Logging equipment and coring and sampling method

A logging instrument and coring technology, which is applied in the direction of extracting undisturbed core devices, earthwork drilling, borehole/well components, etc., can solve the problem of difficulty in improving the operational efficiency of the logging process, increasing the weight of the instrument and the burden of energy consumption, and the structure of the instrument Problems such as the increase of components can be solved to achieve smooth logging operations, reduce structural costs and equipment energy consumption, and reduce the number of trips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

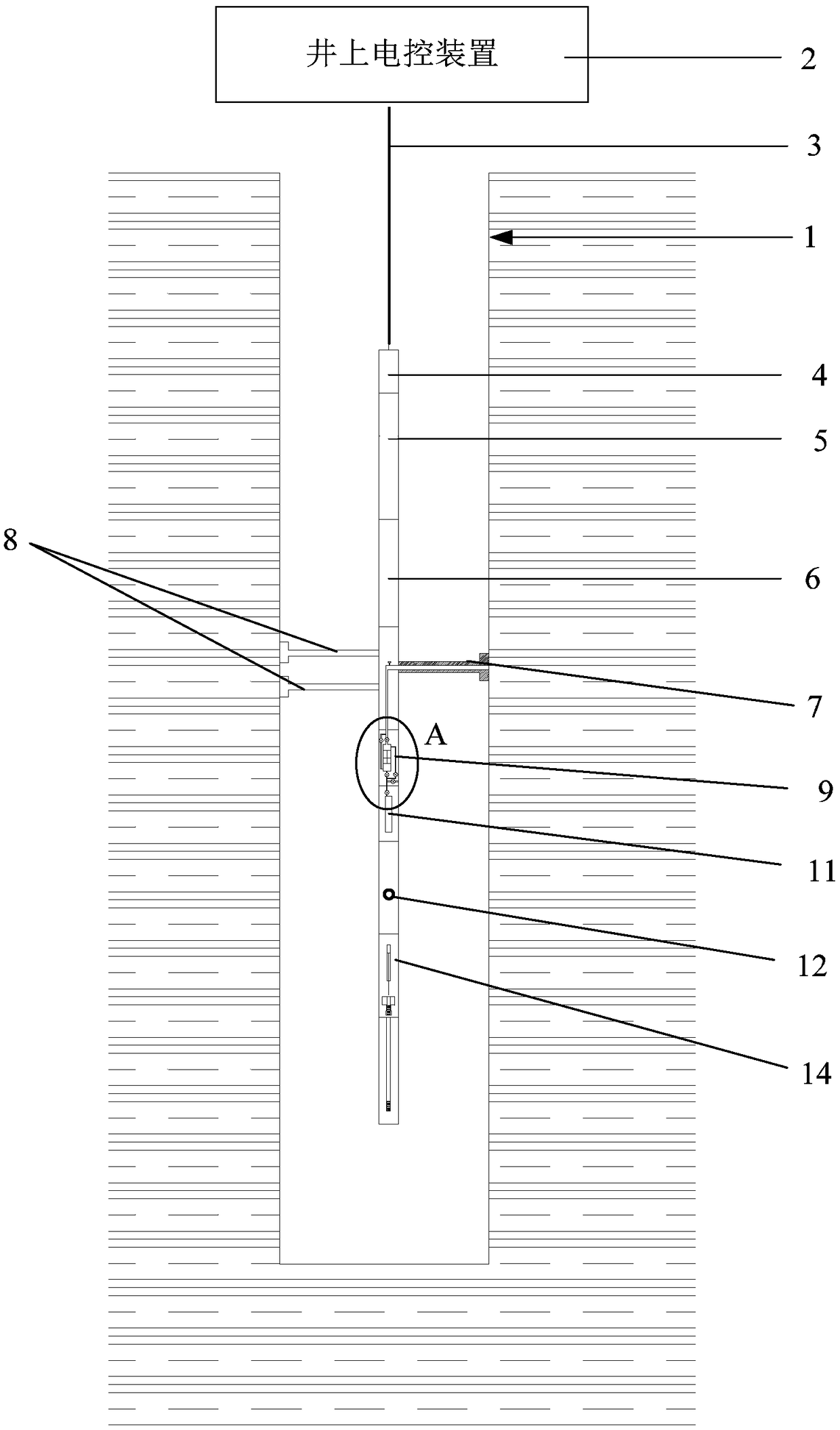

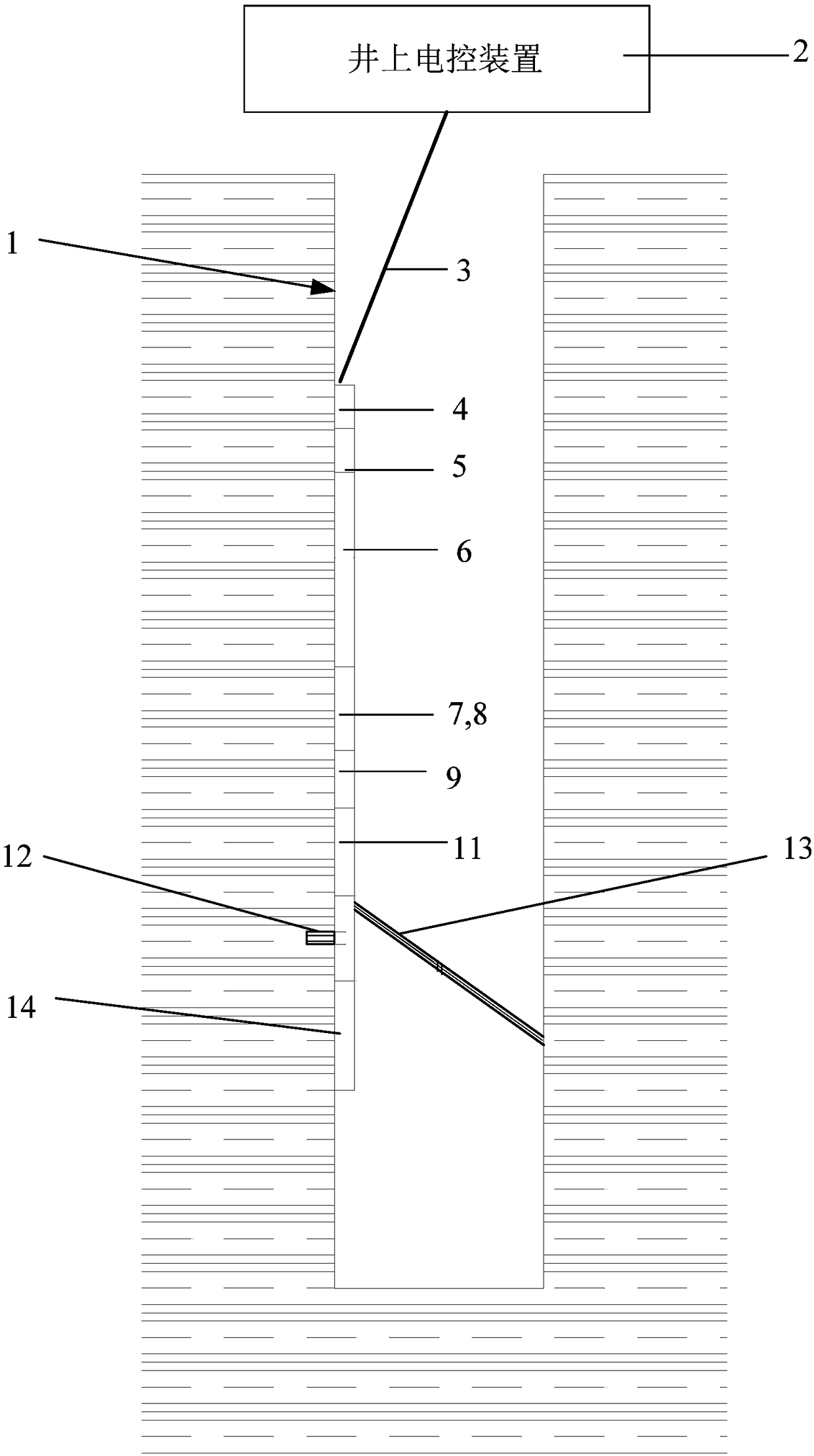

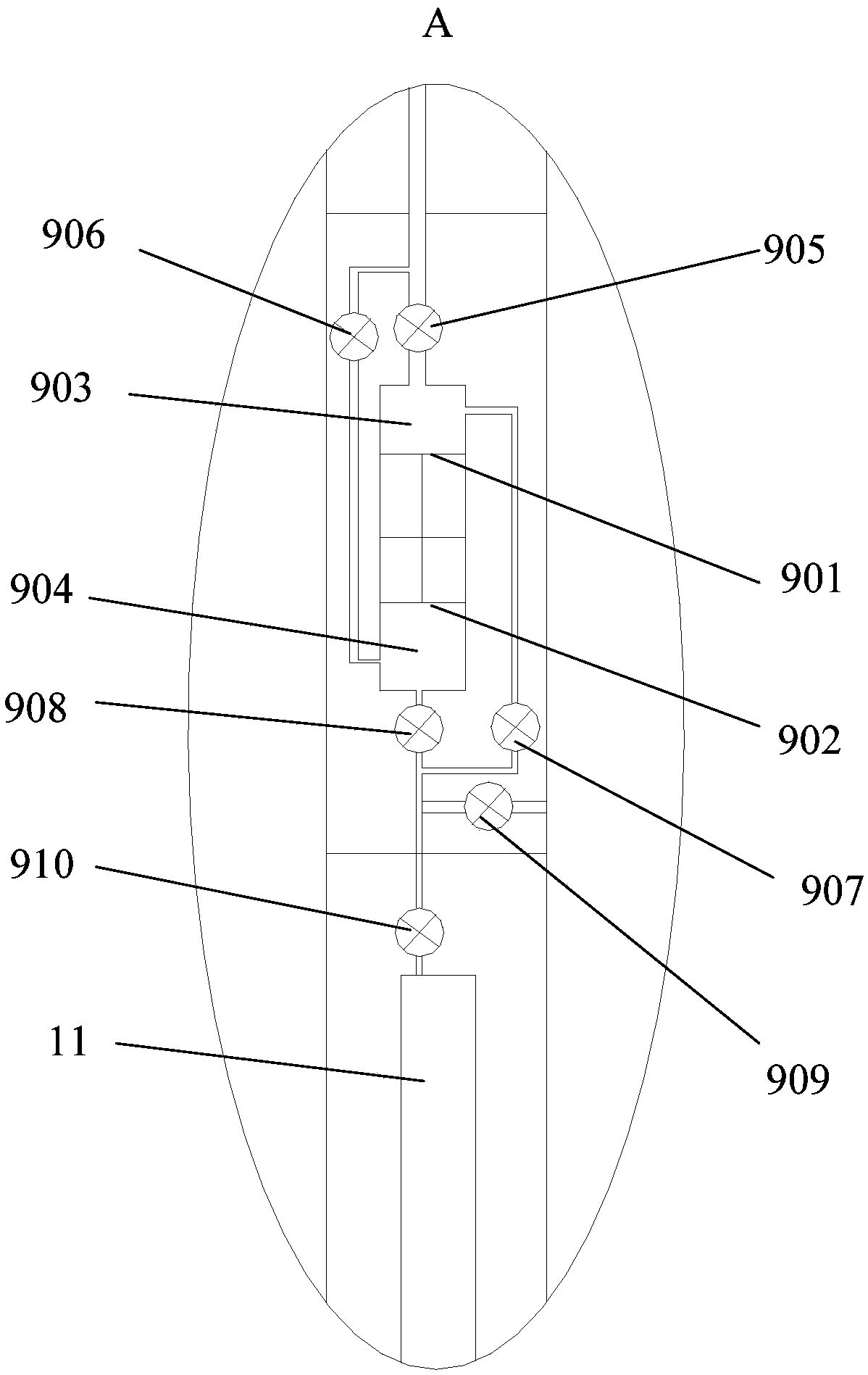

[0037] The embodiment of the present invention provides a logging instrument, comprising: a main body; a sampling mechanism including a probe 7 and a first pushing arm 8 telescopically arranged on opposite sides of the main body; a coring mechanism including a telescopic The coring bit 12 and the second pushing arm 13 that are arranged on the opposite sides of the main body; The electric control device 2 is used to control the main body, the sampling mechanism, and the coring mechanism to perform sampling and coring operations; wherein, the second pushing arm The arm 13 can be used as the back push arm of the sampling mechanism, and the first push back arm 8 can be used as the back push arm of the coring mechanism.

[0038] Such as figure 1 and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com