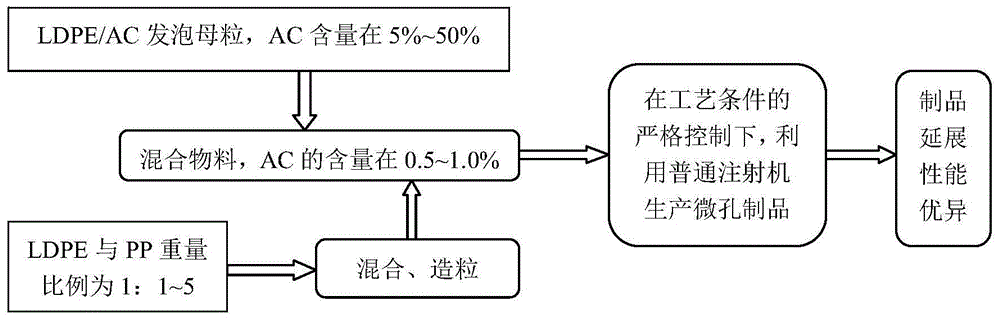

Method for producing ultra-extended pp/ldpe microporous products in ordinary injection machine

An injection machine, a common technology, applied in the direction of coating, etc., can solve the problems of difficult control of process conditions, uncertain super-ductile products, and inconvenient production, so as to reduce internal stress of products, reduce equipment operating costs, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

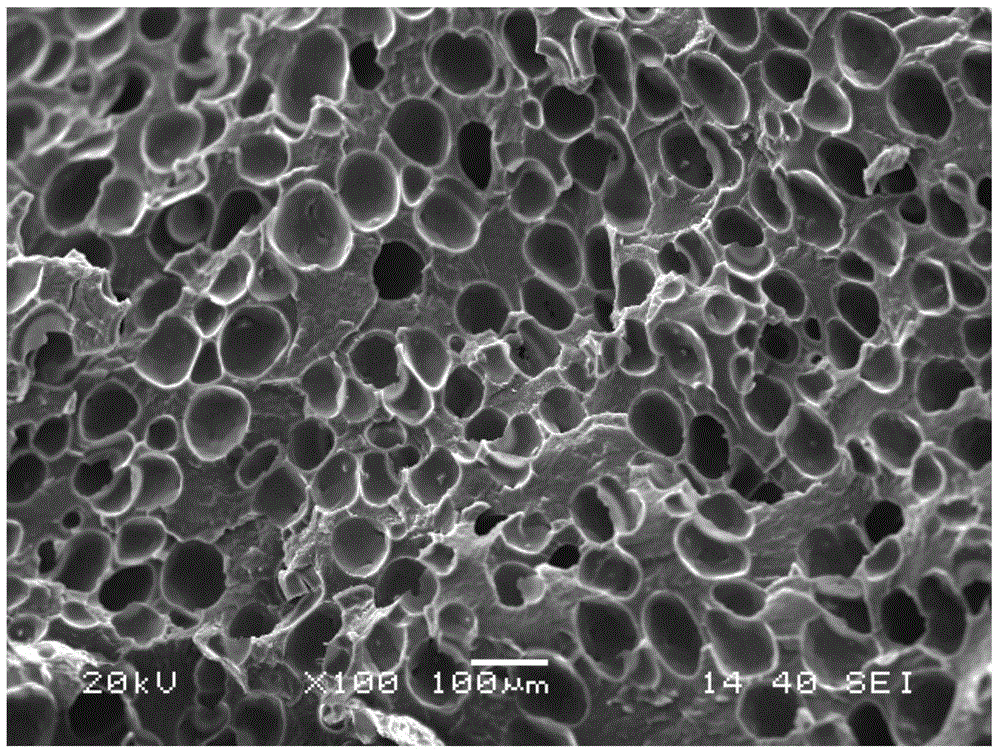

[0030] First, make foam masterbatch. Weigh the raw materials according to the following weight: LDPE: 1.2kg, AC foaming agent: 0.3kg, the mass ratio of AC to LDPE is 1:4. After mixing AC foaming agent and LDPE raw materials, the foaming masterbatch is obtained through an ordinary plastic extruder, and the melt temperature is 165°C during the extrusion process;

[0031] Secondly, weigh the raw materials PP: 4.85KG, LDPE: 4.85KG, the ratio of LDPE to PP mass is 1:1, after mixing evenly, melt, extrude and pelletize through an ordinary plastic extruder, then add 300g of the above foam masterbatch , the mass percentage content of AC formed after mixing is 0.6%, the mass percentage content of PP is 48.5%, and the mass percentage content of LDPE is 50.9%;

[0032] Then, the materials prepared according to the above proportions are evenly mixed and divided into several parts, each with a mass of 24g, which is just enough to ensure that the cavity of the standard drawing mold used is ...

Embodiment 2

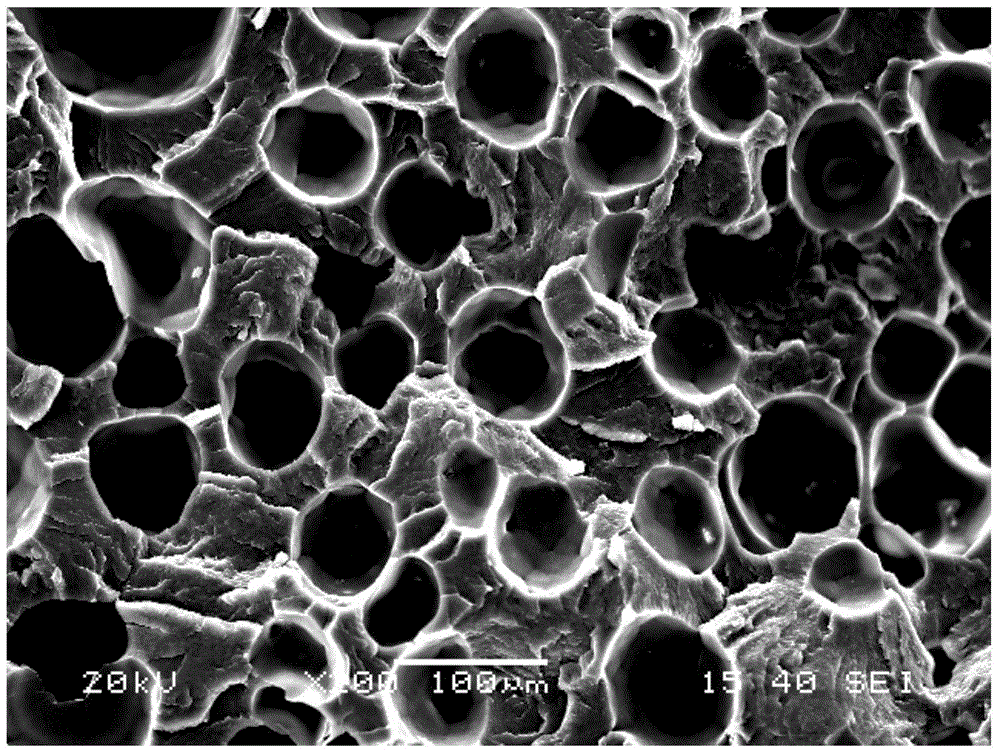

[0036] First, make the foaming masterbatch, weigh the raw materials according to the following weight: LDPE: 1.2kg, AC foaming agent: 0.3kg, the mass ratio of AC to LDPE is 1:4, after mixing the AC foaming agent and LDPE raw materials The foaming masterbatch is produced by ordinary plastic extruder, and the melt temperature is controlled at about 170°C during the extrusion process;

[0037] Next, weigh the raw materials PP: 6.47KG, LDPE: 3.23KG, the mass ratio of LDPE to PP is 1:2, after mixing evenly, melt, extrude and pelletize through an ordinary plastic extruder, then add 300g of the above-mentioned foaming masterbatch , the mass percentage content of AC formed after mixing is 0.6%, the mass percentage content of PP is 64.7%, and the mass percentage content of LDPE is 34.7%;

[0038] Then, mix the materials prepared according to the above ratio evenly and divide them into several parts, the mass of each part is about 48g, which is just enough to ensure that the cavity of t...

Embodiment 3

[0042] First, make foam masterbatch. Weigh the raw materials according to the following weight: LDPE: 1.2kg, AC foaming agent: 0.3kg, the mass ratio of AC to LDPE is 1:4. After mixing AC foaming agent and LDPE raw materials, the foaming masterbatch is obtained through an ordinary plastic extruder, and the melt temperature is controlled at about 165°C during the extrusion process;

[0043] Next, weigh the raw materials PP: 7.275KG, LDPE: 2.425KG, the mass ratio of LDPE to PP is 1:3, after mixing evenly, melt, extrude and pelletize through an ordinary plastic extruder, then add 300g of the above-mentioned foaming masterbatch , the mass percentage content of AC formed after mixing is 0.6%, the mass percentage content of PP is 72.75%, and the mass percentage content of LDPE is 26.65%;

[0044] Then, the materials prepared according to the above proportions are evenly mixed and divided into several parts, each with a mass of 24g, which is just enough to ensure that the cavity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com