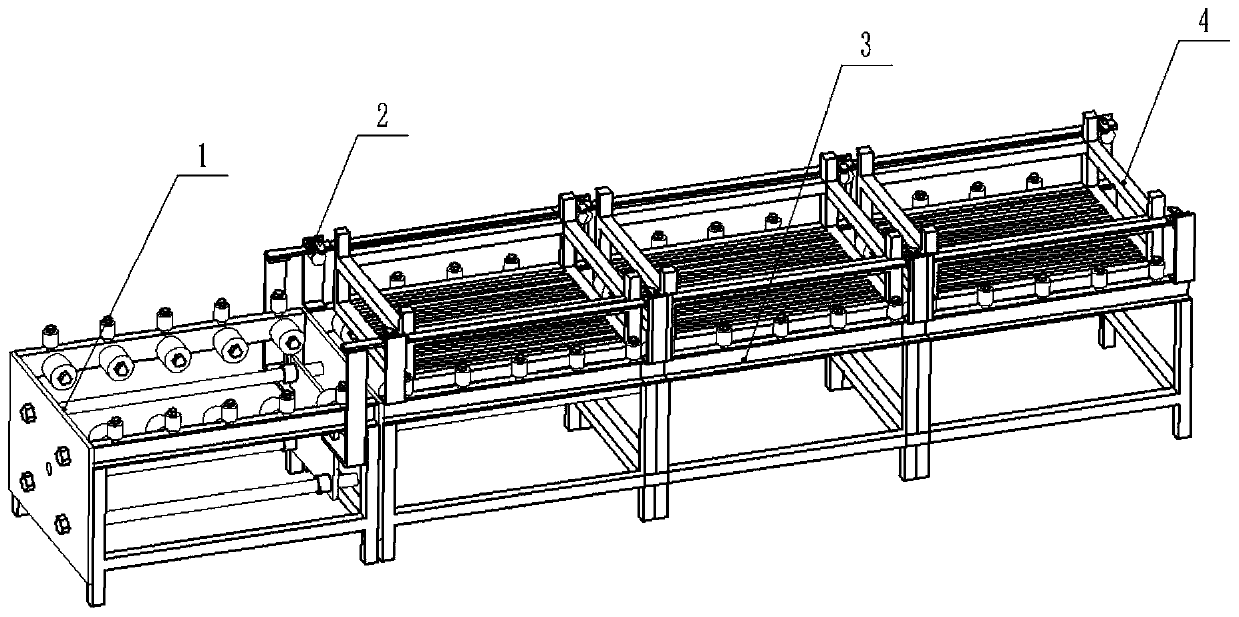

Multi-station conveying facility

A transmission equipment and multi-station technology, applied in the direction of conveyors, conveyor objects, rollers, etc., can solve problems such as many fault points, high equipment manufacturing costs, complex electronic control and mechanical systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

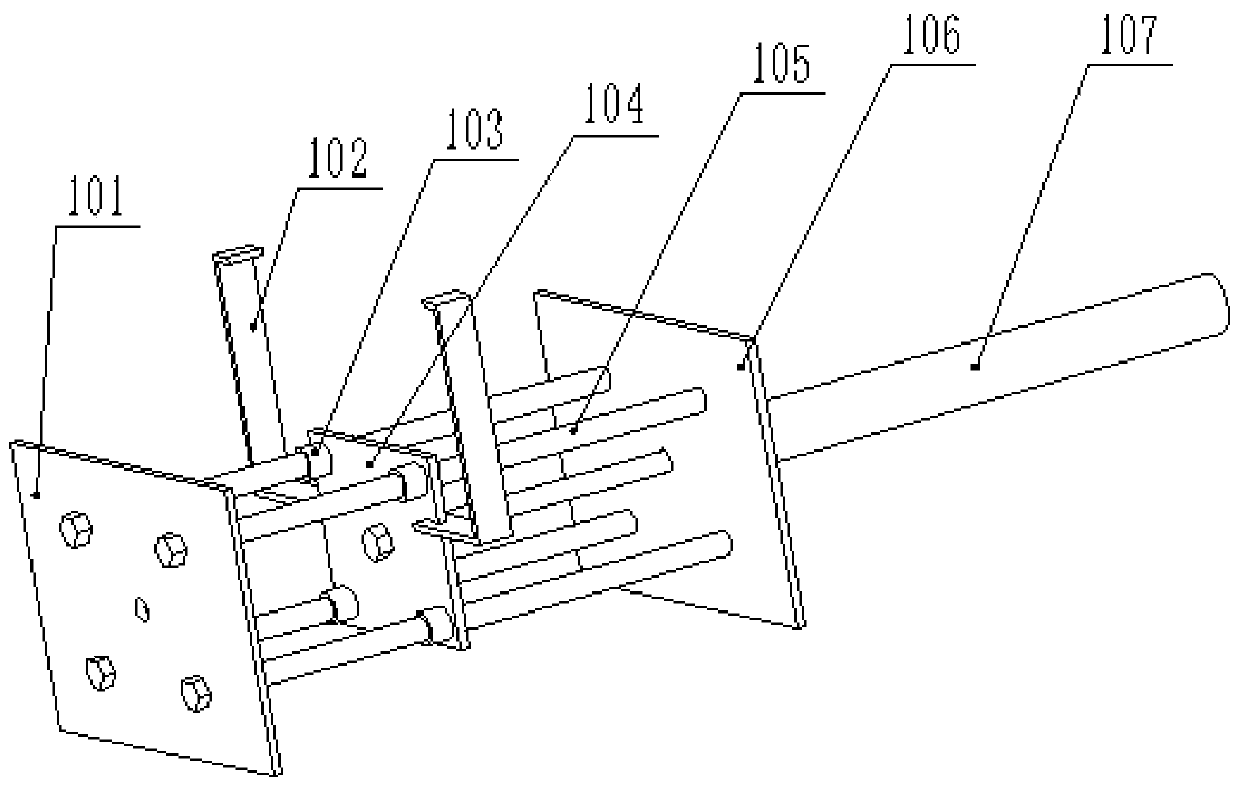

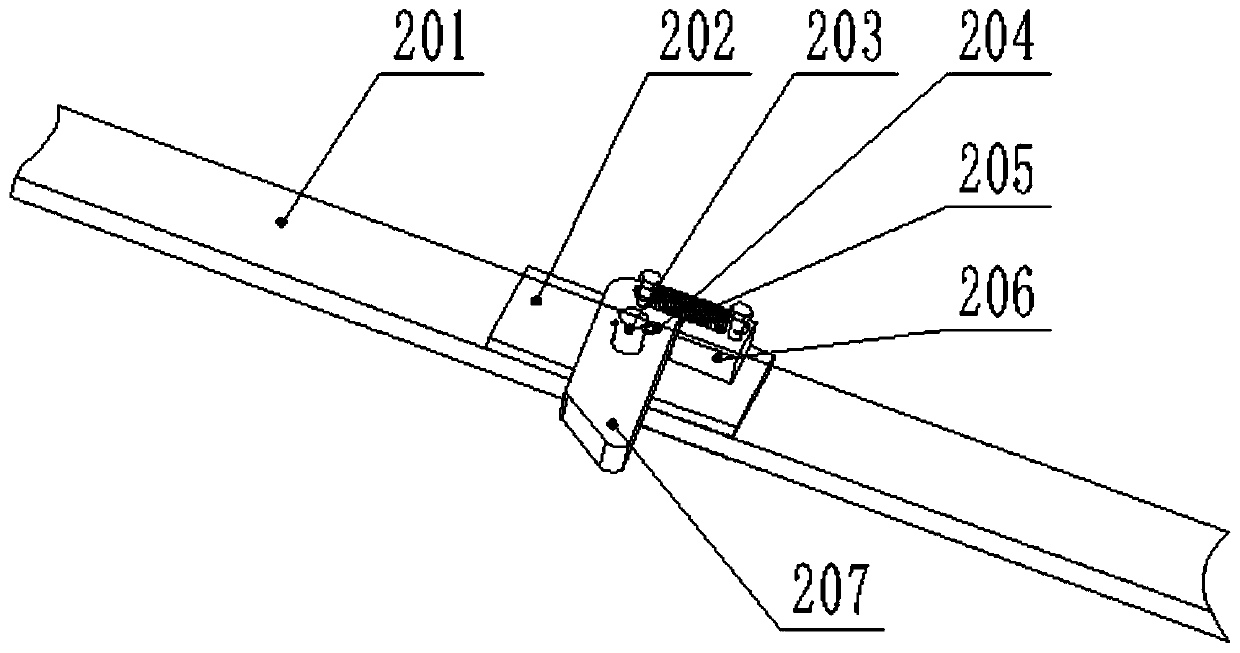

[0034] Embodiment 1 of the present invention will be specifically described below in conjunction with the accompanying drawings: a reciprocating pull belt type pneumatic synchronous transmission mechanism, including a cylinder drive mechanism, a pull belt shifting fork mechanism, and a transmission station mechanism, wherein the cylinder drive mechanism includes a front fixing plate, a connecting Arm, guide sleeve, movable plate, guide rod, rear fixed plate, cylinder; pull belt fork mechanism includes pull belt, bottom plate, pin shaft, cotter pin, spring, stopper, fork; transmission station mechanism includes bracket, slot Steel, support roller bracket, support roller, guide wheel, bottom transfer wheel.

[0035] In the cylinder drive mechanism, the two ends of the four guide rods are respectively fixed on the front fixed plate and the rear fixed plate through screw connections, and a guide sleeve is installed on each guide rod, and the four guide sleeves are fixed on the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com