Heat treatment method for improving consistency of intrinsic coercive force of neodymium iron boron blank

A technology of intrinsic coercive force and heat treatment method, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of long heat treatment time and poor consistency of intrinsic coercive force, so as to ensure consistency and improve consistency , Improve the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

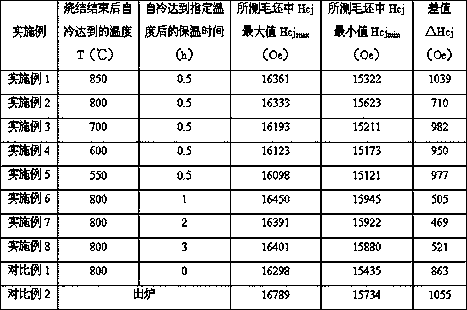

Examples

Embodiment 1

[0021] Embodiment 1: choose the compact of 45M grade, adopt the heat treatment method of the present invention, comprise the following specific steps:

[0022] Step 1: Put the oriented NdFeB compact into a stone mill box in a nitrogen-filled glove box, cover the stone mill box, and push it into a vacuum sintering furnace for sintering;

[0023] Step 2: After sintering, the magnet is self-cooled to 850°C, then kept for 0.5h, and then heated up to enter the primary aging stage;

[0024] Step 3: After the primary aging is over, the magnet is air-cooled to 80°C, and then the temperature is raised to enter the secondary aging stage;

[0025] Step 4: After the secondary aging, air-cool the magnet to 80°C and take it out of the furnace, remove the lid of the stone mill box, and cool the magnet to 40°C with a fan to obtain a NdFeB blank.

[0026] Among them, the heating process of primary aging is as follows: the temperature in the sintering furnace is raised to 905°C at a speed of 4...

Embodiment 2

[0031] Embodiment 2: choose the compact of 45M grade, adopt the heat treatment method of the present invention, comprise the following concrete steps:

[0032] Step 1: Put the oriented NdFeB compact into a stone mill box in a nitrogen-filled glove box, cover the stone mill box, and push it into a vacuum sintering furnace for sintering;

[0033] Step 2: After sintering, the magnet is self-cooled to 800°C, then kept for 0.5h, and then heated up to enter the primary aging stage;

[0034] Step 3: After the primary aging is over, the magnet is air-cooled to 80°C, and then the temperature is raised to enter the secondary aging stage;

[0035] Step 4: After the secondary aging, air-cool the magnet to 80°C and take it out of the furnace, remove the lid of the stone mill box, and cool the magnet to 40°C with a fan to obtain a NdFeB blank.

[0036] Among them, the heating process of primary aging is as follows: the temperature in the sintering furnace is raised to 905°C at a speed of 4...

Embodiment 3

[0041] Embodiment 3: choose the 45M brand compact, adopt the heat treatment method of the present invention, comprise the following specific steps:

[0042] Step 1: Put the oriented NdFeB compact into a stone mill box in a nitrogen-filled glove box, cover the stone mill box, and push it into a vacuum sintering furnace for sintering;

[0043] Step 2: After sintering, the magnet is self-cooled to 700°C, then kept for 0.5h, and then heated up to enter the primary aging stage;

[0044] Step 3: After the primary aging is over, the magnet is air-cooled to 80°C, and then the temperature is raised to enter the secondary aging stage;

[0045] Step 4: After the secondary aging, air-cool the magnet to 80°C and take it out of the furnace, remove the lid of the stone mill box, and cool the magnet to 40°C with a fan to obtain a NdFeB blank.

[0046] Among them, the heating process of primary aging is as follows: the temperature in the sintering furnace is raised to 905°C at a speed of 4°C / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com