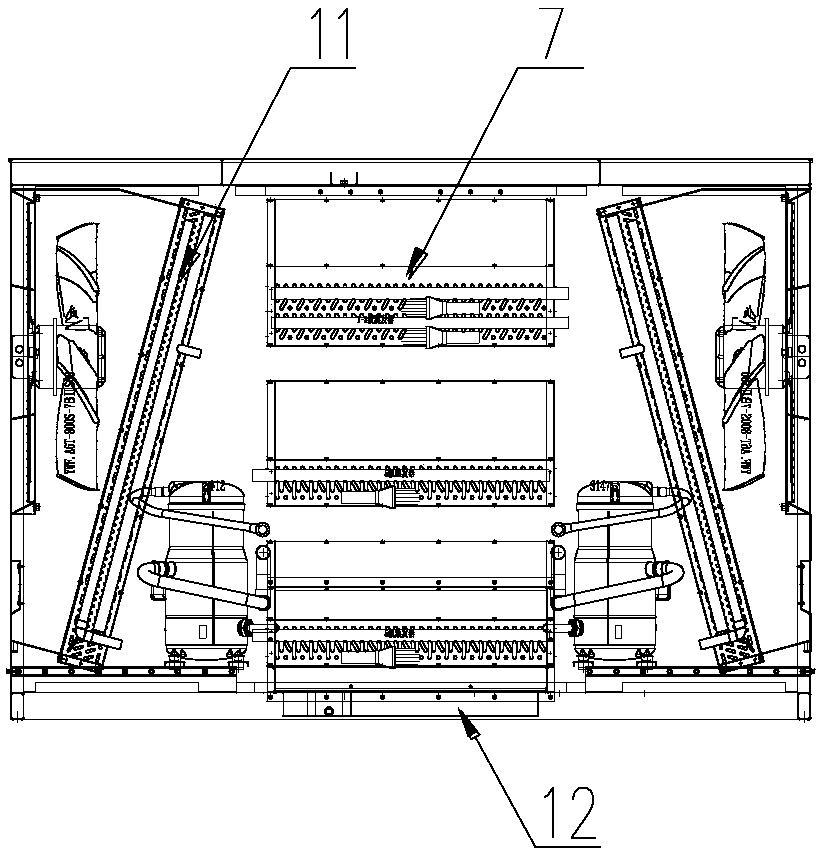

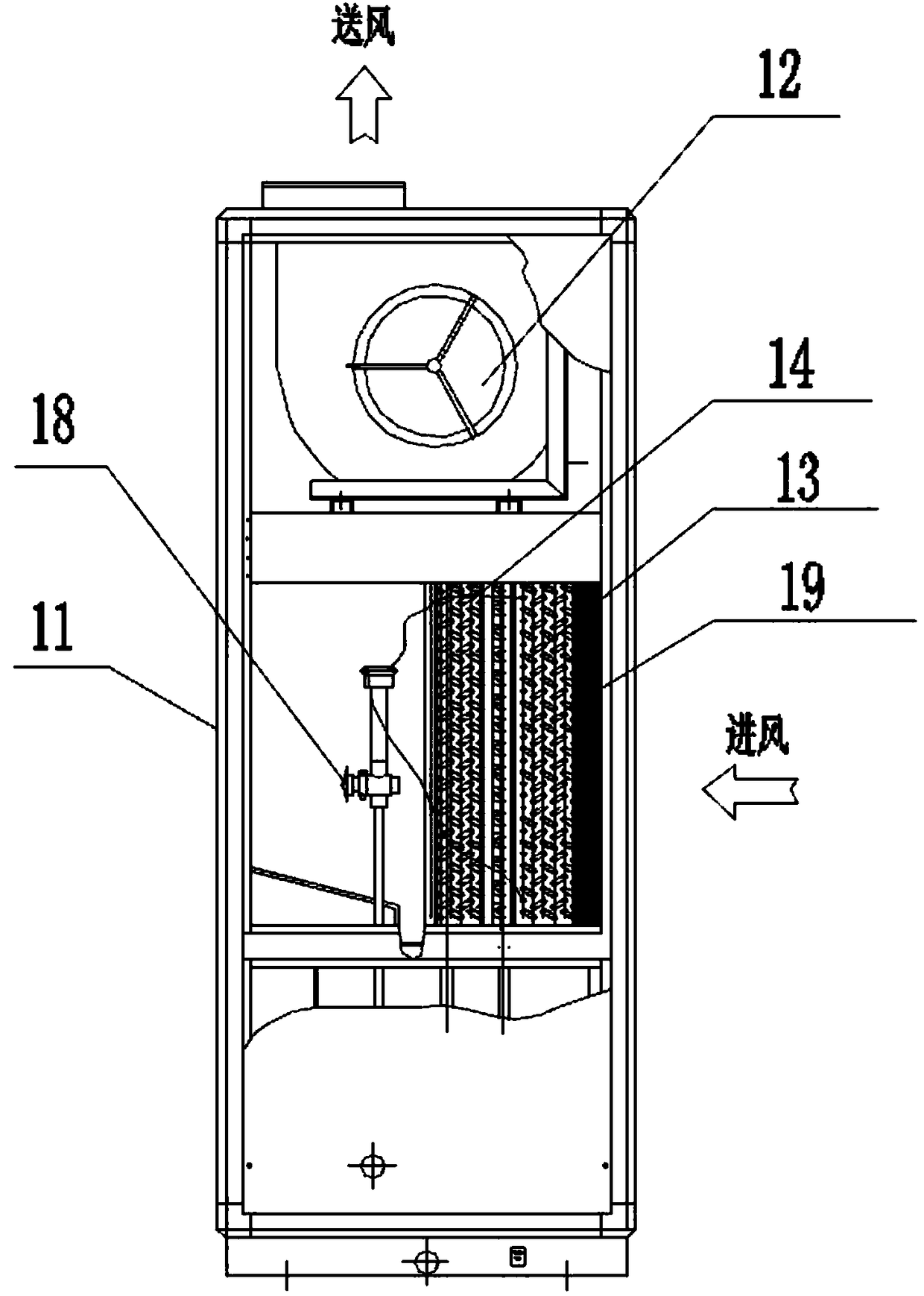

Modular constant-temperature dehumidification and purification air conditioning unit

InactiveCN108302743AReduce equipment energy consumptionReduce the harm of air conditioning diseaseEnergy recovery in ventilation and heatingMechanical apparatusAirflowEngineering

The invention provides a modular constant-temperature dehumidification and purification air conditioning unit, and belongs to the field of refrigeration and air conditioning. By means of the modular constant-temperature dehumidification and purification air conditioning unit, an energy recovery module is used to recover a part of heat which is discharged out of the modular constant-temperature dehumidification and purification air conditioning unit and the heat is used for raising the air supply temperature of the modular constant-temperature dehumidification and purification air conditioningunit, so that the energy-saving purpose is achieved. To achieve the technical effects, the following technical scheme is adopted. The modular constant-temperature dehumidification and purification airconditioning unit comprises an indoor unit and an outdoor unit; the outdoor unit is internally provided with a condenser; the indoor unit comprises a unit housing, an air supply fan, an evaporative cooling and dehumidification module, the energy recovery module and a compressor; after an air flow enters, the air flow passes through the evaporative cooling and dehumidification module for cooling,passes through the energy recovery module for temperature returning, and flows out through the air supply fan; the compressor is connected with the condenser and the energy recovery module; the condenser and the energy recovery module are connected with an expansion valve; the expansion valve is connected with the evaporative cooling and dehumidification module; and the evaporative cooling and dehumidification module is connected with the compressor.

Owner:上海非众制冷设备有限公司

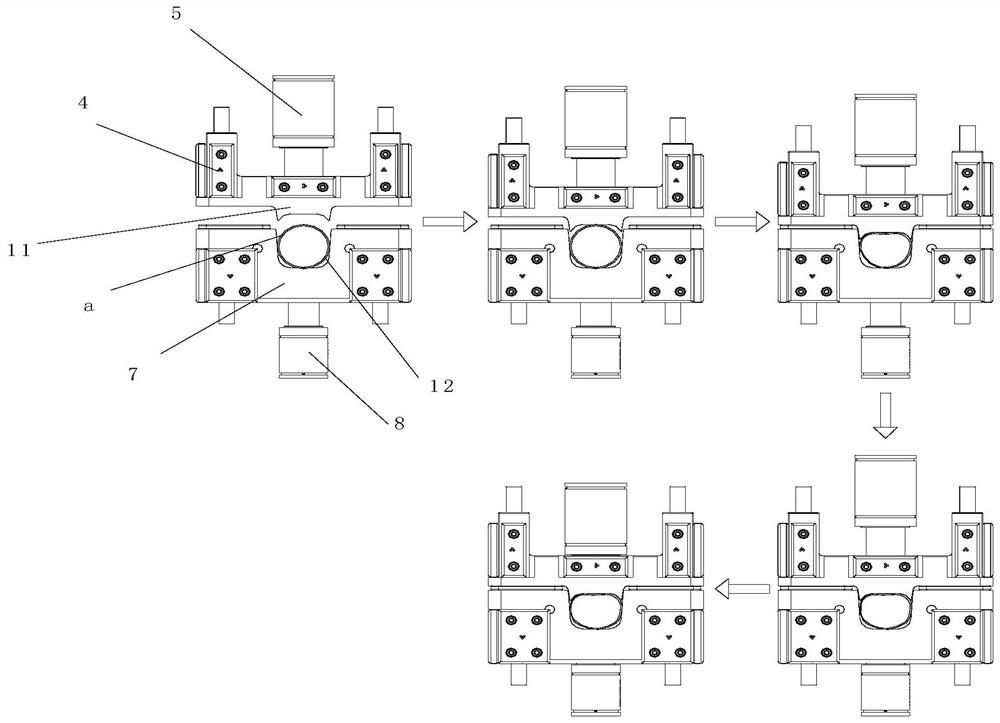

Torsion beam internal high-pressure one-time forming method

The invention provides a torsion beam internal high-pressure one-time forming method. The torsion beam internal high-pressure one-time forming method comprises the following steps that S1, a forming mold is opened; s2, the two ends of the pipe are placed on two material supporting blocks correspondingly, an upper die base is driven to move downwards, and when the two material pressing blocks make contact with the two ends of the pipe, the material supporting blocks are driven to move downwards; when the material supporting block moves downwards to a preset distance, the upper die base and the material supporting block stop moving downwards, and profiling core rods are inserted into preset positions at the two ends of the pipe correspondingly; s3, the upper die base and the material supporting block continue to move downwards, when the material supporting block moves downwards to a preset distance, the material supporting block stops moving, and the material pressing block is driven to move upwards; when the material pressing block moves upwards to a preset distance, the upper die base and the material pressing block stop moving, and sealing heads are inserted into preset positions at the two ends of the pipe correspondingly; and S4, the interior of the pipe is filled with water, and internal high-pressure one-time forming of the pipe is completed through pressurization, pressure maintaining and pressure relief actions. An intermediate procedure is omitted, the equipment requirement and energy consumption are reduced, the mold input cost is reduced, the efficiency is improved, and the product stability is improved.

Owner:BAOLONG ANHUI AUTO PARTS

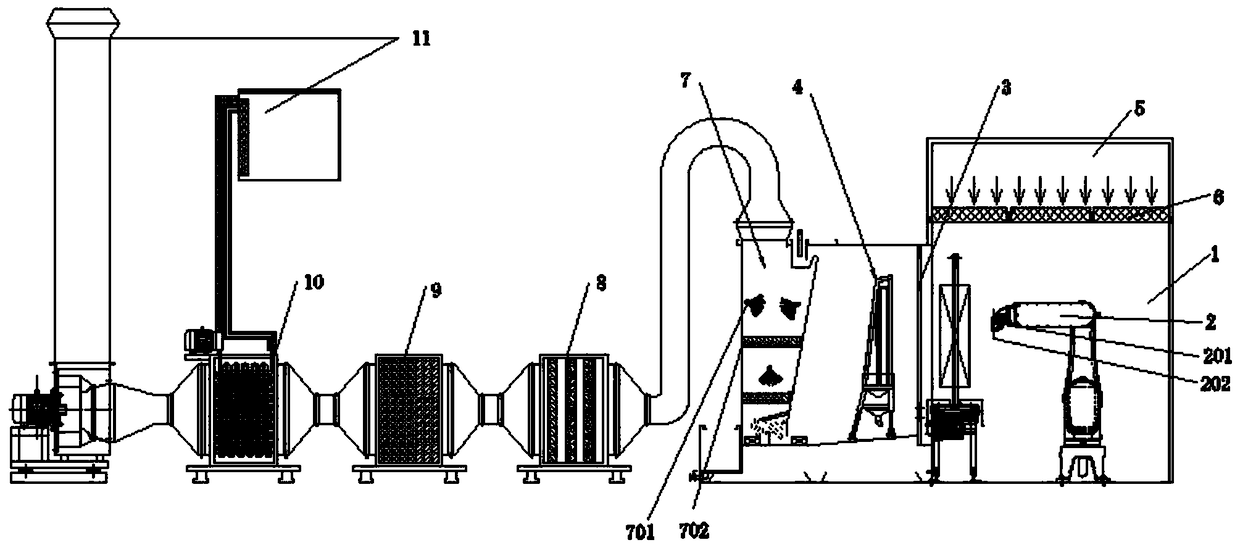

Spraying device

The invention discloses a spraying device. The device comprises a spraying chamber, a product placing area and a spray gun arranged in the spraying chamber, wherein the spray gun is provided with a nozzle, one side, close to the nozzle, in the spraying chamber is provided with a profiled partition plate, an opening is formed in the partition plate, the product placing area is arranged between thepartition plate and the nozzle, the opening in the partition plate is used for allowing a sprayed material to pass through the opening; the spraying device further comprises a collecting device arranged in the spraying chamber, the collecting device is arranged at the side, away from the spray gun, of the partition plate, and the collecting device is used for recovering the sprayed material passing through the opening; the spraying device not only can greatly reduce the air volume and energy consumption, but also can greatly improve the utilization rate of the sprayed material and reduce the pollution to the environment; generated exhaust heat energy can be reused to greatly reduce the cost.

Owner:XIAMEN RUNNER IND CORP

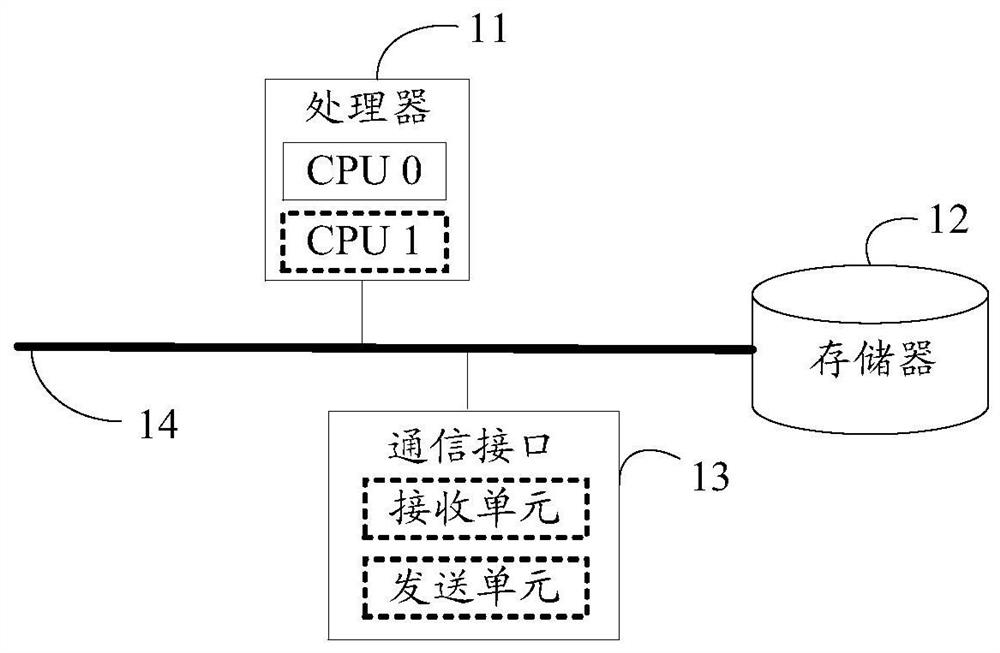

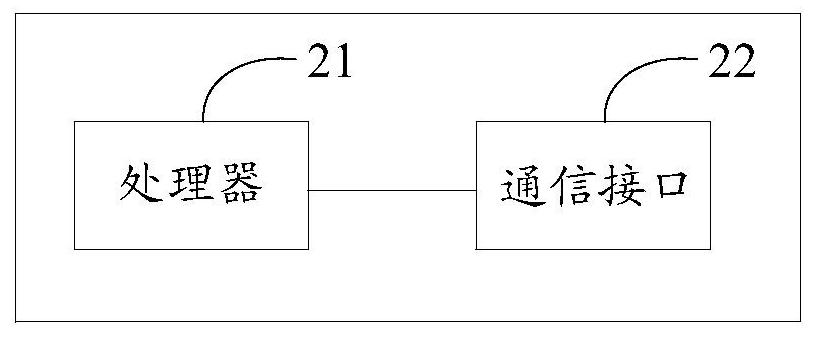

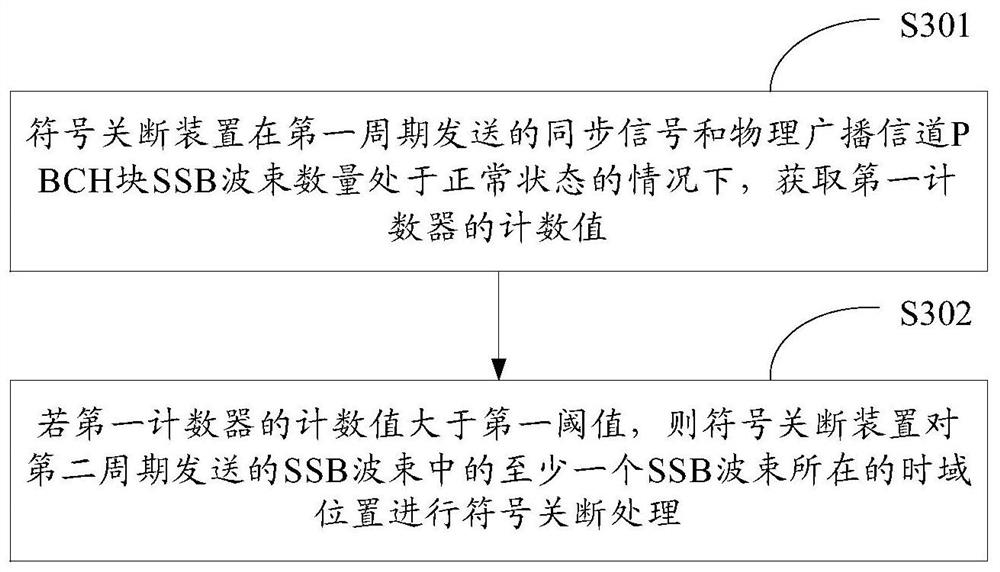

Symbol turn-off method and device

ActiveCN112654079AReduce equipment energy consumptionImprove energy saving effectPower managementConnection managementTelecommunicationsElectrical and Electronics engineering

The embodiment of the invention provides a symbol turn-off method and device, relates to the technical field of communication, and is used for improving the use frequency of a symbol turn-off technology in the prior art and improving the energy-saving effect. The symbol turn-off method comprises the steps of obtaining a count value of a first counter under the condition that a synchronization signal sent in a first period and the number of SSB beams of a PBCH block are in a normal state; if the count value of the first counter is greater than the first threshold value, symbol turn-off processing is performed on the time domain position where at least one SSB beam in the SSB beams sent in the second period is located, wherein the second period is an SSB wave beam sending period adjacent to the first period, and the first counter is used for counting the number of times that the cell is in a low-load state in periodic load detection.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

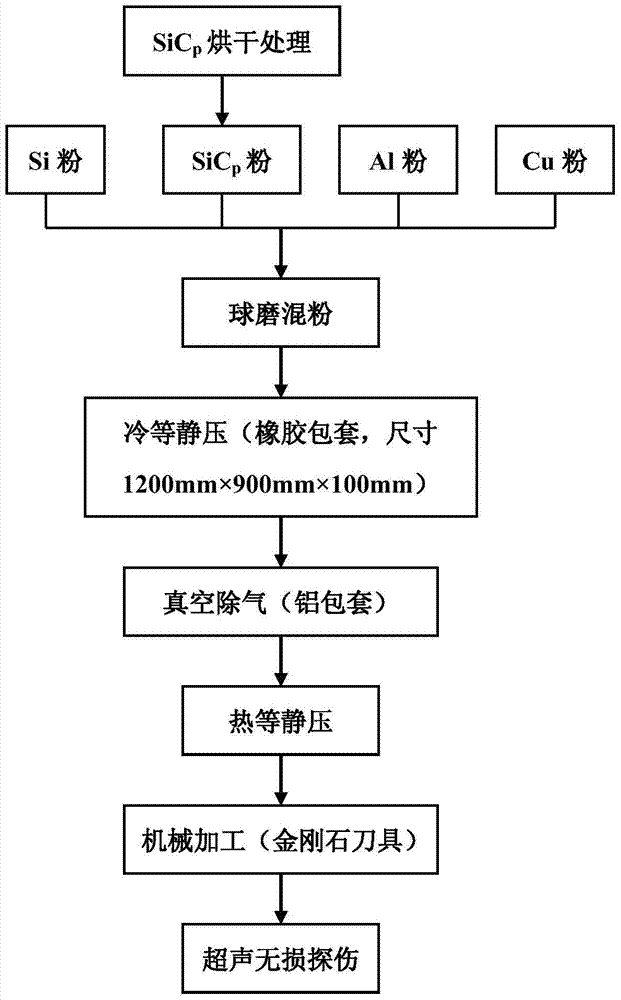

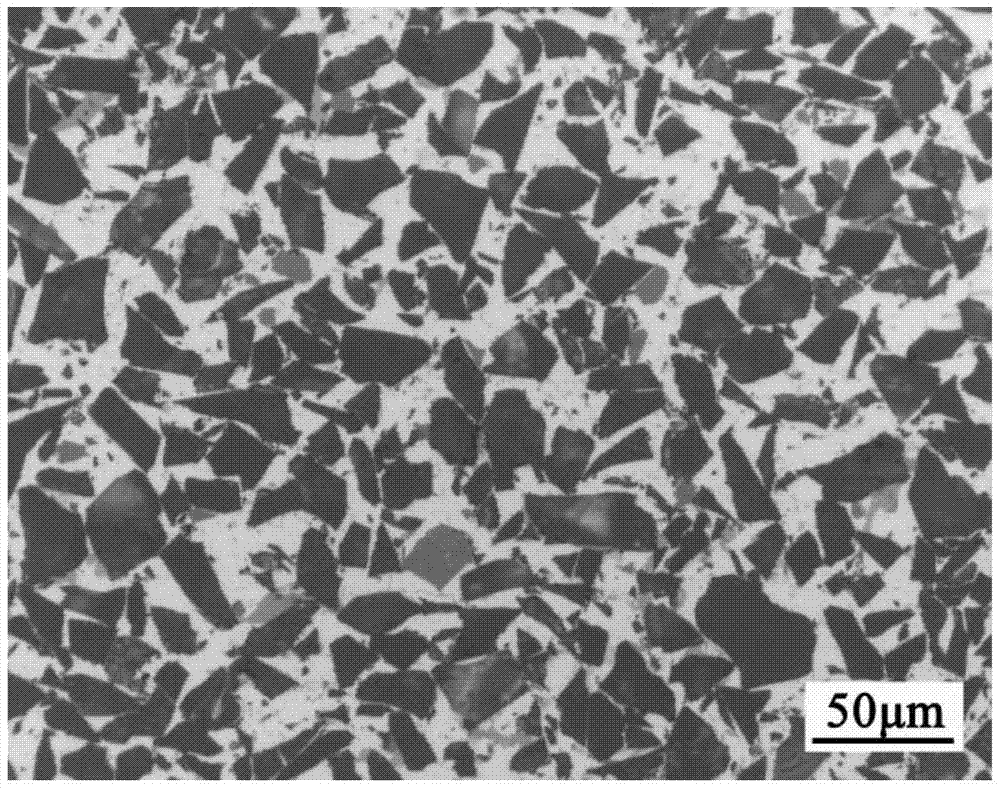

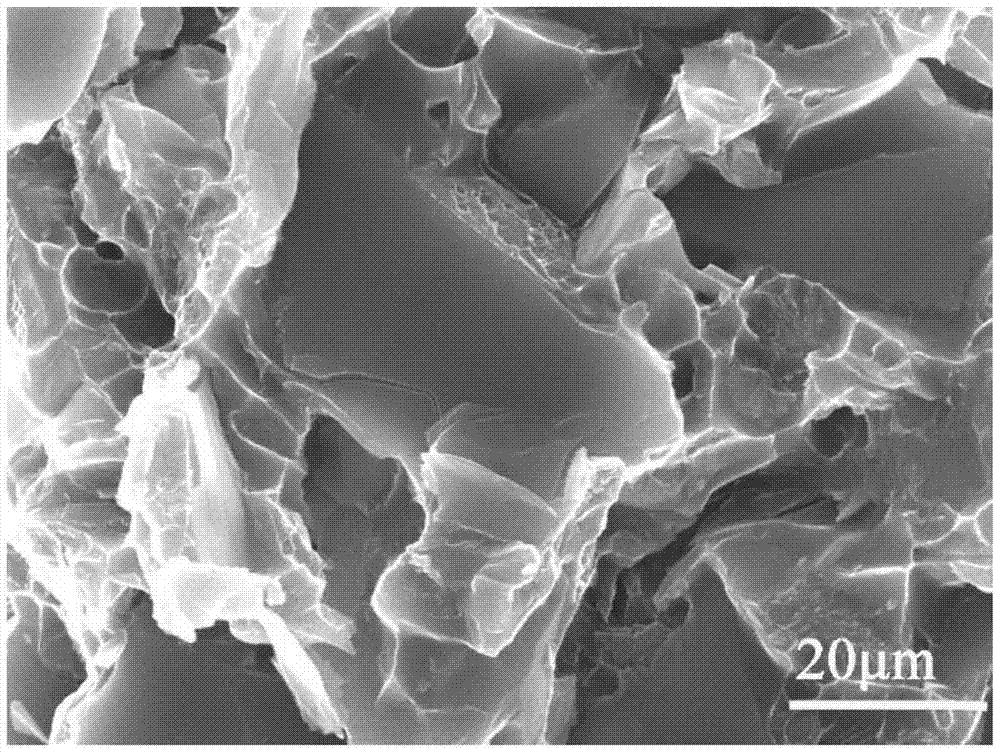

High volume fraction silicon carbide particle reinforced aluminum matrix composite material and its preparation method

ActiveCN105714137BImprove mechanical propertiesGood physical propertiesFlexural strengthThermal expansion

The invention relates to a high-volume-fraction silicon carbide particle-reinforced aluminum-based composite material and a preparation method thereof, belonging to the field of new material research and development. The material is composed of silicon carbide particle reinforcement phase and aluminum alloy matrix, the volume fraction of silicon carbide particles is 55-60vol.%, the aluminum alloy matrix is 40-45vol.%, and the aluminum alloy matrix is Al-Cu-Si alloy. The invention adopts the powder metallurgy process to prepare the composite material, and obtains the aluminum-based composite material with large size, thin wall, high elastic modulus, high bending strength, low thermal expansion coefficient, low thermal conductivity, high compactness and comprehensive performance, and the composite material The overall size is 900mm×700mm×60mm. The excellent comprehensive performance of this material can better meet the requirements of the optical-mechanical structural parts of aerospace optical remote sensors.

Owner:有研金属复材技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com